ASTM D5615-07

(Test Method)Standard Test Method for Operating Characteristics of Home Reverse Osmosis Devices

Standard Test Method for Operating Characteristics of Home Reverse Osmosis Devices

SIGNIFICANCE AND USE

Home reverse osmosis devices are typically used to remove salts and other impurities from drinking water at the point of use. They are usually operated at tap water line pressure, with water containing up to several hundred milligrams per litre of total dissolved solids. This test method permits measurement of the performance of home reverse osmosis devices using a standard set of conditions and is intended for short-term testing (less than 24 h). This test method can be used to determine changes that may have occurred in the operating characteristics of home reverse osmosis devices during use, but it is not intended to be used for system design. This test method does not necessarily determine the device’performance when solutes other than sodium chloride are present. Use Practice D 4516 and Test Methods D 4194 to standardize actual field data to a standard set of conditions.

This test method is applicable for spiral-wound devices.

SCOPE

1.1 This test method covers determination of the operating characteristics of home reverse osmosis devices using standard test conditions. It does not necessarily determine the characteristics of the devices operating on natural waters.

1.2 This test method is applicable for spiral-wound devices.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5615–07

Standard Test Method for

Operating Characteristics of Home Reverse Osmosis

1

Devices

This standard is issued under the fixed designation D5615; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers determination of the operating 3.1 Definitions—For definitions of terms used in this test

characteristicsofhomereverseosmosisdevicesusingstandard method,refertoTerminologyD1129.Fordescriptionsofterms

test conditions. It does not necessarily determine the charac- relating to reverse osmosis, refer to Test Methods D4194 and

teristics of the devices operating on natural waters. D6161.

1.2 This test method is applicable for spiral-wound devices.

4. Summary of Test Method

1.3 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information 4.1 This test method consists of determining the permeate

flow rate and sodium chloride rejection for reverse osmosis

only.

1.4 This standard does not purport to address all of the devicesat345-kPa(50-psi)feedgagepressure,25°Cand22%

conversion using an aqueous 300-mg/L sodium chloride solu-

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- tion.

priate safety and health practices and determine the applica-

5. Significance and Use

bility of regulatory limitations prior to use.

5.1 Home reverse osmosis devices are typically used to

2. Referenced Documents

remove salts and other impurities from drinking water at the

2

2.1 ASTM Standards: point of use. They are usually operated at tap water line

pressure, with water containing up to several hundred milli-

D512 Test Methods for Chloride Ion In Water

D1125 Test Methods for Electrical Conductivity and Resis- grams per litre of total dissolved solids. This test method

tivity of Water permits measurement of the performance of home reverse

osmosis devices using a standard set of conditions and is

D1129 Terminology Relating to Water

D1193 Specification for Reagent Water intended for short-term testing (less than 24 h). This test

method can be used to determine changes that may have

D1293 Test Methods for pH of Water

D2777 Practice for Determination of Precision and Bias of occurred in the operating characteristics of home reverse

osmosisdevicesduringuse,butitisnotintendedtobeusedfor

Applicable Test Methods of Committee D19 on Water

D4194 Test Methods for Operating Characteristics of Re- systemdesign.Thistestmethoddoesnotnecessarilydetermine

the device’s performance when solutes other than sodium

verse Osmosis and Nanofiltration Devices

D4516 Practice for Standardizing Reverse Osmosis Perfor- chloride are present. Use Practice D4516 and Test Methods

D4194 to standardize actual field data to a standard set of

mance Data

D6161 Terminology Used for Microfiltration, Ultrafiltra- conditions.

5.2 This test method is applicable for spiral-wound devices.

tion, Nanofiltration and Reverse Osmosis Membrane Pro-

cesses

6. Apparatus

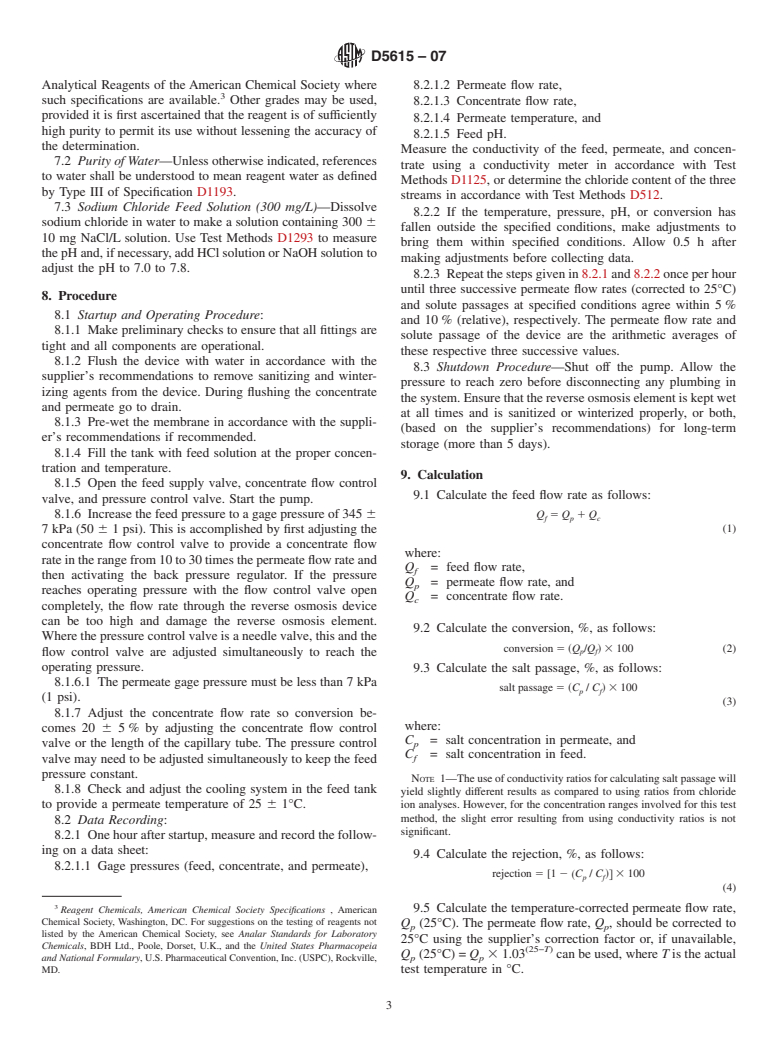

6.1 Theapparatusforthetestmethodisdescribedschemati-

1

This test method is under the jurisdiction of ASTM Committee D19 on Water

cally in Fig. 1.Aconductivity meter can be used to determine

and is the direct responsibility of Subcommittee D19.08 on Membranes and Ion

thesaltconcentrationinaccordancewithTestMethodsD1125.

Exchange Materials.

6.2 Installation:

Current edition approved June 15, 2007. Published July 2007. Originally

6.2.1 Materials of construction shall preferably be of plastic

approved in 1994. Last previous edition approved in 2001 as D5615–95 (2001).

DOI: 10.1520/D5615-07.

or stainless steel (use 316 or better to minimize corrosion) for

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

all wetted parts to prevent contamination of the feed solution

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

bycorrosionproducts.Donotusereactivepipingmaterialsuch

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. as plain carbon steel, galvanized or cadmium-plated carbon

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5615–07

FIG. 1 Flow Schematic of Testing Apparatus

steel, and cast iron for piping. Ensure that no contamination measuring individual pressures and the device pressure drop

will occur from oil films on new metal piping, release agents (DP). Individual gages are also satisfactory but are not as

onrawplasticco

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.