ASTM F2882-12

(Specification)Standard Specification for Screws, Alloy Steel, Heat Treated, 170 ksi Minimum Tensile Strength

Standard Specification for Screws, Alloy Steel, Heat Treated, 170 ksi Minimum Tensile Strength

ABSTRACT

This specification covers the requirements for quenched and tempered alloy steel screws 0.060 through 1 1/2 inches in diameter having a minimum ultimate tensile strength of 170 KSI. High strength screws shall be heat treated by quenching in oil from above the transformation temperature and then tempered by reheating to at least 797°F to within the hardness range. One or more of the following alloying elements: chromium, nickel, molybdenum, or vanadium shall be present in sufficient quantity to ensure that the specified strength properties are met after oil quenching and tempering. The hardness limits shall be met anywhere on the cross section through the threads, one diameter from the screw point.

SCOPE

1.1 This specification covers the requirements for quenched and tempered alloy steel screws 0.060 through 11/2 inches in diameter having a minimum ultimate tensile strength of 170 KSI.Note 1—This specification is the inch companion of Specification F2882M.

1.2 The following hazard caveat pertains only to the test method portion, Section 10, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2882 −12

Standard Specification for

Screws, Alloy Steel, Heat Treated, 170 ksi Minimum Tensile

1

Strength

This standard is issued under the fixed designation F2882; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope F2328Test Method for Determining Decarburization and

Carburization in Hardened and Tempered Threaded Steel

1.1 This specification covers the requirements for quenched

Bolts, Screws and Studs

1

and tempered alloy steel screws 0.060 through 1 ⁄2 inches in

3

2.2 ASME Standards:

diameter having a minimum ultimate tensile strength of 170

B18.2.1Square and Hex Bolts and Screws

KSI.

B18.2.512 Point Flange Screws

NOTE 1—This specification is the inch companion of Specification

B18.3Socket Cap, Shoulder, and Set Screws, Hex and

F2882M.

Spline Keys (Inch Series)

1.2 The following hazard caveat pertains only to the test

B18.24Part Identifying Number (PIN) Code System Stan-

method portion, Section 10, of this specification: This standard

dard for B18 Fastener Products

does not purport to address all of the safety concerns, if any,

3. Ordering Information

associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices

3.1 Orders for high strength screws under this specification

and determine the applicability of regulatory limitations prior

shall include the following information:

to use.

3.1.1 Quantity (number of screws),

3.1.2 Nominal dimensions, including diameter, thread

2. Referenced Documents

designation, thread, pitch, and nominal screw length,

2

2.1 ASTM Standards: 3.1.3 Name of the screw including specification,

3.1.3.1 ASME B18.2.1, Square and Hex Bolts and Screws,

A751Test Methods, Practices, and Terminology for Chemi-

cal Analysis of Steel Products 3.1.3.2 ASME B18.2.5, 12 Point Flange Screws,

3.1.3.3 ASME B18.3, Socket Cap, Shoulder, and Set

E112Test Methods for Determining Average Grain Size

F606Test Methods for Determining the Mechanical Proper- Screws, Hex and Spline Keys (Inch Series),

3.1.4 ASTM designation and year of issue.

ties of Externally and Internally Threaded Fasteners,

Washers, Direct Tension Indicators, and Rivets

3.2 Ordersforhighstrengthscrewsmayincludethefollow-

F788/F788MSpecification for Surface Discontinuities of

ing optional requirements:

Bolts, Screws, and Studs, Inch and Metric Series

3.2.1 Inspection at point of manufacture.

F1470Practice for Fastener Sampling for Specified Me-

3.2.2 Coating, if required (see 4.6).

chanical Properties and Performance Inspection

3.2.3 Additional Testing (see 11.1).

F1940Test Method for Process Control Verification to

3.2.4 Special Packaging (see 14.1.2).

Prevent Hydrogen Embrittlement in Plated or Coated

3.2.5 Supplementary Requirement (see S1).

Fasteners

3.2.6 Special Requirements.

F2282SpecificationforQualityAssuranceRequirementsfor

3.2.7 For establishment of a part identifying system, see

Carbon and Alloy Steel Wire, Rods, and Bars for Me-

ASME B18.24.

chanical Fasteners

4. Materials and Manufacture

4.1 The screws shall be fabricated from steel made to fine

1

This test method is under the jurisdiction of ASTM Committee F16 on

grain practice and shall have an austenitic grain size of 5 or

Fasteners and is the direct responsibility of Subcommittee F16.02 on Steel Bolts,

finer. In the event of controversy over grain size, referee tests

Nuts, Rivets and Washers.

Current edition approved Oct. 1, 2012. Published November 2012. DOI:

onfinishedscrewsconductedinaccordancewithTestMethods

10.1520/F2882-12.

E112 shall prevail.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from American Society of Mechanical Engineers (ASME), ASME

the ASTM website. International Headquarters, Three Park Ave., New York, NY 10016-5990.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

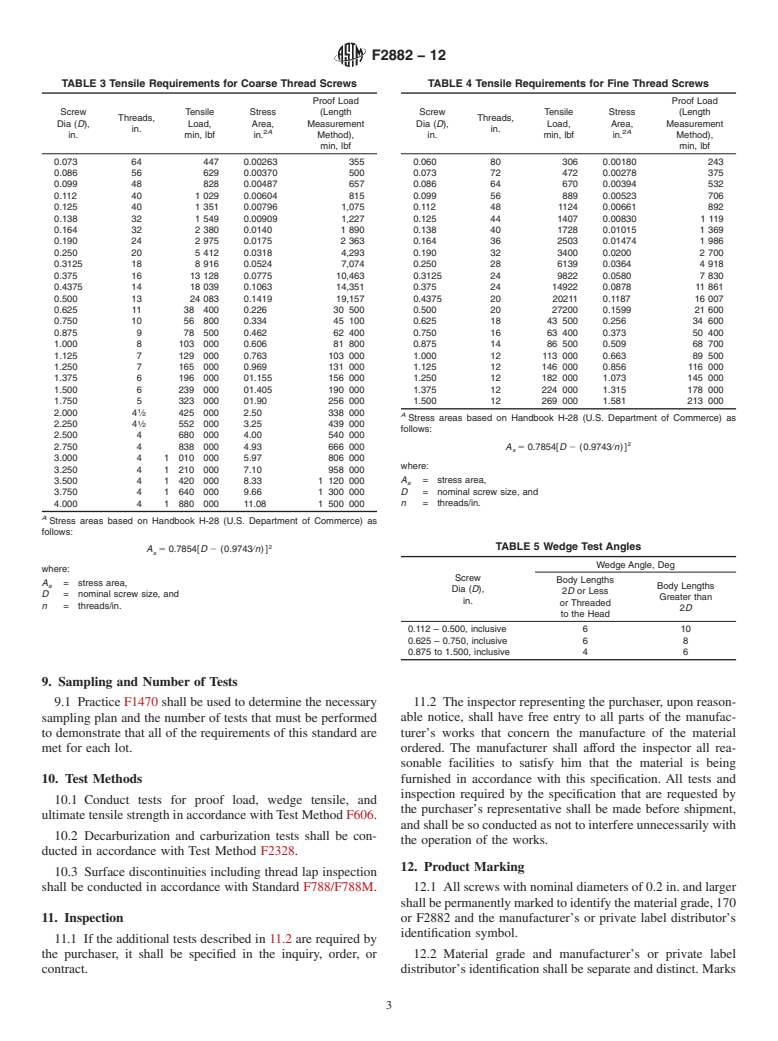

F2882−12

TABLE 2 Chemical Requirements

4.2 High strength screws shall be heat treated by quenching

in oil from above the transformation temperature and then Composition, %

Element

tempered by reheating to at least 797°F to within the hardness Heat Analysis Product Analysis

range specified in Table 1. Carbon 0.33 to 0.48 0.31 to 0.50

Manganese, max 1.25 1.25

4.2.1 The minimum tempering temperature may be verified

Phosphorus, max 0.035 0.040

by submitting screws to 777°F for 30 min at temperature.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.