ASTM D6013-00(2018)

(Test Method)Standard Test Method for Determination of Area Stability of Leather to Laundering

Standard Test Method for Determination of Area Stability of Leather to Laundering

SIGNIFICANCE AND USE

3.1 The procedure is primarily intended to evaluate the ability of a leather specimen to withstand fixed, and rather strenuous, laundering conditions. This test method is not intended as a recommended washing procedure, neither household nor commercial. The resulting area stability is determined.

SCOPE

1.1 This test method2 covers the determination of launderability of dyed leathers with or without a pigment finish. This test method does not apply to wet blue.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6013 − 00 (Reapproved 2018)

Standard Test Method for

Determination of Area Stability of Leather to Laundering

This standard is issued under the fixed designation D6013; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Apparatus

2 5

4.1 Washing Machine—ALaunder-Ometer, or an assembly

1.1 This test method covers the determination of launder-

of apparatus capable of similar test conditions (see Note). In

ability of dyed leathers with or without a pigment finish. This

test method does not apply to wet blue. either machine, 1-pt (500-mL) specimen containers are held

withtheirbasestowardahorizontalshaftand2in.(50mm)out

1.2 The values stated in inch-pound units are to be regarded

from its center of rotation. Speed of rotation shall be 40 to 45

as the standard. The values given in parentheses are for

rpm. Provision shall be made for maintaining the initial

information only.

temperature of the specimen containers throughout the test.

1.3 This standard does not purport to address all of the

Additional agitation shall be provided by ⁄4-in. (6.4-mm)

safety concerns, if any, associated with its use. It is the

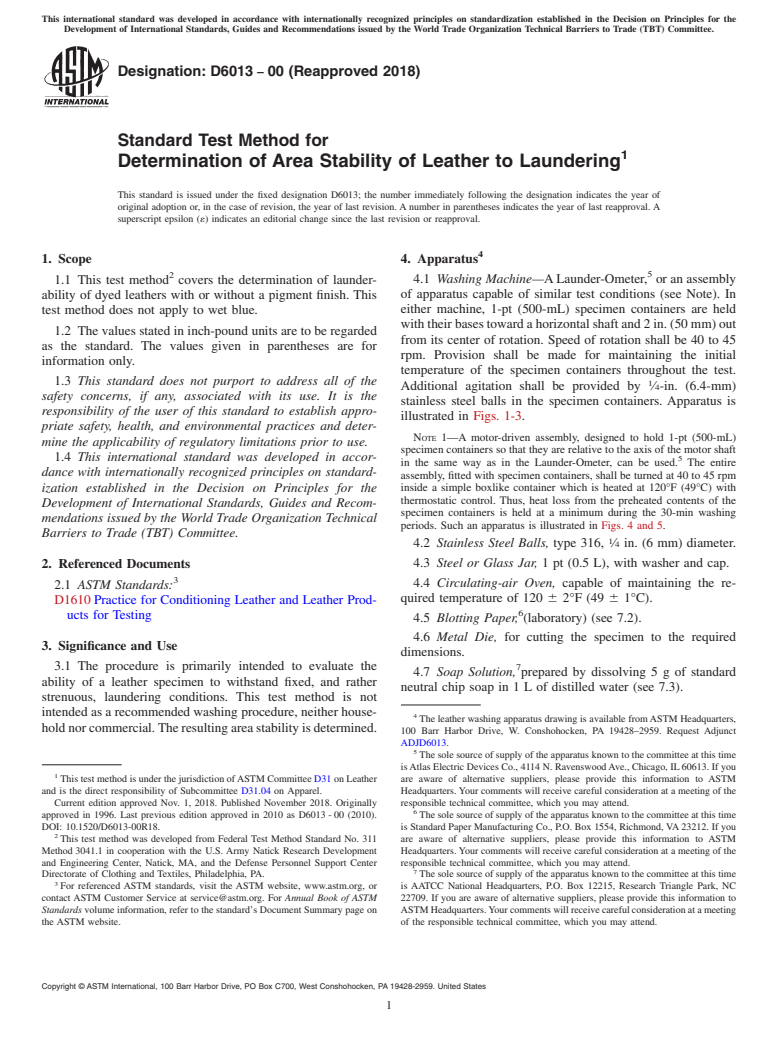

stainless steel balls in the specimen containers. Apparatus is

responsibility of the user of this standard to establish appro-

illustrated in Figs. 1-3.

priate safety, health, and environmental practices and deter-

NOTE 1—A motor-driven assembly, designed to hold 1-pt (500-mL)

mine the applicability of regulatory limitations prior to use.

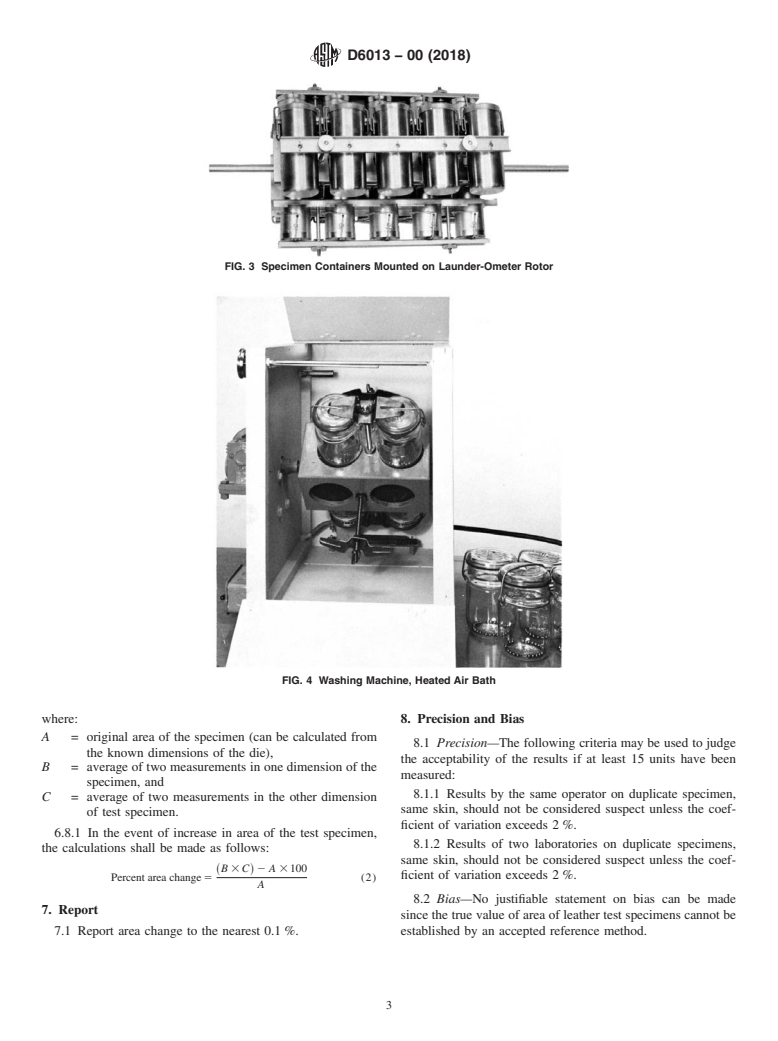

specimen containers so that they are relative to the axis of the motor shaft

1.4 This international standard was developed in accor- 5

in the same way as in the Launder-Ometer, can be used. The entire

dance with internationally recognized principles on standard-

assembly, fitted with specimen containers, shall be turned at 40 to 45 rpm

inside a simple boxlike container which is heated at 120°F (49°C) with

ization established in the Decision on Principles for the

thermostatic control. Thus, heat loss from the preheated contents of the

Development of International Standards, Guides and Recom-

specimen containers is held at a minimum during the 30-min washing

mendations issued by the World Trade Organization Technical

periods. Such an apparatus is illustrated in Figs. 4 and 5.

Barriers to Trade (TBT) Committee.

4.2 Stainless Steel Balls, type 316, ⁄4 in. (6 mm) diameter.

4.3 Steel or Glass Jar, 1 pt (0.5 L), with washer and cap.

2. Referenced Documents

4.4 Circulating-air Oven, capable of maintaining the re-

2.1 ASTM Standards:

quired temperature of 120 6 2°F (49 6 1°C).

D1610 Practice for Conditioning Leather and Leather Prod-

ucts for Testing

4.5 Blotting Paper, (laboratory) (see 7.2).

4.6 Metal Die, for cutting the specimen to the required

3. Significance and Use

dimensions.

3.1 The procedure is primarily intended to evaluate the 7

4.7 Soap Solution, prepared by dissolving5gof standard

ability of a leather specimen to withstand fixed, and rather

neutral chip soap in 1 L of distilled water (see 7.3).

strenuous, laundering conditions. This test method is not

intended as a recommended washing procedure, neither house-

The leather washing apparatus drawing is available fromASTM Headquarters,

holdnorcommercial.Theresultingareastabilityisdetermined.

100 Barr Harbor Drive, W. Conshohocken, PA 19428–2959. Request Adjunct

ADJD6013.

The sole source of supply of the apparatus known to the committee at this time

isAtlas Electric Devices Co., 4114 N. RavenswoodAve., Chicago, IL60613. If you

This test method is under the jurisdiction ofASTM Committee D31 on Leather are aware of alternative suppliers, please provide this information to ASTM

and is the direct responsibility of Subcommittee D31.04 on Apparel. Headquarters.Your comments will receive careful consideration at a meeting of the

Current edition approved Nov. 1, 2018. Published November 2018. Originally responsible technical committee, which you may attend.

approved in 1996. Last previous edition approved in 2010 as D6013 - 00 (2010). The sole source of supply of the apparatus known to the committee at this time

DOI: 10.1520/D6013-00R18. is Standard Paper Manufacturing Co., P.O. Box 1554, Richmond, VA23212. If you

This test method was developed from Federal Test Method Standard No. 311 are aware of alternative suppliers, please provide this information to ASTM

Method 3041.1 in cooperation with the U.S. Army Natick Research Development Headquarters.Your comments will receive careful consideration at a meeting of the

and Engineering Center, Natick, MA, and the Defense Personnel Support Center responsible technical committee, which you may attend.

Directorate of Clothing and Textiles, Philadelphia, PA. The sole source of supply of the apparatus known to the committee at this time

For referenced ASTM standards, visit the ASTM website, www.astm.org, or is AATCC National Headquarters, P.O. Box 12215, Research Triangle Park, NC

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 22709. If you are aware of alternative suppliers, please provide this information to

Standards volume information, refer to the standard’s Document Summary page on ASTMHeadquarters.Yourcommentswillreceivecarefulconsiderationatameeting

the ASTM website. of the responsible technical committee, which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6013 − 00 (2018)

Use the average measurement to determine the original area of

the specimen, and record this area as A. (The known dimen-

sions of the die may be used instead of actually measuring the

specimen.When this option is taken, the specimen sh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.