ASTM C844-04(2010)

(Specification)Standard Specification for Application of Gypsum Base to Receive Gypsum Veneer Plaster

Standard Specification for Application of Gypsum Base to Receive Gypsum Veneer Plaster

ABSTRACT

This specification covers the minimum requirements for, and methods of, application of gypsum veneer base for gypsum veneer plasters. Details of construction for a specific assembly to achieve the required fire resistance shall be obtained from reports of fire-resistance tests, engineering evaluations, or listings from recognized fire testing laboratories. The materials shall be classified as follows: gypsum base for veneer plasters; gypsum backing board for coreboard; special fire-retardant gypsum base; foil-backed gypsum base; gypsum veneer plaster; nails; non-load bearing steel; load bearing steel; steel framing, non-load bearing; accessories; adhesives; steel framing load bearing; and wood framing. The maximum spacing of framing members for singly gypsum base construction shall be not more than then specified values. Application of gypsum base, single-ply gypsum base, adhesive-mechanical fastener, foil-backed gypsum base, two-ply gypsum base, and application over existing surfaces shall be indicated. Solid gypsum base partitions shall include face ply, core, and runners. Direct adhesive application shall be used only on interior masonry or concrete walls above grade, or inside of exterior masonry cavity walls. Gypsum base application over steel framing and furring shall include screw application, framing space, and screw spacing. Gypsum base applied to the soffit of arches shall be carefully bent into place and shall conform to the specified values of bending radii.

SCOPE

1.1 This specification covers the minimum requirements for, and methods of, application of gypsum veneer base for gypsum veneer plasters.

1.2 Gypsum veneer base shall not be used as a base for direct adhesive application of ceramic, metal, or plastic tile in areas exposed to abnormal moisture or humidity or temperature.

1.3 Details of construction for a specific assembly to achieve the required fire resistance shall be obtained from reports of fire-resistance tests, engineering evaluations, or listings from recognized fire testing laboratories.

1.4 Where a specific degree of sound control is required for veneer plaster assemblies and constructions, details of construction shall be in accordance with official reports of tests conducted in recognized sound testing laboratories in accordance with the applicable sound tests, Test Method C423, Test Method E90, or Test Method E492.

1.5 Where this specification is more stringent (size or thickness of framing; spacing of fasteners) than the fire-rated construction, this specification shall govern; otherwise, the construction described in the fire test report shall govern.

1.6 Unheated spaces above gypsum veneer base ceilings shall be properly ventilated (see Appendix X3).

1.7 The values stated in inch-pound units are to be regarded as the standard. The SI (metric) values given in parentheses are approximate and are provided for information purposes only.

1.8 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C844 −04(Reapproved 2010)

Standard Specification for

Application of Gypsum Base to Receive

Gypsum Veneer Plaster

This standard is issued under the fixed designation C844; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

1.1 Thisspecificationcoverstheminimumrequirementsfor, 2.1 ASTM Standards:

andmethodsof,applicationofgypsumveneerbaseforgypsum C11 Terminology Relating to Gypsum and Related Building

veneer plasters. Materials and Systems

C423 Test Method for SoundAbsorption and SoundAbsorp-

1.2 Gypsum veneer base shall not be used as a base for

tion Coefficients by the Reverberation Room Method

direct adhesive application of ceramic, metal, or plastic tile in

C514 Specification for Nails for the Application of Gypsum

areas exposed to abnormal moisture or humidity or tempera-

Board

ture.

C587 Specification for Gypsum Veneer Plaster

1.3 Details of construction for a specific assembly to

C588/C588M Specification for Gypsum Base for Veneer

achieve the required fire resistance shall be obtained from

Plasters (Withdrawn 2005)

reports of fire-resistance tests, engineering evaluations, or

C754 Specification for Installation of Steel Framing Mem-

listings from recognized fire testing laboratories.

bers to Receive Screw-Attached Gypsum Panel Products

C954 SpecificationforSteelDrillScrewsfortheApplication

1.4 Where a specific degree of sound control is required for

veneer plaster assemblies and constructions, details of con- of Gypsum Panel Products or Metal Plaster Bases to Steel

Studs from 0.033 in. (0.84 mm) to 0.112 in. (2.84 mm) in

struction shall be in accordance with official reports of tests

conducted in recognized sound testing laboratories in accor- Thickness

C955 Specification for Load-Bearing (Transverse andAxial)

dance with the applicable sound tests, Test Method C423, Test

Method E90, or Test Method E492. Steel Studs, Runners (Tracks), and Bracing or Bridging

for Screw Application of Gypsum Panel Products and

1.5 Where this specification is more stringent (size or

Metal Plaster Bases

thickness of framing; spacing of fasteners) than the fire-rated

C1002 Specification for Steel Self-Piercing Tapping Screws

construction, this specification shall govern; otherwise, the

for the Application of Gypsum Panel Products or Metal

construction described in the fire test report shall govern.

Plaster Bases to Wood Studs or Steel Studs

1.6 Unheated spaces above gypsum veneer base ceilings

C1007 Specification for Installation of Load Bearing (Trans-

shall be properly ventilated (see Appendix X3).

verse and Axial) Steel Studs and Related Accessories

C1047 Specification for Accessories for Gypsum Wallboard

1.7 The values stated in inch-pound units are to be regarded

and Gypsum Veneer Base

as the standard.The SI (metric) values given in parentheses are

C1546 Guide for Installation of Gypsum Products in Con-

approximate and are provided for information purposes only.

cealed Radiant Ceiling Heating Systems

1.8 The text of this standard references notes and footnotes

E90 Test Method for Laboratory Measurement of Airborne

which provide explanatory material. These notes and footnotes

Sound Transmission Loss of Building Partitions and

(excluding those in tables and figures) shall not be considered

Elements

as requirements of the standard.

E492 Test Method for Laboratory Measurement of Impact

Sound Transmission Through Floor-Ceiling Assemblies

This specification is under the jurisdiction of ASTM Committee C11 on

Gypsum and Related Building Materials and Systems and is the direct responsibility For referenced ASTM standards, visit the ASTM website, www.astm.org, or

ofSubcommitteeC11.03onSpecificationsfortheApplicationofGypsumandOther contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Products in Assemblies. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved May 15, 2010. Published September 2010. Originally the ASTM website.

approved in 1978. Last previous edition approved in 2004 as C844–04. DOI: The last approved version of this historical standard is referenced on

10.1520/C0844-04R10. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C844−04 (2010)

Using the Tapping Machine 4.10 Steel Framing, Non-load bearing—Specification C645

for the specified design criteria.

2.2 American Softwood Lumber Standard:

PS–20 American Softwood Lumber Standard 4.11 Accessories—Specification C1047.

4.12 Adhesive:

3. Terminology

4.12.1 For application of gypsum base to steel framing, the

3.1 Definitions—Definitions shall be in accordance with

adhesive shall be as recommended by the manufacturer of the

Terminology C11.

gypsum base.

3.2 Definitions of Terms Specific to This Standard:

4.13 Steel Framing Load Bearing—Specification C955.

3.2.1 base ply—first ply of gypsum base in multiple ply

4.14 Wood Framing—American Lumber Softwood Stan-

application.

dard PS–20.

3.2.2 face ply—outer or visible layer of gypsum base in

multiple ply application.

5. Delivery of Materials

3.2.3 fastener, n—nails, screws, or staples used for the

5.1 All materials shall be delivered in the original packages,

application of the gypsum base or backing board.

containers, or bundles bearing the brand name and manufac-

3.2.4 framing member, n—that portion of the framing,

turer (or supplier) identification.

furring, blocking, etc., to which the gypsum base is attached.

Unless otherwise specified, the surface to which abutting edges

6. Shipping, Handling and Storage

or ends are attached shall be not less than 1 ⁄2 in. (38 mm)

6.1 Gypsum board shall be shipped so as to be kept dry.

wide for wood members, not less than 1 ⁄4 in. (32 mm) wide

6.2 Gypsum board shall be stored so as to be kept dry,

for steel members, and not less than 6 in. (152 mm) wide for

preferably inside a building, under a roof. Gypsum board shall

gypsum studs. For internal corners or angles, the bearing

be neatly stacked flat with care taken to prevent sagging or

surface shall be not less than ⁄4 in. (19 mm).

damage to edges, ends, and surfaces.

3.2.5 parallel application, n—gypsum base application

where the gypsum base edge is applied parallel to the framing 6.3 Where necessary to store gypsum board outside, it shall

be stacked flat, off the ground, supported on a level platform

members.

and fully protected from weather and direct sunlight exposure.

3.2.6 perpendicular application, n—gypsum base applica-

tion where the gypsum base edge is applied at right angles to 6.4 Prior to application, the building exterior shall be so

the framing members.

enclosed to protect the gypsum base from exposure to weather

and direct sunlight.

4. Materials

NOTE 1—The bond of alkaline veneer plaster to gypsum base will be

4.1 Materials shall conform to the respective specifications impaired if the base is exposed to direct light or sunlight for extended

periods.

and standards and to the requirements specified herein.

4.2 Gypsum Base for Veneer Plasters (hereinafter referred

7. Environmental Conditions

to as “gypsum base”)—Specification C588/C588M.

7.1 Application of Gypsum Base and Adhesives—A room

4.3 Gypsum Backing Board or Coreboard—Specification

temperature of not less than 40 °F (4 °C) shall be maintained

C442.

during application of gypsum base except when adhesive is

used for the attachment of gypsum base. For the bonding of

4.4 Special Fire-Retardant Gypsum Base—Specification

adhesive, a room temperature of not less than 50 °F (10 °C)

C588/C588M, Type X.

shall be maintained for 48 h prior to application and continu-

4.5 Foil-Backed Gypsum Base—Specification C588/

ously thereafter until adhesive is completely dry. When a

C588M.

temporary heat source is used, the temperature shall not exceed

4.6 Gypsum Veneer Plaster—Specification C587.

95 °F (35 °C) in any room or area. Adequate ventilation shall

be maintained in the working area during the application and

4.7 Nails—Specification C514.

adhesive curing process.

4.8 Screws:

4.8.1 Non-load bearing steel—Specification C1002.

8. Application of Gypsum Base

4.8.2 Load bearing steel—Specification C954.

8.1 General Requirements:

4.9 Staples—No. 16 USS gage 0.063 in. (1.6-mm) flattened

8.1.1 Installation of steel framing shall be in accordance

galvanized wire with ⁄16-in. (11.1-mm) wide-crown minimum

with applicable Specifications C754 or C1007 except where

outside measure and divergent points. Staples shall be used

superseded by requirements of Table 1.

only for the base ply of two-ply application over wood

NOTE 2—For general wood framing requirements, see Appendix X2.

framing.

8.1.2 Method of Cutting—The gypsum base shall be cut by

scoring and breaking or by sawing, working from the face side.

When cutting by scoring, the face shall be cut with a knife or

Available from National Institute of Standards and Technology (NIST), 100

Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov. other suitable tool and the gypsum base snapped back away

C844−04 (2010)

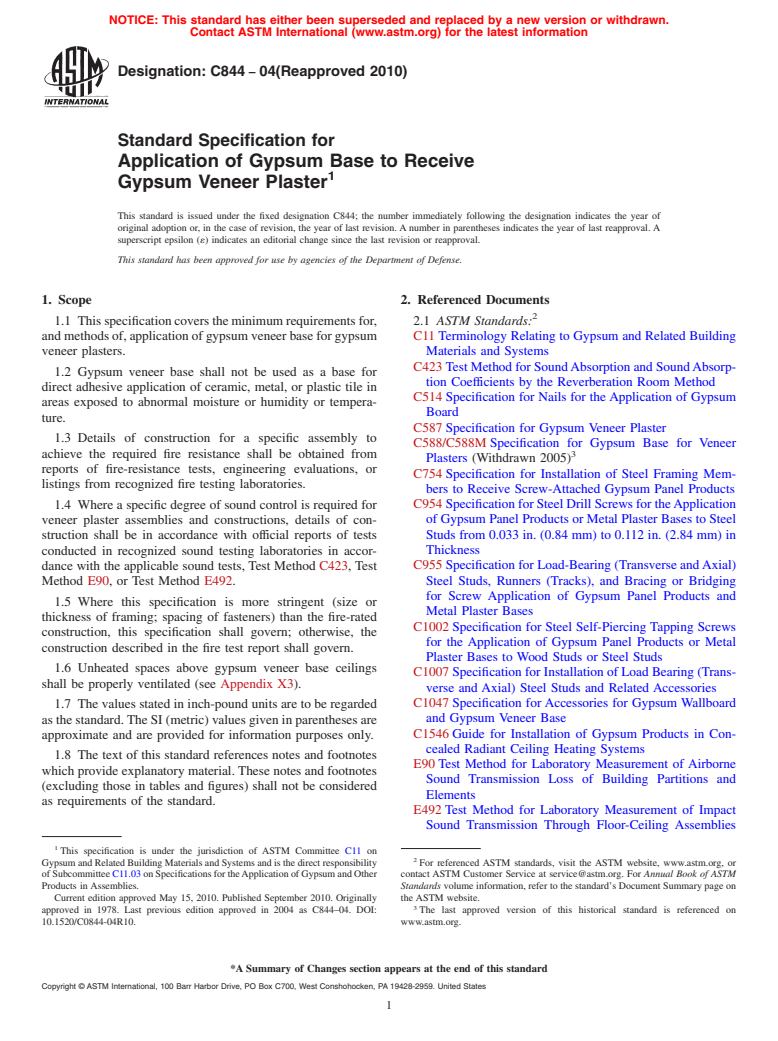

TABLE 1 Maximum Framing Spacing

Maximum On Center Spacing of

Single-ply Base (Thickness), in. (mm) Application to Framing

Framing, in. (mm)

Ceilings:

⁄2 (12.7) parallel 16 (406)

A

⁄2 (12.7) perpendicular 24 (610)

B

⁄8(15.9)

perpendicular 24 (610)

Sidewalls:

C

⁄8 (9.5) perpendicular 16 (406)

⁄2 (12.7) parallel 16 (406)

A

⁄2 (12.7) perpendicular 24 (610)

B

⁄8 (15.9) parallel or perpendicular 24 (610)

A

⁄2-in. (12.7-mm) gypsum base applied perpendicular on 24-in. (610-mm) on centers framing shall be considered to be minimum construction.

B

For ⁄8-in.(15.9-mm)base,perpendicularonceilingsandeitherperpendicularorparallelonsidewallsat24-in.(610-mm)oncentersspacing,onlytwo-componentveneer

plaster or special joint reinforcement, as recommended by the gypsum veneer plaster manufacturer, shall be used.

C 3

⁄8-in. (9.5-mm) gypsum base shall be used over wood framing with two-component veneer plaster systems only.

from the cut face. The back shall be broken by snapping the 8.3 Control Joints

gypsum base in the reverse direction, or by cutting with a knife

8.3.1 Control joints shall be installed in ceilings more than

2 2

or other suitable tool.

2500 ft (232 m ) in area that are constructed with perimeter

8.1.3 All cut edges and ends of the gypsum base shall be

relief. The distance between control joints shall be not more

smoothed to obtain neat jointing. Cut-outs for pipes, fixtures,

than 50 ft (15 m) in either direction.

2 2

or other small openings on the face and back of the base shall

8.3.2 Ceilings of more than 900 ft (85 m ) in area con-

be scribed in outline before removing or cut out with a saw or

structed without perimeter relief shall have control joints

other suitable tool. The gypsum base shall be scribed where it

installed with spacing not to exceed 30 ft (9 m) in either

meets projecting surfaces. Base shall be brought lightly into

direction.

contact with adjacent panels but not forced into place.Abutting

8.3.3 Control joints shall be installed where ceiling framing

ends and edges shall fit neatly.

or furring changes direction or where construction joints occur

8.1.4 When gypsum base is to be applied to both ceiling and

in the base building construction. In partitions, walls, or wall

walls, the base shall be applied to the ceiling and then to the

furring, the distance between control joints shall be not more

walls.

than 30 ft (9 m).

8.2 Fastening, Mechanical:

8.3.4 A ceiling height door frame, installed in accordance

8.2.1 The gypsum base shall be held in firm contact with the

with the spacing requirements set forth in 8.3, functions as a

underlying support while driving any fastener.

control joint.

8.2.2 Fastener application shall proceed from the center of

the field of the gypsum base to the ends and edges or shall

9. Application of Single-Ply Gypsum Base

begin along one edge and proceed toward the other edge.

9.1 The maximum spacing of framing members for single-

8.2.3 Except where required for fire rating, structural

ply gypsum base construction shall be not more than those

performance, or other special considerations, fastening to top

shown in Table 1.

or bottom plates shall not be required.

8.2.4 Fastenersshallbespacednotlessthan ⁄8 in.(9.5mm)

9.2 In single-ply installation, all ends and edges of gypsum

from the edges and ends of the gypsum base. Fasteners used at

base shall occur over framing members or other solid backing

edges or at base ends in horizontal application shall not be

except where treated joints occur at right angles to framing or

more than 1 in. from edges or ends.

furring members.

8.2.5 Nails and screws shall be driven to a point flush with

9.3 Joints on opposite sides of a partition shall be arranged

the gypsum base surface without breaking the surface paper or

to occur on different framing members.

damaging the surrounding gypsum core and without stripping

the framing member around the screws.

9.4 Fasteners (Single Ply Application):

8.2.6 Staples shall be driven so that both legs penetrate the

9.4.1 Nail Spacing—Space nails a maximum of 7 in. (178

support member and the crown bears tightly against the

mm) on centers on the ceiling and a maximum of 8 in. (203

backing board, but does not cut into the face paper. The staple

mm) on centers on the walls.

shall be driven with the crown parallel to framing members.

9.4.2 Double Nailing—Nails shall be spaced as shown in

Staples shall be used only for the first ply in two-ply gypsum

Fig. 1 and applied as follows:

base systems.

9.4.2.1 Starting at the center of the base, nails shown as

8.2.7 Penetration of mechanical fasteners into supporting

solid dots shall be applied by row starting with row 1, then

framing members shall be not less than:

rows 2 and 2A, 3 and 3A, 4 and 4A. Base shall be kept tight

Nails Screws Staples

against the framing throughout the procedure.

7 5 5

Wood: ⁄8 in. (22 mm) ⁄8 in. (15 mm) ⁄8 in. (15 mm), each leg 9.4.2.2 Using the procedure in 9.4.2.1, second nails shown

Steel: . ⁄8 in. (9 mm) .

by circles shall be applied.

C844−04 (2010)

FIG. 1 Double Nailing

9.4.2.3 As an alternative procedure, second nails shall be 10. Adhesive-Mechanical Fastener Application

permitted to be applied immediately after all first nails

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.