ASTM F2338-03

(Test Method)Standard Test Method for Nondestructive Detection of Leaks in Packages by Vacuum Decay Method

Standard Test Method for Nondestructive Detection of Leaks in Packages by Vacuum Decay Method

SCOPE

1.1 Test PackagesPackages that can be nondestructively evaluated by this test method include:

1.1.1 Rigid and semi-rigid non-lidded trays.

1.1.2 Trays or cups sealed with porous barrier lidding material.

1.2 Leaks DetectedThis test method is capable of detecting package leaks using an absolute or differential pressure transducer leak detector. The sensitivity of a test is a function of the sensitivity of the transducer, the package design, the design of the package test fixture, and critical test parameters of time and pressure. Types and sizes of leaks that may be detected for various package systems, as well as test sensitivities are described below. These data are based on precision and bias confirmation studies.

1.2.1 Trays or Cups (Non-lidded)Hole or crack defects in the wall of the tray/cup of at least 50 m in diameter can be detected at a Target Vacuum of 4104 Pa (400 mbar) using an absolute pressure transducer test instrument.

1.2.2 Trays Sealed with Porous Barrier Lidding MaterialHole or crack defects in the wall of the tray/cup of at least 100 m in diameter can be detected. Channel defects in the seal area (made using wires of 125 m in diameter) can be detected. Severe seal bonding defects in both continuous adhesive and dot matrix adhesive package systems can be detected. Slightly incomplete dot matrix adhesive bonding defects can also be detected. All porous barrier lidding material packages were tested at a Target Vacuum of 4104 Pa (400 mbar) using an absolute pressure transducer test instrument. Using a calibrated volumetric airflow meter, the sensitivity of the test for porous lidded packages is shown to be approximately 10-2 Pam3s-1.

1.3 Test ResultsThe test results are qualitative (Accept/Reject). Acceptance criteria for test results are established from quantitative baseline vacuum decay measurements obtained from control, non-leaking packages.

1.4 Standard Value UnitsThe values used in this test method are stated in SI units and are to be regarded as standard units. Values in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 2338 – 03

Standard Test Method for

Nondestructive Detection of Leaks in Packages by Vacuum

Decay Method

This standard is issued under the fixed designation F 2338; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 Test Packages—Packages that can be nondestructively

responsibility of the user of this standard to establish appro-

evaluated by this test method include:

priate safety and health practices and determine the applica-

1.1.1 Rigid and semi-rigid non-lidded trays.

bility of regulatory limitations prior to use.

1.1.2 Trays or cups sealed with porous barrier lidding

material.

2. Referenced Documents

1.2 Leaks Detected—This test method is capable of detect-

2.1 ASTM Standards:

ing package leaks using an absolute or differential pressure

D 996 Terminology of Packaging and Distribution

transducer leak detector. The sensitivity of a test is a function

E 691 Practice for Conducting an Interlaboratory Study to

of the sensitivity of the transducer, the package design, the

Determine the Precision of a Test Method

design of the package test fixture, and critical test parameters

F 17 Terminology Relating to Flexible Barrier Materials

of time and pressure. Types and sizes of leaks that may be

F 1327 Terminology Relating to Barrier Materials for Medi-

detected for various package systems, as well as test sensitivi-

cal Packaging

ties are described below. These data are based on precision and

bias confirmation studies.

3. Terminology

1.2.1 Trays or Cups (Non-lidded)—Hole or crack defects in

3.1 Definitions—For definitions used in this test method,

the wall of the tray/cup of at least 50 μm in diameter can be

4 see Terminologies D 996, F 17, and F 1327.

detected at a Target Vacuum of 4·10 Pa (400 mbar) using an

3.2 Definitions of Terms Specific to This Standard:

absolute pressure transducer test instrument.

3.2.1 baseline vacuum decay, n—the extent of vacuum

1.2.2 Trays Sealed with Porous Barrier Lidding Material—

change within the test chamber over time demonstrated by a

Hole or crack defects in the wall of the tray/cup of at least 100

control, non-leaking package.

μm in diameter can be detected. Channel defects in the seal

3.2.2 control, non-leaking packages, n—packages without

area (made using wires of 125 μm in diameter) can be detected.

defects and properly sealed according to manufacturer’s speci-

Severe seal bonding defects in both continuous adhesive and

fications with non-defective lidding materials.

dot matrix adhesive package systems can be detected. Slightly

3.2.3 semi-rigid trays or cups, n—trays made of material

incomplete dot matrix adhesive bonding defects can also be

that retain shape upon deflection. For example, thermoformed

detected. All porous barrier lidding material packages were

4 PETE or PETG trays are considered semi-rigid trays.

tested at a Target Vacuum of 4·10 Pa (400 mbar) using an

3.2.4 spotty or mottled seals, n—an incomplete adhesive

absolute pressure transducer test instrument. Using a calibrated

bond made between a package tray or cup and porous lidding

volumetric airflow meter, the sensitivity of the test for porous

-2 3 -1 material that can be visibly identified by a distinctive pattern of

lidded packages is shown to be approximately 10 Pa·m ·s .

dots, spotting or mottling on the tray sealing surface after the

1.3 Test Results—The test results are qualitative (Accept/

lid is removed.

Reject). Acceptance criteria for test results are established from

3.2.5 volumetric airflow meter, n—a calibration tool that

quantitative baseline vacuum decay measurements obtained

can be used to provide an artificial leak of known volumetric

from control, non-leaking packages.

airflow rate into the test chamber for verification of instrument

1.4 Standard Value Units—The values used in this test

sensitivity. Airflow meters should be calibrated to NIST

method are stated in SI units and are to be regarded as standard

standards. The operational range of the meter should reflect the

units. Values in parentheses are for information only.

desired limit of sensitivity for the intended leak test.

1 2

This test method is under the jurisdiction of ASTM Committee F02 on Flexible For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Barrier Materials and is the direct responsibility of Subcommittee F02.60 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Medical Device Packaging. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Nov. 1, 2003. Published January 2004. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2338–03

3.3 Definitions of Test Cycle and Critical Parameters block off any porous barrier surface of the package during the

Terms—For terms and abbreviations relating to the test cycle test to prevent a rapid loss of chamber vacuum resulting

and the critical parameters for establishing accept/reject limits, primarily from gas migration through the porous surface. Leak

see Annex A1. detection is based solely on the ability to detect the change in

pressure inside the test chamber as a result of air egress from

4. Summary of Test Method

the properly masked package when challenged with vacuum

4.1 The test package is placed in a test chamber to which

conditions.

vacuum is applied. The chamber is then isolated from the

5.3 This test is a useful research tool for optimization of

vacuum source and an absolute or differential vacuum trans-

package sealing parameters and for comparative evaluation of

ducer is used to monitor the test chamber for both the level of

various package and materials. This test method is also

vacuum, as well as the change in vacuum over time. Vacuum

applicable to production settings as it is rapid, non-invasive

decay, or rise in chamber pressure, is a result of package

and non-destructive, making it useful for either 100 % on-line

headspace gas being drawn out of the package through any

testing or to perform tests on a statistical sampling from the

leaks present, plus background noise. Leak detection requires

production operation.

vacuum decay in excess of the background noise level.

5.4 Leak test results that exceed the permissible limits for

Background noise vacuum decay may result from package

the vacuum decay test are indicated by audible or visual signal

expansion when exposed to vacuum, or from residual gases

responses, or both.

inherent in the test chamber or test system lines.

4.2 Porous barrier lidded tray or cup packages are tested for

6. Apparatus

leaks located in the tray or cup, and at the lidding material/tray

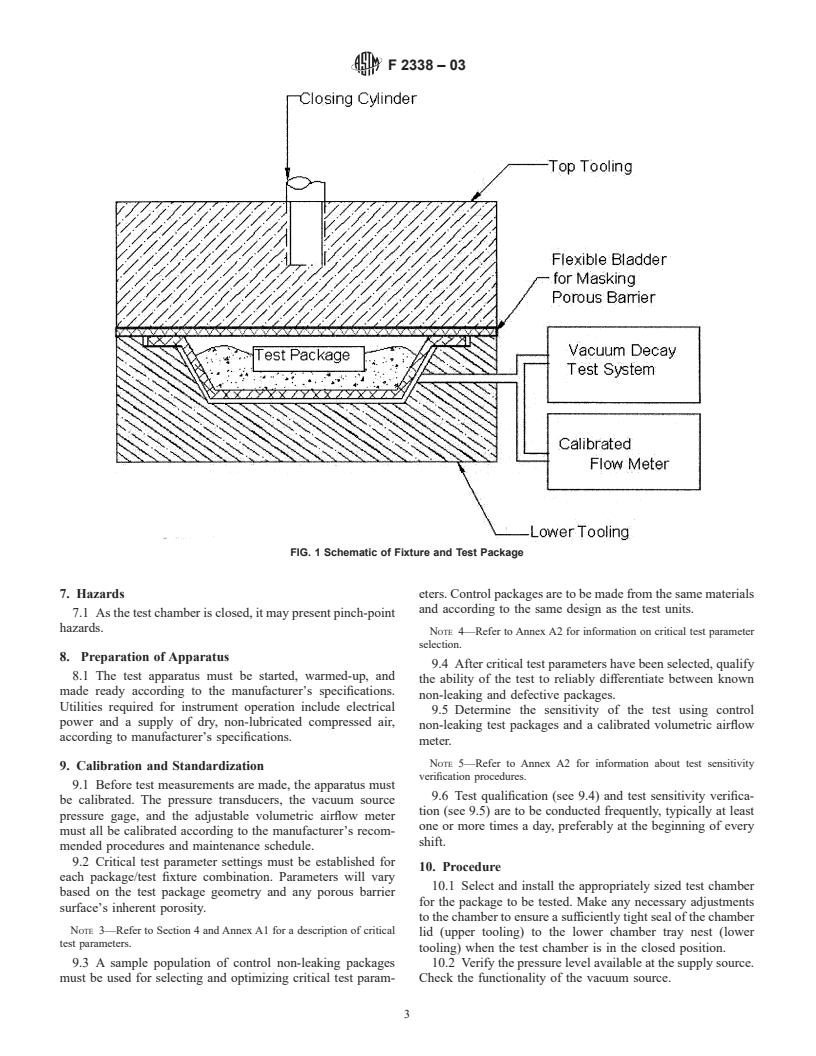

6.1 Vacuum Decay Leak Detection Apparatus—All vacuum

seal junction. Leaks in the porous lidding material itself cannot

decay test systems include a test chamber with a lower

be detected. When testing such packages, steps are taken to

compartment (lower tooling) designed to nest the test package,

physically mask or block the porous barrier surface to prevent

and an upper lid (top tooling) for closing the test chamber. Fig.

the migration of package gas through the porous lid. These

1 illustrates a test chamber designed for testing packages with

steps may require some sample preparation, depending on the

porous barrier lidding material. The test fixture upper lid

masking approach required, but must be nondestructive and

consists of a flexible bladder to mask the package’s porous

noninvasive. Vacuum decay from porous barrier lidded pack-

barrier during the test cycle. The test chamber is connected to

ages may potentially include background noise from gas

the vacuum decay test system. This system includes a vacuum

trapped between the lidding material and the masking surface,

source for establishing vacuum within the chamber at the

or from transverse gas flow through the porous barrier material

beginning of the test cycle, and an absolute or differential

itself at the lid/tray seal junction.

pressure transducer for monitoring the level of vacuum as well

4.3 The sensitivity of a vacuum decay leak test is a function

as the pressure change as a function of time during the test

of several factors. Smaller leaks can be detected with more

cycle. A calibrated volumetric airflow meter may be placed

sensitive pressure transducers, and with longer test times. Also,

in-line with the test system for verifying the sensitivity of a

pressure changes can be more readily detected with smaller

leak test.

void volumes between the test package and the test chamber,

6.2 Tray Nest or Lower Tooling—The bottom half of the test

and with smaller test system line volumes. Steps to reduce

chamber is dimensionally designed to closely nest the test

background noise can also improve sensitivity. For example,

package, while still allowing for easy gas flow around the test

for porous barrier lidded packages, more effective masking

package. Without ready gas flow around the package, leakage

techniques will minimize background noise.

sites can be blocked. Conversely, the larger the gap between

NOTE 1—Further information on the “Leak Test Theory” may be found

the test chamber and the test package, the less sensitive the leak

in Annex A1.

test, as vacuum decay from package leakage will be minimized

in a larger net test chamber volume.

5. Significance and Use

6.3 Upper Lid or Upper Tooling—The upper lid is designed

5.1 Leaks in medical device, pharmaceutical and food

to tightly seal the closed test chamber during the vacuum cycle.

packages may result in the ingress of unwanted gases (most

6.4 Mask or Block—The porous barrier lidding material of

commonly oxygen), harmful microbiological or particulate

packages must be masked or blocked during testing to mini-

contaminants. Package leaks may appear as imperfections in

mize egress of air from the package through the lidding.

the tray or cup, or in the lid materials themselves (holes or

Various masking techniques may be used, including a test

cracks), or they may be found at the juncture of the seal made

chamber designed with a flexible bladder in the upper tooling

between the tray and the lid material (channel defects, tears,

(refer to Fig. 1).

spotty or mottled seals). The ability to detect leaks is necessary

6.5 Volumetric Airflow Meter—An adjustable volumetric

to ensure consistency and integrity of packages.

airflow meter is placed in-line with the test chamber to

5.2 After initial set-up and calibration, the operations of

introduce an artificial leak of variable size. It is recommended

individual tests may be semi-automatic, automatic or manual.

that an airflow meter be used to verify the sensitivity of the leak

The test method permits the non-destructive detection of leaks

test parameters.

not visibly detectable. The test method does not require the

introduction of any extraneous materials or substances, such as

NOTE 2—Refer to Annex A2 for further information about the use of a

dyes or gases. However, it is important to physically mask or volumetric airflow meter for verifying leak test sensitivity.

F2338–03

FIG. 1 Schematic of Fixture and Test Package

7. Hazards eters. Control packages are to be made from the same materials

and according to the same design as the test units.

7.1 As the test chamber is closed, it may present pinch-point

hazards.

NOTE 4—Refer to Annex A2 for information on critical test parameter

selection.

8. Preparation of Apparatus

9.4 After critical test parameters have been selected, qualify

8.1 The test apparatus must be started, warmed-up, and

the ability of the test to reliably differentiate between known

made ready according to the manufacturer’s specifications.

non-leaking and defective packages.

Utilities required for instrument operation include electrical

9.5 Determine the sensitivity of the test using control

power and a supply of dry, non-lubricated compressed air,

non-leaking test packages and a calibrated volumetric airflow

according to manufacturer’s specifications.

meter.

NOTE 5—Refer to Annex A2 for information about test sensitivity

9. Calibration and Standardization

verification procedures.

9.1 Before test measurements are made, the apparatus must

9.6 Test qualification (see 9.4) and test sensitivity verifica-

be calibrated. The pressure transducers, the vacuum source

tion (see 9.5) are to be conducted frequently, typically at least

pressure gage, and the adjustable volumetric airflow meter

one or more times a day, preferably at the beginning of every

must all be calibrated according to the manufacturer’s recom-

shift.

mended procedures and maintenance schedule.

9.2 Critical test parameter settings must be established for

10. Procedure

each package/test fixture combination. Parameters will vary

10.1 Select and install the appropriately sized test chamber

based on the test package geometry and any porous barrier

for the package to be tested. Make any necessary adjustments

surface’s inherent porosity.

to the chamber to ensure a sufficiently tight seal of the chamber

NOTE 3—Refer to Section 4 and Annex A1 for a description of critical

lid (upper tooling) to the lower chamber tray nest (lower

test parameters.

tooling) when the test chamber is in the closed position.

9.3 A sample population of control non-leaking packages 10.2 Verify the pressure level available at the supply source.

must be used for selecting and optimizing critical test param- Check the functionality of the vacuum source.

F2338–03

10.3 Program the test instrument with all necessary test 12.1.1 As summarized in Table 1, two populations of

parameters and accept/reject criteria. non-lidded trays representing two tray sizes were tested.

10.4 Place the assembled package into the tray nest and Defective samples contained a single hole in the tray wall of

close the test chamber. Take appropriate steps to mask or block either 50 μm or 100 μm in diameter. Two of the five larger

any porous barrier surface of the package. trays, each with a 50 μm hole, repeatedly failed to be detected

at more than one test site, while the other three trays were

NOTE 6—Inspect and clean the masking or blocking surface according

consistently identified as leaking. At the completion of the

to a regularly established routine according to the instrument manufac-

study the two suspect trays were independently reexamin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.