ASTM D6249-98(2004)

(Guide)Standard Guide for Alkaline Stabilization of Wastewater Treatment Plant Residuals

Standard Guide for Alkaline Stabilization of Wastewater Treatment Plant Residuals

SCOPE

1.1 This document provides guidance for use of reactive alkaline materials (quicklime, hydrated lime, high lime fly ash, or other byproducts) for treating wastewater solids (biosolids) to reduce pathogen levels and achieve compliance with regulatory requirements. Federal (40 CFR, Part 503) regulations for use or disposal of biosolids became effective on March 22, 1993; refer to USEPA regulations and guidance documents for information on other treatment processes or for specific requirements for use or disposal of biosolids.

1.2 Additional requirements may be imposed by individual states, and these are available through state regulatory agencies that issue permits for treatment and use or disposal, or both, of biosolids.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6249–98 (Reapproved2004)

Standard Guide for

Alkaline Stabilization of Wastewater Treatment Plant

Residuals

This standard is issued under the fixed designation D 6249; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 PSRP—Processes to Significantly Reduce Pathogens

(equivalent to 503 Class B).

1.1 This document provides guidance for use of reactive

alkaline materials (quicklime, hydrated lime, high lime fly ash,

4. Significance and Use

or other byproducts) for treating wastewater solids (biosolids)

4.1 Operators of power and other plants producing alkaline

to reduce pathogen levels and achieve compliance with regu-

by-products and wastewater treatment plant operators needing

latoryrequirements.Federal(40CFR,Part503)regulationsfor

to treat and manage wastewater solids will find this guide

use or disposal of biosolids became effective on March 22,

helpful in dealing with their materials.

1993; refer to USEPAregulations and guidance documents for

4.2 This guide provides the tests, procedures, and param-

information on other treatment processes or for specific re-

eters that should be considered to significantly reduce patho-

quirements for use or disposal of biosolids.

gens in wastewater treatment plant solids by the addition of

1.2 Additional requirements may be imposed by individual

manufactured or by-product alkaline materials (1).

states,andtheseareavailablethroughstateregulatoryagencies

that issue permits for treatment and use or disposal, or both, of

5. Alkaline Materials Characteristics

biosolids.

5.1 Chemical Composition:

Alkaline materials may be tested for Available Lime Index

2. Referenced Documents

(ALI) in accordance with the optional chemical test ofTable 1.

2.1 ASTM Standards:

Other chemical components, if required, may be determined in

C 25 Test Methods for Chemical Analysis of Limestone,

accordance with the appropriate procedure when requested by

Quicklime, and Hydrated Lime

the purchaser.

C 110 Test Methods for Physical Testing of Quicklime,

5.2 Reactivity:

Hydrated Lime, and Limestone

5.2.1 Alkaline materials should be tested for pH and heat of

2.2 USEPA Publication:

hydration (heat rise or slaking rate) in accordance with the

Title 40, Code of Federal Regulations (CFR), Part 503,

recommended tests of Table 2.

StandardsfortheUseorDisposalofSewageSludge;Final

3 5.3 Physical Characteristics:

Rules, 58 FR 9248-9404

5.3.1 Alkaline materials should be tested to determine the

3. Terminology particle size in accordance with the recommended physical

tests of Table 3.

3.1 Acronyms:acronyms—these are defined by operating

parameters (for example, time, temperature) whose values

6. Process Performance

must be met in order for biosolids to be used in various ways

6.1 PFRP (Class A) Alkaline Treatment of Biosolids:

as a nutrient source/soil conditioner. Ref. 40 CFR Part 257.

6.1.1 Mixing—Thorough mixing of the biosolids and stabi-

3.1.1 PFRP—Processes to Further Reduce Pathogens

lization reagent must be provided to ensure uniform pH

(equivalent to 503 Class A).

distribution and pathogen reduction throughout the biosolids

mass (2). Effective mixing depends upon achieving the appro-

priate ratio of alkaline material to biosolids cake uniformly

This guide is under the jurisdiction of ASTM Committee C07 on Lime and is

the direct responsibility of Subcommittee C07.04 on Environmental Uses.

distributed throughout the treated biosolids.

Current edition approved April 10, 1998. Published September 1998.

6.1.1.1 Biosolids with a high moisture content will require

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

less mixing energy than high-solids biosolids cake.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

Available from the Superintendent of Documents, U.S. Government Printing The boldface numbers in parentheses refer to the list of references at the end of

Office, Washington, DC 20402. this guide.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6249–98 (2004)

TABLE 1 Optional Chemical Test

TestMethodsC 25)togenerateheatandelevatepH.Generally,

Test Method Component Specification drybiosolidscakes(18to30 %)requireamoreintimatemixto

A

C 25 Available Lime Index (ALI), %

ensure proper penetration and reaction than is required by wet

A

To be specified only as required by purchaser.

biosolids (less than 18 %).

6.1.4.2 The calcium oxide in the reagent must react with the

TABLE 2 Recommended Reactivity Tests

moisture in biosolids (hydration) producing calcium hydroxide

ASTM Test Method Component Specification and heat. The moisture content in the biosolids mass must be

A

C25 pH $ 12.0

sufficient to allow the hydration reaction to occur between the

B C

C110 Heat rise, C

selected reagent (CaO concentration and fineness) and biosol-

A

Based on 40 CFR Part 503 for pH >12 for 2 h or more.

ids mass.

B

Modify Test Method C 110 to proportion alkaline reagent in lieu of quicklime.

6.1.4.3 Biosolids cakes with a high moisture content will

Alkaline material and water ratio may need to be modified to obtain measurable

results. Any modification of Test Method C 110 must be clearly stated on the

tend to react faster than biosolids with a low moisture content.

analysis report.

6.1.5 Biosolids Type:

C

To be specified only as required by purchaser.

6.1.5.1 Case-by-case alkaline material demand should be

determined for each biosolids type through pilot testing using

TABLE 3 Recommended Physical Test

the actual biosolids cake and proposed reagents for each

ASTM Test Method Component Specification

project. Develop process guidelines for alkaline additions by

A

C 110 Amount retained on 600 µm

biosolids type and alkaline additive characteristics.

(No. 30 mesh), %

6.1.5.2 Biosolids with a high moisture content may require

C 110 Amount retained on 75 µm

A

(No. 200 mesh), %

a higher dose ratio than drier dewatered biosolids cake when

A

To be specified only as required by purchaser.

dosage ratios are expressed on a dry weight basis.

6.1.6 Reaction Time and Curing Time:

6.1.6.1 Heatwillbegeneratedashydrationofcalciumoxide

6.1.1.2 Biosolids characteristics will determine the proper

occurs. The reaction time will vary depending on reagent

type of equipment or system required for adequate mixing.

composition moisture content of the biosolids mass, and mixer

Incomplete mixing can cause odor release during product

efficiency.

storage or application and may lead to failure to meet regula-

6.1.6.2 Reaction times to effect pathogen reduction are

tory requirements for pathogen and vector control.

established by applicable federal and state regulations.

6.1.2 Particle Size:

Reaction/cure times depend upon a number of variables and

6.1.2.1 Given an adequate moisture supply using alkaline

should be pilot-tested using the actual biosolids cake, alkaline

agents (for example, CaO) with smaller particle sizes will

admixture, mix unit, cure vessel, and testing protocol and

facilitate rapid and efficient mixing of agents with biosolids

acceptance criteria to assure compliance with regulatory stan-

and increase reaction rates and pH, resulting in higher tem-

dards.

peratures and greater pathogen reduction.

6.1.6.3 For alkaline treatment processes, one of the three

6.1.2.2 Since dusts are more easily generated from finely

performance criteria is required:

divided particles, precautions should be taken to prevent

(1) The time-temperature relation established in 40 CFR

exposure to eyes and mucous membranes, which may result in

503.32 (a) (3) (Alternative 1). Selected time-temperature

irritation.

values are as follows:

6.1.2.3 Reactivity and particle size also affect the rate of

Biosolids Temp, °C 50 55 60 65 70 75 80

dust and mist emissions from reactors or mixing devices, or Moisture >7 % Time, hours 316 63 13 2.5 0.5 0.10 0.020

Moisture <7 % Time, hours 120 24 4.8 0.95 0.19 0.04 0.008

both. Particulate release may require scrubbing, water spray, or

other emission controls on reactors or mixing devices for (2) The pH-time, temperature-time, drying procedure in 40

aesthetic reasons or to meet regulatory requirements.

CFR 503.32 (a) (4) (Alternative 2). Basically, the biosolids are

6.1.2.4 Very small particle size may also lead to “air held at a pH above 12 for 72 hours with a 12-hour period in

slaking”orrecarbonationofactivelimeparticlesifthematerial

which the temperature exceeds 52°C, followed by air drying to

is exposed to high humidity.Air slaked/recarbonated materials a solids content exceeding 50 %.

will not achieve the pH necessary to meet regulatory require- (3) Pasteurization (40 CFR 503, App. B, Part B—PFRP

ments. Option 7) in which the biosolids are maintained at a minimum

6.1.3 Reactivity (Heat and pH Elevation): temperature of 70°C for 30 minutes.

6.1.3.1 Reactivity is dependent upon the interaction be- 6.1.6.4 Ammonia or other odors released may require water

tween the alkaline reagent and the material to be treated. spray, scrubbing, gas capture, or control of emission.

Reactions occur as the alkaline material contacts the biosolids. 6.1.7 Reaction/Cure Vessels or Containers:

The finer the alkaline product, the greater the potential for a 6.1.7.1 Consideration should be given to minimize heat

more rapid pH/temperature elevation. losses through materials management, configuration, and ma-

6.1.3.2 Reagent reactivity affects mixing time and dosage terials of construction for processes that require extended

rate and must be considered in process design. curing times.

6.1.4 Moisture Content: 6.1.7.2 Proper temperatures can be maintained without an

6.1.4.1 Adequate moisture must be present to react with the insulated vessel by adding adequate alkaline reagent to com-

free CaO (as measured by Available Lime Index, ALI, as per pensate for heat loss. However, some situations may benefit

D6249–98 (2004)

from an insulated vessel to efficiently retain the heat to meet 6.2.1 Mixing—Thorough mixing of the biosolids and

PFRP temperature requirements. chemical reagent must be provided to ensure uniform pH

distribution and pathogen reduction (2). Mechanical mixing to

6.1.7.3 For processes using a windrow, at a minimum, the

achieve a homogeneous blend of reagent throughout the

mixture should be at least 18 inches thick at all locations in the

biosolids mass depends upon a number of factors, including

pile to ensure heat retention throughout the entire mass for the

achieving the proper ratio of alkaline reagent to biosolids, and

applicablecuringtime.Thinareasatthepileextremitiesshould

sufficient moisture to enable the reaction to occur.

be avoided as they will not retain adequate heat and can lead to

potential regrowth and recontamination of the entire mass. 6.2.1.1 Incomplete mixing or an inadequate reagent dosage

rate can cause odor generation and release during product

6.1.8 Process Testing Requirements:

storage or application and failure to meet regulatory pathogen

6.1.8.1 Process testing requirements vary with the specific

or vector control requirements.

alkaline process selected.

6.2.2 Alkaline Reagent Particle Size:

6.1.8.2 Temperature and pH measurements for the requisite

6.2.2.1 Reactions occur as the alkaline reagents contact the

time periods should be recorded to comply with pathogen

moist biosolids particles. The rate of reaction of the alkaline

reduction (and vector attraction reduction). Daily testing may

reagent tends to increase with: (1) finer reagent particle size,

include monitoring and documenting the elevated temperature

and (2) increased free moisture content. Reagents with a finer

and pH for a predetermined period of time (see 6.2.6 for

(smaller) particle size distribution generally are more easily

details). Some methods also require documentation of reduced

and uniformly blended into the biosolids.

moisture content and mixing.

6.2.2.2 When using an alkaline slurry, or treating liquid

6.1.8.3 Procedures to monitor or collect samples for analy-

biosolids, particle size may not be as critical as long as

sis are developed for each project based upon site-specific

sufficient mixing and reaction time are provided.

conditions considering the process selected, equipment uti-

lized, volumes of materials to be processed, local state and 6.2.3 Reactivity (pH elevation):

federal regulatory requirements, and local conditions (3).

6.2.3.1 Caremustbetakentoensuremoisturewillnotcome

into contact with the reagent prior to entering the mixer. Air

6.1.9 Process Testing Schedule:

slaking of the alkaline reagent can be a problem in long-term

6.1.9.1 Testing must be conducted in accordance with fed-

storage or pneumatic transfer systems. Guidance for proper

eral, state, and local regulations. Product testing, to meet

storage of reactive alkaline materials can be found in Lime—

end-use requirements, will be site-specific. Under 40 CFR Part

Handling,Application and Storage, National LimeAssociation

503 regulations, pathogen (salmonella, virus, protozoan, and

Bulletin 213.

helminth egg) or indicator organism testing and pollutant

concentration (metals) testing requirements are: 6.2.3.2 Increasing the alkaline reagent oxide concentration

may increase potential for reactivity.

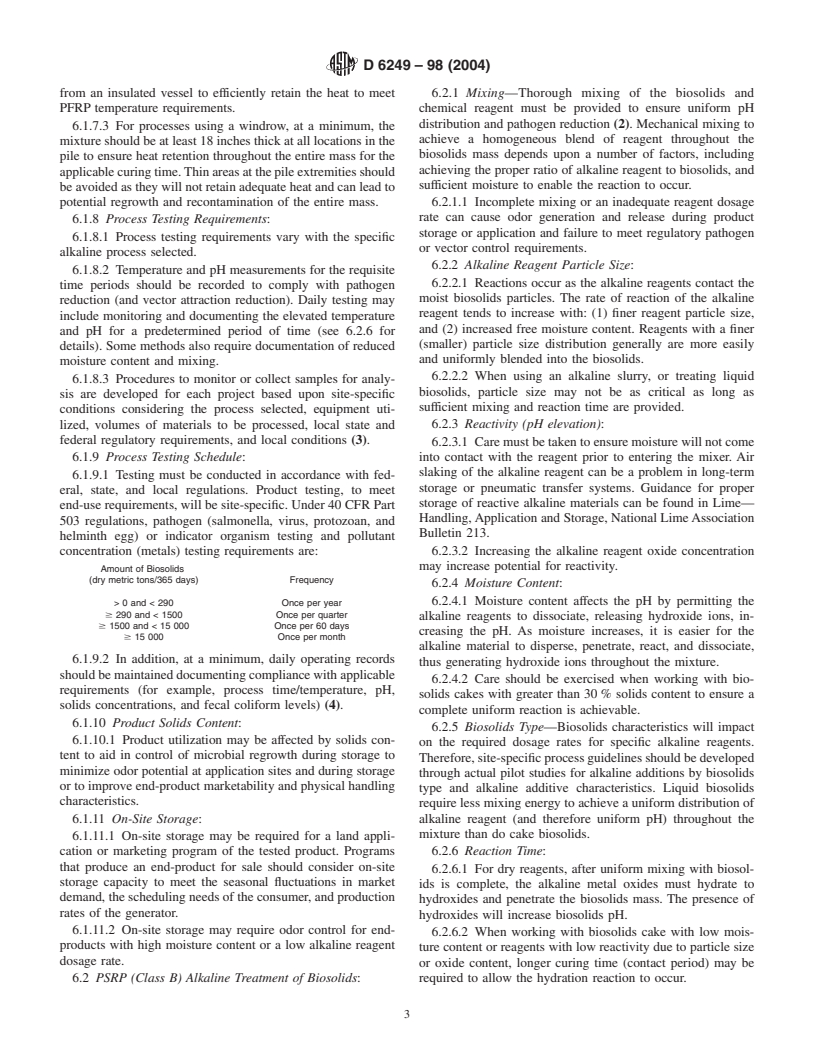

Amount of Biosolids

(dry metric tons/365 days) Frequency

6.2.4 Moisture Content:

6.2.4.1 Moisture content affects the pH by permitting the

> 0 and < 290 Once per year

$ 290 and < 1500 Once per quarter

alkaline reagents to dissociate, releasing hydroxide ions, in-

$ 1500 and < 15 000 Once per 60 days

creasing the pH. As moisture increases, it is easier for the

$ 15 000 Once per month

alkaline material to disperse, penetrate, react, and dissociate,

6.1.9.2 In addition, at a minimum, daily operating records

thus generating hydroxide ions throughout the mixture.

shouldbemaintaineddocumentingcompliancewithapplicable

6.2.4.2 Care should be exercised when working with bio-

requirements (for example, process time/temperature, pH,

solids cakes with greater than 30 % solids content to ensure a

solids concentrations, and fecal coliform levels) (4).

complete uniform reaction is achievable.

6.1.10 Product Solids Content:

6.2.5 Biosolids Type—Biosolids characteristics will impact

6.1.10.1 Product utilization may be affected by solids con-

on the required dosage rates for specific alkaline reagents.

tent to aid in control of microbial regrowth during storage to

There

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.