ASTM F3094-14(2022)

(Test Method)Standard Test Method for Determining Protection Provided By X-ray Shielding Garments Used in Medical X-ray Fluoroscopy from Sources of Scattered X-Rays

Standard Test Method for Determining Protection Provided By X-ray Shielding Garments Used in Medical X-ray Fluoroscopy from Sources of Scattered X-Rays

SIGNIFICANCE AND USE

5.1 This test method is designed to provide a standardized procedure to ensure comparable results between manufacturers, testing laboratories, and users.

5.2 This test method attempts to realistically quantify the radiation protection provided by radiation protective garments under real-world conditions for workers primarily exposed to scattered radiation in medical fluoroscopy work.

5.3 This test method is designed to simulate exposure conditions to radiation scattered from the body of the patient undergoing fluoroscopy through an angle of 90° from the primary X-ray beam.

5.4 The test method is designed to include contributions of radiation dose to the wearer from secondary radiation emitted from the shielding material.

SCOPE

1.1 This test method establishes a procedure for measuring the relative reduction in the intensity of X-radiation provided by shielding garments to the human user under conditions simulating actual use.

1.2 This test method provides a condition simulating X-rays generated between 60 and 130 kV that are scattered through an angle of 90° by a water equivalent material.

1.3 This test method applies to both leaded and no-leaded radiation protective materials.

1.4 This test method provides a method for inclusion of secondary radiations generated within the protective material into a more realistic evaluation of radiation protection.

1.5 The values given in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Some specific hazards statements are given in Section 7.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F3094 − 14 (Reapproved 2022)

Standard Test Method for

Determining Protection Provided By X-ray Shielding

Garments Used in Medical X-ray Fluoroscopy from Sources

of Scattered X-Rays

This standard is issued under the fixed designation F3094; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method establishes a procedure for measuring 2.1 ASTM Standards:

the relative reduction in the intensity of X-radiation provided F1494Terminology Relating to Protective Clothing

by shielding garments to the human user under conditions F2547Test Method for Determining the Attenuation Prop-

simulating actual use. erties in a Primary X-ray Beam of Materials Used to

Protect Against Radiation Generated During the Use of

1.2 ThistestmethodprovidesaconditionsimulatingX-rays

X-ray Equipment

generatedbetween60and130kVthatarescatteredthroughan

2.2 IEC Standard:

angle of 90° by a water equivalent material.

IEC 61331-1 Ed. 2.0Protective DevicesAgainst Diagnostic

1.3 This test method applies to both leaded and no-leaded

Medical X-radiation: Part 1—Determination of Attenua-

radiation protective materials.

tion Properties of Materials

1.4 This test method provides a method for inclusion of

3. Terminology

secondary radiations generated within the protective material

into a more realistic evaluation of radiation protection. 3.1 Definitions:

3.1.1 attenuation, n—for radiological protective material,

1.5 The values given in SI units are to be regarded as

the fractional reduction in the intensity of the X-ray beam

standard. No other units of measurement are included in this

resultingfromtheinteractionsbetweentheX-raybeamandthe

standard.

protective material when the X-ray beam passes through the

1.6 This standard does not purport to address all of the

protective material.

safety concerns, if any, associated with its use. It is the

3.1.1.1 Discussion—Itisimportanttonotethatthemeasure-

responsibility of the user of this standard to establish appro-

ment of attenuation (as specified by Test Method F2547)

priate safety, health, and environmental practices and deter-

specifically excludes the contribution of secondary radiation

mine the applicability of regulatory limitations prior to use.

from the measurement. The present standard provides a

Some specific hazards statements are given in Section 7.

method for incorporating those contributions of radiation dose

1.7 This international standard was developed in accor-

to the wearer of protective garments. (See 3.1.10.)

dance with internationally recognized principles on standard-

3.1.2 coeffıcient of variation—the ratio of the standard

ization established in the Decision on Principles for the

deviation of a sample to the sample mean.

Development of International Standards, Guides and Recom-

3.1.3 exposure, n—for radiological purposes the amount of

mendations issued by the World Trade Organization Technical

ionization charge of one sign produced in a defined volume of

Barriers to Trade (TBT) Committee.

dry air at standard temperature and pressure, caused by

1 2

ThistestmethodisunderthejurisdictionofASTMCommitteeF23onPersonal For referenced ASTM standards, visit the ASTM website, www.astm.org, or

ProtectiveClothingandEquipmentandisthedirectresponsibilityofSubcommittee contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

F23.70 on Radiological Hazards. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Dec. 1, 2022. Published December 2022. Originally the ASTM website.

approved in 2014. Last previous edition approved in 2014 as F3094–14. DOI: Available from International Electrotechnical Commission (IEC), 3, rue de

10.1520/F3094-14R22. Varembé, P.O. Box 131, CH-1211 Geneva 20, Switzerland, http://www.iec.ch.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F3094 − 14 (2022)

interaction with X-rays. Exposure is expressed in units of 3.1.10 protection rating, n—forthepurposesofradiological

coulombs/kg of air in SI units. An older unit called the protectioninthistestmethod,thepercentageofexposureatthe

–4

Roentgen (R) is also used, where1R= 2.58 × 10 C/kg. skin surface of the wearer of the protective garment relative to

the exposure on that surface in the absence of the protective

3.1.4 fluorescent radiation, n—a form of secondary radia-

garment, measured under scatter equivalent conditions for a

tion following photoelectric collisions between X-rays and

particular radiation quality.

orbital electrons of heavier elements such as those used in

protectivematerials,whereuponelectronrearrangementsatthe

3.1.11 scatter equivalent conditions—specific primary

atomic level result in the emission of one or more fluorescent X-ray spectra defined in terms of kV and HVL that simulate

photons.

radiation scattered from a water equivalent medium measured

3.1.4.1 Discussion—Measurements to include fluorescent at 90° to the beam incidence on that medium.

radiation are important because they may contribute to the

3.1.11.1 Discussion—Measuring the actual degree of pro-

radiation exposure to the wearer of radiation protective gar-

tection from scattered X-rays provided by radiation protective

ments.

garments under real-world conditions is technically difficult

and subject to large uncertainties.Actual scatter intensities are

3.1.5 half-value layer (HV), n—thethicknessof99.9%pure

too low and measurements have excessively high uncertainties

aluminum in millimetres (commonly designated mm Al) that

when evaluated in practical conditions. The scatter equivalent

reducestheintensityofanX-raybeambyonehalfofitsinitial

conditionsdescribeconditionsthatconservativelyapproximate

value.

the energies of 90° scatter produced when a water medium

3.1.5.1 Discussion—HVL is commonly used to designate

(body of a human or animal) is exposed toTest Method F2547

the penetrating ability of an X-ray beam containing many

beam qualities. Use of the surrogate primary beams provides

X-ray energies (as is the case with standard X-ray sources).A

conditions that are practical to test under field conditions.

highervalueofAlinmmAlwouldindicateamorepenetrating

X-ray beam. Note that HVLmay also be specified in materials

3.1.12 scatter radiation, n—a form of secondary radiation

other than Al, although only Al is used in this document.

where X-radiation is deflected to a changed direction with or

without a loss in energy by collisions between X-ray photons

3.1.6 ionization chamber—a device that measures the elec-

and orbital electrons of atoms in the path of the X-rays;

tricalchargeliberatedduringtheionizationofairmoleculesby

scattering events in medical procedures mainly occur with loss

electromagnetic radiation (X-rays for the purposes of this test

of energy due to the Compton Effect such that the average

method), expressed in units of coulombs per kg of air.

energies of scattered X-rays are less than those of the direct

3.1.6.1 Discussion—The measurement of exposure is de-

primary beam.

fined for an air ionization chamber. The chamber used in this

method must be of a flat, parallel-plate design.

3.1.13 secondary radiation, n—radiation that is produced in

a material by scattering or emission when the material is

3.1.7 kilovolts, or kilovolts peak (kV or kVp), n—for the

exposed to a source of X-rays.

purposes of radiological protection, the maximum electrical

potential across an X-ray tube during exposure. 3.1.13.1 Discussion—Secondary radiation is of importance

because: (1) the hazard to medical X-ray fluoroscopy workers

3.1.7.1 Discussion—The kV or kVp determines the maxi-

mum photon energy in kilo-electron volts (keV) of an X-ray is principally from X-rays scattered from the patient and other

materials within the primary X-ray beam, and (2) fluorescent

beam; standard X-ray beams contain many photon energies

radiation produced within the protective material can contrib-

most of which are less than this maximum value.

ute to the radiation exposure to the wearer of the radiation

3.1.8 lead equivalency—for radiological protective material

protective garments.

the thickness in millimetres (commonly designated mm Pb) of

greaterthan99.9%puritythatprovidesthesameattenuationas 3.1.14 standard sample dimensions—test samples and lead

standardscuttoanareasuitedtothemeasurementsetupinFig.

a given protective material.

3.1.8.1 Discussion—Radiationprotectivematerialsarecom- 1, ideally by using a template.

monly made with little or no lead, thus lead equivalence will 3.1.14.1 Discussion—It may be desired to test finished

vary with X-ray energy and with the composition of the

protective clothing that are not cut to standard sample dimen-

protective material. Lead equivalence should be specified at a sionsusingthistestmethod.Thismaybedone,butmayrequire

specific energy. This test method specifies a method for

a special test jig to support the material in proper orientation

determining the attenuation in pure lead materials but does not andconfigurationtomeetthistestmethod.Suchaprocedureis

require a specific lead equivalence. If lead equivalence is not described in this test method.

specified, it should be specified at a single scatter equivalent

3.1.15 wave form ripple, n—for radiological purposes, the

condition.

peak-to-peak variation in the voltage potential applied to the

3.1.9 primary X-rays, n—the X-rays emitted from the target

X-raytubeduringexposure.Greatervoltageripple(commonin

of an X-ray tube subjected to an accelerating potential suffi-

older X-ray generators) tends to reduce the intensity and

cient to cause X-ray emission.

3.1.9.1 Discussion—Primary X-rays are distinguished from

secondary X-rays emitted from a material exposed to primary

McCaffrey, J. P., Tessier, F., and Shen, H., “Radiation Shielding Materials and

X-rays. Secondary X-rays are generally less penetrating than

RadiationScatterEffectsforInterventionalRadiology(IR)Physicians,” Med. Phys.,

primary X-rays. Vol 39, No. 7, July 2012.

F3094 − 14 (2022)

ments correspond to most common fluoroscopic conditions at

80 kV, a high kV condition for a standard fluoroscope at

100kV, and a condition corresponding to scatter produced

from CT scanning at 130 kV. These scatter equivalent condi-

tions correspond to direct beam measurement at 70, 85, and

105 kV with filtrations adjusted to achieve HVLs of 3.4, 4.0,

and 5.1 mm Al respectively.

5. Significance and Use

5.1 This test method is designed to provide a standardized

procedure to ensure comparable results between

manufacturers, testing laboratories, and users.

5.2 This test method attempts to realistically quantify the

radiation protection provided by radiation protective garments

under real-world conditions for workers primarily exposed to

scattered radiation in medical fluoroscopy work.

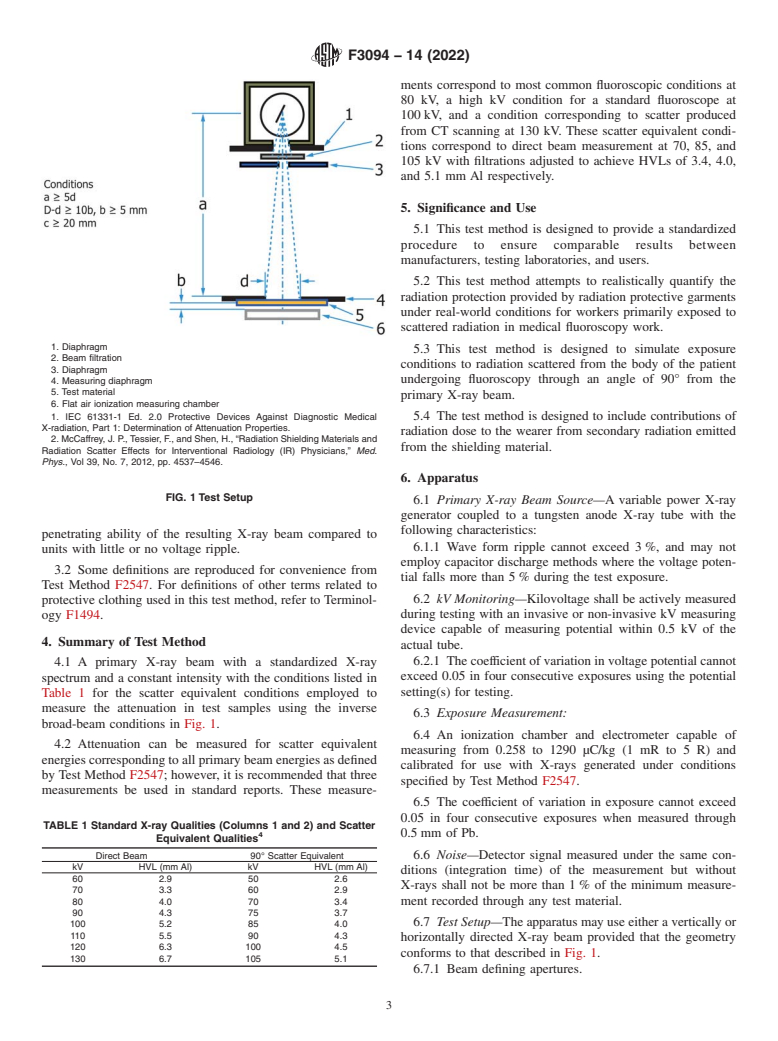

1. Diaphragm

5.3 This test method is designed to simulate exposure

2. Beam filtration

conditions to radiation scattered from the body of the patient

3. Diaphragm

undergoing fluoroscopy through an angle of 90° from the

4. Measuring diaphragm

5. Test material

primary X-ray beam.

6. Flat air ionization measuring chamber

1. IEC 61331-1 Ed. 2.0 Protective Devices Against Diagnostic Medical 5.4 The test method is designed to include contributions of

X-radiation, Part 1: Determination of Attenuation Properties.

radiation dose to the wearer from secondary radiation emitted

2. McCaffrey, J. P., Tessier, F., and Shen, H., “Radiation Shielding Materials and

from the shielding material.

Radiation Scatter Effects for Interventional Radiology (IR) Physicians,” Med.

Phys., Vol 39, No. 7, 2012, pp. 4537–4546.

6. Apparatus

FIG. 1 Test Setup

6.1 Primary X-ray Beam Source—A variable power X-ray

generator coupled to a tungsten anode X-ray tube with the

following characteristics:

penetrating ability of the resulting X-ray beam compared to

6.1.1 Wave form ripple cannot exceed 3%, and may not

units with little or no voltage ripple.

employ capacitor discharge methods where the voltage poten-

3.2 Some definitions are reproduced for convenience from

tial falls more than 5% during the test exposure.

Test Method F2547. For definitions of other terms related to

6.2 kV Monitoring—Kilovoltage shall be actively measured

protective clothing used in this test method, refer to Terminol-

during testing with an invasive or non-invasive kV measuring

ogy F1494.

device capable of measuring potential within 0.5 kV of the

4. Summary of Test Method

actual tube.

6.2.1 Thecoefficientofvariationinvoltagepotentialcannot

4.1 A primary X-ray beam with a standardized X-ray

exceed 0.05 in four consecutive exposures using the potential

spectrum and a constant intensity with the conditions listed in

setting(s) for testing.

Table 1 for the scatter equivalent conditions employed to

measure the attenuation in test samples using the inverse

6.3 Exposure Measurement:

broad-beam conditions in Fig. 1.

6.4 An ionization chamber and electrometer capable of

4.2 Attenuation can be measured for scatter equivalent

measuring from 0.258 to 1290 µC/kg (1 mR to 5 R) and

energiescorrespondingtoallprimarybeamenergiesasdefined

calibrated for use with X-rays generated under conditions

by Test Method F2547; however, it is recommended that three

specified by Test Method F2547.

measurements be used in standard reports. These measure-

6.5 The coefficient of variation in exposure cannot exceed

0.05 in four consecutive exposures when measured through

TABLE 1 Standard X-ray Qualities (Columns 1 and 2) and Scatter

4 0.5mm of Pb.

Equivalent Qualities

Direct Beam 90° Scatter Equivalent 6.6 Noise—Detector signal measured under the same con-

kV HVL (mm Al) kV HVL (mm Al)

ditions (integration time) of the measurement but without

60 2.9 50 2.6

X-rays shall not be more than 1% of the minimum measure-

70 3.3 60 2.9

80 4.0 70 3.4 ment recorded through any test material.

90 4.3 75 3.7

6.7 Test Setup—Theapparatusmayuseeitheraverticallyor

100 5.2 85 4.0

110 5.5 90 4.3

horizontally directed X-ray beam provided that the geometry

120 6.3 100 4.5

conforms to that described in Fig. 1.

130 6.7 105 5.1

6.7.1 Beam defining apertures.

F3094 − 14 (2022)

6.7.1.1 Beam apertures designated 1 and 3 in Fig. 1 are 9.2 Measure and document the exposure reproducibility

normally incorporated i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.