ASTM D7137/D7137M-12

(Test Method)Standard Test Method for Compressive Residual Strength Properties of Damaged Polymer Matrix Composite Plates

Standard Test Method for Compressive Residual Strength Properties of Damaged Polymer Matrix Composite Plates

SIGNIFICANCE AND USE

Susceptibility to damage from concentrated out-of-plane forces is one of the major design concerns of many structures made of advanced composite laminates. Knowledge of the damage resistance and damage tolerance properties of a laminated composite plate is useful for product development and material selection.

The residual strength data obtained using this test method is most commonly used in material specifications and research and development activities. The data are not intended for use in establishing design allowables, as the results are specific to the geometry and physical conditions tested and are generally not scalable to other configurations. Its usefulness in establishing quality assurance requirements is also limited, due to the inherent variability of induced damage, as well as the dependency of damage tolerance response upon the pre-existent damage state.

The properties obtained using this test method can provide guidance in regard to the anticipated damage tolerance capability of composite structures of similar material, thickness, stacking sequence, and so forth. However, it must be understood that the damage tolerance of a composite structure is highly dependent upon several factors including geometry, stiffness, support conditions, and so forth. Significant differences in the relationships between the existent damage state and the residual compressive strength can result due to differences in these parameters. For example, residual strength and stiffness properties obtained using this test method would more likely reflect the damage tolerance characteristics of an un-stiffened monolithic skin or web than that of a skin attached to substructure which resists out-of-plane deformation. Similarly, test specimen properties would be expected to be similar to those of a panel with equivalent length and width dimensions, in comparison to those of a panel significantly larger than the test specimen.

The reporting section requires items that tend to in...

SCOPE

1.1 This test method covers compression residual strength properties of multidirectional polymer matrix composite laminated plates, which have been subjected to quasi-static indentation per Test Method D6264/D6264M or drop-weight impact per Test Method D7136/D7136M prior to application of compressive force. The composite material forms are limited to continuous-fiber reinforced polymer matrix composites with multidirectional fiber orientations, and which are both symmetric and balanced with respect to the test direction. The range of acceptable test laminates and thicknesses is defined in 8.2.

Note 1—When used to determine the residual strength of drop-weight impacted plates, this test method is commonly referred to as the Compression After Impact, or CAI, method.

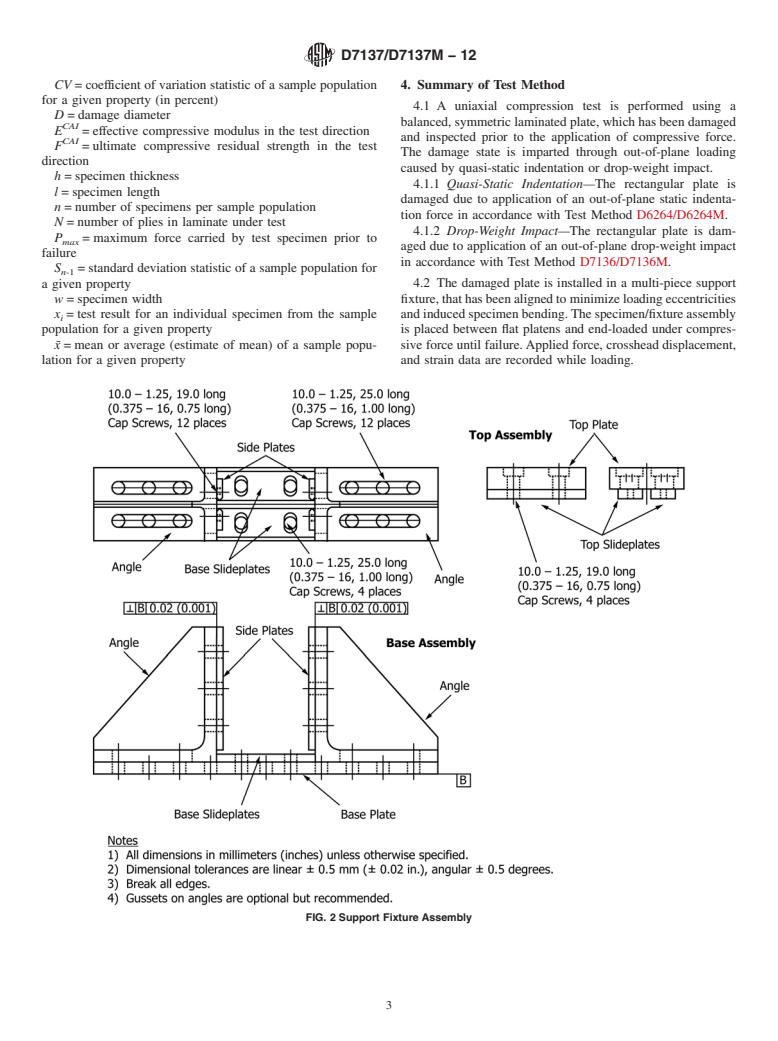

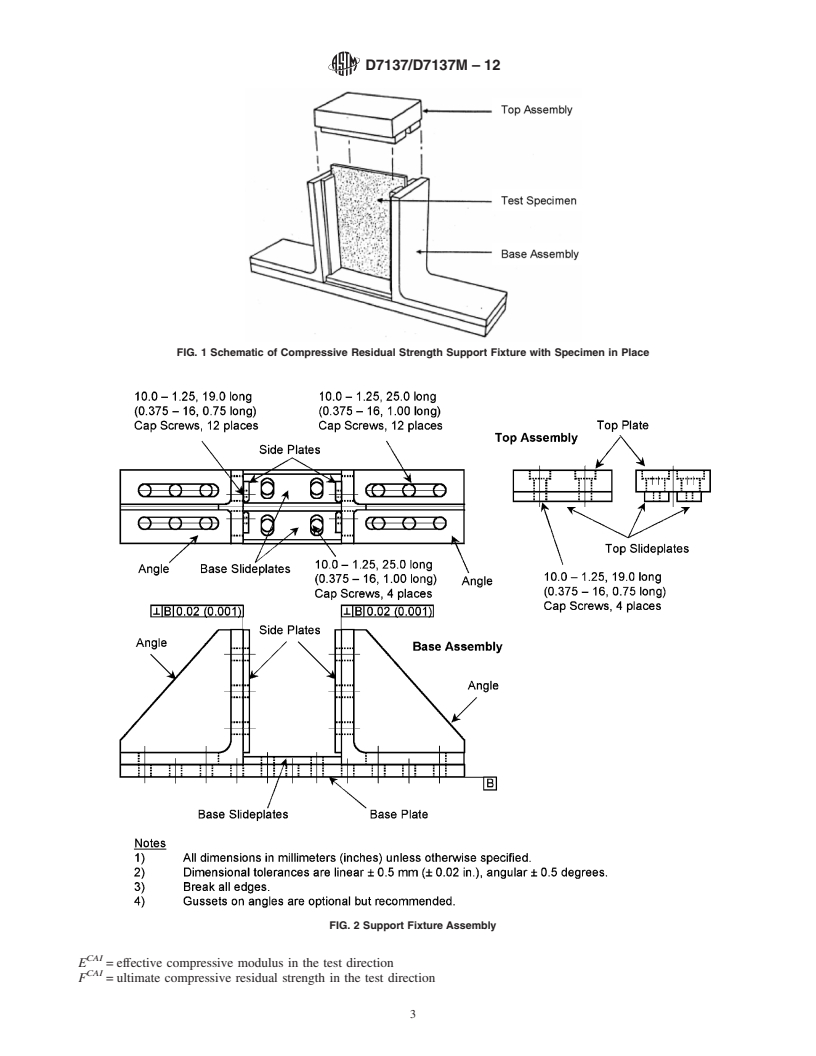

1.2 The method utilizes a flat, rectangular composite plate, previously subjected to a damaging event, which is tested under compressive loading using a stabilization fixture.

Note 2—The damage tolerance properties obtained are particular to the type, geometry and location of damage inflicted upon the plate.

1.3 The properties generated by this test method are highly dependent upon several factors, which include specimen geometry, layup, damage type, damage size, damage location, and boundary conditions. Thus, results are generally not scalable to other configurations, and are particular to the combination of geometric and physical conditions tested.

1.4 This test method can be used to test undamaged polymer matrix composite plates, but historically such tests have demonstrated a relatively high incidence of undesirable failure modes (such as end crushing). Test Method D6641/D6641M is recommended for obtaining compressive properties of undamaged polymer matrix composites.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, ...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7137/D7137M − 12

Standard Test Method for

Compressive Residual Strength Properties of Damaged

1

Polymer Matrix Composite Plates

This standard is issued under the fixed designation D7137/D7137M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope system shall be used independently of the other. Combining

values from the two systems may result in non-conformance

1.1 This test method covers compression residual strength

with the standard.

properties of multidirectional polymer matrix composite lami-

1.5.1 Within the text the inch-pound units are shown in

nated plates, which have been subjected to quasi-static inden-

brackets.

tation per Test Method D6264/D6264M or drop-weight impact

1.6 This standard does not purport to address all of the

per Test Method D7136/D7136M prior to application of

safety concerns, if any, associated with its use. It is the

compressiveforce.Thecompositematerialformsarelimitedto

responsibility of the user of this standard to establish appro-

continuous-fiber reinforced polymer matrix composites with

priate safety and health practices and determine the applica-

multidirectionalfiberorientations,andwhicharebothsymmet-

bility of regulatory limitations prior to use.

ric and balanced with respect to the test direction.The range of

acceptable test laminates and thicknesses is defined in 8.2.

2. Referenced Documents

NOTE 1—When used to determine the residual strength of drop-weight

2

impacted plates, this test method is commonly referred to as the

2.1 ASTM Standards:

Compression After Impact, or CAI, method.

D792 Test Methods for Density and Specific Gravity (Rela-

1.2 The method utilizes a flat, rectangular composite plate,

tive Density) of Plastics by Displacement

previously subjected to a damaging event, which is tested D883 Terminology Relating to Plastics

under compressive loading using a stabilization fixture.

D3171 Test Methods for Constituent Content of Composite

NOTE 2—The damage tolerance properties obtained are particular to the Materials

type, geometry and location of damage inflicted upon the plate.

D3878 Terminology for Composite Materials

D5229/D5229M TestMethodforMoistureAbsorptionProp-

1.3 The properties generated by this test method are highly

erties and Equilibrium Conditioning of Polymer Matrix

dependent upon several factors, which include specimen

Composite Materials

geometry, layup, damage type, damage size, damage location,

D5687/D5687M Guide for Preparation of Flat Composite

and boundary conditions. Thus, results are generally not

Panels with Processing Guidelines for Specimen Prepara-

scalable to other configurations, and are particular to the

tion

combination of geometric and physical conditions tested.

D6264/D6264M Test Method for Measuring the Damage

1.4 Thistestmethodcanbeusedtotestundamagedpolymer

Resistance of a Fiber-Reinforced Polymer-Matrix Com-

matrix composite plates, but historically such tests have

posite to a Concentrated Quasi-Static Indentation Force

demonstrated a relatively high incidence of undesirable failure

D6641/D6641M Test Method for Compressive Properties of

modes (such as end crushing). Test Method D6641/D6641M is

Polymer Matrix Composite Materials Using a Combined

recommended for obtaining compressive properties of undam-

Loading Compression (CLC) Test Fixture

aged polymer matrix composites.

D7136/D7136M Test Method for Measuring the Damage

Resistance of a Fiber-Reinforced Polymer Matrix Com-

1.5 The values stated in either SI units or inch-pound units

posite to a Drop-Weight Impact Event

are to be regarded separately as standard. The values stated in

E4 Practices for Force Verification of Testing Machines

each system may not be exact equivalents; therefore, each

E6 Terminology Relating to Methods of Mechanical Testing

E122 Practice for Calculating Sample Size to Estimate,With

1

This test method is under the jurisdiction of ASTM Committee D30 on

Composite Materials and is the direct responsibility of Subcommittee D30.05 on

2

Structural Test Methods. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 1, 2012. Published May 2012. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2005. Last previous edition approved in 2007 as D7137/D7137M-07. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D7137_D7137M-12. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D7137/D7137M–07 Designation:D7137/D7137M–12

Standard Test Method for

Compressive Residual Strength Properties of Damaged

1

Polymer Matrix Composite Plates

This standard is issued under the fixed designation D7137/D7137M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers compression residual strength properties of multidirectional polymer matrix composite laminated

plates, which have been subjected to quasi-static indentation per Test Method D6264/D6264M or drop-weight impact per Test

Method D7136/D7136M prior to application of compressive force. The composite material forms are limited to continuous-fiber

reinforced polymer matrix composites with multidirectional fiber orientations, and which are both symmetric and balanced with

respect to the test direction. The range of acceptable test laminates and thicknesses is defined in 8.2.

NOTE 1—When used to determine the residual strength of drop-weight impacted plates, this test method is commonly referred to as the Compression

After Impact, or CAI, method.

1.2 The method utilizes a flat, rectangular composite plate, previously subjected to a damaging event, which is tested under

compressive loading using a stabilization fixture.

NOTE 2—The damage tolerance properties obtained are particular to the type, geometry and location of damage inflicted upon the plate.

1.3 The properties generated by this test method are highly dependent upon several factors, which include specimen geometry,

layup, damage type, damage size, damage location, and boundary conditions. Thus, results are generally not scalable to other

configurations, and are particular to the combination of geometric and physical conditions tested.

1.4 This test method can be used to test undamaged polymer matrix composite plates, but historically such tests have

demonstrated a relatively high incidence of undesirable failure modes (such as end crushing). Test Method D6641/D6641M is

recommended for obtaining compressive properties of undamaged polymer matrix composites.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text the

inch-pound units are shown in brackets. The values stated in each system aremay not be exact equivalents; therefore, each system

mustshall be used independently of the other. Combining values from the two systems may result in non-conformance with the

standard.

1.5.1 Within the text the inch-pound units are shown in brackets.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D792 Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement

D883 Terminology Relating to Plastics

D3171 Test Methods for Constituent Content of Composite Materials

D3878 Terminology for Composite Materials

D5229/D5229M Test Method for MoistureAbsorption Properties and Equilibrium Conditioning of Polymer Matrix Composite

Materials

D5687/D5687M Guide for Preparation of Flat Composite Panels with Processing Guidelines for Specimen Preparation

1

This test method is under the jurisdiction ofASTM Committee D30 on Composite Materials and is the direct responsibility of Subcommittee D30.05 on Structural Test

Methods.

´1

Current edition approved Nov. 15, 2007. Published December 2007. Originally approved in 2005. Last previous edition approved in 2005 as D7137/D7137M-05 . DOI:

10.1520/D7137_D7137M-07.

Current edition approved April 1, 2012. Published May 2012. Originally approved in 2005. Last previous edition approved in 2007 as D7137/D7137M-07. DOI:

10.1520/D7137_D7137M-12.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D7137/D7137M–12

D6264/D6264M Test Meth

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.