ASTM B311-93(1997)

(Test Method)Test Method for Density Determination for Powder Metallurgy (P/M) Materials Containing Less Than Two Percent Porosity

Test Method for Density Determination for Powder Metallurgy (P/M) Materials Containing Less Than Two Percent Porosity

SCOPE

1.1 This test method covers the determination of density for powder metallurgy (P/M) materials containing less than two percent porosity and for cemented carbides. This test method is based on the water displacement method. Note 1-A test specimen that gains mass when immersed in water indicates the specimen contains surface-connected porosity. Unsealed surface porosity will absorb water and cause density values higher than the true value. This test method is not applicable if this problem occurs.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

Designation: B 311 – 93 (Reapproved 1997)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Test Method for

Density Determination for Powder Metallurgy (P/M) Materials

Containing Less Than Two Percent Porosity

This standard is issued under the fixed designation B 311; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Density alone cannot be used for evaluating the degree of

densification because chemical composition and heat treatment

1.1 This test method covers the determination of density for

affect the pore-free density.

powder metallurgy (P/M) materials containing less than two

4.2 For cemented carbides, a density measurement is nor-

percent porosity and for cemented carbides. This test method is

mally used to determine if there is any significant deviation in

based on the water displacement method.

composition of the carbide grade. For straight tungsten

NOTE 1—A test specimen that gains mass when immersed in water

carbide-cobalt grades, the relationship is straightforward. For

indicates the specimen contains surface-connected porosity. Unsealed

complex carbide grades (for example, grades containing tan-

surface porosity will absorb water and cause density values higher than the

talum carbide or titanium carbide, or both, in addition to

true value. This test method is not applicable if this problem occurs.

tungsten carbide-cobalt), the situation is more complicated. If

1.2 The values stated in SI units are to be regarded as the

the measured density is beyond the specified limits, the

standard. The values given in parentheses are for information

composition is undoubtedly also outside of the specified limits.

only.

A measured density within the specified limits does not ensure

1.3 This standard does not purport to address all of the

correct composition; compensation between two or more

safety concerns, if any, associated with its use. It is the

constituents could result in the expected density with the wrong

responsibility of the user of this standard to establish appro-

composition. Density alone cannot be used for evaluating a

priate safety and health practices and determine the applica-

cemented carbide grade.

bility of regulatory limitations prior to use.

5. Apparatus

2. Referenced Documents

5.1 Analytical Balance, precision single-pan analytical bal-

2.1 ISO Standard:

ance that will permit readings within 0.01 % of the test

3369 Impermeable Sintered Metal Materials and

specimen mass. The analytical balance shall be supported in a

Hardmetals—Determination of Density

manner to eliminate mechanical vibrations and be shielded

from air drafts.

NOTE 2—The water density table in ISO 3369 differs from the table

contained in this test method.

5.2 Weighing Liquid—Distilled or deionized water to which

0.05 to 0.1 weight percent of a wetting agent has been added to

3. Summary of Test Method

reduce the effects of surface tension.

3.1 The test specimen is cleaned and the cut surfaces

NOTE 3—Degassing the water by evacuation, boiling, or ultrasonic

prepared. Using an analytical balance, the test specimen is first

agitation helps to prevent air bubbles from collecting on the test specimen

weighed in air and then in water. The density is determined by

and specimen support when immersed in water.

calculation.

5.3 Water Container—A glass beaker or other suitable

4. Significance and Use transparent container should be used to contain the water.

4.1 For P/M materials containing less than two percent

NOTE 4—A transparent container makes it easier to see air bubbles

porosity, a density measurement is normally used to determine adhering to the test specimen and specimen support when immersed in

water.

if the part has been densified, either overall or in a critical

NOTE 5—For the most precise density determination, the water con-

region, to the degree required for the intended application.

tainer should be of a size that the level of the water does not rise more than

2.5 mm (0.10 in.) when the test specimen is lowered into the water.

This test method is under the jurisdiction of ASTM Committee B-9 on Metal

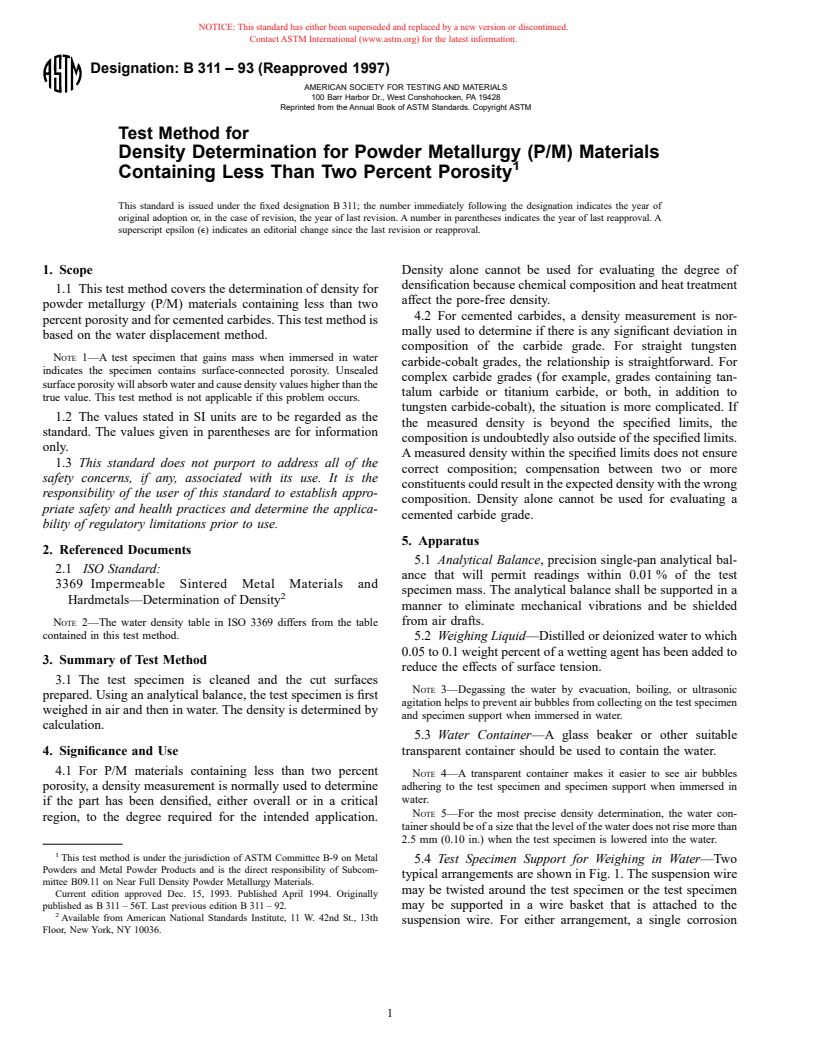

5.4 Test Specimen Support for Weighing in Water—Two

Powders and Metal Powder Products and is the direct responsibility of Subcom-

typical arrangements are shown in Fig. 1. The suspension wire

mittee B09.11 on Near Full Density Powder Metallurgy Materials.

may be twisted around the test specimen or the test specimen

Current edition approved Dec. 15, 1993. Published April 1994. Originally

published as B 311 – 56T. Last previous edition B 311 – 92. may be supported in a wire basket that is attached to the

Available from American National Standards Institute, 11 W. 42nd St., 13th

suspension wire. For either arrangement, a single corrosion

Floor, New York, NY 10036.

B311

should be adjusted to zero prior to each weighing. Duplicate mass

determinations should be averaged before calculating the density.

NOTE 8—For improved reproducibility, the analytical balance should be

periodically calibrated with a standard mass that is approximately equal to

the test specimen mass.

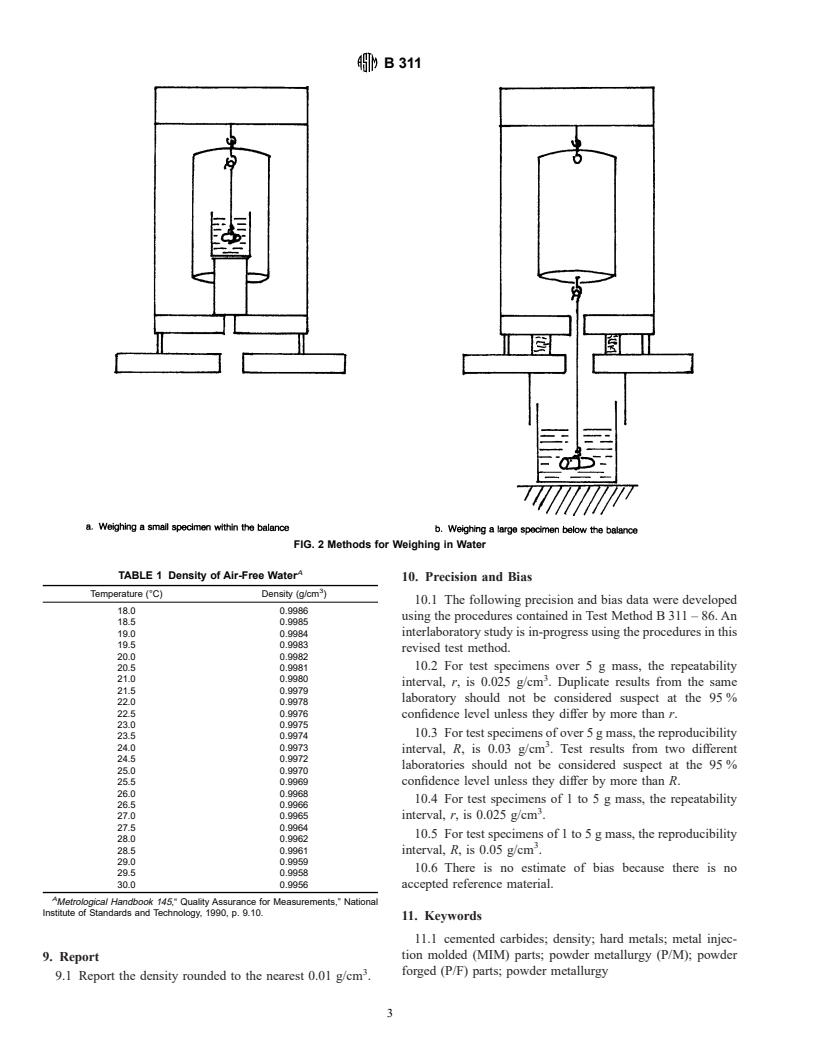

7.2 Support the container of water over the pan of the

balance using an suitable bridge as shown in Fig. 2. The

container of water may also be supported below the balance for

weighing larger specimens if the balance has a lower beam

hook for this purpose. See Fig. 2b. If this arrangement is used,

it is important to shield the suspension wire between the

a. Twisted wire arrangement b. Basket support arrangement

container of water and the bottom of the balance from air

FIG. 1 Methods for Holding the Test Specimen When Weighing in

drafts.

Water

7.3 Suspend the test specimen support with the test speci-

men from the beam hook of the balance. The water should

resistant wire—for example, austenitic stainless steel, copper,

cover any wire twists and the specimen support basket by at

nichrome—shall be used for the basket and suspension wire.

least 6 mm ( ⁄4 in.) to minimize the effect of surface tension

The maximum recommended diameter of suspension wire to

fo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.