ASTM D5403-93(2007)

(Test Method)Standard Test Methods for Volatile Content of Radiation Curable Materials

Standard Test Methods for Volatile Content of Radiation Curable Materials

SIGNIFICANCE AND USE

These test methods are the procedures of choice for determining volatile content of materials designed to be cured by exposure to ultraviolet light or electron beam irradiation. These types of materials contain liquid reactants that react to become part of the film during cure, but, which under the test conditions of Test Method D 2369, will be erroneously measured as volatiles. The conditions of these test methods are similar to Test Method D 2369 with the inclusion of a step to cure the material prior to weight loss determination. Volatile content is determined as two separate components—processing volatiles and potential volatiles. Processing volatiles is a measure of volatile loss during the actual cure process. Potential volatiles is a measure of volatile loss that might occur during aging or under extreme storage conditions. These volatile content measurements are useful to the producer and user of a material and to environmental interests for determining emissions.

SCOPE

1.1 These test methods cover procedures for the determination of weight percent volatile content of coatings, inks, and adhesives designed to be cured by exposure to ultraviolet light or to a beam of accelerated electrons.

1.2 Test Method A is applicable to radiation curable materials that are essentially 100 % reactive but may contain traces (no more than 3 %) of volatile materials as impurities or introduced by the inclusion of various additives.

1.3 Test Method B is applicable to all radiation curable materials but must be used for materials that contain volatile solvents intentionally introduced to control application viscosity and which are intended to be removed from the material prior to cure.

1.4 These test methods may not be applicable to radiation curable materials wherein the volatile material is water, and other procedures may be substituted by mutual consent of the producer and user.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. A specific hazard statement is given in 15.7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5403 − 93 (Reapproved2007)

Standard Test Methods for

Volatile Content of Radiation Curable Materials

This standard is issued under the fixed designation D5403; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E145 Specification for Gravity-Convection and Forced-

Ventilation Ovens

1.1 These test methods cover procedures for the determina-

E177 Practice for Use of the Terms Precision and Bias in

tion of weight percent volatile content of coatings, inks, and

ASTM Test Methods

adhesives designed to be cured by exposure to ultraviolet light

E691 Practice for Conducting an Interlaboratory Study to

or to a beam of accelerated electrons.

Determine the Precision of a Test Method

1.2 Test Method A is applicable to radiation curable mate-

3. Terminology

rials that are essentially 100 % reactive but may contain traces

(no more than 3 %) of volatile materials as impurities or

3.1 Definitions:

introduced by the inclusion of various additives.

3.1.1 cure, n—the condition of a coating after conversion to

1.3 Test Method B is applicable to all radiation curable the final state of cure as measured by tests generally related to

end use performance and mutually agreeable to supplier and

materials but must be used for materials that contain volatile

solvents intentionally introduced to control application viscos- purchaser.

ity and which are intended to be removed from the material

3.1.2 ultraviolet (UV) curing, n—conversion of a coating

prior to cure.

from its application state to its final use state by means of a

mechanism initiated by ultraviolet radiation generated by

1.4 These test methods may not be applicable to radiation

equipment designed for that purpose.

curable materials wherein the volatile material is water, and

other procedures may be substituted by mutual consent of the

3.1.3 electron beam (EB) curing, n—conversionofacoating

producer and user.

from its application state to its final use state by means of a

mechanism initiated by electron beam radiation generated by

1.5 The values stated in SI units are to be regarded as

equipment designed for that purpose.

standard. No other units of measurement are included in this

standard. 3.1.4 processingvolatiles,n—lossinspecimenweightunder

test conditions that are designed to simulate actual industrial

1.6 This standard does not purport to address all of the

cure processing conditions.

safety problems, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.1.5 potential volatiles, n—loss in specimen weight upon

priate safety and health practices and determine the applica-

heating at 110°C for 60 min after radiation curing.

bility of regulatory limitations prior to use. A specific hazard 3.1.5.1 Discussion—This value is an estimation of volatile

statement is given in 15.7.

loss that may occur during aging or under extreme storage

conditions. Potential volatiles may also be referred to as

2. Referenced Documents

residual volatiles.

2.1 ASTM Standards: 3.1.6 total volatiles, n—sum of the processing volatiles and

D2369 Test Method for Volatile Content of Coatings the potential volatiles.

4. Summary of Test Methods

1 4.1 Adesignated quantity of material is weighed before and

These test methods are under the jurisdiction of ASTM Committee D01 on

Paint and Related Coatings, Materials, and Applications and are the direct

after a cure step that simulates normal industrial processing.

responsibility of Subcommittee D01.55 on FactoryApplied Coatings on Preformed

The test specimen is weighed again after heating at 110 6 5°C

Products.

for 60 min.The percent volatile is calculated from the losses in

CurrenteditionapprovedJune1,2007.PublishedJuly2007.Originallyapproved

weight.

in 1993. Last previous edition approved in 2002 as D5403 - 93 (2002). DOI:

10.1520/D5403-93R07.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 5. Significance and Use

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1 These test methods are the procedures of choice for

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. determining volatile content of materials designed to be cured

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5403 − 93 (2007)

by exposure to ultraviolet light or electron beam irradiation. 9.3 Apply a minimum of 0.2 g of test specimen to the

These types of materials contain liquid reactants that react to aluminum substrate and reweigh to 0.1 mg (B). Prepare a total

become part of the film during cure, but, which under the test of three test specimens.

conditions of Test Method D2369, will be erroneously mea-

NOTE1—Theelapsedtimebetweenapplicationandweighingshouldbe

sured as volatiles. The conditions of these test methods are

no greater than 30 s. If the sample to be tested contains any reactive

similar to Test Method D2369 with the inclusion of a step to

diluent with a vapor pressure at room temperature greater than 1.0 mm Hg

(forexample,styrene),theelapsedtimebetweenspecimenapplicationand

cure the material prior to weight loss determination. Volatile

weighing must be no greater than 15 s.

contentisdeterminedastwoseparatecomponents—processing

volatiles and potential volatiles. Processing volatiles is a 9.4 Cure the test specimen by exposure to UV or EB as

measure of volatile loss during the actual cure process. prescribed by the supplier of the material.

Potential volatiles is a measure of volatile loss that might occur

NOTE 2—If there is any doubt as to the adequacy of the exposure for

during aging or under extreme storage conditions. These

affecting proper cure (6.1), an additional sample can be tested utilizing

volatile content measurements are useful to the producer and

50 % additional exposure and the volatile content results compared. If the

original exposure was adequate, there should be no difference in the

user of a material and to environmental interests for determin-

results within the precision of the test method. If the results are different,

ing emissions.

the supplier of the material must be contacted and a revised cure schedule

established.

6. Interferences

9.5 Allow the test specimen to cool 15 min at room

6.1 The degree to which the results of these procedures

temperature and reweigh to 0.1 mg (C).

accurately measure the volatiles emitted during actual use is

9.6 Heatthetestspecimeninaforceddraftoven(8.2)for60

absolutely dependent upon proper cure during the test proce-

min at 110 6 5°C.

dure. Although overcure will have little or no effect upon

measured volatiles, undercure may lead to erroneously high

NOTE 3—Materials that can react with atmospheric moisture during

values. Since various pieces of cure equipment may vary

post cure, that is, UV cationic-curable epoxy materials, may exhibit a

weight gain during procedure in 9.6. If this occurs, the sample should be

widely in efficiency, it is essential that dialogue between

retested and allowed to post cure at room temperature for 48 h after

material manufacturer and testing laboratory establish a cure

procedurein9.5,andthenreweighedpriortoprocedurein9.6.Theweight

scheduleappropriatebothtothematerialtobetestedandtothe

after post cure should then be used as Weight C in the calculation of

cure equipment to be used in the procedure.

percent potential volatiles in 10.1.

9.7 Allow the test specimen to cool to room temperature in

TEST METHOD A

a desiccator and reweigh to 0.1 mg, (D).

7. Scope

10. Calculations

7.1 This test method is applicable to radiation curable

10.1 Calculate the weight percent volatiles as follows:

materials with solvent content less than or equal to 3 %.

Processing Volatiles 5 100 @~B 2 C!/~B 2 A!# (1)

8. Apparatus

Potential Volatiles 5 100 C 2 D / B 2 A (2)

@~ ! ~ !#

8.1 Aluminum Substrate, standard test panels (102 mm by

305 mm) or heavy gage (0.05 mm minimum) foil. Test panels

Total volatiles 5 % Processing Volatiles1% Potential Volatiles

aremostconvenientandmaybecutintosmallerpiecesforease

where:

of weighing. Precondition the substrate for 30 min at 110 6

A = weight of aluminum substrate, g,

5°C and store in a desiccator prior to use.

B = weight of aluminum substrate plus test specimen, g,

8.2 Forced Draft Oven, Type IIAorType IIB as specified in

C = weight of aluminum substrate plus test specimen after

Specification E145.

cure, g, and

D = weight of aluminum substrate plus cured test specimen

8.3 Ultraviolet Light or Electron Beam Curing Equipment—

after heating.

There are several commercial suppliers of laboratory scale

equipment that simulates industrial curing processes.

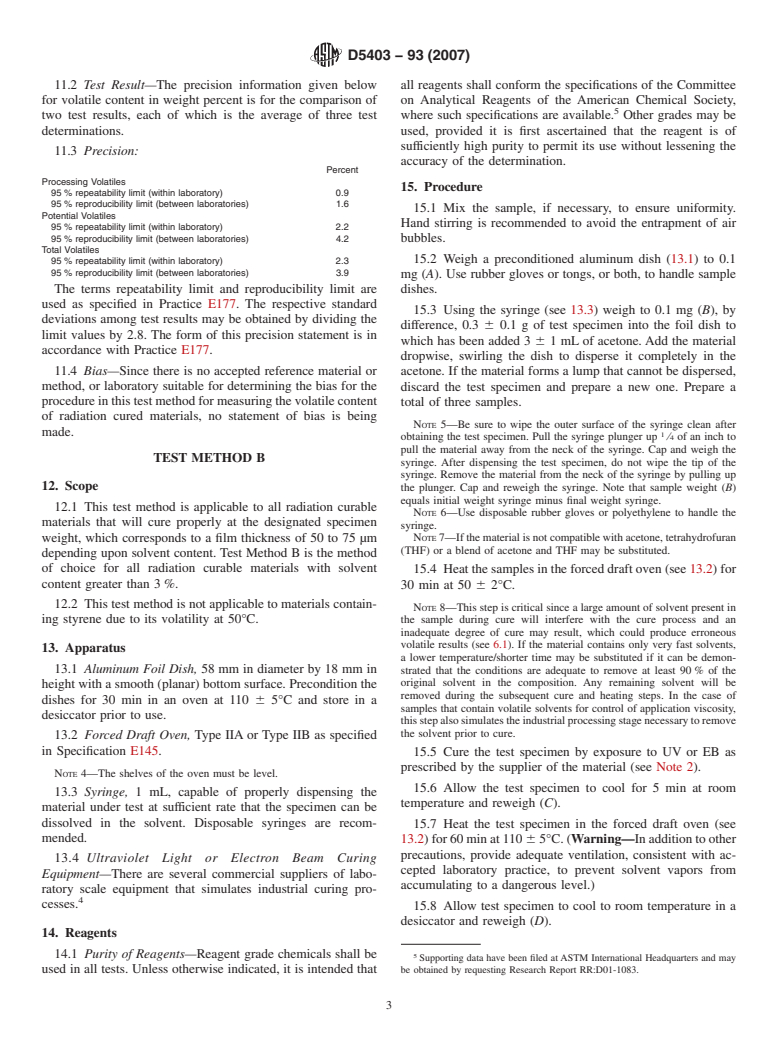

11. Precision and Bias

9. Procedure

11.1 Interlaboratory Test Program—An interlaboratory

9.1 Mixthesample,ifnecessary,toensureuniformity.Hand study of volatile content of radiation cured materials (Test

MethodA) was conducted in accordance with Practice E691 in

stirringisrecommendedtoavoidtheentrapmentofairbubbles.

nine laboratories with three materials, with each laboratory

9.2 Weigh the preconditioned aluminum substrate, (8.1)to

obtaining three test results for each material.

0.1 mg (A). The size of the aluminum substrate must allow a

minimum of 0.2 g of material to be applied at the supplier’s

recommended film thickness

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.