ASTM D4034-92

(Test Method)Standard Test Method for Resistance to Yarn Slippage at the Sewn Seam in Woven Upholstery Fabrics (Withdrawn 2001)

Standard Test Method for Resistance to Yarn Slippage at the Sewn Seam in Woven Upholstery Fabrics (Withdrawn 2001)

SCOPE

1.1 This test method covers the measurement of the resistance to slippage of warp yarns or filling yarns in woven upholstery fabrics, when testing for yarn slippage at the seam. Note 1-This test method is derived from Test Method D434, from which appropriate changes have been made to make the method more applicable for upholstery fabrics.

1.2 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the inch-pound units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4034 – 92

Standard Test Method for

Resistance to Yarn Slippage at the Sewn Seam in Woven

Upholstery Fabrics

This standard is issued under the fixed designation D 4034; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope movement parallel to either the filling or the warp on a woven

fabric in which minimum force is required to produce yarn

1.1 This test method covers the measurement of the resis-

slippage.

tance to slippage of warp yarns or filling yarns in woven

3.1.1.1 Discussion—The fabric may be pulled in both di-

upholstery fabrics, when testing for yarn slippage at the seam.

rections in many cases.

NOTE 1—This test method is derived from Test Method D 434, from

3.1.2 resistance to yarn slippage, n—at the seam, the force

which appropriate changes have been made to make the method more

required to displace one or more yarns in a fabric from the

applicable for upholstery fabrics.

original position, causing differences in alignment or spacing,

1.2 The values stated in either inch-pound units or SI units

or both.

are to be regarded separately as standard. Within the text, the

3.1.3 sewn seam, n—in sewn fabrics, a juncture at which

inch-pound units are shown in brackets. The values stated in

two or more planar structures such as textile fabrics, are joined

each system are not exact equivalents; therefore, each system

by sewing, usually near the edge.

must be used independently of the other. Combining values

3.1.4 yarn slippage, n—at the seam in sewn fabrics, the

from the two systems may result in nonconformance with the

displacement of one or more yarns from the original position,

specification.

causing differences in alignment or spacing, or both.

1.3 This standard does not purport to address all of the

3.2 For definitions of other textile terms used in this test

safety problems, if any, associated with its use. It is the

method, refer to Terminology D 123.

responsibility of the user of this standard to establish appro-

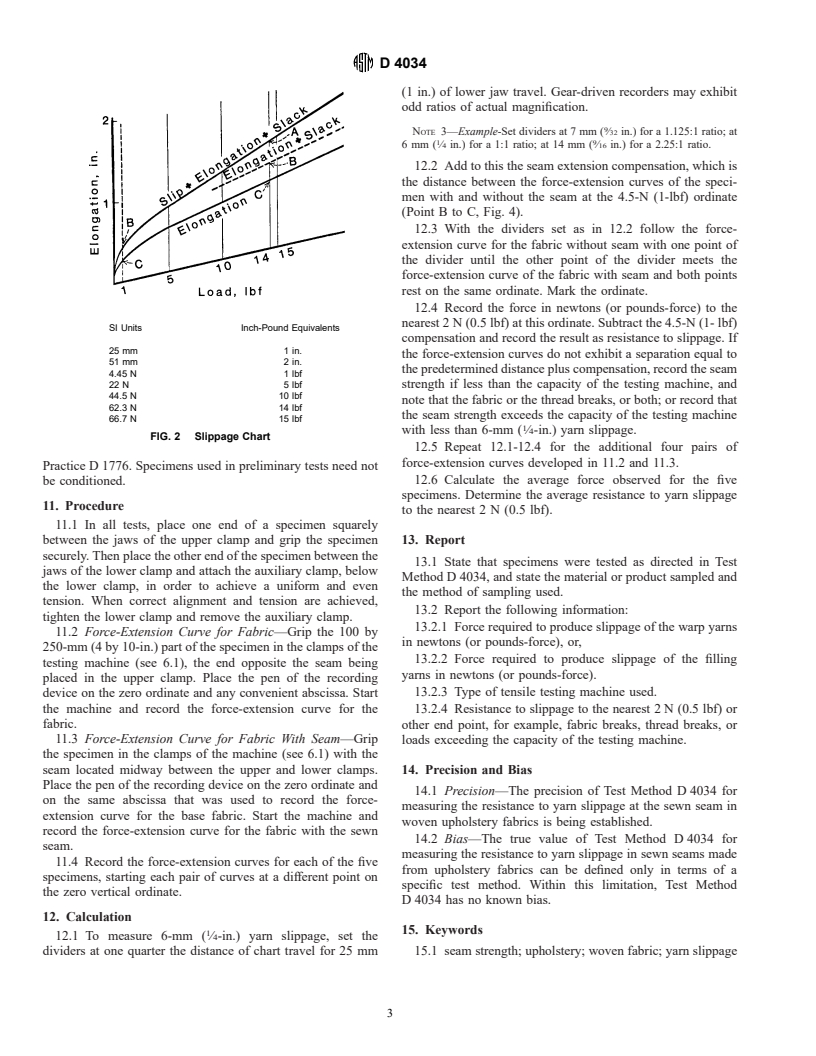

4. Summary of Test Method

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

4.1 Resistance to yarn slippage is determined on a specimen

made from pieces of the same fabric that have been stitched

2. Referenced Documents

together in a specified manner (see 9.3). First, tension is

2.1 ASTM Standards:

applied to the unseamed part of the specimen using a constant

D 76 Specification for Tensile Testing Machines for Tex-

rate-of-extension or a constant rate-of-traverse type machine

tiles

and the curve recorded. Next, tension is applied across the

D 123 Terminology Relating to Textiles

seam and results are recorded on the same chart. The distance

D 434 Test Method for Resistance to Slippage of Yarns In

between the recorded force-extension curves is measured from

Woven Fabrics Using a Standard Seam

the point where slippage began (see 12.1).

D 1776 Practice for Conditioning Textiles for Testing

2.2 Federal Standard: 5. Significance and Use

Fed. Std. No. 751a Stitches, Seams, and Stitching

5.1 Test Method D 4034 for measuring the resistance to

yarn slippage at the sewn seam is considered satisfactory for

3. Terminology

acceptance testing of woven upholstery fabrics.

3.1 Definitions:

5.1.1 In case of disagreement arising from differences in

3.1.1 direction of slippage, n—at the seam, the line of

values reported by the purchaser and the supplier when using

this test method for acceptance testing, the statistical bias, if

any, between the laboratory of the supplier and the laboratory

This test method is under the jurisdiction of ASTM Committee D-13 on Textiles

and is the direct responsibility of Subcommittee D13.59 on Fabric Test Methods,

of the purchaser should be determined with comparisons being

General.

based on the testing of specimens taken from a lot of material

Current edition approved August 15, 1992. Published May 1993. Originally

of the type evaluated to be as nearly homogeneous as possible

published as D 4034 – 81. Last previous edition D 4034 – 81.

Annual Book of ASTM Standards, Vol 07.01. and then randomly assigned in equal numbers to each of the

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

laboratories.

Robbins Ave., Philadelphia, Pa. 19111-5094, Attn: NPODS.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 4034

5.2 This test method is intended to measure yarn slippage at warp and one with the long dimension parallel to the filling.

the sewn seam in upholstery fabrics under controlled condi- Preliminary tests are not necessary if the direction with the

tions. This test method may not indicate actual field perfor- lower resistance to yarn slippage is known.

mance. 7.3.1 For final testing, five specimens in the direction of the

5.3 Fabrics that do not meet the requirements agreed upon greater slippage are required.

between the purchaser and supplier should be classified as

8. Number of Specimens

“delicate in seam slippage resistance” and the purchaser and

8.1 For preliminary testing, two specimens are required, one

furniture manufacturer so notified.

with the long dimension parallel to the warp and one with the

6. Apparatus

long dimension parallel to the filling. Preliminary tests are not

6.1 Tensile Testing Machine—A constant rate-of-traverse required if the direction with the lower resistance to yarn

(CRT) or constant rate-of-extension (CRE) type machine con- slippage is known.

forming to the requirements of Specification D 76. The ma- 8.2 For final testing, five specimens in the direction of the

greater slippage are required.

chine shall be equipped with an autographic recording device

and with clamps having front jaws 25 mm (1 in.) in width with

9. Preparation of Specimen

back jaws of 50 mm (2 in.) or more in width, except as

9.1 Cut two pieces of fabric, one 100 by 100 mm (4 by 4 in.)

otherwise provided (Note 2). The clamps shall be set 76 mm (3

and one 100 by 250 mm (4 by 10 in.) from both warp and

in.) apart. The speed of the pulling clamp shall be 5.0 6 0.2

filling directions. When testing resistance to warp yarn slip-

mm/s (12.0 6 0.5 in./min).

page, the long dimension should be parallel to the warp yarns

NOTE 2—In comparing results with those from another laboratory, both

(see Fig. 1). When testing filling yarn slippage over the warp

laboratories should use the same type of tensile testing machine, or have

yarn, the long dimension is parallel to the filling yarns (see Fig.

established the relationship between test results obtained using a CRT

2).

machine and those obtained using a CRE machine when testing fabrics of

9.2 Place the 100 by 100-mm (4 by 4-in.) piece on top of the

the type being evaluated.

100 by 250-mm (4 by 10-in.) piece, face to face, with one end

6.1.1 Tensile Testing Machine (Other)—A tensile testing

even with the end of the 100 by 250-mm piece. For testing

machine other than a CRT or CRE type that conforms to the

resistance to warp yarn slippage, the warp yarn in both pieces

requirements of Specification D 76 and gives results that

should be lengthwise or perpendicular to the seam, and for

correlate with those for CRT or CRE testers. The machine must

testing resistance to filling yarn slippage, the filling yarn should

be acceptable to both the purchaser and supplier if the results

run lengthwise in both pieces, perpendicular to the seam.

are to be used for acceptance testing of commercial shipments.

9.3 Stitch a seam across the short dimension of the speci-

6.2 Needle—Size 22 ball point needle.

mens, placing the seam 12 mm (0.5 in.) from the edge of the

6.3 Sewing Thread, 100 % nylon bonded monocord thread.

specimen, using 7 6 0.5 stitches per 25 mm (1 in.) and a plain

The needle thre

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.