ASTM E477-06a

(Test Method)Standard Test Method for Measuring Acoustical and Airflow Performance of Duct Liner Materials and Prefabricated Silencers

Standard Test Method for Measuring Acoustical and Airflow Performance of Duct Liner Materials and Prefabricated Silencers

SIGNIFICANCE AND USE

Specimens tested using this standard, for example, duct silencers, are used to control sound propagation through ventilation ducts. The results gathered from testing specimens to this standard can be used to estimate the reduction in fan sound levels in ducted airflow systems caused by including a sound attenuating device in the system. The device can be a component in a source-path-receiver analysis where calculations are performed to determine the resultant sound level in an occupied space. Proper selection of a sound attenuating device can enable a designer to achieve in-space background noise criteria.

The insertion loss of a silencer is a matter of degree, and varies with frequency and with the direction and speed of airflow. Because silencers partially obstruct the air path and provide resistance to airflow, two other effects must be quantified: pressure drop and airflow-generated noise. Both increase with increasing air speeds; thus data are required for several airflows to correctly characterize performance.

The aerodynamic results from testing specimens to the standard can be used as information for the system design engineer to determine the amount of static pressure drop resistance to be overcome by the system fan(s). Guidelines for appropriate maximum allowable pressure drop for a sound attenuating element have been established in the design community and are based on the procedures described herein.

As stated previously in 1.5 of this test method, the actual performance of a sound attenuating device as installed in an air duct system may be significantly different than reported based on the test procedure herein. This standard does not provide guidance to the user on these system effects.

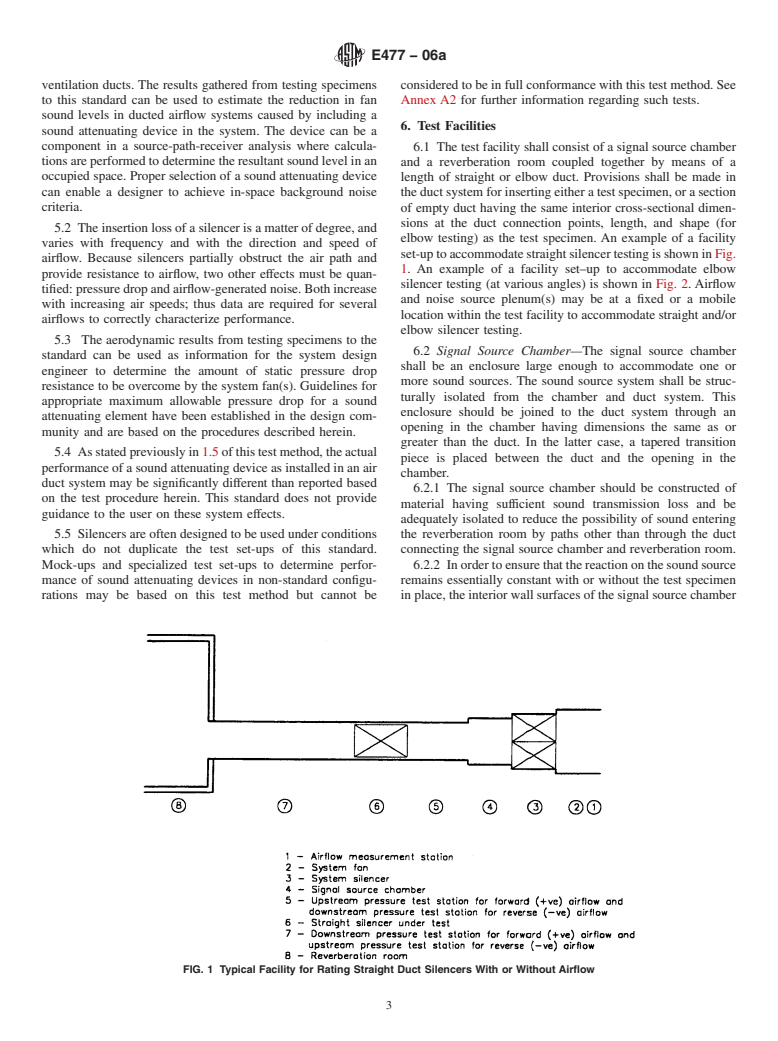

Silencers are often designed to be used under conditions which do not duplicate the test set-ups of this standard. Mock-ups and specialized test set-ups to determine performance of sound attenuating devices in non-standard configurations may be based on this t...

SCOPE

1.1 This test method covers the laboratory testing of some of the acoustical properties of sound attenuating devices including duct liner materials, integral ducts, and in-duct absorptive straight and elbow silencers used in the ventilation systems of buildings. Procedures are described for the measurement of acoustical insertion loss, airflow generated noise, and pressure drop as a function of airflow.

1.2 Excluded from the scope are reactive mufflers and those designed for uses other than in ventilation systems, such as automobile mufflers.

1.3 This test method includes a provision for a simulated semi-reflective plenum to fit around thin-walled duct and silencer test specimens, since the acoustical environments around such thin-walled specimens can affect the measured insertion loss.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 This method tests the performance of the specimen in well-defined and controlled conditions. If the specimen is installed in the field in any different manner, the results may be different. This standard does not provide estimating procedures for determining the actual installed performance of the specimen field conditions.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E477 −06a

StandardTest Method for

Measuring Acoustical and Airflow Performance of Duct

1

Liner Materials and Prefabricated Silencers

This standard is issued under the fixed designation E477; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C423TestMethodforSoundAbsorptionandSoundAbsorp-

tion Coefficients by the Reverberation Room Method

1.1 This test method covers the laboratory testing of some

C634Terminology Relating to Building and Environmental

of the acoustical properties of sound attenuating devices

Acoustics

including duct liner materials, integral ducts, and in-duct

E90Test Method for Laboratory Measurement of Airborne

absorptive straight and elbow silencers used in the ventilation

Sound Transmission Loss of Building Partitions and

systems of buildings. Procedures are described for the mea-

Elements

surement of acoustical insertion loss, airflow generated noise,

E795Practices for Mounting Test Specimens During Sound

and pressure drop as a function of airflow.

Absorption Tests

3

1.2 Excluded from the scope are reactive mufflers and those

2.2 ANSI Standards:

designed for uses other than in ventilation systems, such as

S1.1–1994(R2004)Acoustical Terminology

automobile mufflers.

S1.11–2004Specification Octave, Half-Octave and Third-

1.3 This test method includes a provision for a simulated Octave Band Filter Sets

semi-reflective plenum to fit around thin-walled duct and S12.51–2002/ISO 3741:1999 Acoustics-Determination of

silencer test specimens, since the acoustical environments Sound Power Levels of Noise Sources Using Sound

around such thin-walled specimens can affect the measured Pressure-Precision Method for Reverberation Rooms

4

insertion loss. 2.3 AMCA Standards:

AMCA 300–96, Reverberant Room Method for Sound

1.4 This standard does not purport to address all of the

Testing of Fans

safety concerns, if any, associated with its use. It is the

5

2.4 ASHRAE Documents and Standards:

responsibility of the user of this standard to establish appro-

2001ASHRAE Handbook, Fundamentals Volume, Chapter

priate safety and health practices and determine the applica-

14, Chapter on Measurement and Instruments

bility of regulatory limitations prior to use.

ANSI/ASHRAE 41.3Method for Pressure Measurement

1.5 This method tests the performance of the specimen in

6

2.5 NAIMA Documents and Standards:

well-defined and controlled conditions. If the specimen is

Fibrous Glass Duct Liner Standard3rd ed., 2002

installedinthefieldinanydifferentmanner,theresultsmaybe

different.Thisstandarddoesnotprovideestimatingprocedures

3. Terminology

for determining the actual installed performance of the speci-

3.1 Definitions—The acoustical terms used in this method

men field conditions.

are consistent with Terminology C634, and ANSI S1.1.

2. Referenced Documents

3.2 Definitions of Terms Specific to This Standard:

2

3.2.1 acoustical duct liner material—a material that has

2.1 ASTM Standards:

soundabsorptivepropertiesandisattachedtotheinsidewallof

C384Test Method for Impedance andAbsorption ofAcous-

a duct to attenuate the sound that propagates down that section

tical Materials by Impedance Tube Method

of duct.

1

ThistestmethodisunderthejurisdictionofASTMCommitteeE33onBuilding

3

and Environmental Acoustics and is the direct responsibility of Subcommittee Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

E33.08 on Mechanical and Electrical System Noise. 4th Floor, New York, NY 10036.

4

Current edition approved May 1, 2006. Published May 2006. Originally Available from Air Movement and Control Association, 30 W. University Dr.,

approved in 1973. Last previous edition approved in 2006 as E477–06. DOI: Arlington Heights, IL 60004.

5

10.1520/E0477-06A. Available from American Society of Heating, Refrigerating, and Air-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Conditioning Engineers, Inc. (ASHRAE), 1791 Tullie Circle, NE, Atlanta, GA

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 30329.

6

Standards volume information, refer to the standard’s Document Summary page on AvailablefromNorthAmericanInsulationManufacturesAssociation(NAIMA)

the ASTM website. 44 Canal Center Plaza, Suite 310 Alexandria, VA 22314.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E477−06a

3.2.2 airflow generated noise—the noise created by aerody- 3.2.18 traverse—a series of readings made with a pitot tube

namic turbulence caused by air flowing through

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.