ASTM E1260-95

(Test Method)Standard Test Method for Determining Liquid Drop Size Characteristics in a Spray Using Optical Nonimaging Light-Scattering Instruments

Standard Test Method for Determining Liquid Drop Size Characteristics in a Spray Using Optical Nonimaging Light-Scattering Instruments

SCOPE

1.1 The purpose of this test method is to obtain data which characterize the sizes of liquid particles or drops such as are produced by a spray nozzle or similar device under specified conditions using a specified liquid. The drops will generally be in the size range from 5-[mu]m to the order of 1000-[mu]m diameter; they will occur in sprays which may be as small as a few cubic centimetres or as large as several cubic metres. Typically the number density of the particles can vary significantly from one point to another.

1.2 This test method is intended primarily for use in standardizing measurements of the performance of spray- producing devices. It is limited to those techniques and instruments that operate by passing a beam of light through the spray and analyzing the light scattered by the droplets to derive size information. Such techniques do not produce images of individual drops, and therefore, are known as "optical (nonimaging) instruments."

1.3 The measurements made, when referred to the entire spray being sampled, may be flux sensitive or spatial, as defined in Practice E799, depending on the techniques used with a particular instrument.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1260 – 95

Standard Test Method for

Determining Liquid Drop Size Characteristics in a Spray

Using Optical Nonimaging Light-Scattering Instruments

This standard is issued under the fixed designation E 1260; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This standard is one of several describing a different class of test methods for determining liquid

drop size characteristics in a spray. These test methods can be broadly distinguished as “optical” or“

non-optical.” In the optical category there are test methods that essentially make images (such as

photographs) of drops that can be measured either manually or automatically, and test methods that

do not make images but use optical phenomena exhibited by single drops or ensembles of drops which

can be recorded and used to calculate either individual drop sizes or the distribution of drop sizes in

an ensemble. This test method deals with the latter class, and hence, is described as “nonimaging.” The

various optical phenomena involved are commonly described as “light-scattering.” Using any of these

test methods, the spray is observed for a period of time during which a large number of drops is

examined, and the data are treated so as to derive drop-size statistics for the sample investigated.

In most cases it will not be possible to examine more than a partial region of the entire spray

produced by the nozzle, so some judgment will be required of the operator in choosing a representative

location.

1. Scope 1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 The purpose of this test method is to obtain data which

responsibility of the user of this standard to establish appro-

characterize the sizes of liquid particles or drops such as are

priate safety and health practices and determine the applica-

produced by a spray nozzle or similar device under specified

bility of regulatory limitations prior to use.

conditions using a specified liquid. The drops will generally be

in the size range from 5-μm to the order of 1 000-μm diameter;

2. Referenced Documents

they will occur in sprays which may be as small as a few cubic

2.1 ASTM Standards:

centimetres or as large as several cubic metres. Typically the

E 177 Practice for Use of the Terms Precision and Bias in

number density of the particles can vary significantly from one

ASTM Test Methods

point to another.

E 456 Terminology Relating to Quality and Statistics

1.2 This test method is intended primarily for use in

E 799 Practice for Determining Data Criteria and Process-

standardizing measurements of the performance of spraypro-

ing for Liquid Drop Size Analysis

ducing devices. It is limited to those techniques and instru-

E 1088 Definition of Terms Relating to Atomizing Devices

ments that operate by passing a beam of light through the spray

E 1296 Terminology Relating to Liquid Particle Statistics

and analyzing the light scattered by the droplets to derive size

E 1620 Terminology Relating to Liquid Particles and At-

information. Such techniques do not produce images of indi-

omization

vidual drops, and therefore, are known as “optical (nonimag-

2.2 NFPA Standards:

ing) instruments.”

NFPA 30 Flammable and Combustible Liquids Code

1.3 The measurements made, when referred to the entire

NFPA 33 Spray Application Using Flammable and Combus-

spray being sampled, may be flux sensitive or spatial, as

tible Materials

defined in Practice E 799, depending on the techniques used

with a particular instrument.

3. Terminology

3.1 For terminology pertaining to this test method, refer to

This test method is under the jurisdiction of ASTM Committee E-29 on Particle

Size Measurement and is the direct responsibility of Subcommittee E29.04 on

Liquid Particle Measurement. Annual Book of ASTM Standards, Vol 14.02.

Current edition approved July 15, 1995. Published September 1995. Originally Available from the National Fire Protection Association, Battery-March Park,

published as E 1260 – 88. Last previous edition E 1260 – 88. Quincey, MA 02269.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1260

Terminology E 456, Practice E 799, Definitions E 1088, and 6.2 Care must be exercised to prevent the ingress of liquid

Terminology E 1296. drops into the instrument. The surfaces of lenses, mirrors, and

3.2 Definitions of Terms Specific to This Standard: windows should be inspected at frequent intervals for cleanli-

3.2.1 spray—the term “spray” in this test method includes ness or damage and the manufacturer’s recommendations

all ensembles, arrays, or clouds composed of liquid particles or followed.

drops whether produced artificially or naturally. Although it is

7. Apparatus

usual to consider a spray as implying significant motion of the

drops relative to the atmosphere there are situations in which 7.1 Light Source, (including lasers),

7.1.1 Optical Means, for producing a suitable beam that

the relative velocity is or becomes sufficiently low to be

negligible. In this case, a “spray” is indistinguishable from a passes through a region of the spray,

7.1.2 Detecting Means, for recording light-scattering phe-

“cloud” which implies a static ensemble of drops.

nomena resulting from the liquid drops and means for trans-

4. Summary of Test Method

forming the observations into statistical estimates of drop size

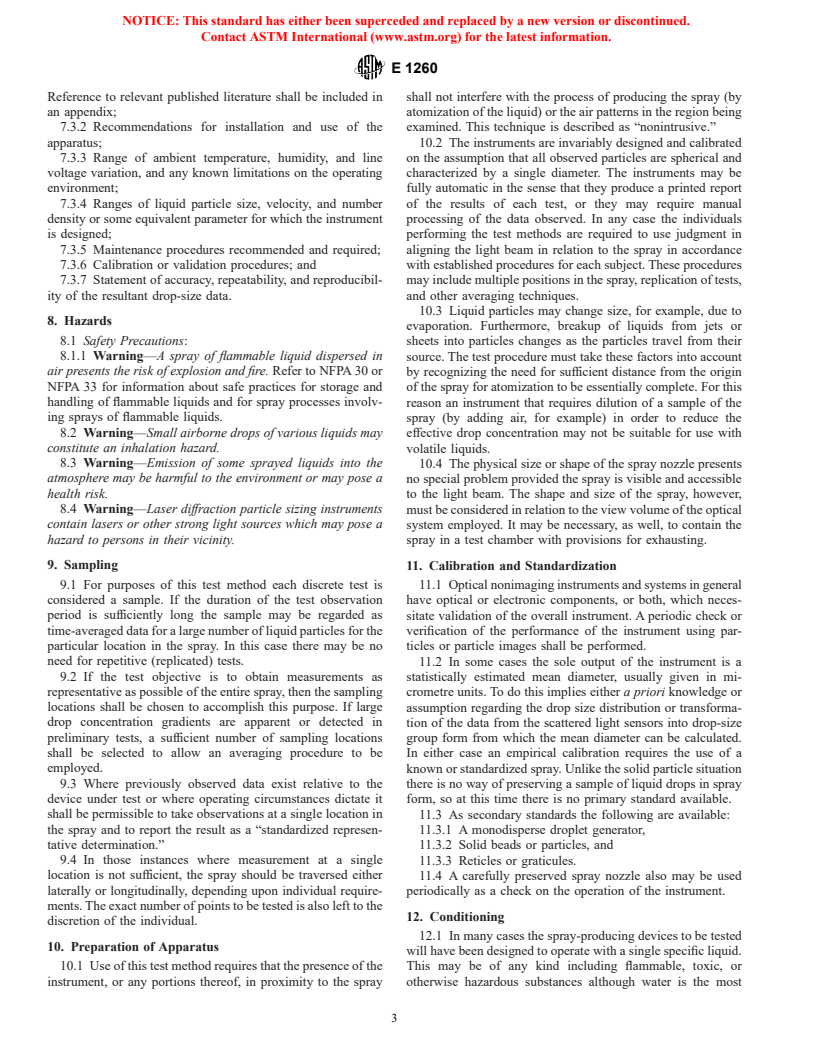

4.1 The spray is examined by nonintrusive means whereby and dispersion characteristics, as shown in Fig. 1.

a beam of light passes through a local region, which is judged 7.2 Spray Chamber, having transparent walls or windows

to be a representative sample, and one of the forms of which allow the light beam to pass through the spray. It is

light-scattering phenomena that occur is detected by the convenient to employ this when the spray or spray-producing

instrument. The data are recorded, usually by data-processing device to be tested is small in size relative to the apparatus. Use

equipment, and are transformed mathematically into statistics of this chamber may be desirable to protect the optical and

characterizing the size distribution such as mean drop size and

electronic components of the apparatus from damage by the

dispersion. These operations may be performed manually or liquid spray (see also Section 8). In this case the apparatus is

automatically and the instrument may provide a visual display

preferably permanently installed in a suitable location, and the

or a printed report. devices to be tested shall be brought to the testing site for

operation.

5. Significance and Use

7.2.1 Where the spray is larger or is produced in a large

5.1 The purpose of this test method is to provide data on structure the apparatus shall be designed to be portable and as

liquid drop-size characteristics for sprays, as indicated by

far as possible nonintrusive.

optical nonimaging light-scattering instruments. The results 7.2.2 In cases where there are known or suspected steep

obtained generally will be statistical in nature and will give

drop concentration gradients or variations in the spray, for

information on mean drop sizes and measures of dispersion of example, in hollow-cone spray patterns, means shall be pro-

size. The number of variables concerned in the production of

vided for accurately locating the spraying device relative to the

liquid spray, together with the variety of optical, electronic, and light beam source and sensor. Provision may also be made for

sampling systems used in different instruments, may contribute

selectively examining a number of different locations or

to variations in the test results. Care must be exercised, regions in the spray.

therefore, when attempting to compare data from samples

7.3 Operating instructions shall be supplied by the manu-

obtained by different means.

facturer or contractor of the apparatus or instrument. The

instructions shall contain:

6. Interferences

7.3.1 Brief description of the operational principles of the

6.1 Spray Nozzle—Many spray nozzles are designed with

instrument, oriented towards a trained technical operator.

internal liquid passages of small dimensions and it is important

to ensure that these passages do not become blocked with

foreign matter. Some nozzles have built-in filters or screens but

in all cases it is advisable to fit a filter in the liquid supply line

immediately upstream of the nozzle inlet to remove any solid

particles that are considered likely to cause problems.

6.1.1 The use of water instead of a hydrocarbon liquid to

simulate fuel may affect the performance of certain types of

nozzle due to differences in density, viscosity, and surface

tension. In addition, however, occasionally a problem may

occur due to differences in wetting the surfaces, for example, a

nozzle tested previously in fuel (or other hydrocarbon) may

exhibit a poor quality spray when first tested with water and

may require the use of a degreasing agent to remove traces of

hydrocarbon from the surfaces containing the liquid.

6.1.2 It is very important to protect the edges of the

discharge orifice of a spray nozzle from accidental damage

prior to testing. This protection is best accomplished by the use

of a cover over the discharge orifice of the nozzle during

storage and installation on the test stand. FIG. 1 Diagram of Test Arrangement

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1260

Reference to relevant published literature shall be included in shall not interfere with the process of producing the spray (by

an appendix; atomization of the liquid) or the air patterns in the region being

7.3.2 Recommendations for installation and use of the examined. This technique is described as “nonintrusive.”

apparatus; 10.2 The

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.