ASTM F541-12(2020)

(Specification)Standard Specification for Alloy Steel Eyebolts

Standard Specification for Alloy Steel Eyebolts

ABSTRACT

This specification covers the basic requirements and corresponding test methods for forged, quenched, and tempered, alloy steel threaded eyebolts with improved toughness properties and that are chemically and metallurgically constituted to produce a low transition temperature to minimize brittle failure, intended primarily for low temperature applications. The eyebolts are furnished either as straight shank eyebolts (Type 1), or shoulder eyebolts (Type 2). Sampled specimens shall be tested, and conform accordingly to chemical (carbon, manganese, phosphorus, sulfur, silicon, chromium, molybdenum, and nickel), metallurgical (grain size, decarburization, and macrotech properties), and mechanical (Brinell hardness, tensile strength, breaking strength, proof load, impact strength, and bend strength) requirements.

SCOPE

1.1 This specification covers forged, quenched and tempered, alloy steel threaded eyebolts with improved toughness properties and intended primarily for low temperature applications. The eyebolts are chemically and metallurgically constituted to produce a low transition temperature to minimize brittle failure. Maximum thread size is 2.500 in. (63.50 mm).

1.2 The eyebolts are furnished in two types, as follows:

1.2.1 Type 1—Straight Shank Eyebolt.

1.2.2 Type 2—Shoulder Eyebolt.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are for information only.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F541 −12 (Reapproved 2020)

Standard Specification for

1

Alloy Steel Eyebolts

ThisstandardisissuedunderthefixeddesignationF541;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* E709Guide for Magnetic Particle Testing

F606/F606MTest Methods for Determining the Mechanical

1.1 This specification covers forged, quenched and

Properties of Externally and Internally Threaded

tempered, alloy steel threaded eyebolts with improved tough-

Fasteners, Washers, Direct Tension Indicators, and Rivets

ness properties and intended primarily for low temperature

F1470Practice for Fastener Sampling for Specified Me-

applications. The eyebolts are chemically and metallurgically

chanical Properties and Performance Inspection

constitutedtoproducealowtransitiontemperaturetominimize

3

brittle failure. Maximum thread size is 2.500 in. (63.50 mm). 2.2 ASME Standards:

B1.1Unified Screw Threads

1.2 The eyebolts are furnished in two types, as follows:

B18.15Forged Eyebolts

1.2.1 Type 1—Straight Shank Eyebolt.

B18.24Part Identifying Number (PIN) Code System Stan-

1.2.2 Type 2—Shoulder Eyebolt.

dard for B18 Fastener Products

1.3 Thevaluesstatedininch-poundunitsaretoberegarded

as the standard. The values in parentheses are for information

3. Ordering Information

only.

3.1 Ordersforeyeboltsunderthisspecificationshallinclude

1.4 This international standard was developed in accor-

the following information to adequately describe the part:

dance with internationally recognized principles on standard-

3.1.1 ASTM specification number and date of issue,

ization established in the Decision on Principles for the

3.1.2 Name of part (alloy steel eyebolts),

Development of International Standards, Guides and Recom-

3.1.3 Regular or shoulder pattern (8.1),

mendations issued by the World Trade Organization Technical

3.1.4 Size (nominal diameter and threads),

Barriers to Trade (TBT) Committee.

3.1.5 Number of pieces,

3.1.6 Certification or test reports (if required) (14.1),

2. Referenced Documents

3.1.7 Additional requirements (if required), and

2

2.1 ASTM Standards:

3.1.8 Supplementary requirements (if required).

A370Test Methods and Definitions for Mechanical Testing

3.1.9 For establishment of a part identifying system, see

of Steel Products

ASME B18.24.

A574SpecificationforAlloySteelSocket-HeadCapScrews

A751Test Methods, Practices, and Terminology for Chemi-

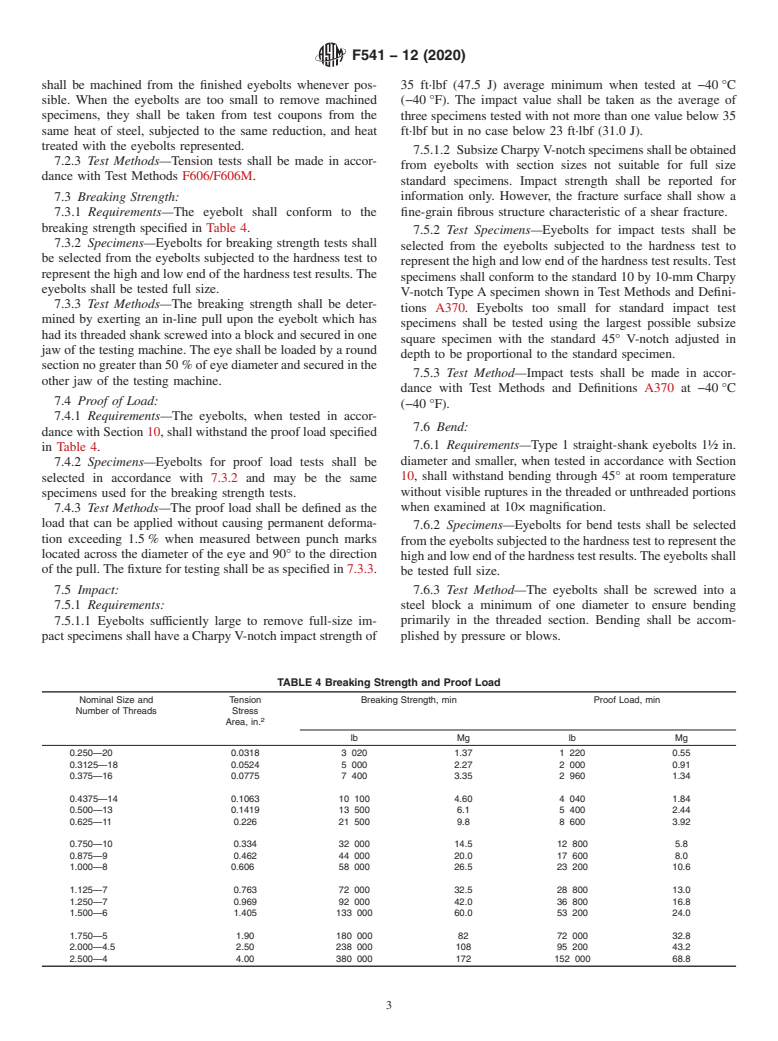

4. Materials and Manufacture

cal Analysis of Steel Products

4.1 MeltingProcess—Thesteelshallbemadetoafine-grain

E10Test Method for Brinell Hardness of Metallic Materials

practiceusingameltingprocessyieldingaproductconforming

E18Test Methods for Rockwell Hardness of Metallic Ma-

to the requirements of this specification.

terials

E112Test Methods for Determining Average Grain Size 4.2 Forging—Eyebolts shall be forged without welds.

E340Practice for Macroetching Metals and Alloys

4.3 Heat Treatment—The eyebolts shall be quenched and

tempered in accordance with proper practice to yield a product

1 conforming to the requirements of this specification.

This specification is under the jurisdiction of ASTM Committee F16 on

Fasteners and is the direct responsibility of Subcommittee F16.02 on Steel Bolts,

4.4 Machining—The eyebolt shall be machined prior to or

Nuts, Rivets and Washers.

after heat treatment at the manufacturer’s option.

Current edition approved Dec. 1, 2020. Published December 2020. Originally

approved in 1977. Last previous edition approved in 2012 as F541–12. DOI:

10.1520/F0541-12R20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from American Society of Mechanical Engineers (ASME), ASME

Standards volume information, refer to the standard’s Document Summary page on International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

the ASTM website. www.asme.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F541−12 (2020)

TABLE 2 Decarburization Limits

5. Chemical Composition

Nominal Size, In. Depth of Decarburization, Total + Partial, max

5.1 Limits—The eyebolts shall be manufactured from steels

in. mm

havingaheatanalysisconformingtotherequirementsinTable

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.