ASTM C115-96a(2003)

(Test Method)Standard Test Method for Fineness of Portland Cement by the Turbidimeter

Standard Test Method for Fineness of Portland Cement by the Turbidimeter

SIGNIFICANCE AND USE

The purpose of this test method is to determine whether or not the hydraulic cement under test meets the Wagner turbidimetric fineness requirements of the applicable hydraulic cement specification for which the test is being made. Fineness of the cement component is only one of the many characteristics that influence the strength capabilities of concrete.

SCOPE

1.1 This test method covers determination of the fineness of portland cement as represented by a calculated measure of specific surface, expressed as square centimetres of total surface area per gram, or square metres of total surface area per kilogram, of cement, using the Wagner turbidimeter.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.3 The values stated in SI units are to regarded as the standard. The inch-pound equivalents may be approximate.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C115 – 96a (Reapproved 2003)

Standard Test Method for

1

Fineness of Portland Cement by the Turbidimeter

This standard is issued under the fixed designation C115; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope of the cement component is only one of the many character-

istics that influence the strength capabilities of concrete.

1.1 This test method covers determination of the fineness of

portland cement as represented by a calculated measure of

4. Apparatus

specific surface, expressed as square centimetres of total

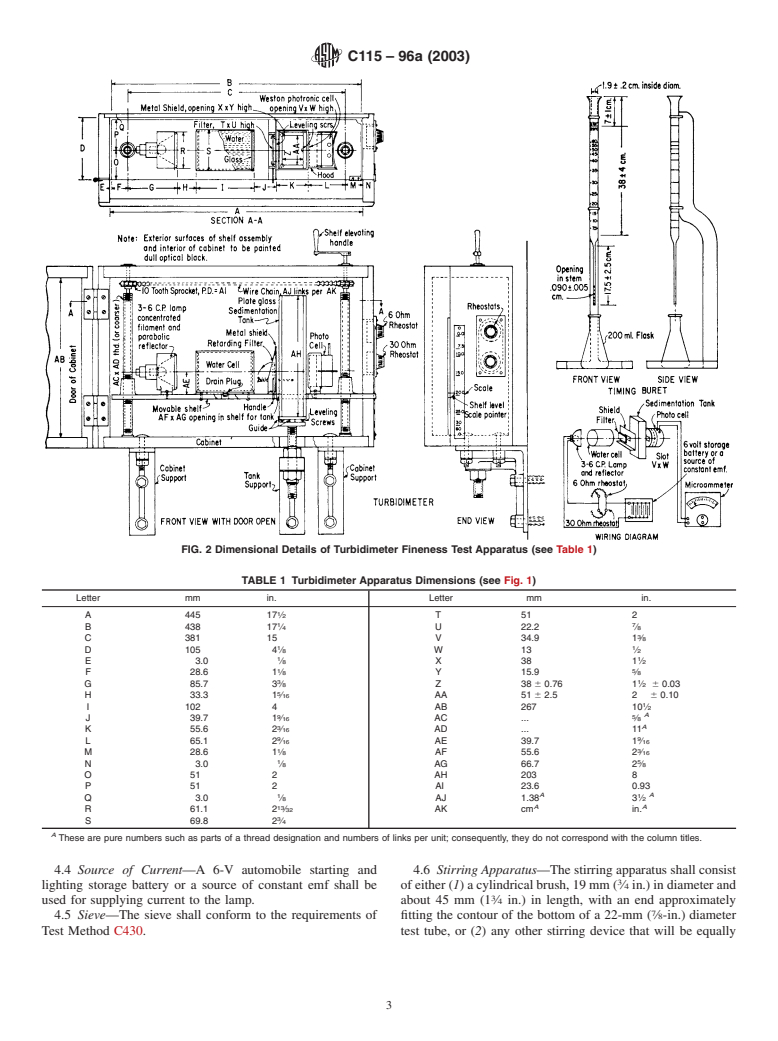

4.1 Nature of Apparatus—TheWagnerturbidimeterconsists

surfaceareapergram,orsquaremetresoftotalsurfaceareaper

2 essentially of a source of light maintained at constant intensity

kilogram, of cement, using the Wagner turbidimeter.

and adjusted so that approximately parallel rays of light pass

1.2 This standard does not purport to address all of the

through a suspension of the cement to be tested and impinge

safety concerns, if any, associated with its use. It is the

upon the sensitive plate of a photoelectric cell. The current

responsibility of the user of this standard to establish appro-

generated in the cell is measured by means of a microammeter

priate safety and health practices and determine the applica-

and the indicated reading is a measure of the turbidity of the

bility of regulatory limitations prior to use.

suspension. General considerations indicate that turbidity is in

1.3 The values stated in SI units are to regarded as the

turn a measure of the surface area of the suspended sample of

standard. The inch-pound equivalents may be approximate.

cement. The apparatus shall consist specifically of the parts

2. Referenced Documents described in 4.2-4.7 and shall be constructed in accordance

3

with the detailed design and dimensional requirements shown

2.1 ASTM Standards:

in Fig. 1 and Table 1, except that the case may be either of

C114 Test Methods for Chemical Analysis of Hydraulic

wood or of metal.

Cement

4.2 Turbidimeter, mounted in a suitable wood or metal case

C430 TestMethodforFinenessofHydraulicCementbythe

including the following features:

45-µm (No. 325) Sieve

4.2.1 Source of Light—The source of light (Fig. 1) shall

C670 Practice for Preparing Precision and Bias Statements

consist of a concentrated-filament electric lamp of between 3

for Test Methods for Construction Materials

and 6 cd operated by a source of constant emf. The lamp shall

3. Significance and Use be mounted rigidly in the socket. A clean, bright parabolic

metallic reflector shall be rigidly mounted behind the lamp,

3.1 The purpose of this test method is to determine whether

focused so that approximately parallel rays of light will pass

or not the hydraulic cement under test meets the Wagner

through the sedimentation tank and impinge upon the photo-

turbidimetric fineness requirements of the applicable hydraulic

electric cell. The light intensity shall be regulated by two

cementspecificationforwhichthetestisbeingmade.Fineness

rheostats of approximately 6 and 30 V, respectively, and they

shall possess such characteristics that uniform changes in light

1

ThistestmethodisunderthejurisdictionofASTMCommitteeC01onCement intensitymaybeobtainedoverthefullrangeofresistance.The

and is the direct responsibility of Subcommittee C01.25 on Fineness.

rheostats shall be mounted in parallel with each other and in

Current edition approved July 10, 2003. Published September 2003. Originally

series with the lamp.

approved in 1934. Last previous edition approved in 1996 as C115–96a. DOI:

4.2.2 Heat-Absorbing Device—The light shall pass through

10.1520/C0115-96AR03.

2

This turbidimeter was developed by L. A. Wagner, Research Associate of the

a suitable heat absorbing device before entering the sedimen-

Cement Reference Laboratory, National Institute of Standards and Technology,

tation tank in order that radiant heat from the beam shall be

Washington, DC. A description of the apparatus and the original mathematical

absorbed, the device being either (1) a water cell or (2)a

derivationsofformulasusedaregiveninthepaper:Wagner,L.A.,“ARapidMethod

specialheat-absorbingglassfilter.Thewatercellshallbemade

for the Determination of the Specific Surface of Portland Cement,” Proceedings,

ASTM, ASTEA, Vol 33, Part II, 1933, p. 553.

from 76-mm (3-in.) outside diameter seamless brass tubing,

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

3-mm ( ⁄8-in.) thick wall, 102-mm (4 in.) in length with glass

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

windows sealed in the ends. The cell s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.