ASTM D2259-02(2016)e1

(Test Method)Standard Test Method for Shrinkage of Yarns

Standard Test Method for Shrinkage of Yarns

SIGNIFICANCE AND USE

5.1 Test Method D2259 for testing yarn for shrinkage in boiling water, saturated steam, dry heat, or solvents is considered satisfactory for acceptance testing of commercial shipments of yarn because the test method has been used extensively in the trade for that purpose.

5.1.1 If there are differences of practical significance between reported test results for two laboratories (or more), comparative tests should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum, use the samples for such comparative tests that are as homogeneous as possible, drawn from the same lot of material as the samples that resulted in disparate results during initial testing and randomly assigned in equal numbers to each laboratory. The test results from the laboratories involved should be compared using a statistical test for unpaired data, a probability level chosen prior to the testing series. If a bias is found, either its cause must be found and corrected, or future test results for that material must be adjusted in consideration of the known bias.

5.2 Results obtained by this test method can be used for the following purposes:

5.2.1 As an aid in predicting the dimensional stability of fabrics to wet processing,

5.2.2 As an aid in predicting the dimensional stability of fabrics during processing at elevated temperatures, and

5.2.3 As a control measure in the manufacture of some types of fibers.

5.3 The shrinkage medium to be used in the test depends on the requirements of the parties involved.

5.4 The procedure for shrinkage in boiling water is described in Section 12, for shrinkage in dry heat in Section 13, for shrinkage in saturated steam in Section 14, and for shrinkage in solvents in Section 15. A 30-min exposure time is prescribed for boiling water. In exposure to dry heat, saturated steam, or solvents, the extent of change in the length of yarn is dependent upon the fiber type and upon t...

SCOPE

1.1 This test method is used to determine the shrinkage of yarns in skein form when treated in boiling water, dry heat, saturated steam, or solvents. This test method is applicable to yarns made from any fiber or combination of fibers where the tex of the yarn is known or can be determined. This test method is not recommended for elastomeric yarns and those yarns that stretch more than 5 % under the tension loadings prescribed, although it has been used for the latter.

Note 1: Procedures for determining yarn shrinkage and bulk properties of textured yarns are covered in Test Method D4031.

1.2 This test method shows the values in both SI and inch-pound units. “SI” units is the technically correct name for the system of metric units known as the International System of Units. “Inch-pound” units is the technically correct name for the customary units used in the United States. The values stated in either SI units or in other units shall be regarded as standard. The values expressed in each system may not be exact equivalents; therefore each system must be used independently of the other without combining in any way.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D2259 − 02 (Reapproved 2016)

Standard Test Method for

Shrinkage of Yarns

This standard is issued under the fixed designation D2259; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—In 6.1, “1 cN/tex or 1.0 gf/den” was corrected editorially to “1 cN/tex or 0.1 gf/den” in April 2020.

1. Scope 2. Referenced Documents

1.1 This test method is used to determine the shrinkage of 2.1 ASTM Standards:

yarns in skein form when treated in boiling water, dry heat, D123Terminology Relating to Textiles

saturated steam, or solvents. This test method is applicable to D1059Test Method for Yarn Number Based on Short-

yarns made from any fiber or combination of fibers where the Length Specimens

texoftheyarnisknownorcanbedetermined.Thistestmethod D1776Practice for Conditioning and Testing Textiles

is not recommended for elastomeric yarns and those yarns that D1907Test Method for Linear Density ofYarn (Yarn Num-

stretch more than 5% under the tension loadings prescribed, ber) by the Skein Method

although it has been used for the latter. D2258Practice for Sampling Yarn for Testing

D3888Terminology for Yarn Spinning Systems

NOTE 1—Procedures for determining yarn shrinkage and bulk proper-

D3990Terminology Relating to Fabric Defects

ties of textured yarns are covered in Test Method D4031.

D4031Test Method for Bulk Properties of Textured Yarns

1.2 This test method shows the values in both SI and

D4848Terminology Related to Force, Deformation and

inch-pound units. “SI” units is the technically correct name for

Related Properties of Textiles

thesystemofmetricunitsknownastheInternationalSystemof

D4849Terminology Related to Yarns and Fibers

Units. “Inch-pound” units is the technically correct name for

E145Specification for Gravity-Convection and Forced-

thecustomaryunitsusedintheUnitedStates.Thevaluesstated

Ventilation Ovens

ineitherSIunitsorinotherunitsshallberegardedasstandard.

The values expressed in each system may not be exact

3. Terminology

equivalents;thereforeeachsystemmustbeusedindependently

3.1 Definitions:

of the other without combining in any way.

3.1.1 For definitions of textile terms used in this test

1.3 This standard does not purport to address all of the

method: skein and skein loop-length, refer to Terminology

safety concerns, if any, associated with its use. It is the

D4849.

responsibility of the user of this standard to establish appro-

3.1.2 For definition of the term extension used in this test

priate safety, health, and environmental practices and deter-

method, refer to Terminology D4848.

mine the applicability of regulatory limitations prior to use.

3.1.3 Forothertextiletermsusedinthistestmethod,referto

1.4 This international standard was developed in accor-

Terminology Standards, D123, D3888, D3990, D4848 and

dance with internationally recognized principles on standard-

D4849.

ization established in the Decision on Principles for the

4. Summary of Test Method

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

4.1 The loop length of a conditioned skein of yarn is

Barriers to Trade (TBT) Committee.

measured under a specific tension, which is sufficient to

straighten but not stretch the skein. The tension-free skein is

This test method is under the jurisdiction of Committee D13 on Textiles and is

the direct responsibility of Subcommittee D13.58 on Yarns and Fibers. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Jan. 1, 2016. Published February 2016. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1964. Last previous edition approved in 2011 as D2259–02(2011). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D2259-02R16E01. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D2259 − 02 (2016)

then immersed in boiling water or exposed to dry heat or ends on the reel, a yarn-tensioning device capable of maintain-

saturated steam or in the solvent reconditioned, and remea- ing tension below 1 cN/tex or 0.1 gf/den, and a yarn length or

sured.Theshrinkage(orinsomecases,growth)iscalculatedas revolution indicator.Awarning bell that will ring just prior to

the change in length expressed as a percentage of the length the specified number of reel revolutions is recommended. A

before immersion or exposure. collapsible arm is advisable for convenience in skein removal.

NOTE 2—By agreement, reels of other perimeters, between 1 and 2 m

5. Significance and Use

(1 and 2 yd) may be used.

5.1 Test Method D2259 for testing yarn for shrinkage in

6.2 Measuring Scale—A tape or scale accurate to 1 part in

boiling water, saturated steam, dry heat, or solvents is consid-

1000 is recommended. Any scale length exceeding the reel

ered satisfactory for acceptance testing of commercial ship-

diameterby250mmor10in.allowingfortheextensionofthe

ments of yarn because the test method has been used exten-

skein is satisfactory.The scale should be mounted vertically.A

sively in the trade for that purpose.

top hook holds the skein and is mounted with support surface

5.1.1 If there are differences of practical significance be-

in line with the zero index of the scale.

tween reported test results for two laboratories (or more),

6.3 Metal Hook—A hook designed to hang from the skein,

comparative tests should be performed to determine if there is

a statistical bias between them, using competent statistical shaped to receive the tensioning weights, and with a mass

known to 1 part in 1000.The hook may have a pointer located

assistance.As a minimum, use the samples for such compara-

tive tests that are as homogeneous as possible, drawn from the and attached for ease in reading the measuring scale at a point

level with the inside bottom of the skein.

same lot of material as the samples that resulted in disparate

results during initial testing and randomly assigned in equal

6.4 Tensioning Masses—Accurate to 1 part in 1000.

numbers to each laboratory. The test results from the labora-

6.5 For Boiling Water:

tories involved should be compared using a statistical test for

6.5.1 Container, of sufficient size for 40:1 mass ratio water

unpaired data, a probability level chosen prior to the testing

bath.

series. If a bias is found, either its cause must be found and

6.5.2 Roller Wringer or Centrifugal Extractor.

corrected, or future test results for that material must be

6.5.3 Heat Source, for water bath.

adjusted in consideration of the known bias.

6.5.4 Distilled or Demineralized Water.

5.2 Results obtained by this test method can be used for the

6.5.5 Nonionic Wetting Agent.

following purposes:

6.6 For Dry Heat:

5.2.1 As an aid in predicting the dimensional stability of

6.6.1 Heating Oven—A forced-draft oven capable of meet-

fabrics to wet processing,

ing the required temperature and that meets the temperature

5.2.2 As an aid in predicting the dimensional stability of

uniformity requirements for a Type IIB oven as described in

fabrics during processing at elevated temperatures, and

Specification E145, Table 1. There must be a means of

5.2.3 Asacontrolmeasureinthemanufactureofsometypes

suspending the skeins in the oven. This may be accomplished

of fibers.

with a rod with cup hooks from which to suspend skeins. The

5.3 Theshrinkagemediumtobeusedinthetestdependson

rod may be mounted on a stand for placement in the oven;

the requirements of the parties involved.

skeins should not be allowed to touch the sides of the oven.

5.4 The procedure for shrinkage in boiling water is de-

6.7 For Saturated Steam:

scribed in Section 12, for shrinkage in dry heat in Section 13,

6.7.1 Autoclave—A pressure vessel capable of sustaining

for shrinkage in saturated steam in Section 14, and for

thetemperaturesandpressuresrequired,andofsuchasizethat

shrinkage in solvents in Section 15.A30-min exposure time is

thetestskeinsofyarncanbesuspendedwithouttouchingsides

prescribed for boiling water. In exposure to dry heat, saturated

or bottom of the autoclave.

steam, or solvents, the extent of change in the length of yarn is

dependent upon the fiber type and upon the time and tempera-

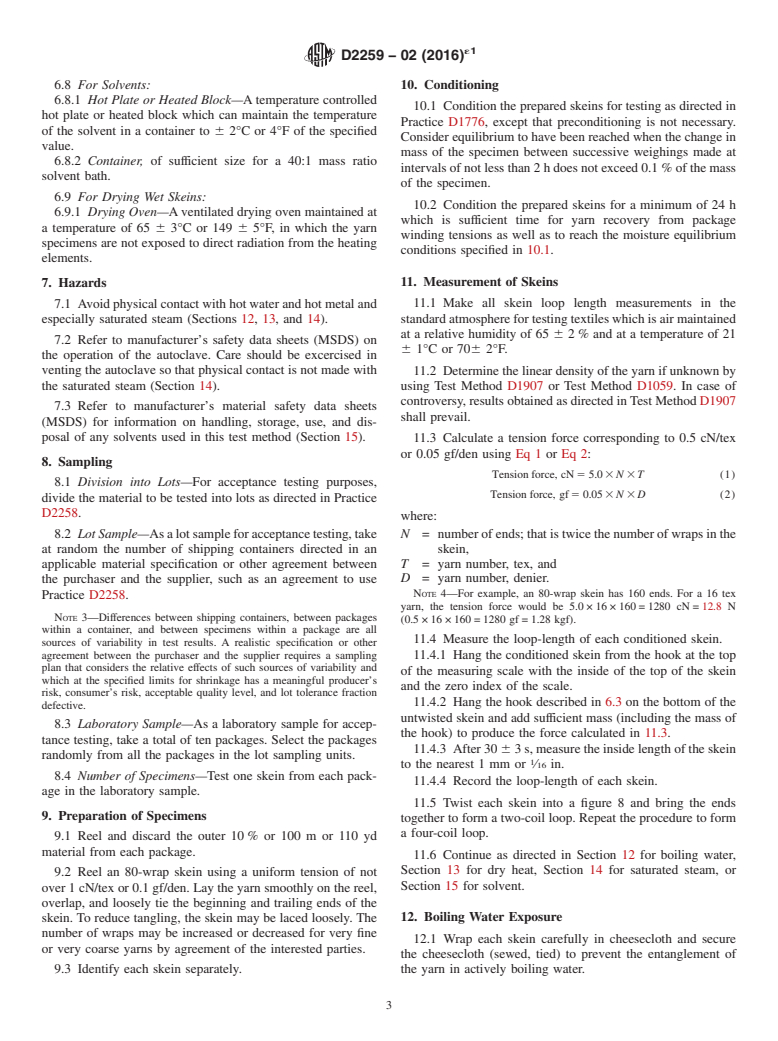

TABLE 1 Components of Variance as Standard Deviations,

ture of the exposure. Fiber types differ in their reaction to

Percentage Points

elevated temperature as well as the nature of the specific

Single- Within- Between-

solvent, and prior fiber history can have a great influence upon

Properties Operator Laboratory Laboratory

the heat and solvent shrinkage of a yarn. Therefore, the time

Component Component Component

and temperature conditions to be used to determine dry heat or

Shrinkage, boiling water:

Nylon spun yarn 0.32 0.60 0.61

saturatedsteamshrinkagemustbeagreeduponfortheparticu-

Nylon filament yarn 0.20 0.76 0.79

lar product involved. In addition, time and temperature

Polyester spun yarn 0.32 0.31 0.26

conditions, and solvent to be used must be agreed upon for

Polyester filament yarn 0.11 0.32 0.25

Acrylic filament yarn 0.22 0.42 0.30

solvent shrinkage determination for the particular product

Cotton yarn 0.16 0.21 0.19

involved.

Rayon spun yarn 0.16 0.25 0.21

Shrinkage, dry heat:

6. Apparatus and Reagents

Nylon spun yarn at 150°C 0.24 0.23 0.17

Nylon filament yarn at 150°C 0.20 0.55 0.51

6.1 Reel—A hand or motor-driven reel having a nominal

Polyester spun yarn at 190°C 0.39 0.38 0.26

perimeter of 1 m, 1.5 yd, or 1.125 m (Note 2).The reel should

Polyester filament yarn at 190°C 0.15 0.65 0.65

have a traversing mechanism that will minimize bunching of

´1

D2259 − 02 (2016)

6.8 For Solvents: 10. Conditioning

6.8.1 Hot Plate or Heated Block—Atemperature controlled

10.1 Condition the prepared skeins for testing as directed in

hot plate or heated block which can maintain the temperature

Practice D1776, except that preconditioning is not necessary.

of the solvent in a container to 6 2°C or 4°F of the specified

Considerequilibriumtohavebeenreachedwhenthechangein

value.

mass of the specimen between successive weighings made at

6.8.2 Container, of sufficient size for a 40:1 mass ratio

intervalsofnotlessthan2hdoesnotexceed0.1%ofthemass

solvent bath.

of the specimen.

6.9 For Drying Wet Skeins:

10.2 Condition the prepared skeins for a minimum of 24 h

6.9.1 Drying Oven—Aventilated drying oven maintained at

which is sufficient time for yarn recovery from package

a temperature of 65 6 3°C or 149 6 5°F, in which the yarn

winding tensions as well as to reach the moisture equilibrium

specimens are not exposed to direct radiation from the heating

conditions specified in 10.1.

elements.

11. Measurement of Skeins

7. Hazards

11.1 Make all skein loop length measurements in the

7.1 Avoidphysicalcontactwithhotwaterandhotmetaland

especially saturated steam (Sections 12, 13, and 14). standardatmospherefortestingtextileswhichisairmaintained

at a relative humidity of 65 6 2% and at a temperature of 21

7.2 Refer to manufacturer’s safety data sheets (MSDS) on

6 1°C or 706 2°F.

the operation of the autoclave. Care should be excercised in

venting the autoclave so that physical contact is not made with 11.2 Determinethelineardensityoftheyarnifunknownby

the saturated steam (Section 14). using Test Method D1907 or Test Method D1059. In case of

controversy,resultsobtainedasdirectedinTestMethodD1907

7.3 Refer to manufacturer’s material safety data sheets

shall prevail.

(MSDS) for information on handling, storage, use, and dis-

posal of any solvents used in this test method (Section 15).

11.3 Calculate a tension force corresponding to 0.5 cN/tex

or 0.05 gf/den using Eq 1 or Eq 2:

8. Sampling

Tensionforce, cN 55.0 3N 3T (1)

8.1 Division into Lots—For acceptance testing purposes,

Tensionforce, gf 50.05 3N 3D (2)

divide the material to be tested into lots as directed in Practice

D2258.

where:

8.2 LotSample—Asalotsampleforacceptancetesting,take

N = numberofends;thatistwicethenumberofwrapsinthe

at random the number of shipping containers directed in an skein,

applicable material specification or other agreement between T = yarn number, tex, and

D = yarn number, denier.

the purchaser and the supplier, such as an agreement to use

NOTE 4—For example, an 80-wrap skein has 160 ends. For a 16 tex

Practice D2258.

yarn, the tension force would be 5.0×16×160=1280 cN=12.8 N

NOTE 3—Differences between shipping containers, between packages

(0.5×16×160=1280 gf=1.28 kgf).

within a container, and between specimens within a package are all

11.4 Measure the loop-length of each conditioned skein.

sources of variability in test results. A realistic specification or other

agreement between the purchaser and the supplier requires a sampling

11.4.1 Hang the conditioned skein from the hook at the top

plan that considers the relative effects of such sources of variability and

of the measuring scale with the inside of the top of the skein

which at the specified limits for shrinkage has a meaningful producer’s

and the zero index of the scale.

risk, consumer’s risk, acceptable quality level, and lot tolerance fraction

11.4.2 Hang the hook described in 6.3 on the bottom of the

defective.

untwisted skein and add sufficient mass (including the mass of

8.3 Laboratory Sample—As a laboratory sample for accep-

the hook) to produce the force calculated in 11.3.

tance testing, take a total of ten packages. Select the packages

11.4.3 After30 63s,measuretheinsidelengthoftheskein

randomly from all the packages in the lot sampling units.

to the nearest 1 mm or ⁄16 in.

8.4 Number of Specimens—Test one skein from each pack-

11.4.4 Record the loop-length of each skein.

age in the laboratory sample.

11.5 Twist each skein into a figure 8 and bring the ends

9. Preparation of Specimens

together to form a two-coil loop. Repeat the procedure to form

a four-coil loop.

9.1 Reel and discard the outer 10% or 100 m or 110 yd

material from each package.

11.6 Continue as directed in Section 12 for boiling water,

Section 13 for dry heat, Section 14 for saturated steam, or

9.2 Reel an 80-wrap skein using a uniform tension of not

Section 15 for solvent.

over 1 cN/tex or 0.1 gf/den. Lay the yarn smoothly on the reel,

overlap, and loosely tie the beginning and trailing ends of the

12. Boiling Water Exposure

skein. To reduce tangling, the skein may be laced loosely. The

number of wraps may be increased or decreased for very fine

12.1 Wrap each skein carefully in cheesecloth and secure

or very coarse yar

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D2259 − 02 (Reapproved 2016) D2259 − 02 (Reapproved 2016)

Standard Test Method for

Shrinkage of Yarns

This standard is issued under the fixed designation D2259; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—In 6.1, “1 cN/tex or 1.0 gf/den” was corrected editorially to “1 cN/tex or 0.1 gf/den” in April 2020.

1. Scope

1.1 This test method is used to determine the shrinkage of yarns in skein form when treated in boiling water, dry heat, saturated

steam, or solvents. This test method is applicable to yarns made from any fiber or combination of fibers where the tex of the yarn

is known or can be determined. This test method is not recommended for elastomeric yarns and those yarns that stretch more than

5 % under the tension loadings prescribed, although it has been used for the latter.

NOTE 1—Procedures for determining yarn shrinkage and bulk properties of textured yarns are covered in Test Method D4031.

1.2 This test method shows the values in both SI and inch-pound units. “SI” units is the technically correct name for the system

of metric units known as the International System of Units. “Inch-pound” units is the technically correct name for the customary

units used in the United States. The values stated in either SI units or in other units shall be regarded as standard. The values

expressed in each system may not be exact equivalents; therefore each system must be used independently of the other without

combining in any way.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D123 Terminology Relating to Textiles

D1059 Test Method for Yarn Number Based on Short-Length Specimens

D1776 Practice for Conditioning and Testing Textiles

D1907 Test Method for Linear Density of Yarn (Yarn Number) by the Skein Method

D2258 Practice for Sampling Yarn for Testing

D3888 Terminology for Yarn Spinning Systems

D3990 Terminology Relating to Fabric Defects

D4031 Test Method for Bulk Properties of Textured Yarns

D4848 Terminology Related to Force, Deformation and Related Properties of Textiles

D4849 Terminology Related to Yarns and Fibers

E145 Specification for Gravity-Convection and Forced-Ventilation Ovens

3. Terminology

3.1 Definitions:

3.1.1 For definitions of textile terms used in this test method: skein and skein loop-length, refer to Terminology D4849.

3.1.2 For definition of the term extension used in this test method, refer to Terminology D4848.

3.1.3 For other textile terms used in this test method, refer to Terminology Standards, D123, D3888, D3990, D4848 and D4849.

This test method is under the jurisdiction of Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.58 on Yarns and Fibers.

Current edition approved Jan. 1, 2016. Published February 2016. Originally approved in 1964. Last previous edition approved in 2011 as D2259 – 02(2011). DOI:

10.1520/D2259-02R16.10.1520/D2259-02R16E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D2259 − 02 (2016)

4. Summary of Test Method

4.1 The loop length of a conditioned skein of yarn is measured under a specific tension, which is sufficient to straighten but not

stretch the skein. The tension-free skein is then immersed in boiling water or exposed to dry heat or saturated steam or in the

solvent reconditioned, and remeasured. The shrinkage (or in some cases, growth) is calculated as the change in length expressed

as a percentage of the length before immersion or exposure.

5. Significance and Use

5.1 Test Method D2259 for testing yarn for shrinkage in boiling water, saturated steam, dry heat, or solvents is considered

satisfactory for acceptance testing of commercial shipments of yarn because the test method has been used extensively in the trade

for that purpose.

5.1.1 If there are differences of practical significance between reported test results for two laboratories (or more), comparative

tests should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a

minimum, use the samples for such comparative tests that are as homogeneous as possible, drawn from the same lot of material

as the samples that resulted in disparate results during initial testing and randomly assigned in equal numbers to each laboratory.

The test results from the laboratories involved should be compared using a statistical test for unpaired data, a probability level

chosen prior to the testing series. If a bias is found, either its cause must be found and corrected, or future test results for that

material must be adjusted in consideration of the known bias.

5.2 Results obtained by this test method can be used for the following purposes:

5.2.1 As an aid in predicting the dimensional stability of fabrics to wet processing,

5.2.2 As an aid in predicting the dimensional stability of fabrics during processing at elevated temperatures, and

5.2.3 As a control measure in the manufacture of some types of fibers.

5.3 The shrinkage medium to be used in the test depends on the requirements of the parties involved.

5.4 The procedure for shrinkage in boiling water is described in Section 12, for shrinkage in dry heat in Section 13, for shrinkage

in saturated steam in Section 14, and for shrinkage in solvents in Section 15. A 30-min exposure time is prescribed for boiling

water. In exposure to dry heat, saturated steam, or solvents, the extent of change in the length of yarn is dependent upon the fiber

type and upon the time and temperature of the exposure. Fiber types differ in their reaction to elevated temperature as well as the

nature of the specific solvent, and prior fiber history can have a great influence upon the heat and solvent shrinkage of a yarn.

Therefore, the time and temperature conditions to be used to determine dry heat or saturated steam shrinkage must be agreed upon

for the particular product involved. In addition, time and temperature conditions, and solvent to be used must be agreed upon for

solvent shrinkage determination for the particular product involved.

6. Apparatus and Reagents

6.1 Reel—A hand or motor-driven reel having a nominal perimeter of 1 m, 1.5 yd, or 1.125 m (Note 2). The reel should have

a traversing mechanism that will minimize bunching of ends on the reel, a yarn-tensioning device capable of maintaining tension

below 1 cN/tex or 1.00.1 gf/den, and a yarn length or revolution indicator. A warning bell that will ring just prior to the specified

number of reel revolutions is recommended. A collapsible arm is advisable for convenience in skein removal.

NOTE 2—By agreement, reels of other perimeters, between 1 and 2 m (1 and 2 yd) may be used.

6.2 Measuring Scale—A tape or scale accurate to 1 part in 1000 is recommended. Any scale length exceeding the reel diameter

by 250 mm or 10 in. allowing for the extension of the skein is satisfactory. The scale should be mounted vertically. A top hook

holds the skein and is mounted with support surface in line with the zero index of the scale.

6.3 Metal Hook—A hook designed to hang from the skein, shaped to receive the tensioning weights, and with a mass known

to 1 part in 1000. The hook may have a pointer located and attached for ease in reading the measuring scale at a point level with

the inside bottom of the skein.

6.4 Tensioning Masses—Accurate to 1 part in 1000.

6.5 For Boiling Water:

6.5.1 Container, of sufficient size for 40:1 mass ratio water bath.

6.5.2 Roller Wringer or Centrifugal Extractor.

6.5.3 Heat Source, for water bath.

6.5.4 Distilled or Demineralized Water.

6.5.5 Nonionic Wetting Agent.

6.6 For Dry Heat:

6.6.1 Heating Oven—A forced-draft oven capable of meeting the required temperature and that meets the temperature

uniformity requirements for a Type IIB oven as described in Specification E145, Table 1. There must be a means of suspending

the skeins in the oven. This may be accomplished with a rod with cup hooks from which to suspend skeins. The rod may be

mounted on a stand for placement in the oven; skeins should not be allowed to touch the sides of the oven.

´1

D2259 − 02 (2016)

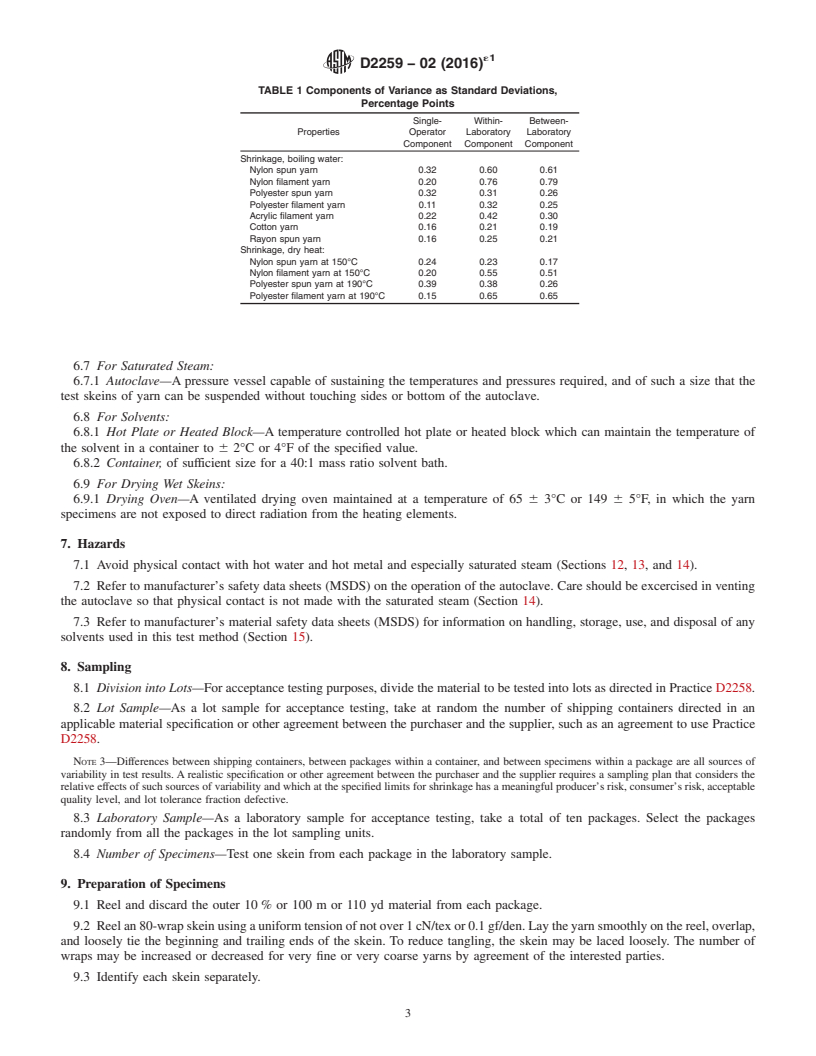

TABLE 1 Components of Variance as Standard Deviations,

Percentage Points

Single- Within- Between-

Properties Operator Laboratory Laboratory

Component Component Component

Shrinkage, boiling water:

Nylon spun yarn 0.32 0.60 0.61

Nylon filament yarn 0.20 0.76 0.79

Polyester spun yarn 0.32 0.31 0.26

Polyester filament yarn 0.11 0.32 0.25

Acrylic filament yarn 0.22 0.42 0.30

Cotton yarn 0.16 0.21 0.19

Rayon spun yarn 0.16 0.25 0.21

Shrinkage, dry heat:

Nylon spun yarn at 150°C 0.24 0.23 0.17

Nylon filament yarn at 150°C 0.20 0.55 0.51

Polyester spun yarn at 190°C 0.39 0.38 0.26

Polyester filament yarn at 190°C 0.15 0.65 0.65

6.7 For Saturated Steam:

6.7.1 Autoclave—A pressure vessel capable of sustaining the temperatures and pressures required, and of such a size that the

test skeins of yarn can be suspended without touching sides or bottom of the autoclave.

6.8 For Solvents:

6.8.1 Hot Plate or Heated Block—A temperature controlled hot plate or heated block which can maintain the temperature of

the solvent in a container to 6 2°C or 4°F of the specified value.

6.8.2 Container, of sufficient size for a 40:1 mass ratio solvent bath.

6.9 For Drying Wet Skeins:

6.9.1 Drying Oven—A ventilated drying oven maintained at a temperature of 65 6 3°C or 149 6 5°F, in which the yarn

specimens are not exposed to direct radiation from the heating elements.

7. Hazards

7.1 Avoid physical contact with hot water and hot metal and especially saturated steam (Sections 12, 13, and 14).

7.2 Refer to manufacturer’s safety data sheets (MSDS) on the operation of the autoclave. Care should be excercised in venting

the autoclave so that physical contact is not made with the saturated steam (Section 14).

7.3 Refer to manufacturer’s material safety data sheets (MSDS) for information on handling, storage, use, and disposal of any

solvents used in this test method (Section 15).

8. Sampling

8.1 Division into Lots—For acceptance testing purposes, divide the material to be tested into lots as directed in Practice D2258.

8.2 Lot Sample—As a lot sample for acceptance testing, take at random the number of shipping containers directed in an

applicable material specification or other agreement between the purchaser and the supplier, such as an agreement to use Practice

D2258.

NOTE 3—Differences between shipping containers, between packages within a container, and between specimens within a package are all sources of

variability in test results. A realistic specification or other agreement between the purchaser and the supplier requires a sampling plan that considers the

relative effects of such sources of variability and which at the specified limits for shrinkage has a meaningful producer’s risk, consumer’s risk, acceptable

quality level, and lot tolerance fraction defective.

8.3 Laboratory Sample—As a laboratory sample for acceptance testing, take a total of ten packages. Select the packages

randomly from all the packages in the lot sampling units.

8.4 Number of Specimens—Test one skein from each package in the laboratory sample.

9. Preparation of Specimens

9.1 Reel and discard the outer 10 % or 100 m or 110 yd material from each package.

9.2 Reel an 80-wrap skein using a uniform tension of not over 1 cN/tex or 0.1 gf/den. Lay the yarn smoothly on the reel, overlap,

and loosely tie the beginning and trailing ends of the skein. To reduce tangling, the skein may be laced loosely. The number of

wraps may be increased or decreased for very fine or very coarse yarns by agreement of the interested parties.

9.3 Identify each skein separately.

´1

D2259 − 02 (2016)

10. Conditioning

10.1 Condition the prepared skeins for testing as directed in Practice D1776, except that preconditioning is not necessary.

Consider equilibrium to have been reached when the change in mass of the specimen between successive weighings made at

intervals of not less than 2 h does not exceed 0.1 % of the mass of the specimen.

10.2 Condition the prepared skeins for a minimum of 24 h which is sufficient time for yarn recovery from package winding

tensions as well as to reach the moisture equilibrium conditions specified in 10.1.

11. Measurement of Skeins

11.1 Make all skein loop length measurements in the standard atmosphere for testing textiles which is air maintained at a

relative humidity of 65 6 2 % and at a temperature of 21 6 1°C or 706 2°F.

11.2 Determine the linear density of the yarn if unknown by using Test Method D1907 or Test Method D1059. In case of

controversy, results obtained as directed in Test Method D1907 shall prevail.

11.3 Calculate a tension force corresponding to 0.5 cN/tex or 0.05 gf/den using Eq 1 or Eq 2:

Tension force, cN 5 5.0 3N 3T (1)

Tension force, gf 5 0.05 3N 3D (2)

where:

N = number of ends; that is twice the number of wraps in the skein,

T = yarn number, tex, and

D = yarn number, denier.

NOTE 4—For example, an 80-wrap skein has 160 ends. For a 16 tex yarn, the tension force would be 5.0 × 16 × 160 = 1280 cN = 12.8 N

(0.5 × 16 × 160 = 1280 gf = 1.28 kgf).

11.4 Measure the loop-length of each conditioned skein.

11.4.1 Hang the conditioned skein from the hook at the top of the measuring scale with the inside of the t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.