ASTM F330-89(1999)

(Test Method)Standard Test Method for Bird Impact Testing of Aerospace Transparent Enclosures

Standard Test Method for Bird Impact Testing of Aerospace Transparent Enclosures

SCOPE

1.1 This test method covers conducting bird impact tests under a standard set of conditions by firing a packaged bird at a stationary transparency mounted in a support structure.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 8.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 330 – 89 (Reapproved 1999)

Standard Test Method for

Bird Impact Testing of Aerospace Transparent Enclosures

This standard is issued under the fixed designation F 330; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.2 The specific parameters described by this method are:

3.2.1 Bird weight and condition,

1.1 This test method covers conducting bird impact tests

3.2.2 Bird velocity, and

under a standard set of conditions by firing a packaged bird at

3.2.3 Instrumentation.

a stationary transparency mounted in a support structure.

1.2 This standard does not purport to address all of the

4. Significance and Use

safety concerns, if any, associated with its use. It is the

4.1 This method may be used for: bird impact testing of

responsibility of the user of this standard to establish appro-

aircraft crew compartment transparencies and supporting struc-

priate safety and health practices and determine the applica-

ture to verify the design; compilation of test data for use in

bility of regulatory limitations prior to use. For specific hazard

verification of future transparency and supporting structure

statements, see Section 8.

design and analytical methods; and comparative evaluation of

1.3 The values stated in inch-pound units are to be regarded

materials.

as the standard. The values given in parentheses are for

information only.

5. Apparatus

2. Terminology 5.1 Gun, compressed gas, conforming in principle to Fig. 1,

comprising:

2.1 Definitions:

5.1.1 Pressure Tank, of capacity and working pressure as

2.1.1 bird—the carcass that is used to impact the test article.

discussed in Note 1.

2.1.2 bird package—the bird and container that encases the

bird to prevent disintegration enroute to target.

NOTE 1—A gun capable of propelling a 4-lb (1.81-kg) bird in excess of

2.1.3 gun—the device that propels the bird toward the 650 knots (334 m/s) has a barrel 60 ft (18.3 m) long, bore of 6 in. (153

3 3

mm), and a pressure tank volume of 30 ft (0.849 m ) with an allowable

target.

working pressure of 250 psi (1.725 3 10 Pa).

2.1.4 sabot—the container that is used to adapt the bird

package to the gun barrel. 5.1.2 Release Mechanism, comprised of a firing solenoid,

2.1.5 stripper—the device that stops the sabot at the end of

diaphragm, and a cutter. Upon initiation of the firing sequence,

the gun barrel so that only the bird and package exits from the the release mechanism allows the compressed gas stored in the

barrel.

pressure tank to flow rapidly into the gun barrel and propel the

2.1.6 test article—the transparency and supporting struc- projectile.

ture.

NOTE 2—The most common designs normally use either one or two

diaphragms in the release mechanism. In the single diaphragm design, the

3. Summary of Test Method

diaphragm is mechanically ruptured upon firing (see Fig. 1). In the dual

3.1 The method employs a smooth-bore bird gun that fires a

diaphragm system, pressurized gas between the two pressurized gas

chicken carcass so that it impacts a stationary aerospace diaphragms is bled to initiate firing by allowing the stored gas to burst

each diaphragm in rapid succession.

transparency mounted in a supporting structure.

5.1.3 Barrel (Launch Tube), a smooth bore tube that guides

the packaged bird (and sabot if used) during its acceleration by

This method is under the jurisdiction of ASTM Committee F-7 on Aerospace

the expanding air from the pressure tank. The bore and length

and Aircraft and is the direct responsibility of Subcommittee F07.08 on Transparent

of the barrel is chosen both to accommodate the largest of the

Enclosures and Materials.

projectiles to be used and for the overall performance require-

Current edition approved Feb. 24, 1989. Published May 1989. Originally

published as F 330 – 79. Last previous edition F 330 – 79. ments of the gun.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 330

FIG. 1 Representative Air Gun

5.1.4 Sabot Stripper may be mounted at the end of the ambient temperatures. Hot air, heat lamps, or energized elec-

launcher tube. The purpose of the sabot stripper is to arrest or trical conductive coatings within the test article may be used to

deflect the sabot, allowing only the packaged bird to impact the raise interior or exterior temperatures. Antiicing or defogging

test article. systems, or both, may also be required.

5.2 Velocity Measurement System: 5.4 Test Instrumentation:

5.2.1 The essential features of the velocity measurement 5.4.1 Weight Measurement—The weight scale shall have an

system are that it be accurate and repeatable, not be triggered accuracy of at least 0.063 oz (1.8 g).

by small stray objects that may be traveling with the projectile,

5.4.2 Mounting Angle Measurements (Pitch, Roll and

and not alter the flight path or damage the projectile. Yaw)—The instrument for measuring the angle, at which the

5.2.2 Preferred velocity measurement systems use timing

test article or its support structure is mounted, shall have an

stations, located between the gun barrel and the test specimen, accuracy of ⁄4° (0.004 36 radian).

which are triggered by the projectiles breakage of a mechanical

5.4.3 Temperature Measurement—The instrument system

link “break wire” or through the interruption of a light beam. for measuring temperatures shall have an accuracy of 65°F

The velocity is then computed and averaged from the known

(2.8°C).

distances between the timing stations. Rapid sequence photog- 5.4.4 Velocity Measurement—The instrumentation used

raphy, in conjunction with a background gridwork, may be

with the velocity measurement system shall provide for an

used to provide a redundant system. overall system accuracy within 62%.

5.4.5 Rapid Sequence, at least one high-speed camera shall

NOTE 3—When using a light beam measuring system under high-

be used to provide records of the bird impacting the target. The

humidity conditions, it is possible that the bird can become enveloped in

camera lighting conditions and controlling instrumentation

a cloud of water droplets that could cause triggering of the light beams and

the bird package shown in the film might not be clear. When using a shall be adjusted to provide a minimum of the following

“break wire” system, it is imperative that the tension of the wires be

camera frames per second at impact:

adjusted to within close tolerances in order to obtain consistent results.

F 5 1000 1 5 V or (1)

5.3 Environmental Control:

5.3.1 The environmental control apparatus may be used to

F 5 1000 1 1.53 v (2)

heat or cool the test article to the desired temperature at the

time of impact. The environmental control required shall be

where:

capable of providing the temperature range surrounding the test

F = exposure rate (frames per second),

article that would critically affect the physical properties of

V = projectile velocity (ft/s), and

aircraft transparencies. This range is normally −65°F (−54°C)

v = projectile velocity (m/s)

to 250°F (121°C). The facility shall be capable of providing

Timing marks may be automatically placed on the film at a

these temperatures for a sufficient time to achieve steady-state

rate of at least 100/s and at an accuracy of at least 1 % to verify

temperature gradients as required in the test article. A uniform

the camera exposure rate during the impact sequence (see

source of heat or cold shall be provided; that is, no “cold” or

Table 1 for camera exposure rate versus impact velocity).

“hot” spots shall be developed in the test article, and this shall

be verified by the use of thermocouples placed at strategic

6. Materials

points throughout the test article or by use of infrared (pho-

6.1 Bird:

tography) thermographs.

5.3.2 Enclose the mounted test article and circulate precon- 6.1.1 The bird combined with the packaging forms the

ditioned air within this enclosure, stabilize the test article at the projectile that impacts the test article. If a real carcass is

desired test temperature, and remove the enclosure immedi- selected, it may be either a domestic or wild bird depending on

ately before the impact test. A coolant, carbon dioxide or liquid the required weight. The standard weight of the bird used in

nitrogen, may be mixed with the air to cool the air below this test shall be 4 lb (1.81 kg). Use a chicken as the bird for

F 330

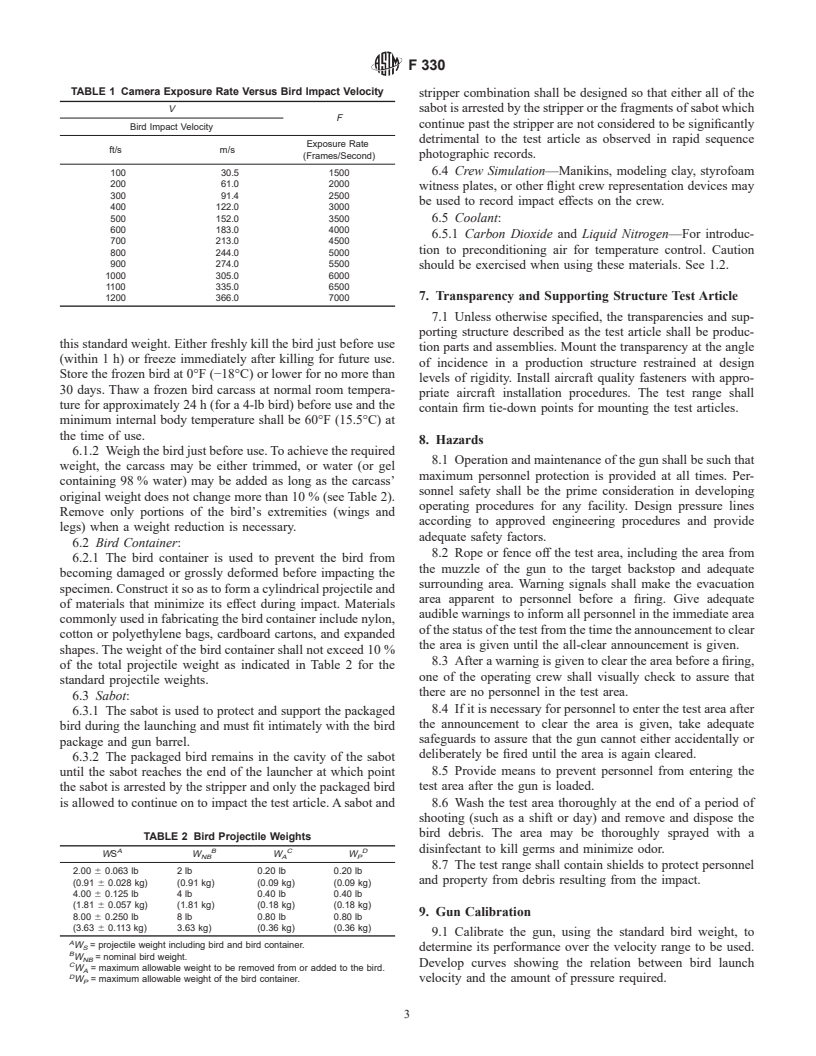

TABLE 1 Camera Exposure Rate Versus Bird Impact Velocity

stripper combination shall be designed so that either all of the

V sabot is arrested by the stripper or the fragments of sabot which

F

continue past the stripper are not considered to be significantly

Bird Impact Velocity

detrimental to the test article as observed in rapid sequence

Exposure Rate

ft/s m/s

(Frames/Second) photographic records.

100 30.5 1500 6.4 Crew Simulation—Manikins, modeling clay, styrofoam

200 61.0 2000

witness plates, or other flight crew representation devices may

300 91.4 2500

be used to record impact effects on the crew.

400 122.0 3000

500 152.0 3500 6.5 Coolant:

600 183.0 4000

6.5.1 Carbon Dioxide and Liquid Nitrogen—For introduc-

700 213.0 4500

tion to preconditioning air for temperature control. Caution

800 244.0 5000

900 274.0 5500

should be exercised when using these materials. See 1.2.

1000 305.0 6000

1100 335.0 6500

7. Transparency and Supporting Structure Test Article

1200 366.0 7000

7.1 Unless otherwise specified, the transparencies and sup-

porting structure described as the test article shall be produc-

this standard weight. Either freshly kill the bird just before use

tion parts and assemblies. Mount the transparency at the angle

(within 1 h) or freeze immediately after killing for future use.

of incidence in a production structure restrained at design

Store the frozen bird at 0°F (−18°C) or lower for no more than

levels of rigidity. Install aircraft quality fasteners with appro-

30 days. Thaw a frozen bird carcass at normal room tempera-

priate aircraft installation procedures. The test range shall

ture for approximately 24 h (for a 4-lb bird) before use and the

contain firm tie-down points for mounting the test articles.

minimum internal body temperature shall be

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.