ASTM A604-93(1998)

(Test Method)Standard Test Method for Macroetch Testing of Consumable Electrode Remelted Steel Bars and Billets

Standard Test Method for Macroetch Testing of Consumable Electrode Remelted Steel Bars and Billets

SCOPE

1.1 This test method for testing and inspection is applicable to bars, billets, and blooms of carbon, alloy, and stainless steel which have been consumable electrode remelted.

1.2 For the purpose of this test method, the consumable electrode remelting process is defined as a steel refining method wherein single or multiple electrodes are remelted into a crucible producing an ingot which is superior to the original electrode by virtue of improved cleanliness or lower gas content or reduced chemical or nonmetallic segregation. See Appendixes X1 and X2 for descriptions of applicable remelting processes.

1.3 This test method and the accompanying comparison macrographs are generally applicable to steel bar and billet sizes up to 225 in. in transverse cross section.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 604 – 93 (Reapproved 1998)

Standard Test Method for

Macroetch Testing of Consumable Electrode Remelted Steel

Bars and Billets

This standard is issued under the fixed designation A 604; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.2 This test method employs the action of an acid or other

corrosive agent to develop the characteristics of a suitably

1.1 This test method for testing and inspection is applicable

prepared specimen. After etching, the sections are compared

to bars, billets, and blooms of carbon, alloy, and stainless steel

visually, or at a very low magnification, if necessary for

which have been consumable electrode remelted.

clarification of conditions, to standard plates describing the

1.2 For the purpose of this test method, the consumable

various conditions which may be found. Materials react differ-

electrode remelting process is defined as a steel refining

ently to etching reagents because of variations in chemical

method wherein single or multiple electrodes are remelted into

composition, method of manufacture, heat treatment, and many

a crucible producing an ingot which is superior to the original

other variables.

electrode by virtue of improved cleanliness or lower gas

content or reduced chemical or nonmetallic segregation. See

4. Application

Appendix X1 and Appendix X2 for descriptions of applicable

4.1 When material is furnished subject to macroetch testing

remelting processes.

and inspection under this test method, the manufacturer and

1.3 This test method and the accompanying comparison

3 purchaser should be in agreement concerning the following:

macrographs are generally applicable to steel bar and billet

2 4.1.1 The stage of manufacture at which the test shall be

sizes up to 225 in. in transverse cross section.

conducted.

2. Referenced Documents 4.1.2 The number and location of the sections to be tested,

4.1.3 The condition and preparation of the surface to be

2.1 ASTM Standards:

macroetched.

E 381 Method of Macroetch Testing, Inspection, and Rating

4.1.4 The etching reagent, temperature and time of etching,

Steel Products, Comprising Bars, Billets, Blooms, and

or degree of etching including any special techniques which

Forgings

must be used, and

3. Description of Macroetch Testing

4.1.5 The type and degree of conditions or combinations

thereof that shall be considered acceptable or subject to

3.1 Macroetch testing, as described herein, is a method for

metallurgical review.

examining and rating transverse sections of bars and billets to

describe certain conditions of macro segregation which are

5. Sample Preparation

often characteristic of consumable electrode remelted materi-

5.1 Unless otherwise specified, the test shall be performed

als. This test method is not intended to define major defects

on specimens, usually ⁄4 to 1 in. thick, cut to reveal a

such as those described by Method E 381.

transverse surface.

5.2 Disks for macroetch inspection may be removed from

This test method is under the jurisdiction of ASTM Committee A01 on Steel, billets by a variety of methods including torch cutting, sawing,

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

machining, or high-speed abrasive wheels. Adequate prepara-

A01.06 on Steel Forgings and Billets.

tion of the surface for macroetching must completely remove

Current edition approved June 15, 1993. Published August 1993. Originally

the effects of torch cutting or high-speed abrasive wheels.

published as A 604 – 70. Last previous edition A 604 – 77 (1992).

ASTM Committee A01 gratefully acknowledges the help of the AISI Commit-

5.3 Due to the nature of the conditions to be detected,

tee on General Metallurgy in preparing the appendix, assembling the macroetch

further surface preparation is usually required.

photographs, and assisting with the text of this test method.

3 5.4 When such further preparation is performed, grinding,

A complete set of the 20 macrographs on glossy paper is available at nominal

cost from ASTM Headquarters, 100 Barr Harbor Drive, W. Conshohocken, PA machining, or sanding should be carried out in such a manner

19428. Request Adjunct ADJA0604.

as not to mask the structure.

Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

A 604 – 93 (1998)

5.5 The surface of the disk to be etched must be free of dirt, 9.1.3 Class 3: Radial Segregation—Radially or spirally

grease, or other foreign material which might impair the result oriented dark etching elongated areas occurring most fre-

of the test. quently at mid-radius which are generally carbide enriched.

This condition may be easily confused with freckles in some

6. Etching Reagents

materials.

6.1 The etching response and appearance is dependent upon

9.1.4 Class 4: Ring Pattern—One or more concentric rings

the type and temperature of the etching reagent and the time of

evidenced by a differential in etch texture associated with

immersion. These details must be established by agreement

minor composition gradients and ingot solidification.

between manufacturer and purchaser.

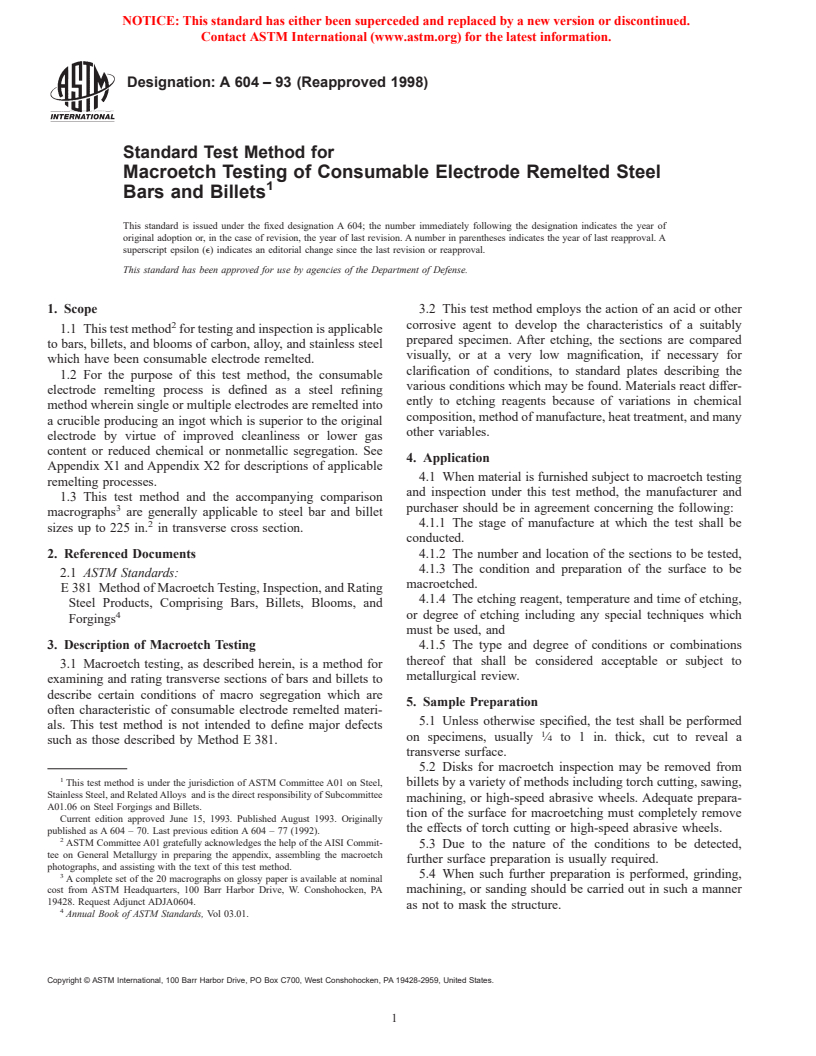

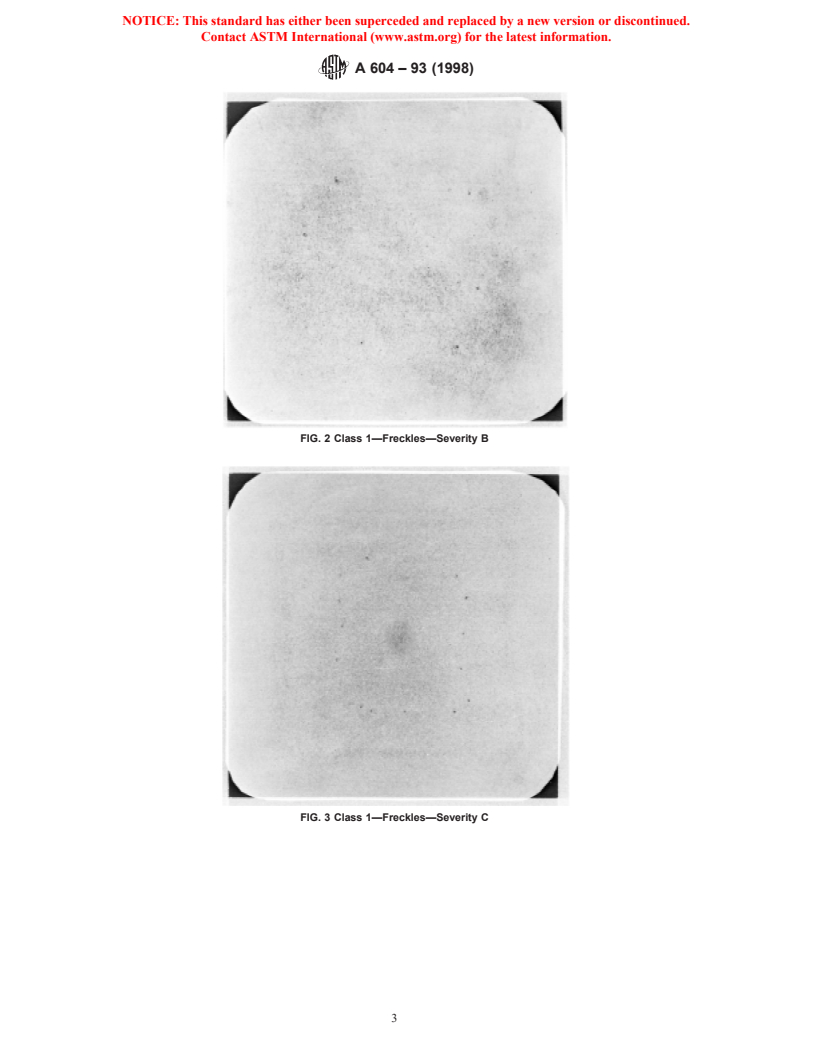

9.2 Macroetch photographs show examples of each of the

6.2 For illustrative purposes some of the commonly used

conditions revealed by macroetch testing, with five degrees of

etching reagents are as follows:

severity, identified as A, B, C, D, and E for each condition.

6.2.1 Hydrochloric Acid—A solution of 1 part commercial

Degree A exhibits the minimum occurrence of each condition

concentrated hydrochloric acid (HCl, sp gr 1.19) and 1 part

detectable by visual examination of the etched surface, while

water is more generally used than any other macroetching

degrees B, C, D, and E represent increasing severity of

reagent. This solution may be heated without significant

occurrence.

change in concentration, and may be reused if it has not

9.3 For each condition, or combination of conditions, rat-

become excessively contaminated or weakened. Etching is

ings shall be obtained by comparing each macroetched section

generally done with the solution at a temperature of approxi- 2

with the standard photographs. Bar or billet sections to 225 in.

mately 160°F.

cross-sectional area may be rated against these standards.

6.2.2 Hydrochloric Acid-Sulfuric Acid Mixture—A mixture

Larger sizes may be rated by agreement between manufacturer

containing 50 % water, 38 % commercial concentrated HCl,

and purchaser, but caution must be exercised in interpretation

and 12 % commercial concentrated sulfuric acid (H SO ,spgr

2 4

of such results. Figs. 1-20 have been reduced 44% in area from

1.84) is sometimes used in place of the previously mentioned

the standard photographs.

50 % HCl solution. The statements in the previous paragraph

9.4 If the appearance of a given condition does not exactly

regarding reuse and temperature of etchant are applicable to

match one of the five standard photographs, it shall be assigned

this reagent.

the rating of the standard that it most nearly matches.

6.2.3 Aqua Regia—A solution consisting of 1 part concen-

9.5 No standards for acceptance are stated or implied in

trated nitric acid (HNO , sp gr 1.42) and 2 parts concentrated

these illustrations. The extent to which each condition may be

HCl is used on corrosion and heat-resistant materials of the

permissible varies with the intended application, and such

18 % chromium, 8 % nickel type and higher alloy types. This

standards should be stated in the applicable product specifica-

reagent is used at room temperature.

tion, or may be the subject of negotiation between manufac-

turer and purchaser.

NOTE 1—The reagents in 6.2.1, 6.2.2, and 6.2.3 should be used under

ventilating hoods or with some provision to remove the corrosive fumes.

6.2.4 Nitric Acid—This etchant consists of 5 % HNO

solution in alcohol or water, and is generally used at room

temperature. When this reagent is used, the etch disk must have

a smooth surface.

7. Etching Containers

7.1 Macroetching must be done in containers that are

resistant to attack from the etching reagents. Caution must be

exerted to prevent the occurrence of electrolytic couples which

can cause uneven attacks and misleading results.

8. Preparation of Etched Surface and Examination

8.1 Upon completion of etching, surfaces of disks should be

cleaned by either chemical or mechanical methods that do not

affect the macroetch quality. Care should be taken to prevent

rusting of the etched surface.

9. Interpretation of Conditions Found by Macroetching

9.1 Four distinct classes of conditions are defined and

described under this method:

9.1.1 Class 1: Freckles—Circular or near-circular dark

etching areas generally enriched with carbides and carbide-

forming elements.

9.1.2 Class 2: White Spots—Light etching areas, having no

definitive configuration or orientation which are generally

reduced in carbide or carbide-forming elements. FIG. 1 Class 1—Freckles—Severity A

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

A 604 – 93 (1998)

FIG. 2 Class 1—Freckles—Severity B

FIG. 3 Class 1—Freckles—Severity C

NOTICE: This standard has either been superceded

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.