ASTM E278-01(2005)

(Test Method)Standard Test Method for the Determination of Phosphorus in Iron Ores by Phosphomolybdate Coprecipitation and Nitric Acid Titrimetry

Standard Test Method for the Determination of Phosphorus in Iron Ores by Phosphomolybdate Coprecipitation and Nitric Acid Titrimetry

SIGNIFICANCE AND USE

This test method is intended to be used for compliance with compositional specifications for phosphorus content. It is assumed that all who use these procedures will be trained analysts capable of performing common laboratory procedures skillfully and safely. It is expected that work will be performed in a properly equipped laboratory and that proper waste disposal procedures will be followed. Appropriate quality control practices shall be followed, such as those described in Guide E 882.

SCOPE

1.1 This test method covers the determination of phosphorus in iron ores, concentrates, and agglomerates.

1.2 This test method covers the determination of phosphorus in the concentration range from 0.01 to 1.00 %.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E278–01(Reapproved2005)

Standard Test Method for the Determination of

Phosphorus in Iron Ores by Phosphomolybdate

Coprecipitation and Nitric Acid Titrimetry

This standard is issued under the fixed designation E278; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E882 Guide for Accountability and Quality Control in the

Chemical Analysis Laboratory

1.1 This test method covers the determination of phospho-

rus in iron ores, concentrates, and agglomerates.

3. Terminology

1.2 This test method covers the determination of phospho-

3.1 Definitions—For definitions of terms used in this test

rus in the concentration range from 0.01 to 1.00 %.

method, refer to Terminology E135.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Summary of Test Method

responsibility of the user of this standard to establish appro-

4.1 Thesampleisdissolvedinhydrochloricandnitricacids.

priate safety and health practices and determine the applica-

After the addition of perchloric acid, the solution is evaporated

bility of regulatory limitations prior to use.

to strong fumes to dehydrate the silica.The insoluble residue is

filtered off, ignited, and treated for the recovery of any

2. Referenced Documents

contained phosphorus. Ammonium molybdate is added to

2.1 ASTM Standards:

precipitate phosphomolybdate. The precipitate is filtered off

D1193 Specification for Reagent Water

and washed free from acid. It is then dissolved in an excess of

E50 Practices for Apparatus, Reagents, and Safety Consid-

standard sodium hydroxide solution. The excess sodium hy-

erations for Chemical Analysis of Metals, Ores, and

droxide is titrated with a standard solution of nitric acid using

Related Materials

phenolphthalein as an indicator.

E135 Terminology Relating to Analytical Chemistry for

Metals, Ores, and Related Materials

5. Significance and Use

E691 Practice for Conducting an Interlaboratory Study to

5.1 This test method is intended to be used for compliance

Determine the Precision of a Test Method

with compositional specifications for phosphorus content. It is

E877 Practice for Sampling and Sample Preparation of Iron

assumed that all who use these procedures will be trained

Ores and Related Materials for Determination of Chemical

analysts capable of performing common laboratory procedures

Composition

skillfully and safely. It is expected that work will be performed

in a properly equipped laboratory and that proper waste

disposal procedures will be followed. Appropriate quality

This test method is under the jurisdiction of ASTM Committee E01 on

Analytical Chemistry for Metals, Ores, and Related Materials and is the direct

control practices shall be followed, such as those described in

responsibility of Subcommittee E01.02 on Ores, Concentrates, and Related Metal-

Guide E882.

lurgical Materials.

Current edition approved May 1, 2005. Published June 2005. Originally

6. Interferences

approved in 1965. Last previous edition approved in 2001 as E278 – 01. DOI:

10.1520/E0278-01R05.

6.1 Vanadium and arsenic, elements commonly found in

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

iron ores, coprecipitate with the phosphorus. Provisions for

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

their removal or elimination of their interference are included

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. in this test method.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

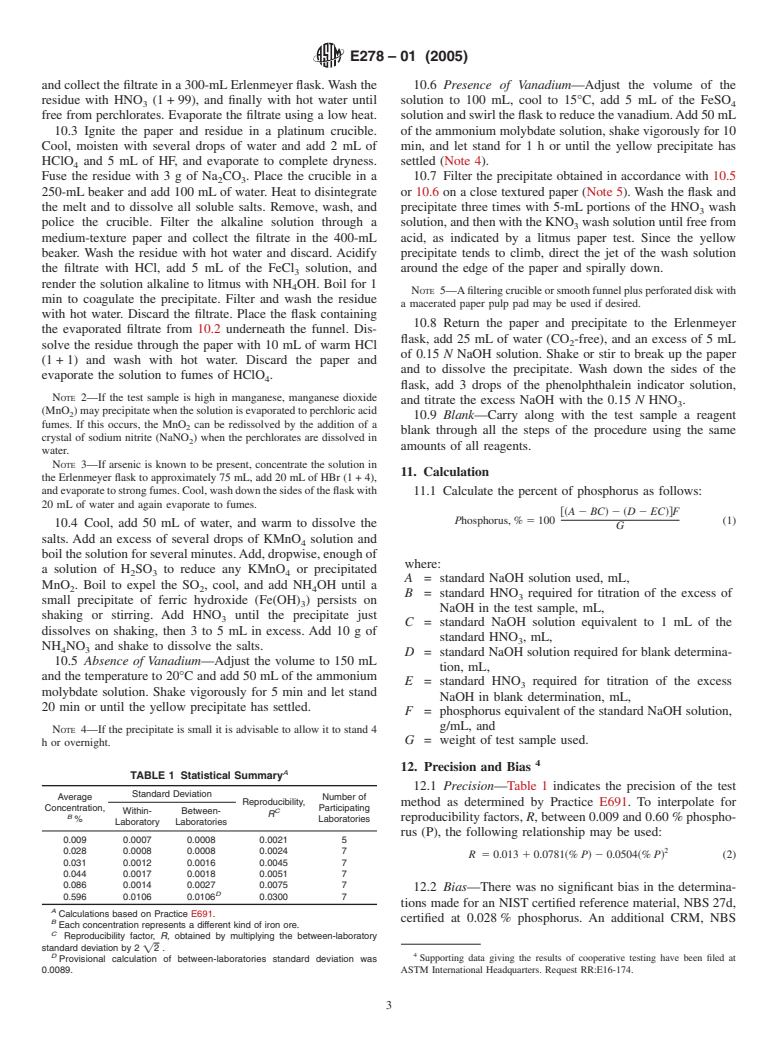

E278–01 (2005)

6.2 Titanium tends to form an insoluble compound with 7.14 Potassium Nitrate, Wash Solution (10 g/L)—Dissolve

phosphorus and thus may cause low values for phosphorus. 10 g of potassium nitrate (KNO ) in water, dilute to 1 L, and

Provision for its removal is included in this test method. mix.

7.15 Potassium Permanganate Solution (25 g/L)—Dissolve

7. Reagents and Materials 25 g of potassium permanganate (KMnO ) in water and dilute

to1L.

7.1 Purity of Reagents—Reagent grade chemicals shall be

7.16 Sodium Carbonate (Na CO ).

2 3

used in all tests. Unless otherwise indicated, it is intended that

7.17 Sodium Hydroxide, Stock Solution—Dissolve 300 g of

all reagents conform to the specifications of the Committee on

sodium hydroxide (NaOH) in 1 Lof water.Add a slight excess

Analytical Reagents of the American Chemical Society where

of barium hydroxide (Ba(OH) ) to precipitate any carbon

such specifications are available. Other grades may be used, 2

dioxide (CO ). Allow any precipitate to settle out. Store the

provided it is first ascertained that the reagent is of sufficient 2

solution in a polyethylene container.

high purity to permit its use without lessening the accuracy of

7.18 Sodium Hydroxide, Standard Solution (0.15 N)—

the determination.

Transfer 20 mLof the clear, supernatant stock solution to a 1-L

7.2 Purity of Water—Unless otherwise indicated, references

flask. Dilute to the mark with freshly boiled and cooled water

to water shall be understood to mean reagent water as defined

and mix thoroughly. Standardize this solution against potas-

by Type I of Specification D1193.

sium acid phthalate. It is convenient to adjust the normality of

7.3 Ammonium Molybdate Solution (Acidic)—

this standard solution to 0.148 N (1 mL = 0.0002 g P). Confirm

7.3.1 Solution No. 1—Transfer 100 g of molybdic acid

the phosphorus value by analyzing a standard of a known

(85% MoO ) to a 600–mL beaker containing 240 mL of water

phosphorus content, preferably an iron ore of similar compo-

and mix thoroughly. Add 140 mL of NH OH while stirring

sition. Protect the NaOH solution from CO by means of a

vigorously. When dissolution is complete, filter through a 2

soda-lime or soda-asbestos tube.

medium paper, add 60 mL of HNO , and cool.

7.19 Sulfurous Acid (H SO ).

7.3.2 Solution No. 2—Add 400 mL of HNO to 960 mL of 2 3

water in a 2–L beaker and cool.

8. Hazards

7.3.3 Add Solution No. 1 to Solution No. 2 while stirring

8.1 For precautions to be observed in this test method, refer

constantly. Add 0.1 g of ammonium phosphate, dibasic

to Practices E50.

((NH ) HPO ), and let stand at least 24 h before using. Use

4 2 4

only the clear supernatant liquid.

9. Sampling and Sample Preparation

7.4 Ammonium Nitrate (NH NO ).

4 3

7.5 Ferric Chloride Solution—Dissolve 0.3 g of pure iron 9.1 Sampling—The gross sample shall be collected and

wire in 25 mL of HCl (1 + 1). Oxidize by adding HNO prepared in accordance with Practice E877.

dropwise to the hot solution. Cool, add 25 mLof HCl, dilute to 9.2 Sample Preparation—The laboratory sample shall be

1 L and mix. pulverized to pass a No. 100 (150-µm) sieve.

7.6 Ferrous Sulfate Solution—Dissolve 100 g of ferrous

NOTE 1—Some ores, such as specular hematites, may require finer

sulfate (FeSO ·7H O) in 1 L of sulfuric acid (H SO , 5 + 95).

4 2 2 4

grinding to pass a No. 200 (75-µm) sieve.

7.7 Hydrobromic Acid (1 + 4)—Mix 20 mLof concentrated

9.3 Sample Weight—Weigh approximately (within 625

hydrobromic acid (HBr, sp gr 1.49) with 80 mL of water.

mg) an amount of sample specified as follows:

7.8 Hydrochloric Acid (1 + 1)—Mix equal volumes of con-

Content of Phosphorus, % Weight of Sample, g

centrated hydrochloric acid (HCl, sp gr 1.19) and water.

7.9 Hydrofluoric Acid (sp gr 1.15)—Concentrated hydrof-

0.01 to 0.10 2.0

0.11 to 0.50 1.0

luoric acid (HF).

0.51 to 1.00 0.5

7.10 Nitric Acid, Standard (0.15 N)—Transfer 10 mL of

clear and water white concentrated nitric acid (HNO,spgr

10. Procedure

1.42) to a 1-L flask, dilute to the mark, and mix. Standardize

10.1 Transfer the test sample to a small dry weighing bottle

this solution against the standard NaOH solution using phe-

and place in a drying oven.After drying at 105 to 110°C for 1

nolphthalein as indicator. If desired, this solution may be made

h, cap the bottle, and cool to room temperature in a desiccator.

equivalent to the standard sodium hydroxide solution by

Momentarilyreleasethecaptoequalizepressureandweighthe

dilution with water.

capped bottle to the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.