ASTM A449-14(2020)

(Specification)Standard Specification for Hex Cap Screws, Bolts and Studs, Steel, Heat Treated, 120/105/90 ksi Minimum Tensile Strength, General Use

Standard Specification for Hex Cap Screws, Bolts and Studs, Steel, Heat Treated, 120/105/90 ksi Minimum Tensile Strength, General Use

ABSTRACT

This specification2 covers quenched and tempered steel hex cap screws, bolts, and studs having a minimum tensile strength. The fasteners are intended for general engineering use. Type 1 fasteners shall be plain carbon steel, carbon boron steel, alloy steel, or alloy boron steels conforming to the requirements. Type 3 fasteners shall be weathering steel and shall conform to one of the chemical compositions specified. Tensile strength, proof load, hardness tests, and axial tension tests shall be performed to conform with the specified requirements.

SCOPE

1.1 This specification2 covers quenched and tempered steel hex cap screws, bolts, and studs having a minimum tensile strength of 120 ksi for diameters 1.0 in. and smaller; 105 ksi for diameters over 1.0 in. to 11/2 in.; and 90 ksi for diameters 13/4 in. to 3.0 in. inclusive. The term "fasteners" in this specification denotes hex cap screws, bolts, and studs.

1.2 The fasteners are intended for general engineering use.

1.3 The fasteners are furnished in diameters 1/4 to 3.0 in. inclusive. They are designated by type denoting chemical composition as follows:

Type

Description

Type I

Plain carbon steel, carbon boron steel, alloy steel, or alloy boron steel

Type 2

Withdrawn 2003

Type 3

Weathering steel

1.4 Terms used in this specification are defined in Terminology F1789 unless otherwise defined in this specification.

1.5 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:A449 −14 (Reapproved 2020)

Standard Specification for

Hex Cap Screws, Bolts and Studs, Steel, Heat Treated, 120/

105/90 ksi Minimum Tensile Strength, General Use

This standard is issued under the fixed designation A449; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 2. Referenced Documents

2 3

1.1 This specification covers quenched and tempered steel 2.1 ASTM Standards:

hex cap screws, bolts, and studs having a minimum tensile A563Specification for Carbon and Alloy Steel Nuts

strengthof120ksifordiameters1.0in.andsmaller;105ksifor A751Test Methods, Practices, and Terminology for Chemi-

1 3

diameters over 1.0 in. to 1 ⁄2 in.; and 90 ksi for diameters 1 ⁄4 cal Analysis of Steel Products

in.to3.0in.inclusive.Theterm "fasteners"inthisspecification B695Specification for Coatings of Zinc Mechanically De-

denotes hex cap screws, bolts, and studs. posited on Iron and Steel

F436/F436MSpecification for Hardened SteelWashers Inch

1.2 The fasteners are intended for general engineering use.

and Metric Dimensions

1.3 The fasteners are furnished in diameters ⁄4 to 3.0 in.

F606/F606MTest Methods for Determining the Mechanical

inclusive. They are designated by type denoting chemical

Properties of Externally and Internally Threaded

composition as follows:

Fasteners, Washers, Direct Tension Indicators, and Rivets

Type Description

F788/F788MSpecification for Surface Discontinuities of

Bolts, Screws, Studs, and Rivets, Inch and Metric Series

Type I Plain carbon steel, carbon boron steel, alloy

F1470Practice for Fastener Sampling for Specified Me-

steel, or alloy boron steel

Type 2 Withdrawn 2003

chanical Properties and Performance Inspection

Type 3 Weathering steel

F1789Terminology for F16 Mechanical Fasteners

1.4 Terms used in this specification are defined in Termi-

F2329Specification for Zinc Coating, Hot-Dip, Require-

nology F1789 unless otherwise defined in this specification.

ments for Application to Carbon and Alloy Steel Bolts,

Screws, Washers, Nuts, and Special Threaded Fasteners

1.5 Thevaluesstatedininch-poundunitsaretoberegarded

G101Guide for Estimating the Atmospheric Corrosion Re-

asstandard.Nootherunitsofmeasurementareincludedinthis

sistance of Low-Alloy Steels

standard.

2.2 ASME Standards:

1.6 This standard does not purport to address all of the

B1.1Unified Screw Threads

safety concerns, if any, associated with its use. It is the

B18.2.1 Square and Hex Bolts and Screws

responsibility of the user of this standard to establish appro-

B18.24Part Identifying Number (PIN) Code System Stan-

priate safety, health, and environmental practices and deter-

dard for B18 Fastener Products

mine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accor-

3. Ordering Information

dance with internationally recognized principles on standard-

3.1 Orders for fasteners under this specification shall in-

ization established in the Decision on Principles for the

clude the following:

Development of International Standards, Guides and Recom-

3.1.1 Quantity (number of pieces),

mendations issued by the World Trade Organization Technical

3.1.2 Size, including nominal diameter and length,

Barriers to Trade (TBT) Committee.

3.1.3 Name of product,

This specification is under the jurisdiction of ASTM Committee F16 on

Fastenersand is the direct responsibility of Subcommittee F16.02 on Steel Bolts, For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Nuts, Rivets and Washers. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Dec. 1, 2020. Published December 2020. Originally Standards volume information, refer to the standard’s Document Summary page on

approved in 1963. Last previous edition approved in 2014 as A449–14. DOI: the ASTM website.

10.1520/A0449-14R20. Available from American Society of Mechanical Engineers (ASME), ASME

For ASME Boiler and Pressure Vessel Code applications see related Specifi- International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

cations SA-449 in Section II of that Code. www.asme.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A449−14 (2020)

3.1.4 Type, that is, Type 1, or Type 3 as required, 5. Protective Coatings

3.1.5 ASTM designation and year of issue, and

5.1 Zinc, Hot Dip, and Mechanically Deposited Requiring

3.1.6 Other components such as nuts and washers if re-

Over-tapped Nuts:

quired.

5.1.1 When zinc-coated fasteners are required, the pur-

3.1.7 Hot-Dip or Mechanically Deposited Zinc Coatings—

chaser shall specify the zinc-coating process, such as, hot-dip,

Forhot-dipormechanicallydepositedzinccoatingscoveredby

mechanically deposited, or no preference.

5.1 and requiring over-tapped nuts, specify the zinc coating

5.1.2 When hot dip is specified, the fasteners shall be zinc

processrequired,thatis,hot-dip,mechanicallydeposited,orno

coated by the hot-dip process in accordance with the require-

preference (see 5.1).

ments of Specification F2329.

3.1.8 Other Coatings—Specify other protective coating if

5.1.3 When mechanically deposited is specified, the fasten-

required (see 5.2).

ers shall be zinc coated by the mechanical deposition process

3.1.9 Specify if inspection at point of manufacture is re-

in accordance with the requirements of Class 55 of Specifica-

quired.

tion B695.

3.1.10 Test reports if required.

5.1.4 When no preference is specified, the supplier may

3.1.11 Supplementary or special requirements.

furnish either a hot-dip zinc coating in accordance with

3.1.12 For establishment of a part identifying system, see

Specification F2329, or a mechanically deposited zinc coating

ASME B18.24.

in accordance with Specification B695, Class 55. Threaded

components (bolts and nuts) shall be coated by the same zinc

NOTE 1—A typical ordering description follows: 1000 pieces ⁄8 in.

diameter × 4.0 in. long hex cap screw, Type 1, ASTM A449–XX, each

coating process, and the suppliers’ option shall be limited to

with one finished hex nut ASTM A563, Grade DH. Each component

one process per item with no mixed processes in a lot.

mechanically zinc coated in accordance with B695, Class 5, Type II.

NOTE 2—When the intended application requires that assembled

3.2 Suitable Nuts and Washers:

tension exceeds 50% of minimum bolt or stud proof load, an anti-galling

3.2.1 Suitable nuts are covered in Specification A563.

lubricantmaybeneeded.Applicationofsuchalubricanttonutsandatest

Unless otherwise specified, the grade and style of nut shall be

ofthelubricantefficiencyareprovidedinSupplementaryRequirementS1

of Specification A563 and should be specified when required.

as follows:

A

Fastener Size and Surface Finish Nut Grade and Style

5.2 Other Coatings:

5.2.1 When other coatings are required, the purchaser shall

1 1

⁄4 to 1 ⁄2 in., plain (or with a coating of insufficient B, hex

specify the coating specification, including the classification

thickness to require over-tapped nuts)

Over 1 ⁄2 to 3 in., plain (or with a coating of insuffi- A, heavy hex

codes or grade numbers to identify the coating material,

cient thickness to require over-tapped nuts)

thickness, supplemental treatments, or other requirements to

⁄4 to 3 in., zinc-coated (or with a coating thickness DH, heavy hex

define the coating. The fasteners shall be coated in accordance

requiring over-tapped nuts)

⁄4 to 3 in., Type 3 C3, DH3, heavy hex

with and conform to the specified coating specification.

5.2.2 When a specification does not apply, the purchaser

A

Nuts of other grades and styles having specified proof load stresses (Specifica-

shallspecifythedesiredcoating,coatingthickness,supplemen-

tion A563, Table 3) greater than the specified grade and style of nut are suitable.

tal treatments, or other requirements to define the coating.

3.2.2 Unless otherwise specified, washers ordered with

fastenersshallbefurnishedtotherequirementsofSpecification

6. Chemical Composition

F436/F436M, Type 1 or Specification F436/F436M, Type 3.

6.1 Type 1 fasteners shall be plain carbon steel, carbon

Washers for A449 Type 3 fasteners shall conform to Specifi-

boron steel, alloy steel, or alloy boron steels, at the manufac-

cation F436/F436M Type 3.

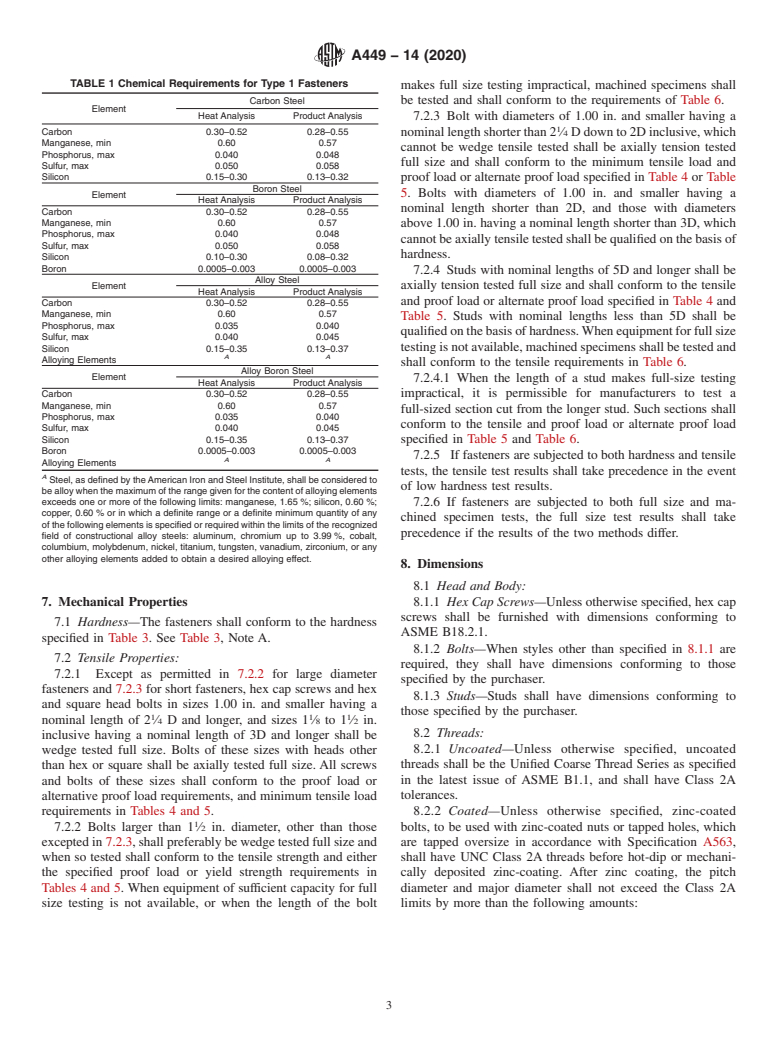

turers option, conforming to the requirements in Table 1.

4. Materials and Manufacture 6.2 Type 3 fasteners shall be weathering steel and shall

conformtooneofthechemicalcompositionsspecifiedinTable

4.1 Heat Treatment:

2.The selection of the chemical composition,A, B, C, D, E or

4.1.1 Type 1 fasteners produced from medium carbon steel

F, shall be a the option of the manufacturer. See Guide G101

shall be quenched in a liquid medium from the austenitizing

formethodsofestimatingtheatmosphericcorrosionresistance

temperature.

of low alloy steel.

4.1.2 Type 1 fasteners produced from medium carbon steel

to which chromium, nickel, molybdenum, or boron were 6.3 Product analyses made on finished fasteners represent-

intentionally added, andType 3 fasteners, shall be quenched in ingeachlotshallconformtotheproductanalysisrequirements

oil from the austenitizing temperature. specified in Table 1 or Table 2, as applicable.

4.1.3 Type 1 and Type 3 fasteners, regardless of the steel

6.4 Heats of steel to which bismuth, selenium, tellurium, or

used, shall be tempered by reheating to not less than 800°F.

lead has been intentionally added shall not be permitted for

4.2 Threading—Threads shall be rolled, cut, or ground. bolts. Compliance shall be based on certification that heats of

steelhavinganyofthelistedelementsintentionallyaddedwere

4.3 Secondary Processing—If any processing which can

not used to produce the bolts.

affect the mechanical properties of the fasteners is performed

after the initial testing, the fasteners shall be retested for all 6.5 Chemical analyses shall be performed in accordance

specified mechanical properties affected by the reprocessing. with Test Methods, Practices, and Terminology A751.

A449−14 (2020)

TABLE 1 Chemical Requirements for Type 1 Fasteners

makes full size testing impractical, machined specimens shall

Carbon Steel be tested and shall conform to the requirements of Table 6.

Element

Heat Analysis Product Analysis

7.2.3 Bolt with diameters of 1.00 in. and smaller having a

Carbon 0.30–0.52 0.28–0.55 nominallengthshorterthan2 ⁄4Ddownto2Dinclusive,which

Manganese, min 0.60 0.57

cannot be wedge tensile tested shall be axially tension tested

Phosphorus, max 0.040 0.048

full size and shall conform to the minimum tensile load and

Sulfur, max 0.050 0.058

Silicon 0.15–0.30 0.13–0.32

proof load or alternate proof load specified in Table 4 or Table

Boron Steel

5. Bolts with diameters of 1.00 in. and smaller having a

Element

Heat Analysis Product Analysis

nominal length shorter than 2D, and those with diameters

Carbon 0.30–0.52 0.28–0.55

Manganese, min 0.60 0.57

above 1.00 in. having a nominal length shorter than 3D, which

Phosphorus, max 0.040 0.048

cannotbeaxiallytensiletestedshallbequalifiedonthebasisof

Sulfur, max 0.050 0.058

hardness.

Silicon 0.10–0.30 0.08–0.32

Boron 0.0005–0.003 0.0005–0.003

7.2.4 Studs with nominal lengths of 5D and longer shall be

Alloy Steel

Element

axially tension tested full size and shall conform to the tensile

Heat Analysis Product Analysis

and proof load or alternate proof load specified in Table 4 and

Carbon 0.30–0.52 0.28–0.55

Manganese, min 0.60 0.57

Table 5. Studs with nominal lengths less than 5D shall be

Phosphorus, max 0.035 0.040

qualifiedonthebasisofhardness.Whenequipmentforfullsize

Sulfur, max 0.040 0.045

testingisnotavailable,machinedspecimensshallbetestedand

Silicon 0.15–0.35 0.13–0.37

AA

Alloying Elements

shall conform to the tensile requirements in Table 6.

Alloy Boron Steel

Element

7.2.4.1 When the length of a stud makes full-size testing

Heat Analysis Product Analysis

Carbon 0.30–0.52 0.28–0.55 impractical, it is permissible for manufacturers to test a

Manganese, min 0.60 0.57

full-sized section cut from the longer stud. Such sections shall

Phosphorus, max 0.035 0.040

conform to the tensile and proof load or alternate proof load

Sulfur, max 0.040 0.045

Silicon 0.15–0.35 0.13–0.37 specified in Table 5 and Table 6.

Boron 0.0005–0.003 0.0005–0.003

7.2.5 If fasteners are subjected to both hardness and tensile

AA

Alloying Elements

tests, the tensile test results shall take precedence in the event

A

Steel,asdefinedbytheAmericanIronandSteelInstitute,shallbeconsideredto

of low hardness test results.

bealloywhenthemaximumoftherangegivenforthecontentofalloyingelements

exceeds one or more of the following limits: manganese, 1.65 %; silicon, 0.60 %;

7.2.6 If fasteners are subjected to both full size and ma-

copper, 0.60 % or in which a definite range or a definite minimum quantity of any

chined specimen tests, the full size test results shall take

ofthefollowingelementsisspecifiedorrequiredwithinthelimitsoftherecognized

precedence if the results of the two methods differ.

field of constructional alloy steels: aluminum, chromium up to 3.99 %, cobalt,

columbium, molybdenum, nickel, titanium, tungsten, vanadium, zirconium, or any

other alloying elements added to obtain a desired alloying effect.

8. Dimensions

8.1 Head and Body:

7. Mechanical Properties 8.1.1 Hex Cap Screws—Unlessotherwisespecified,hexcap

screws shall be furnished with dimensions conforming to

7.1 Hardness—The fasteners shall conform to the hardness

ASME B18.2.1.

specified in Table 3. See Table 3, Note A.

8.1.2 Bolts—When styles other than specified in 8.1.1 are

7.2 Tensile Properties:

required, they shall have dimensions conforming to those

7.2.1 Except as permitted in 7.2.2 for large diameter

specified by the purchaser.

fasteners and 7.2.3 for short fasteners, hex cap screws and hex

8.1.3 Studs—Studs shall have dimensions conforming to

and square head bolts in sizes 1.00 in. and smaller having a

those specified by the purchaser.

1 1 1

nominal length of 2 ⁄4 D and longer, and sizes 1 ⁄8 to 1 ⁄2 in.

8.2 Threads:

inclusive having a nominal length of 3D and longer shall be

8.2.1 Uncoated—Unless otherwise specified, uncoated

wedge tested full size. Bolts of these sizes with heads other

threads shall be the Unified Coarse Thread Series

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.