ASTM D3321-19(2023)

(Test Method)Standard Test Method for Use of the Refractometer for Field Test Determination of the Freezing Point of Aqueous Engine Coolants

Standard Test Method for Use of the Refractometer for Field Test Determination of the Freezing Point of Aqueous Engine Coolants

SIGNIFICANCE AND USE

4.1 This practice is commonly used by vehicle service personnel to determine the freezing point, in degrees Celsius or Fahrenheit, of aqueous solutions of commercial ethylene and propylene glycol-based coolant. A durable hand-held refractometer is available that reads the freezing point, directly, in degrees Celsius or Fahrenheit, when a few drops of engine coolant are properly placed on the temperature-compensated prism surface of the refractometer. This refractometer is for glycol and water solutions, and is not suitable for other coolant solutions.

4.2 The hand-held refractometer should be calibrated before use (see Section 7).

4.3 Care must be taken to use the correct glycol freezing point scale for the glycol type being measured. Use of the wrong glycol scale can result in freezing point errors of 18 and more degrees Fahrenheit.

4.4 Ethylene glycol/propylene glycol mixtures will result in inaccurate freezing point measurements using either freezing point scale.

SCOPE

1.1 This test method covers the use of a portable refractometer for determining the approximate freezing protection provided by ethylene and propylene glycol-based coolant solutions as used in engine cooling systems and special applications.

Note 1: Some instruments have a supplementary freezing protection scale for methoxypropanol coolants. Others carry a supplemental scale calibrated in density or specific gravity readings of sulfuric acid solutions so that the refractometer can be used to determine the charged condition of lead acid storage batteries.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3321 − 19 (Reapproved 2023)

Standard Test Method for

Use of the Refractometer for Field Test Determination of the

Freezing Point of Aqueous Engine Coolants

This standard is issued under the fixed designation D3321; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This test method covers the use of a portable refracto-

meter for determining the approximate freezing protection

3. Summary of Test Method

provided by ethylene and propylene glycol-based coolant

solutions as used in engine cooling systems and special

3.1 These coolant testers are critical-angle refractometers

applications.

designed for rapid, approximate measurement of ethylene and

propylene glycol coolant freezing point protection. Only a few

NOTE 1—Some instruments have a supplementary freezing protection

drops of test solution are required. Some testers automatically

scale for methoxypropanol coolants. Others carry a supplemental scale

calibrated in density or specific gravity readings of sulfuric acid solutions

correct for ambient air temperature and the temperature of the

so that the refractometer can be used to determine the charged condition

solution being tested. The instrument is rugged, simple to read,

of lead acid storage batteries.

and easy to clean and maintain.

1.2 The values stated in SI units are to be regarded as

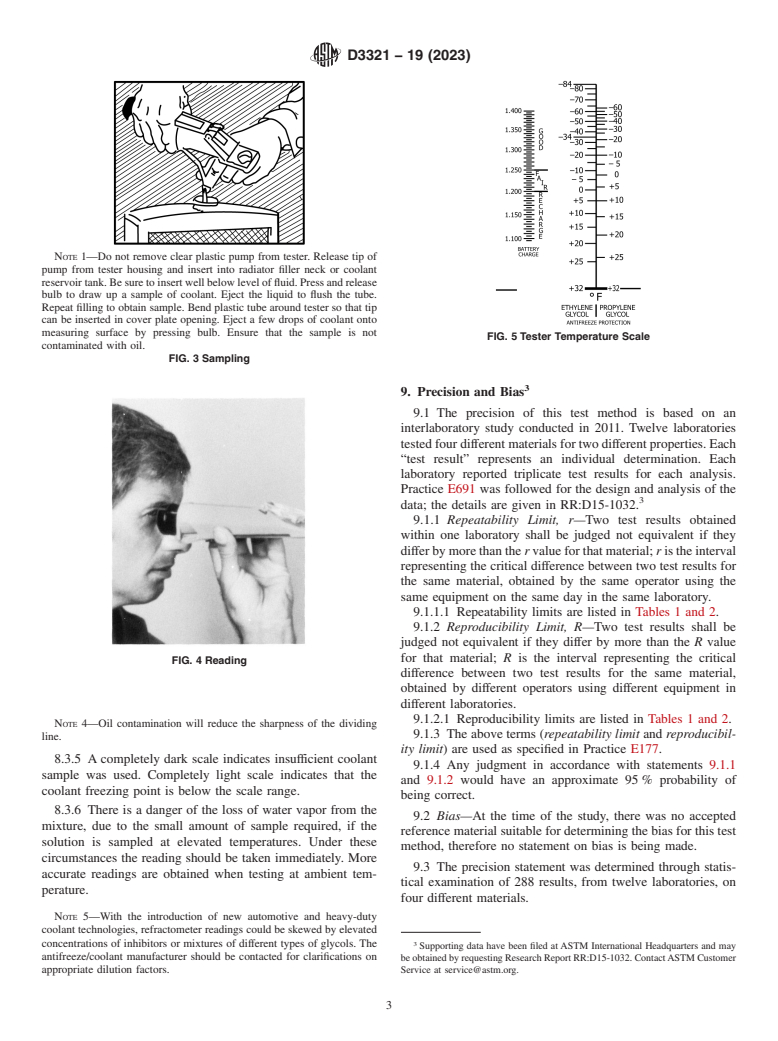

3.2 The coolant freezing point readings are taken at points

standard. The values given in parentheses after SI units are

where the dividing line between light and dark crosses the

provided for information only and are not considered standard.

scales. Some refractometers have a coolant scale for indicating

1.3 This standard does not purport to address all of the

the freezing point of aqueous ethylene glycol coolants only,

safety concerns, if any, associated with its use. It is the

while other refractometers also have a scale for indicating the

responsibility of the user of this standard to establish appro-

freezing point of aqueous propylene glycol coolants. The range

priate safety, health, and environmental practices and deter-

of the scales varies from one device to another.

mine the applicability of regulatory limitations prior to use.

3.3 Freezing point measurements are concentration-related

1.4 This international standard was developed in accor-

values and are in turn directly related to refractive index. It has

dance with internationally recognized principles on standard-

been empirically determined that freezing point measurements

ization established in the Decision on Principles for the

are accurate within 1 °C (2 °F).

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

4. Significance and Use

Barriers to Trade (TBT) Committee.

4.1 This practice is commonly used by vehicle service

2. Referenced Documents

personnel to determine the freezing point, in degrees Celsius or

2.1 ASTM Standards:

Fahrenheit, of aqueous solutions of commercial ethylene and

D1177 Test Method for Freezing Point of Aqueous Engine

propylene glycol-based coolant. A durable hand-held refracto-

Coolants

meter is available that reads the freezing point, directly, in

E177 Practice for Use of the Terms Precision and Bias in

degrees Celsius or Fahrenheit, when a few drops of engine

ASTM Test Methods

coolant are properly placed on the temperature-compensated

prism surface of the refractometer. This refractometer is for

glycol and water solutions, and is not suitable for other coolant

This test method is under the jurisdiction of ASTM Committee D15 on Engine

solutions.

Coolants and Related Fluids and is the direct responsibility of Subcommittee

D15.03 on Physical Properties. 4.2 The hand-held refractometer should be calibrated before

Current edition approved Sept. 1, 2023. Published September 2023. Originally

use (see Section 7).

approved in 1974. Last previous edition approved in 2019 as D3321 – 19. DOI:

10.1520/D3321-19R23.

4.3 Care must be taken to use the correct glycol freezing

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

point scale for the glycol type being measured. Use of the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

wrong glycol scale can result in freezing point errors of 18 and

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. more degrees Fahrenheit.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

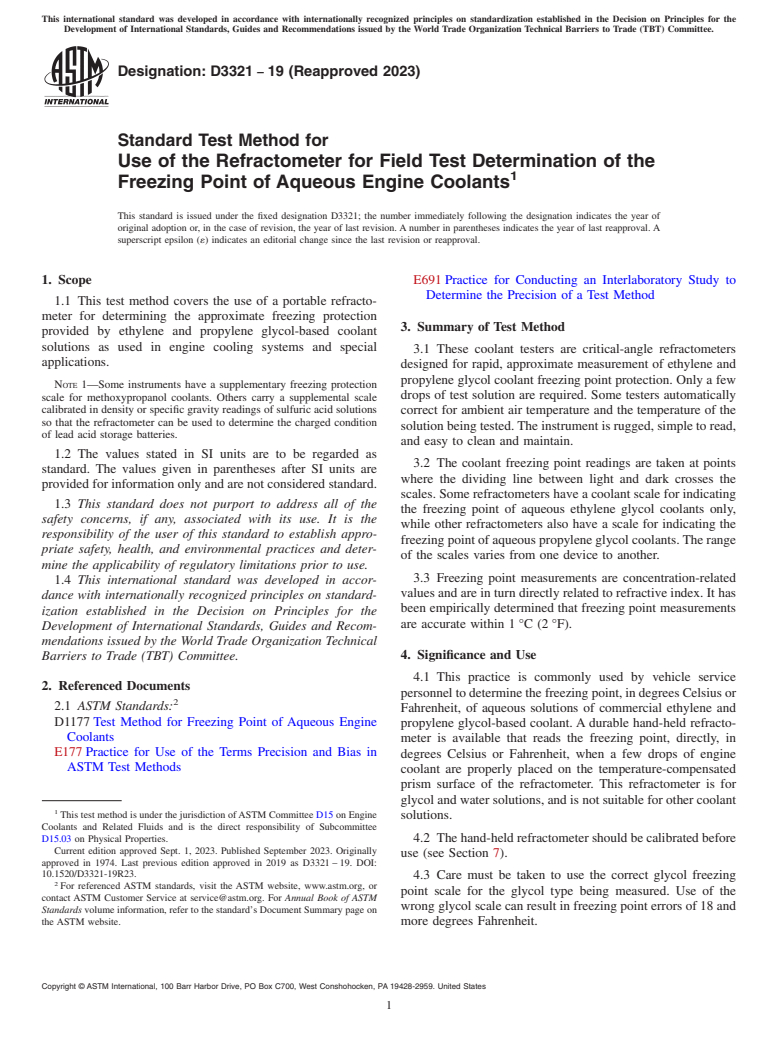

D3321 − 19 (2023)

4.4 Ethylene glycol/propylene glycol mixtures will result in

inaccurate freezing point measurements using either freezing

point scale.

5. Interferences

5.1 Interference can occur if the mixture is contaminated or

if the prism surface is not clean. The presence of other glycols

such as diethylene glycol in small amounts will not cause

interference.

6. Apparatus

6.1 The hand-held critical angle refractometer is a rugged

die-cast portable instrument that is covered with a high-impact

plastic to minimize damage to the eyepiece lens if dropped. A

polished glass prism is opposite the viewing end. A hinged

plastic cover is moved over the prism (sampling end) to allow

for even sample distribution and prevent liquid sample spillage

during the test. No eyepiece or prism adjustments are required

for sample testing.

6.2 The telescopic recessed eyepiece is located at one end

and the graduated, translucent prism on the opposite end (see

Fig. 1).

7. Calibration

7.1 Calibration of these coolant testers should periodically

be verified by testing a water sample in accordance with the

procedure outlined in Section 8.

7.2 If the sample tested deviates from 0 °C (+32 °F) the

coolant tester is out of calibration and should be recalibrated.

7.3 This calibration test is best performed with the coolant

tester and water sample at room temperature. If the instrument

used is designed to be automatically temperature compensated,

work within the stated temperature-compensated range.

8. Procedure

8.1 Cleaning—Before using, swing back the plastic cover at

FIG. 2 Cleaning

the slanted end of the tester exposing both the measuring

window and the bottom of the plastic cover. Wipe both clean

and dry with tissue or clean soft cloth. Close the plastic cover

8.3.1 Point the instrument toward any light source (for

(see Fig. 2).

example, a headlight) and look into the eyepiece (Fig. 4).

8.3.2 The freeze point protection is the point where the

8.2 Testing Coolant Solution—Commercial instruments are

dividing line between light and dark (edge of t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.