ASTM D6013-00(2010)

(Test Method)Standard Test Method for Determination of Area Stability of Leather to Laundering

Standard Test Method for Determination of Area Stability of Leather to Laundering

SIGNIFICANCE AND USE

The procedure is primarily intended to evaluate the ability of a leather specimen to withstand fixed, and rather strenuous, laundering conditions. This test method is not intended as a recommended washing procedure, neither household nor commercial. The resulting area stability is determined.

SCOPE

1.1 This test method covers the determination of launderability of dyed leathers with or without a pigment finish. This test method does not apply to wet blue.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6013 − 00 (Reapproved 2010)

Standard Test Method for

Determination of Area Stability of Leather to Laundering

This standard is issued under the fixed designation D6013; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Apparatus

2 5

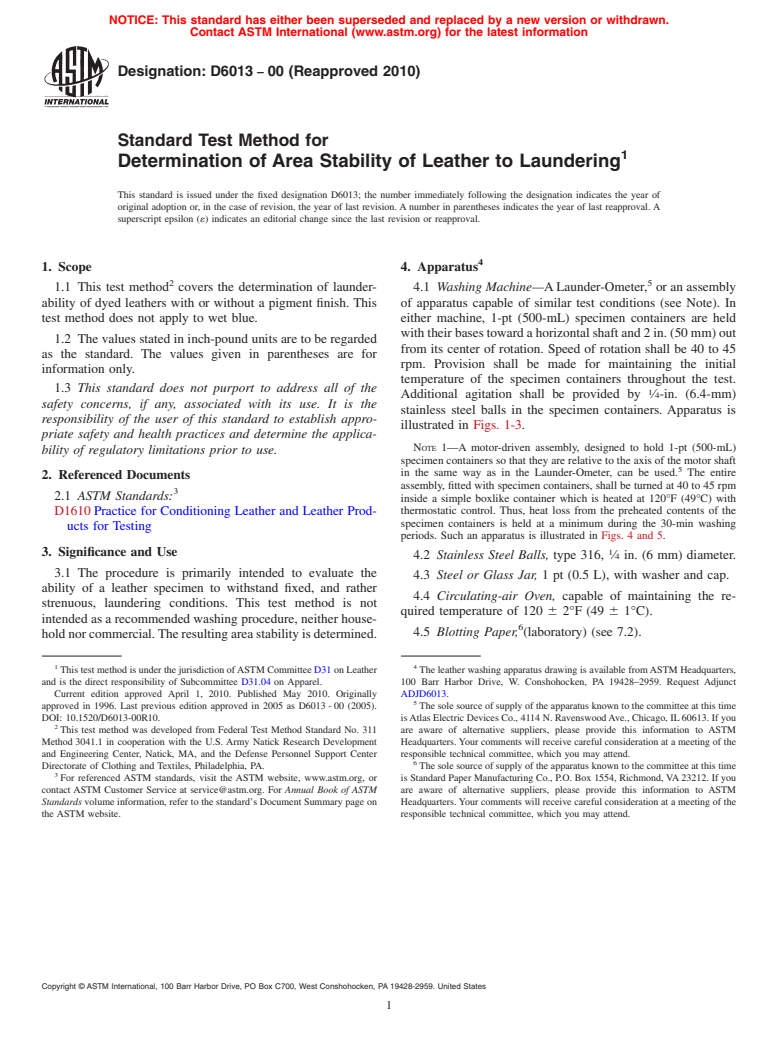

1.1 This test method covers the determination of launder- 4.1 Washing Machine—ALaunder-Ometer, or an assembly

ability of dyed leathers with or without a pigment finish. This of apparatus capable of similar test conditions (see Note). In

test method does not apply to wet blue. either machine, 1-pt (500-mL) specimen containers are held

withtheirbasestowardahorizontalshaftand2in.(50mm)out

1.2 The values stated in inch-pound units are to be regarded

from its center of rotation. Speed of rotation shall be 40 to 45

as the standard. The values given in parentheses are for

rpm. Provision shall be made for maintaining the initial

information only.

temperature of the specimen containers throughout the test.

1.3 This standard does not purport to address all of the

Additional agitation shall be provided by ⁄4-in. (6.4-mm)

safety concerns, if any, associated with its use. It is the

stainless steel balls in the specimen containers. Apparatus is

responsibility of the user of this standard to establish appro-

illustrated in Figs. 1-3.

priate safety and health practices and determine the applica-

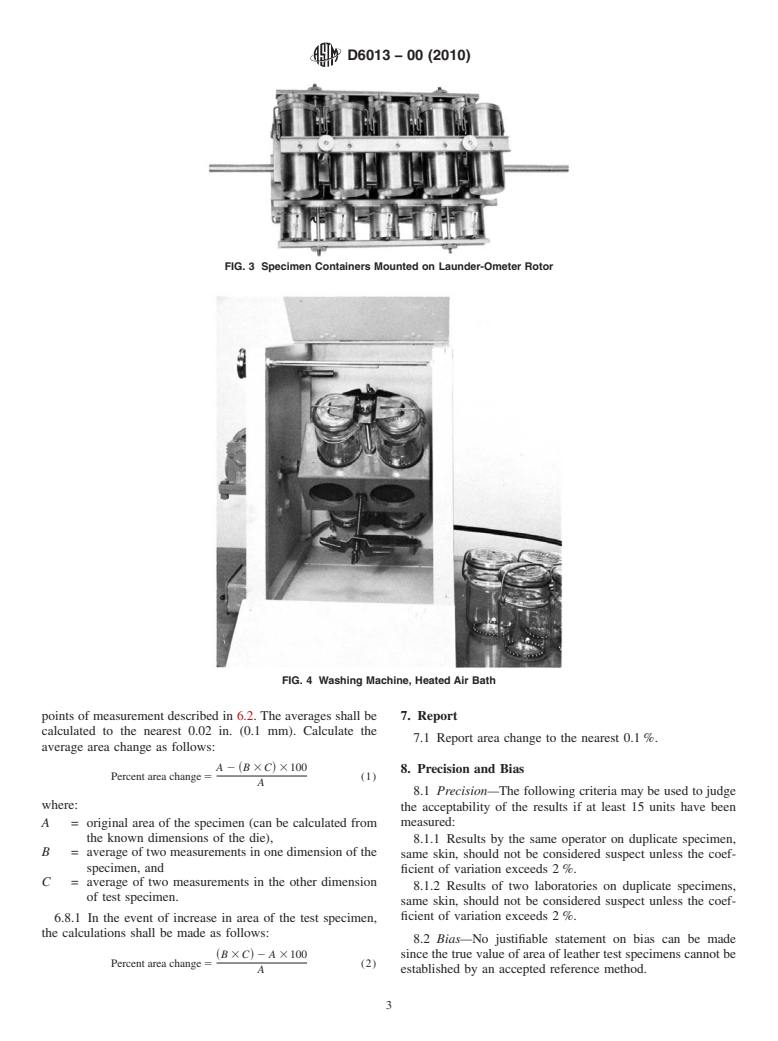

NOTE 1—A motor-driven assembly, designed to hold 1-pt (500-mL)

bility of regulatory limitations prior to use.

specimen containers so that they are relative to the axis of the motor shaft

in the same way as in the Launder-Ometer, can be used. The entire

2. Referenced Documents

assembly, fitted with specimen containers, shall be turned at 40 to 45 rpm

2.1 ASTM Standards:

inside a simple boxlike container which is heated at 120°F (49°C) with

D1610 Practice for Conditioning Leather and Leather Prod- thermostatic control. Thus, heat loss from the preheated contents of the

specimen containers is held at a minimum during the 30-min washing

ucts for Testing

periods. Such an apparatus is illustrated in Figs. 4 and 5.

3. Significance and Use

4.2 Stainless Steel Balls, type 316, ⁄4 in. (6 mm) diameter.

3.1 The procedure is primarily intended to evaluate the

4.3 Steel or Glass Jar, 1 pt (0.5 L), with washer and cap.

ability of a leather specimen to withstand fixed, and rather

4.4 Circulating-air Oven, capable of maintaining the re-

strenuous, laundering conditions. This test method is not

quired temperature of 120 6 2°F (49 6 1°C).

intended as a recommended washing procedure, neither house-

4.5 Blotting Paper, (laboratory) (see 7.2).

holdnorcommercial.Theresultingareastabilityisdetermined.

1 4

This test method is under the jurisdiction ofASTM Committee D31 on Leather The leather washing apparatus drawing is available fromASTM Headquarters,

and is the direct responsibility of Subcommittee D31.04 on Apparel. 100 Barr Harbor Drive, W. Conshohocken, PA 19428–2959. Request Adjunct

Current edition approved April 1, 2010. Published May 2010. Originally ADJD6013.

approved in 1996. Last previous edition approved in 2005 as D6013 - 00 (2005). The sole source of supply of the apparatus known to the committee at this time

DOI: 10.1520/D6013-00R10. isAtlas Electric Devices Co., 4114 N. RavenswoodAve., Chicago, IL60613. If you

This test method was developed from Federal Test Method Standard No. 311 are aware of alternative suppliers, please provide this information to ASTM

Method 3041.1 in cooperation with the U.S. Army Natick Research Development Headquarters.Your comments will receive careful consideration at a meeting of the

and Engineering Center, Natick, MA, and the Defense Personnel Support Center responsible technical committee, which you may attend.

Directorate of Clothing and Textiles, Philadelphia, PA. The sole source of supply of the apparatus known to the committee at this time

For referenced ASTM standards, visit the ASTM website, www.astm.org, or is Standard Paper Manufacturing Co., P.O. Box 1554, Richmond, VA23212. If you

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM are aware of alternative suppliers, please provide this information to ASTM

Standards volume information, refer to the standard’s Document Summary page on Headquarters.Your comments will receive careful consideration at a meeting of the

the ASTM website. responsible technical committee, which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6013 − 00 (2010)

6. Procedure

6.1 Unless otherwise specified, perform this test in accor-

dance with standard atmospheric conditions (see Practice

D1610). Weigh the conditioned samples to the nearest 0.1 g.

6.2 Make two measurements of each dimension of the

specimenandaveragethem.Makethemeasurements13mmin

from the edges of the specimen. Indelibly mark the grain

surface of the specimen to indicate the points of measurement.

Use the average measurement to determine the original area of

the specimen, and record this area as A. (The known dimen-

sions of the die may be used instead of actually measuring the

specimen.When this option is taken, the specimen shall still be

indelibly marked at the points of measurement indicated

above.)

6.3 Add three specimens and twenty stainless steel balls to

a 1-pt jar together with 150 mLof a soap solution that has been

preheated to 120 6 2°F (49 6 1°C).

6.4 Seal the jars and clamp them into the rotor of a washing

machine. Run the apparatus at 40 to 45 rpm for 30 min at 120

6 2°F (49 6 1°C).

FIG. 1 Launder-Ometer

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.