ASTM D8206-18

(Test Method)Standard Test Method for Oxidation Stability of Lubricating Greases—Rapid Small-Scale Oxidation Test (RSSOT)

Standard Test Method for Oxidation Stability of Lubricating Greases—Rapid Small-Scale Oxidation Test (RSSOT)

SIGNIFICANCE AND USE

5.1 This test method measures the net change in pressure resulting from consumption of oxygen by oxidation and gain in pressure due to formation of volatile oxidation by-products. This test method may be used for quality control to indicate batch-to-batch uniformity. It predicts neither the stability of greases stored in containers for long periods, nor the stability of films of greases on bearings and motor parts.

5.2 Induction period as determined under the conditions of this test method can be used as an indication of oxidation stability. This test method can be used for research and development, quality control, and specification purposes. However, no correlation has been determined between the results of this test method and service performance.

SCOPE

1.1 This test method covers the quantitative determination of the oxidation stability of lubricating greases with a dropping point above the test temperature.

1.2 This test method determines the resistance of lubricating greases to oxidation when stored statically in an oxygen atmosphere in a sealed system at an elevated temperature under conditions of test.

1.3 The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8206 − 18

Standard Test Method for

Oxidation Stability of Lubricating Greases—Rapid Small-

1

Scale Oxidation Test (RSSOT)

This standard is issued under the fixed designation D8206; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope 2.2 ISO Standard:

EN 60751:2008 Industrial platinum resistance thermometers

1.1 This test method covers the quantitative determination

and platinum temperature

of the oxidation stability of lubricating greases with a dropping

point above the test temperature.

3. Terminology

1.2 Thistestmethoddeterminestheresistanceoflubricating

3.1 Definitions of Terms Specific to This Standard:

greases to oxidation when stored statically in an oxygen

3.1.1 break point, n—pressure in the test instrument, which

atmosphereinasealedsystematanelevatedtemperatureunder

is 10 % below the maximum pressure of the actual test run.

conditions of test.

3.1.2 induction period, n—timeelapsedbetweenstartingthe

1.3 The values stated in SI units are to be regarded as the

heating procedure of the pressure vessel and the break point,

standard. No other units of measurement are included in this

measured in minutes.

standard.

1.4 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

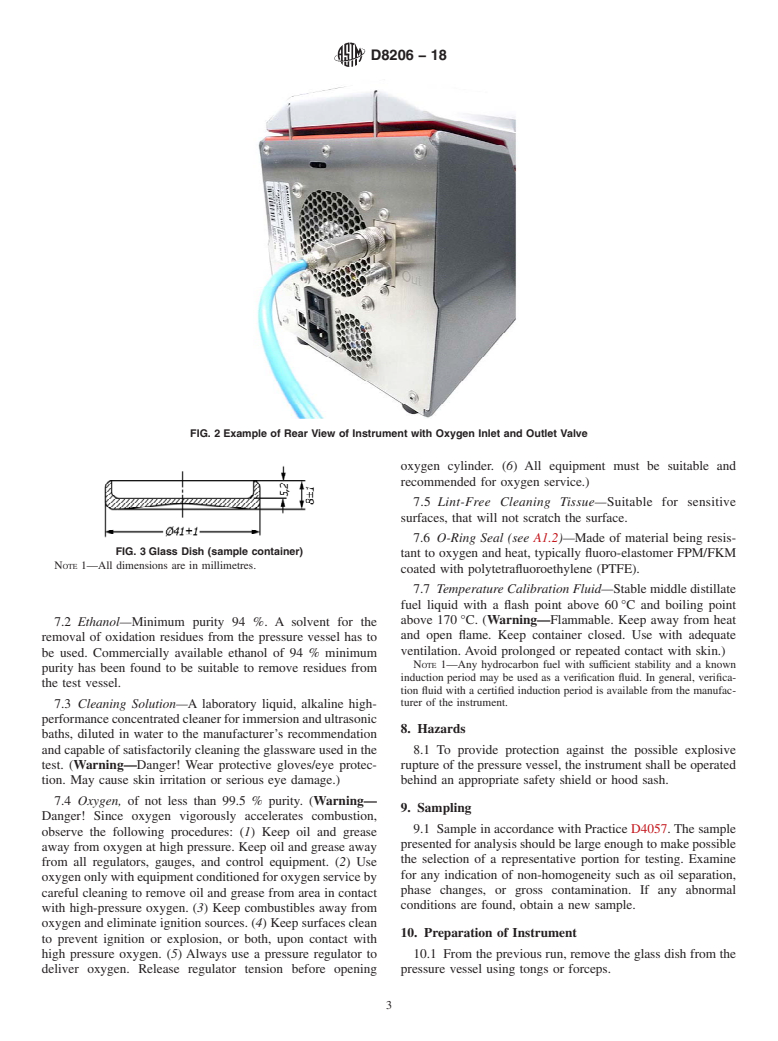

4.1 For this test, 4.00 g 6 0.01 g of sample is weighed in a

responsibility of the user of this standard to establish appro-

glass dish at a temperature of 20 °C 6 5 °C and then

priate safety, health, and environmental practices and deter-

introduced into a pressure vessel, which is subsequently

mine the applicability of regulatory limitations prior to use.

charged with oxygen to 700 kPa 6 5 kPa.

1.5 This international standard was developed in accor-

4.1.1 The test is initiated by heating the pressure vessel to a

dance with internationally recognized principles on standard-

temperatureof140°C 60.5°Cor160°C 60.5°C,depending

ization established in the Decision on Principles for the

on the selected test.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical 4.2 The pressure is recorded continuously until the break

Barriers to Trade (TBT) Committee. point is reached.

2. Referenced Documents 5. Significance and Use

2

2.1 ASTM Standards: 5.1 This test method measures the net change in pressure

D942 Test Method for Oxidation Stability of Lubricating resultingfromconsumptionofoxygenbyoxidationandgainin

Greases by the Oxygen Pressure Vessel Method pressure due to formation of volatile oxidation by-products.

D4057 Practice for Manual Sampling of Petroleum and This test method may be used for quality control to indicate

Petroleum Products batch-to-batch uniformity. It predicts neither the stability of

D6300 Practice for Determination of Precision and Bias greases stored in containers for long periods, nor the stability

Data for Use in Test Methods for Petroleum Products and

of films of greases on bearings and motor parts.

Lubricants

5.2 Induction period as determined under the conditions of

this test method can be used as an indication of oxidation

stability. This test method can be used for research and

1

This test method is under the jurisdiction of ASTM Committee D02 on

development, quality control, and specification purposes.

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

However, no correlation has been determined between the

Subcommittee D02.09.0E on Oxidation of Greases.

results of this test method and service performance.

Current edition approved June 1, 2018. Published July 2018. DOI: 10.1520/

D8206-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D8206 − 18

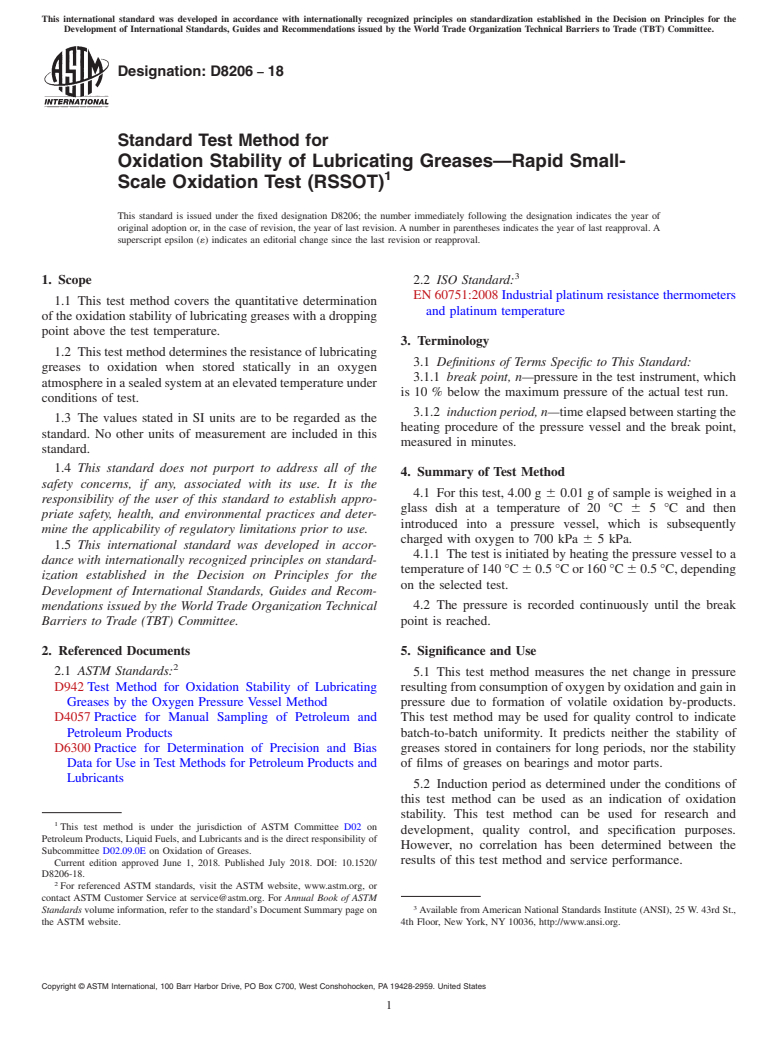

6. Apparatus 0.5 mm. The temperature sensor is calibrated to the nearest

0.1 °C by an approved calibration service, such as one that is

6.1 General—This test method uses an automatically con-

4 traceable to the National Insti

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.