ASTM F1798-97

(Guide)Standard Guide for Evaluating the Static and Fatigue Properties of Interconnection Mechanisms and Subassemblies Used in Spinal Arthrodesis Implants

Standard Guide for Evaluating the Static and Fatigue Properties of Interconnection Mechanisms and Subassemblies Used in Spinal Arthrodesis Implants

SCOPE

1.1 This guide covers the measurement of uniaxial static and fatigue strength, and resistance to loosening of the component interconnection mechanisms of spinal arthrodesis implants.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1798 – 97

Standard Guide for

Evaluating the Static and Fatigue Properties of

Interconnection Mechanisms and Subassemblies Used in

Spinal Arthrodesis Implants

This standard is issued under the fixed designation F 1798; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 739 Practice for Statistical Analysis of Linear or Linear-

ized Stress - Life (S-N) and Strain - Life (e-N) Fatigue

1.1 This guide covers the measurement of uniaxial static

Data

and fatigue strength, and resistance to loosening of the com-

E 1150 Definitions of Terms Relating to Fatigue

ponent interconnection mechanisms of spinal arthrodesis im-

F 383 Practice for Static Bend and Torsion Testing of

plants.

Intramedullary Rods

1.2 The purpose of this guide is to provide a means of

F 1582 Terminology Relating to Spinal Implants

mechanically characterizing different designs of spinal implant

interconnections. Ultimately, the various components and in-

3. Terminology

terconnections should be combined for static and fatigue

3.1 Definitions of Terms Specific to This Standard:

testing of the spinal implant construct. It is not the intention of

3.1.1 active length of longitudinal element—the span be-

this guide to address the analysis of spinal implant constructs

tween rigid supports (for example, 50 mm is the active length

or subconstructs or to define levels of performance of spinal

in Fig. 1, Fig. 2, Fig. 3(a), Fig. 3(b), and Fig. 4.

implants as insufficient knowledge is available to predict the

3.1.2 global coordinate system—spinal column motion has

consequences of the use of particular spinal implant designs.

six degrees of freedom, having translational motion along, and

1.3 This guide sets out definitions for use in measuring the

rotational motion about three axes. The axes are labeled

strength of component interconnections of spinal implants,

anterior-posterior or a-p (X), medial-lateral or transverse (Y),

possible test methods themselves, and the reporting of test

and caudal-cranial or axial (Z). This coordinate system is right

results.

handed with +X in the anterior direction, +Y towards the left

1.4 The values stated in SI units are to be regarded as

side of the body, and +Z in the cranial direction. Positive

standard.

rotations are defined by the right hand rule (See Fig. 5(a)).

1.5 This standard does not purport to address all of the

3.1.3 gripping capacity—the maximum applied load or

safety concerns, if any, associated with its use. It is the

moment across an interconnection mechanism within the first

responsibility of the user of this standard to establish appro-

1.5 mm of permanent displacement or 5° of permanent rotation

priate safety and health practices and determine the applica-

between the connected components.

bility of regulatory limitations prior to use.

3.1.4 local coordinate system—the spine’s global coordi-

2. Referenced Documents nate system shall be applied locally at the position of the

interconnection. The local direction, z, shall be centered

2.1 ASTM Standards:

2 through the longitudinal element of the x-y plane. The local

E 4 Practices for Force Verification of Testing Machines

direction, x, shall be defined parallel to the axis of a screw or

E 6 Terminology Relating to Methods of Mechanical Test-

2 back of a hook. The local transverse axis, y, shall be parallel to

ing

a transverse element (See Fig. 5(b) and Fig. 5(c)).

E 468 Practice for the Presentation of Constant Amplitude

2 3.1.5 loosening torque—the torque required to disconnect

Fatigue Test Results from Metallic Materials

the various threaded fasteners that might comprise the im-

plant’s interconnection mechanism.

3.1.6 major directions of loading—directions of the pre-

This guide is under the jurisdiction of ASTM Committee F-4 onMedical and

dominant forces and moments (relative to the local axes) to

Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.25 on Spinal Devices

Current edition approved April 10, 1997. Published June 1998.

2 3

Annual Book of ASTM Standards, Vol 03.01. Annual Book of ASTM Standards, Vol 13.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F1798–97

3.1.9 spinal arthrodesis implant—an implant applied to the

spine with the specific intention of providing temporary

correction and stability to vertebrae while bony fusion occurs.

3.1.10 subassembly failure—permanent deformation result-

ing from fracture, plastic deformation, loosening or slippage

that renders the subassembly ineffective or unable to ad-

equately resist load.

3.1.11 subassembly permanent deformation—the displace-

ment (mm) or angular displacement (degree of the subassem-

bly relative to the unloaded condition remaining after the

applied load moment or torque has been removed. Care must

be taken to insure the loading fixtures are rigid and do not

contribute to the measurement of deflection.

3.1.12 tightening torque—the specified torque that is ap-

plied to the various threaded fasteners that might comprise the

implant’s interconnection mechanism.

3.1.13 ultimate load/moment of the subassembly—

maximum load or moment applied to a subassembly (see Point

E in Fig. 6).

FIG. 1 A-P Test Apparatus for Subassembly

3.1.14 yield load/moment of the subassembly—the load or

moment required to produce a permanent deformation equal to

0.020 times the active length of the longitudinal element (see

Point D in Fig. 6).

4. Summary of Test Methods

4.1 Vertebral attachment components (for example, hook,

screws, bands) and transverse elements must be attached to

longitudinal elements (for example, rods, plates) to form spinal

implant subassemblies.

4.2 The interconnections are tested only in the relevant

directions of loading by applying loads at specific locations

relative to the local coordinate system.

4.3 The interconnections and subassemblies are tested stati-

cally in a load to failure mode and also can be tested cyclically

to estimate the maximum run out value at 2.5 3 10 cycles.

5. Significance and Use

5.1 Spinal implants are generally composed of several

components that, when connected together, form a spinal

implant construct. Spinal implant constructs are designed to

provide some stability to the spine while arthrodesis takes

FIG. 2 Transverse Test Apparatus for Subassembly

place. This guide outlines standardized evaluations of different

interconnection mechanisms so that comparison between dif-

ferent designs is facilitated. Comparisons must be made

which vertebral connection elements are subjected, (that is,

cautiously and with careful analysis, taking into account the

axial load, Fz; A-P load, Fx; axial torsion, Mz; and flexion-

effects that design differences can have on the loading configu-

extension moment, My).

rations.

3.1.7 maximum run out load/moment—the maximum load

5.2 This guide is used to quantify the static and fatigue

or moment that can be applied to a subassembly where all the

properties of different implant interconnection designs. The

tested constructs have withstood 2.5 3 106 cycles without a

mechanical tests are conducted in vitro using simplified,

failure.

unidirectional loads and moments. Fatigue testing in a simu-

3.1.8 relevant directions of loading—those directions of lated body fluid or saline may have a fretting, corrosive, or

loading in which a particular component interconnection is lubrication effect on the interconnection and thereby affect the

designed to provide resistance to loading. For example, a relative performance of tested devices. Hence, the test envi-

particular spinal hook may be designed to withstand a positive ronment, whether a simulated body fluid, saline (9g NaCl per

axial load, A-P load, and flexion-extension moment, but not a 1000 mL H O), with a saline drip, or dry, is an important

negative axial load or axial torsion. Hence, positive axial load, characteristic of the test and must be reported accurately.

A-P load, and flexion-extension moment are relevant directions 5.3 The loading of spinal implant constructs in vivo will, in

of loading. general, differ from the loading configurations used in this

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F1798–97

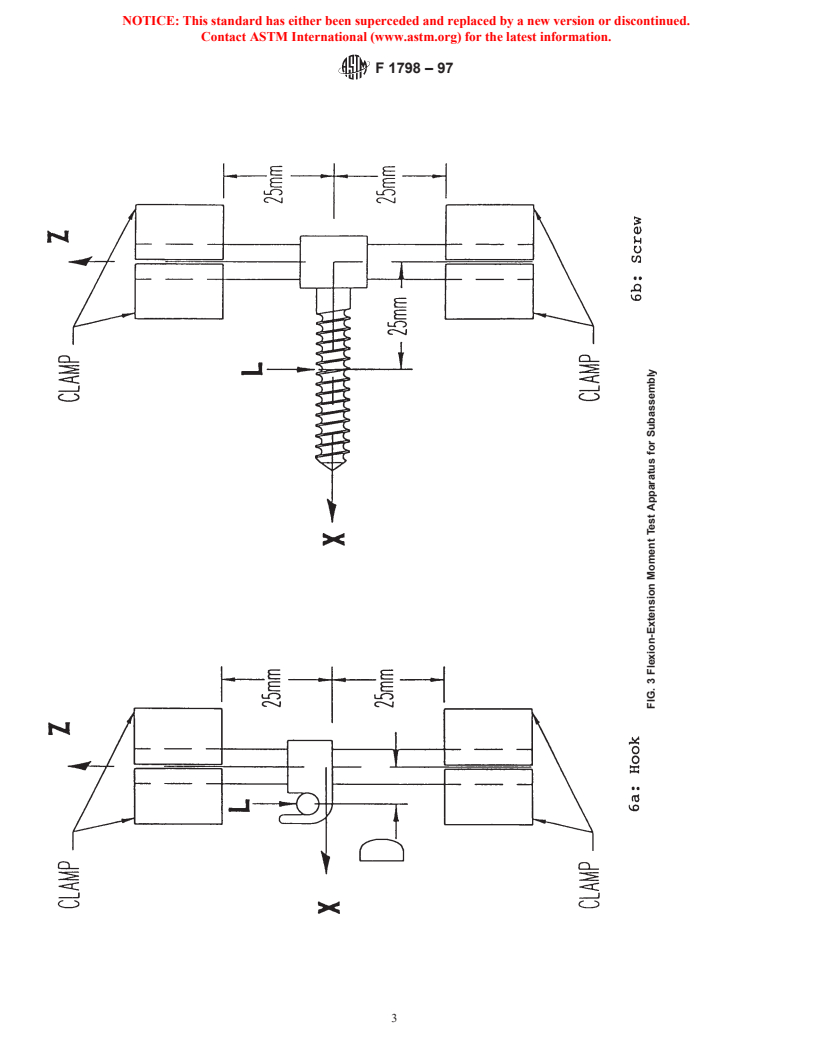

FIG. 3 Flexion-Extension Moment Test Apparatus for Subassembly

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F1798–97

FIG. 4 Transverse Moment Test Apparatus for Subassembly

guide. The results obtained here cannot be used directly to linkage and remain unfixed. Axial loads are applied to the

predict in vivo performance. However, the results can be used interconnection mechanism along the axis of the longitudinal

to compare different component designs in terms of relative element via a sleeve (collar) which freely surrounds the

mechanical parameters. longitudinal element. The sleeve (collar) should evenly distrib-

ute the load around the interconnection. An alternate method,

6. Apparatus

depicted in Fig. 7(b), applies the load to the longitudinal

6.1 Machines used for the test shall conform to the require- element and pushes it through the interconnection clamp.

ments of Practices E 4. 6.3 The apparatus for A-P (x) mechanical property measure-

6.2 The apparatus for axial (z) gripping capacity measure- ments of a subassembly is depicted in Fig. 1. Both ends of the

ments of an interconnection mechanism is depicted in Fig. longitudinal element shall be clamped rigidly, with the inter-

7(a). One end of the longitudinal element shall be clamped connection centered on a 50 mm section of the longitudinal

rigidly, leaving 5 mm exposed between the interconnection element. The local origin of the interconnection mechanism

mechanism and the test machine base. A section of longitudinal shall be centered between the mounts. Loads are applied to the

element at least 5 mm shall extend beyond the interconnection interconnection (perpendicular to the longitudinal element) via

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F1798–97

FIG. 5 Coordinate System

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F1798–97

FIG. 6 Load/Displacement Curve

a clamp on the hook, screw, or band. The load should be applied to the interconnection (perpendicular to the longitudi-

centered through the local x coordinate axis. nal element) via a clamp on the transverse connector. The load

6.4 The apparatus for transverse (y) mechanical property should be centered through the local y coordinate axis.

measurements of a subassembly is depicted in Fig. 2. Both 6.5 The apparatus for flexion-extension moment (My) me-

ends of the longitudinal element shall be clamped rigidly, with chanical property measurements of a subassembly is depicted

the interconnection centered on a 50 mm section of the in Fig. 3. Both ends of the longitudinal element shall be

longitudinal element. The local origin of the interconnection clamped rigidly, with the interconnection centered on a 50 mm

mechanism shall be centered between the mounts. Loads are section of the longitudinal element. The local origin of the

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F1798–97

FIG. 7 Axial Gripping Capacity Test Apparatus

interconnection mechanism shall be centered between the 7.3 Static tests of mechanical properties should have a

mounts. Loads are applied to the interconnection (parallel to minimum sample size of five.

the longitudinal element). For spinal hooks, the load shall be 7.4 Fatigue tests for determining the maximum run out load

applied via a cylinder set in the hook notch, Fig. 3(a). For other or moment of a subassembly at 2.5 3 10 cycles shall utilize a

elements (screws) the load shall be applied 25 mm from the run down, half-interval approach with one specimen per run

local z axis, Fig. 3(b). down interval or half-interval and three consecutive specimens

6.6 The apparatus for transverse moment (Mx) mechanical showing run out to 2.5 3 10 cycles. Alternative methods for

property measurements of a subassembly is depicted in Fig. 4. determining the starting point of the fatigue curve are the

As in the previous test, 6.5, both ends of the longitudinal run-up method or choosing 75 % of the ultimate static load or

element shall be clamped rigidly, with the interconnection moment.

centered on a 50 mm section of the longitudinal element. The

8. Procedure for Measuring Static Mechanical Properties

local origin of the interconnection mechanism shall be centered

8.1 Measure the tightening torques for any set screws or

between the mounts. Loads are applied to the interconnection

(parallel to the longitudinal element), 25 mm from the z axis. nuts which are incorporated into the interconnection linkage.

8.2 Apply all tightening, crimping, or locking mechanisms

6.7 The apparatus for axial torque (Mz) gripping capacity

measurements of an interconnection mechanism is depicted in as specified by the manufacturer.

8.3 The recommended maximum rate for applying a load is

Fig. 8(a) and is similar to that described in 6.2 with the

exception that the axial torque is applied via notches in the 20 N/s (or 25 mm/min) and is 25 N-m/min (or 25 °/min) for

applying a moment or torque. Since rate is machine and

sleeve that surrounds the longitudinal element. An alternative

method is to hold the interconnection rigidly and apply the software dependent, it may be necessary to run the tests slower

to achieve accurate data.

torsional force to the longitudinal element as shown in Fig.

8(b). A third alternative is to apply the torque via a force 8.4 S

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.