ASTM F7-95(2000)

(Specification)Standard Specification for Aluminum Oxide Powder

Standard Specification for Aluminum Oxide Powder

SCOPE

1.1 This specification covers aluminum oxide (alumina) powder in two classes of particle size, two chemical grades, and two levels of acidity, for use as an insulating coating or as an ingredient of ceramic mixtures for components of electronic devices as follows:

1.1.1 Particle Sizes:Class A--Particle size No. 500 nominal mesh (nominal average particle size = 24.3 µm).

Class B--Particle size No. 900 nominal mesh (nominal average particle size = 1.7 µm).

1.1.2 Chemical Grades--Grades 1 and 2 as specified under chemical requirements in Section 3.

1.1.3 Acidity Levels: pH (acid) 4.5 to 6.5 and pH (neutral) 6.5 to 7.5.

1.2 The following safety hazards caveat pertains only to the test methods in this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 7 – 95 (Reapproved 2000)

Standard Specification for

Aluminum Oxide Powder

This standard is issued under the fixed designation F 7; the number immediately following the designation indicates the year of original

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

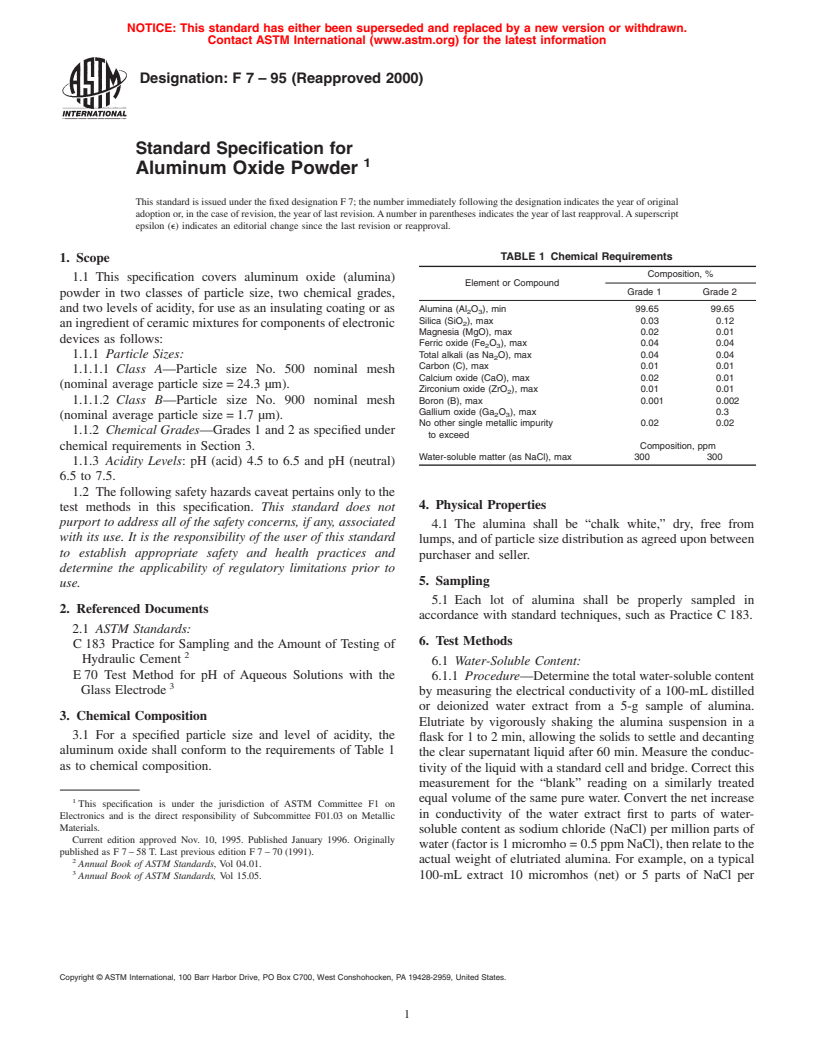

TABLE 1 Chemical Requirements

1. Scope

Composition, %

1.1 This specification covers aluminum oxide (alumina)

Element or Compound

Grade 1 Grade 2

powder in two classes of particle size, two chemical grades,

and two levels of acidity, for use as an insulating coating or as

Alumina (Al O ), min 99.65 99.65

2 3

Silica (SiO ), max 0.03 0.12

aningredientofceramicmixturesforcomponentsofelectronic

Magnesia (MgO), max 0.02 0.01

devices as follows:

Ferric oxide (Fe O ), max 0.04 0.04

2 3

1.1.1 Particle Sizes: Total alkali (as Na O), max 0.04 0.04

Carbon (C), max 0.01 0.01

1.1.1.1 Class A—Particle size No. 500 nominal mesh

Calcium oxide (CaO), max 0.02 0.01

(nominal average particle size=24.3 µm).

Zirconium oxide (ZrO ), max 0.01 0.01

1.1.1.2 Class B—Particle size No. 900 nominal mesh Boron (B), max 0.001 0.002

Gallium oxide (Ga O ), max 0.3

2 3

(nominal average particle size=1.7 µm).

No other single metallic impurity 0.02 0.02

1.1.2 Chemical Grades—Grades 1 and 2 as specified under

to exceed

Composition, ppm

chemical requirements in Section 3.

Water-soluble matter (as NaCl), max 300 300

1.1.3 Acidity Levels: pH (acid) 4.5 to 6.5 and pH (neutral)

6.5 to 7.5.

1.2 The following safety hazards caveat pertains only to the

4. Physical Properties

test methods in this specification. This standard does not

purport to address all of the safety concerns, if any, associated

4.1 The alumina shall be “chalk white,” dry, free from

with its use. It is the responsibility of the user of this standard

lumps,andofparticlesizedistributionasagreeduponbetween

to establish appropriate safety and health practices and

purchaser and seller.

determine the applicability of regulatory limitations prior to

5. Sampling

use.

5.1 Each lot of alumina shall be properly sampled in

2. Referenced Documents

accordance with standard techniques, such as Practice C183.

2.1 ASTM Standards:

6. Test Methods

C183 Practice for Sampling and the Amount of Testing of

Hydraulic Cement

6.1 Water-Soluble Content:

E70 Test Method for pH of Aqueous Solutions with the

6.1.1 Procedure—Determinethetotalwater-solublecontent

Glass Electrode

by measuring the electrical conductivity of a 100-mL distilled

or deionized water extract from a 5-g sample of alumina.

3. Chemical Composition

Elutriate by vigorously shaking the alumina suspension in a

3.1 For a specified particle size and level of acidity, the

flask for 1 to 2 min, allowing the solids to settle and decanting

aluminum oxide shall conform to the requirements of Table 1

the clear supernatant liquid after 60 min. Measure the conduc-

as to chemical composition.

tivity of the liquid with a standard cell and bridge. Correct this

measurement for the “blank” reading on a similarly treated

equal volume of the same pure water. Convert the net increase

This specification is under the jurisdiction of ASTM Committee F1 on

in conductivity of the water extract first to parts of water-

Electronics and is the direct responsibility of Subcommittee F01.03 on Metallic

Materials.

soluble content as sodium chloride (NaCl) per million parts of

Current edition approved Nov. 10, 1995. Published January 1996. Originally

water(factoris1micromho=0.5ppmNaCl),thenrelatetothe

published asF7–58T. Last previous editionF7–70(1991).

2 actual weight of elutriated alumina. For example, on a typical

Annual Book of ASTM Standards, Vol 04.01.

Annual Book of ASTM Standards, Vol 15.05. 100-mL extract 10 micromhos (net) or 5 parts of NaCl per

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

F 7 – 95 (2000)

TABLE 2 Requirements for Sample Sizes and Dispersing Agents

Sample

Sample Dispersing

Method Concentration Dispersing Agent

Size, g Medium

Weight%

A

Coulter counter 0.25 0.1 methanol LiCl-38g/gal

M.S.A. centrifuge 1.0 0.03 HON

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.