ASTM F1196-00(2013)

(Specification)Standard Specification for Sliding Watertight Door Assemblies

Standard Specification for Sliding Watertight Door Assemblies

ABSTRACT

This specification covers the design, manufacture, and testing of sliding watertight door assemblies intended to ensure the watertight integrity of personnel access openings in watertight bulkheads. Sliding watertight doors consist of four types: type IA - horizontal doors, type IB - vertical doors, type IIA - horizontal doors, and type IIB - vertical doors. Watertight doors consist of three classes: class 1 - doors that are hinged and dogged, class 2 - sliding doors that are operable both locally and remotely by hand gear, and class 3 - sliding doors that are operable both locally and remotely by hand and by power. Hydrostatic test and visual examination shall be performed to meet the requirements prescribed.

SCOPE

1.1 This specification covers the design, manufacture, and testing of sliding watertight door assemblies intended to ensure the watertight integrity of personnel access openings in watertight bulkheads.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1196 −00 (Reapproved 2013) An American National Standard

Standard Specification for

Sliding Watertight Door Assemblies

This standard is issued under the fixed designation F1196; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Title 46 Part 163.001, Doors, Watertight, Sliding (and Door

Controls),forMerchantVessels(throughthe1991edition)

1.1 This specification covers the design, manufacture, and

2.5 International Maritime Organization:

testing of sliding watertight door assemblies intended to ensure

International Code for the Application of Fire Test Proce-

the watertight integrity of personnel access openings in water-

dures (FTP)

tight bulkheads.

3. Terminology

1.2 The values stated in inch-pound units are to be regarded

as the standard. The values given in parentheses are for

3.1 Definitions:

information only.

3.1.1 door assembly—a door panel and its associated panel

1.3 This international standard was developed in accor- stiffening.

dance with internationally recognized principles on standard-

3.1.2 frame assembly—arigidframedesignedtobeattached

ization established in the Decision on Principles for the

to a watertight bulkhead. The guide tracks necessary to ensure

Development of International Standards, Guides and Recom-

proper door and frame alignment are also included as part of

mendations issued by the World Trade Organization Technical

the frame assembly.

Barriers to Trade (TBT) Committee.

3.1.3 horizontal sliding watertight door—a sliding water-

tight door that opens and closes with a horizontal movement.

2. Referenced Documents

2 3.1.4 opening hand—the direction in which a horizontal

2.1 ASTM Standards:

sliding watertight door opens. A left-hand opening door opens

A36/A36M Specification for Carbon Structural Steel

totheleftwhenviewedfromthesideofthebulkheadonwhich

F1197 Specification for Sliding Watertight Door Control

the door assembly is located.Aright-hand opening door opens

Systems

3 to the right when viewed from the side of the bulkhead on

2.2 Military Specification:

which the door assembly is located.

MIL-S-901 Shock Test, H.I. (High Impact); Shipboard

3.1.5 pressurehead—thepressurewhichaslidingwatertight

Machinery, Equipment and Systems, Requirements for

door assembly is designed to withstand. For a door located

2.3 American Bureau of Shipping:

below the bulkhead deck, it is equivalent to the pressure

Rules for Building and Classing Steel Vessels

5 exertedbyacolumnofwatertheheightofwhichisequaltothe

2.4 Code of Federal Regulations:

vertical distance from the bulkhead deck to the door sill in its

Title 46 Part 159.010, Independent Laboratory: Acceptance,

installed location. For a door located above the bulkhead deck,

Listing and Termination

itisequivalenttothepressureexertedbythemaximumheadof

water for its location, as determined in the damage stability

This specification is under the jurisdiction of Committee F25 on Ships and

calculations.

Marine Technology and is the direct responsibility of Subcommittee F25.03 on

3.1.6 sliding watertight door assembly—a steel door assem-

Outfitting and Deck Machinery.

Current edition approved May 1, 2013. Published May 2013. Originally

bly and a steel frame assembly fitted with a replaceable

approved in 1989. Last previous edition approved in 2008 as F1196 – 00 (2008).

interface between the two that ensures watertightness between

DOI: 10.1520/F1196-00R13.

door and frame at the design pressure head.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.1.7 vertical sliding watertight door—a sliding watertight

Standards volume information, refer to the standard’s Document Summary page on

door that opens and closes with a vertical movement.

the ASTM website.

Available from DLA Document Services, Building 4/D, 700 Robbins Ave.,

4. Classification

Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

Available from American Bureau of Shipping (ABS), ABS Plaza, 16855

4.1 Sliding watertight doors consist of four types:

Northchase Dr., Houston, TX 77060, http://www.eagle.org.

Available from U.S. Government Printing Office, Superintendent of

Documents, 732 N. Capitol St., NW, Washington, DC 20401-0001, http:// Available from the International Maritime Organization (IMO), 4 Albert

www.access.gpo.gov. Embankment, London, SE1 7SR UK, http://www.imo.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1196−00 (2013)

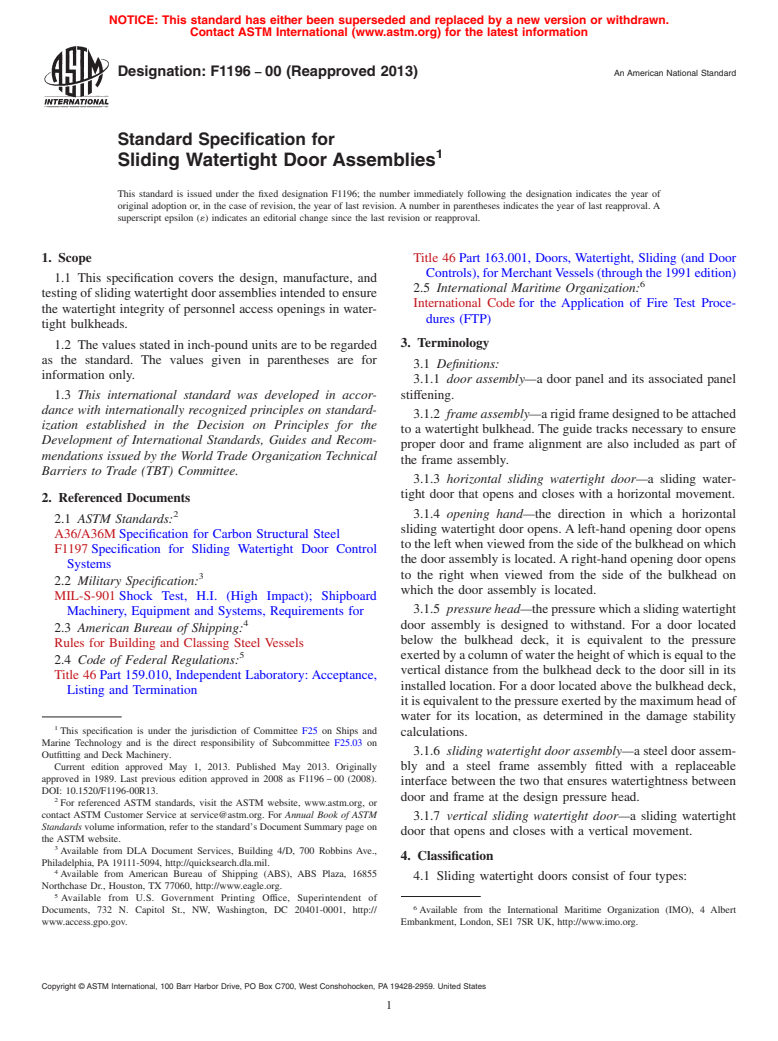

4.1.1 Type IA—Horizontal doors that conform to the sizes

specified in Table 1 as illustrated in Fig. 1.

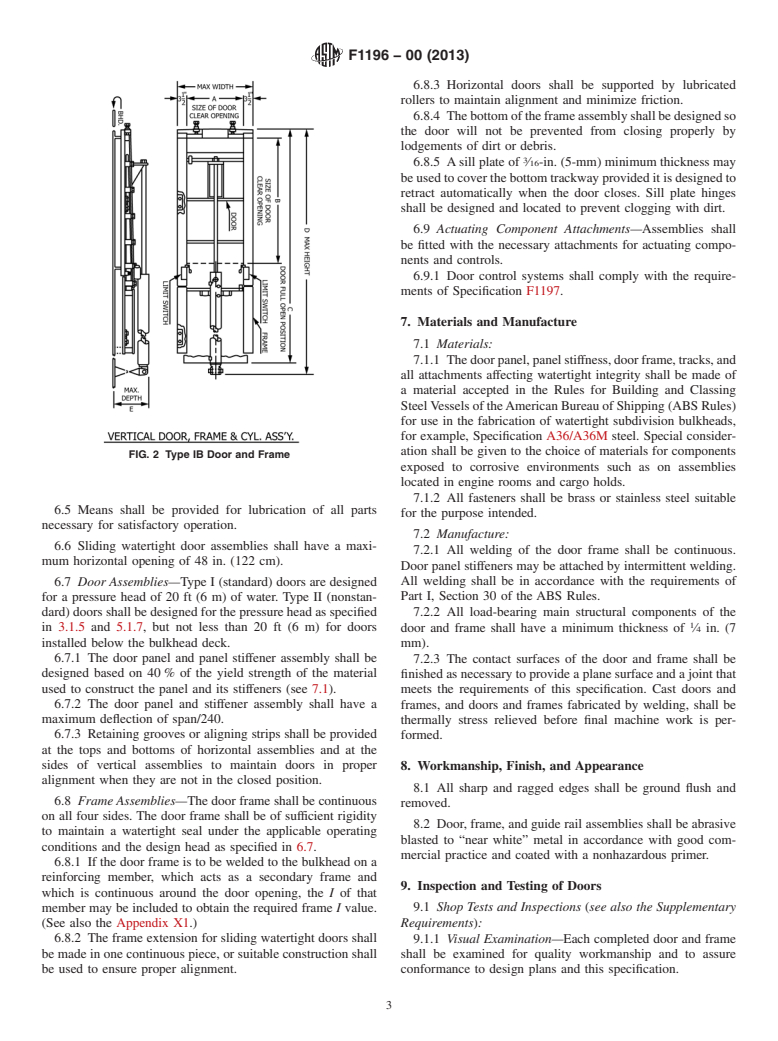

4.1.2 Type IB—Vertical doors that conform to the sizes

specified in Table 2 as illustrated in Fig. 2.

4.1.3 Type IIA—Horizontal doors that conform generally to

the requirements of this specification, but that necessitate

special requirements as indicated in Section 5.

4.1.4 Type IIB—Vertical doors that conform generally to the

requirements of this specification, but that necessitate special

requirements as indicated in Section 5.

4.2 Watertight doors consist of three classes:

NOTE 1—These classifications are in agreement with those defined and

accepted by the International Convention for the Safety of Life at Sea

(SOLAS), regulatory bodies, and classification societies.

4.2.1 Class 1—Doors that are hinged and dogged. This

specification is not applicable to this class of door.

4.2.2 Class 2—Sliding doors that are operable both locally

and remotely by hand gear.

4.2.3 Class 3—Sliding doors that are operable both locally

and remotely by hand and by power.

5. Ordering Information

5.1 The following shall be specified when ordering:

5.1.1 Quantity,

5.1.2 Type,

FIG. 1 Type IA Door and Frame

5.1.3 Class,

5.1.4 Size,

TABLE 2 Type IB Door Dimensions

5.1.5 Opening hand,

A, B, C, D, E,

5.1.6 Door and frame material,

Size Door Size

A

in. in. in. in. in.

5.1.7 Pressure head (if other than standard),

1 2 ft. 2 in. by 5 ft. 6 in. 26 66 142 155 17

5.1.8 Supplementary requirements (if any),

2 2 ft. 6 in. by 5 ft. 0 in. 30 60 130 143 16

5.1.9 Additional requirements as contracted by the manu- 3 2 ft. 6 in. by 6 ft. 0 in. 30 72 154 167 18

4 3 ft. 0 in. by 5 ft. 6 in. 36 66 142 155 18

facturer and purchaser, and

A

1 in. = 25.4 mm.

5.1.10 ASTM specification designation.

6. Design

6.1 Sliding watertight door assemblies shall be designed to

maintain watertightness within the limits set forth in this

6.3.1 Thereplaceableinterfacemaybeincorporatedintothe

specification. Doors shall be designed to open and close within

door assembly, the frame assembly, or both.

the limitations specified in Specification F1197.

6.3.2 Assemblies shall be designed and constructed so as to

6.2 Assembliesshallbeofsubstantialandrigidconstruction

be capable of preventing the passage of smoke and flame to the

to ensure that doors can be closed under a static head

end of the 1-h standard fire test described by IMO FTP. When

equivalent to a water height of at least 1 m above the sill on the

specified by the purchaser, assemblies shall also be insulated to

centerline of the door.

prevent the transfer of heat to at least the same degree as the

adjacent bulkhead. A fire test is not required if the assembly

6.3 There shall be a replaceable interface between the door

design incorporates details that have been demonstrated such

and frame assemblies, such as a brass rubbing strip or resilient

as by a fire test on a similar door with smaller dimensions, to

gasket, to ensure watertightness between door and frame at the

prevent the passage of smoke and flame. Also, a separate

design pressure head.

pressure test to determine continued watertightness after the

standard fire test is not required.

TABLE 1 Type IA Door Dimensions

6.3.3 Assembles shall be designed in such a manner that the

A, B, C, D, E, F,

Size Door Size

A replaceable interface will be protected from damage when the

in. in. in. in. in. in.

door is in the open position.

1 2 ft. 2 in. by 5 ft. 6 in. 26 66 64 76 17 78

2 2 ft. 6 in. by 5 ft. 0 in. 30 60 72 84 16 72

6.4 Sliding watertight door assemblies shall be designed to

3 2 ft. 6 in. by 6 ft. 0 in. 30 72 72 84 18 84

provide sufficient allowance or means of adjustment to main-

4 3 ft. 0 in. by 5 ft. 6 in. 36 66 84 96 18 78

A tain the original watertight integrity as the watertight joint

1 in. = 25.4 mm.

wears through normal usage.

F1196−00 (2013)

6.8.3 Horizontal doors shall be supported by lubricated

rollers to maintain alignment and minimize friction.

6.8.4 Thebottomoftheframeassemblyshallbedesignedso

the door will not be prevented from closing properly by

lodgements of dirt or debris.

6.8.5 Asill plate of ⁄16-in. (5-mm) minimum thickness may

beusedtocoverthebottomtrackwayprovideditisdesignedto

retract automatically when the door closes. Sill plate hinges

shall be designed and located to prevent clogging with dirt.

6.9 Actuating Component Attachments—Assemblies shall

be fitted with the necessary attachments for actuating compo-

nents and controls.

6.9.1 Door control systems shall comply with the require-

ments of Specification F1197.

7. Materials and Manufacture

7.1 Materials:

7.1.1 Thedoorpanel,panelstiffness,doorframe,tracks,and

all attachments affecting watertight integrity shall be made of

a material accepted in the Rules for Building and Classing

SteelVesselsoftheAmericanBureauofShipping(ABSRules)

for use in the fabrication of watertight subdivision bulkheads,

for example, Specification A36/A36M steel. Special consider-

ation shall be given to the choice of materials for components

FIG. 2 Type IB Door and Frame

exposed to corrosive environments such as on assemblies

located in engine rooms and cargo holds.

7.1.2 All fasteners shall be brass or stainless steel suitable

6.5 Means shall be provided for lubrication of all parts

for the purpose intended.

necessary for satisfactory operation.

7.2 Manufacture:

6.6 Sliding watertight door assemblies shall have a maxi-

7.2.1 All welding of the door frame shall be continuous.

mum horizontal opening of 48 in. (122 cm).

Door panel stiffeners may be attached by intermittent welding.

6.7 Door Assemblies—Type I (standard) doors are designed All welding shall be in accordance with the requirements of

Part I, Section 30 of the ABS Rules.

for a pressure head of 20 ft (6 m) of water. Type II (nonstan-

dard) doors shall be designed for the pressure head as specified 7.2.2 All load-bearing main structural components of the

in 3.1.5 and 5.1.7, but not less than 20 ft (6 m) for doors door and frame shall have a minimum thickness of ⁄4 in. (7

installed below the bulkhead deck. mm).

6.7.1 The door panel and panel stiffener assembly shall be 7.2.3 The contact surfaces of the door and frame shall be

designed based on 40 % of the yield strength of the material

finished as necessary to provide a plane surface and a joint that

used to construct the panel and its stiffeners (see 7.1).

meets the requirements of this specification. Cast doors and

6.7.2 The door panel and stiffener assembly shall have a

frames, and doors and frames fabricated by welding, shall be

maximum deflection of span/240.

thermally stress relieved before final machine work is per-

6.7.3 Retaining grooves or aligning strips shall be provided

formed.

at the tops and bottoms of horizontal assemblies and at the

sides of vertical assemblies to maintain doors in proper

8. Workmanship, Finish, and Appearance

alignment when they are not in the closed position.

8.1 All sharp and ragged edges shall be ground flush and

6.8 Frame Assemblies—The door frame shall be continuous

removed.

on all four sides. The door frame shall be of sufficient rigidity

8.2 Door, frame, and guide rail assemblies shall be abrasive

to maintain a watertight seal under the applicable operating

blasted to “near white” metal in accordance with good com-

conditions and the design head as specified in 6.7.

mercial practice and coated with a nonhazardous primer.

6.8.1 If the door frame is to be welded to the bulkhead on a

reinforcing member, which acts as a secondary frame and

9. Inspection and Testing of Doors

which is continuous around the door opening, the I of that

member may be included to obtain the required frame I value. 9.1 Shop Tests and Inspections (see also the Supplementary

Requirements):

(See also the Appendix X1.)

6.8.2 The frame extension for sliding watertight doors shall 9.1.1 Visual Examination—Each completed door and frame

be made in one continuous piece, or suitable construction shall shall be examined for quality workmanship and to assure

be used to ensure proper alignment. conformance to design plans and this specification.

F1196−00 (2013)

9.1.2 Hydrostatic Test—Each completed sliding watertight certification shall specify that the assembly has been

door assembly shall be subjected to a hydrostatic shop test to manufactured, inspected, and tested in accordance with this

verify its strength, rigidity, workmanship, and watertightness. specification and that it has been found to meet the require-

9.1.2.1 Hydrostatic Test Setup—The door frame shall be ments contained herein (see also S3.1.3).

mounted in either a vertical or horizontally flat position on a

reinforcedtestplateorslab.Meansshallbeprovidedtoventair 11. Nameplate

from the enclosure formed by the door, frame, and plate and to

11.1 Watertight Door Nameplate—A substantial corrosion-

supply water, at the required test pressure, to this enclosure.

resistant nameplate shall be permanently attached to each

Means shall also be provided for catching and measuring the

watertight door on which is legibly stamped the name of the

amountofwaterthatleaksbetweensealingsurfacesofthedoor

manufacturer, manufacturer’s serial number, ASTM specifica-

panel and frame. Except in the case of double-seated doors, it

tion designation, pressure head, the fire endurance rating in

will only be necessary to apply pressure to that side of the door

accordance with IMO FTP, and the date (see also Supplemen-

which will tend to separate the sealing surfaces.

tal Requirement S4).

9.1.2.2 Hydrostatic Test Procedure—The door shall be

closed by operating equipment that restricts the amount of

12. Packaging and Package Marking

closing force to that available from the operating gear to be

used in the shipboard installation. The enclosure shall then be 12.1 Sliding watertight door assemblies shall be crated or

completely filled with water, the air shall be vented, and the

att

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.