ASTM E2980-20

(Test Method)Standard Test Methods for Estimating Average Particle Size of Powders Using Air Permeability

Standard Test Methods for Estimating Average Particle Size of Powders Using Air Permeability

SIGNIFICANCE AND USE

4.1 These test methods provide procedures for determining the envelope-specific surface area of powders, from which is calculated an “average” particle diameter, assuming the particles are monosize, smooth surface, nonporous, spherical particles. For this reason, values obtained by these test methods will be reported as an average particle size. The degree of correlation between the results of these test methods and the quality of powders in use will vary with each particular application and has not been fully determined.

4.2 These test methods are generally applicable to all powders, including metals (see Test Methods B330 for specific metal powder requirements), ceramics, and organic materials, for particles having diameters between 0.2 and 75 µm. They should not be used for powders composed of particles whose shape is too far from equiaxed – that is, flakes or fibers. In these cases, it is permissible to use the test methods described only by agreement between the parties concerned. These test methods shall not be used for mixtures of different powders, nor for powders containing binders or lubricants. When the powder contains agglomerates, the measured surface area may be affected by the degree of agglomeration. Methods of de-agglomeration such as that specified in Practice B859 may be used if agreed upon between the parties concerned.

4.3 When an “average” particle size of powders is determined by these methods, it should be clearly kept in mind that this average size is derived from the determination of the specific surface area of the powder using a relationship that is true only for powders of uniform size and spherical shape. Thus, the results of these methods are only estimates of average particle size.

4.4 Reported particle size measurement is a function of both the actual dimension and shape factor as well as the particular physical or chemical properties of the particle being measured. Caution is required when comparing data from instruments op...

SCOPE

1.1 These test methods use air permeability to determine an envelope-specific surface area and its associated average equivalent spherical diameter (from 0.2 to 75 µm) of powders. Two test methods are described: One test method for inorganic materials (Test Method 1), and another test method for organic materials (Test Method 2). The values obtained are not intended to be absolute but are generally useful on a relative basis for control purposes.

1.2 Units—With the exception of the values for density and the mass used to determine density, for which the use of the gram per cubic centimetre (g/cm3) and gram (g) units is the longstanding industry practice; and the units for pressure, cm H2O – also long-standing practice; the values in SI units are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2980 − 20

Standard Test Methods for

Estimating Average Particle Size of Powders Using Air

1

Permeability

This standard is issued under the fixed designation E2980; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* B859 Practice for De-Agglomeration of Refractory Metal

Powders and Their Compounds Prior to Particle Size

1.1 These test methods use air permeability to determine an

Analysis

envelope-specific surface area and its associated average

E29 Practice for Using Significant Digits in Test Data to

equivalent spherical diameter (from 0.2 to 75 µm) of powders.

Determine Conformance with Specifications

Two test methods are described: One test method for inorganic

E1638 Terminology Relating to Sieves, Sieving Methods,

materials (Test Method 1), and another test method for organic

and Screening Media

materials (Test Method 2). The values obtained are not

E2589 Terminology Relating to Nonsieving Methods of

intended to be absolute but are generally useful on a relative

Powder Characterization

basis for control purposes.

3

2.2 ISO Documents:

1.2 Units—With the exception of the values for density and

ISO 10070 Metallic Powders: Determinations of Envelope-

the mass used to determine density, for which the use of the

Specific Surface Area from Measurements of the Perme-

3

gram per cubic centimetre (g/cm ) and gram (g) units is the

ability to Air of a Powder Bed Under Steady-State Flow

longstanding industry practice; and the units for pressure, cm

Conditions

H O – also long-standing practice; the values in SI units are to

2

be regarded as standard. 3. Terminology

1.3 This standard does not purport to address all of the

3.1 Definitions—Many terms used in this test method are

safety concerns, if any, associated with its use. It is the

defined in Terminologies E1638 and E2589.

responsibility of the user of this standard to establish appro-

3.2 Definitions of Terms Specific to This Standard:

priate safety, health, and environmental practices and deter-

3.2.1 air permeability, n—measurement of air pressure drop

mine the applicability of regulatory limitations prior to use.

across a packed bed of powder.

1.4 This international standard was developed in accor-

3.2.2 average particle size, n—for the purposes of these test

dance with internationally recognized principles on standard-

methods only, an estimate of the equivalent average spherical

ization established in the Decision on Principles for the

particle diameter, calculated from the measured envelope-

Development of International Standards, Guides and Recom-

specific surface area, assuming that all the powder particles are

mendations issued by the World Trade Organization Technical

spherical and that all are exactly the same size.

Barriers to Trade (TBT) Committee.

3.2.3 de-agglomeration, n—process used to break up ag-

2. Referenced Documents

glomerates of particles.

2

2.1 ASTM Standards:

3.2.4 envelope-specific surface area, n—specific surface

B330 Test Methods for Estimating Average Particle Size of

area of a powder as determined by gas permeametry in

Metal Powders and Related Compounds Using Air Per-

accordance with ISO 10070.

meability

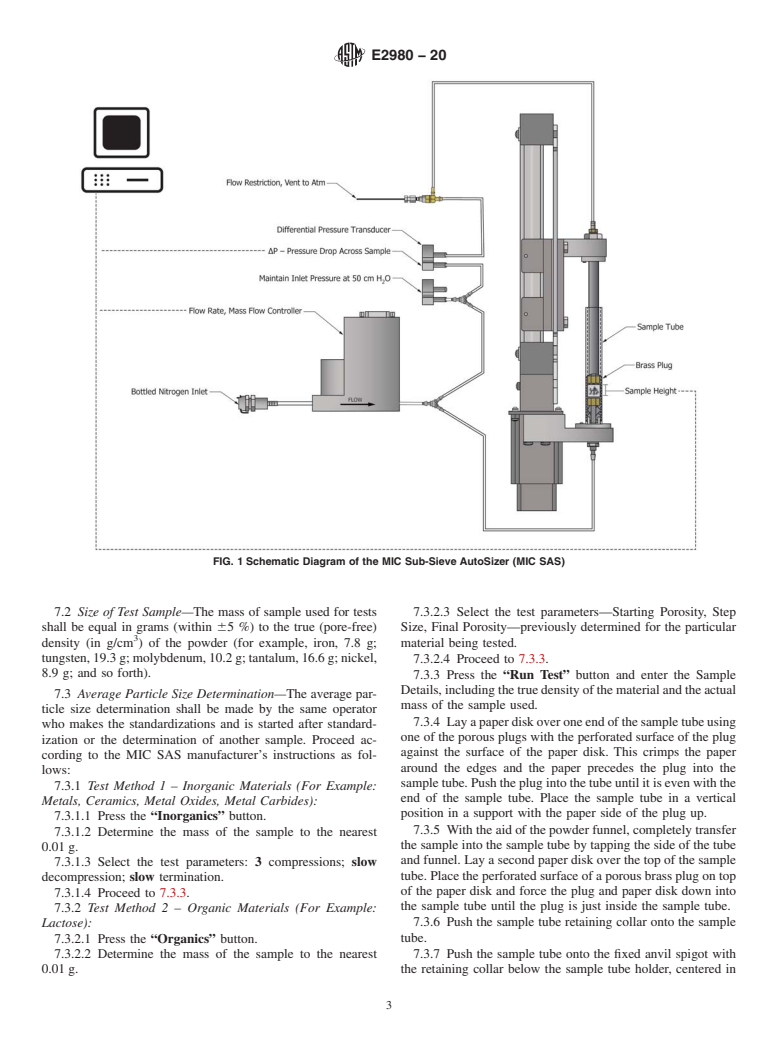

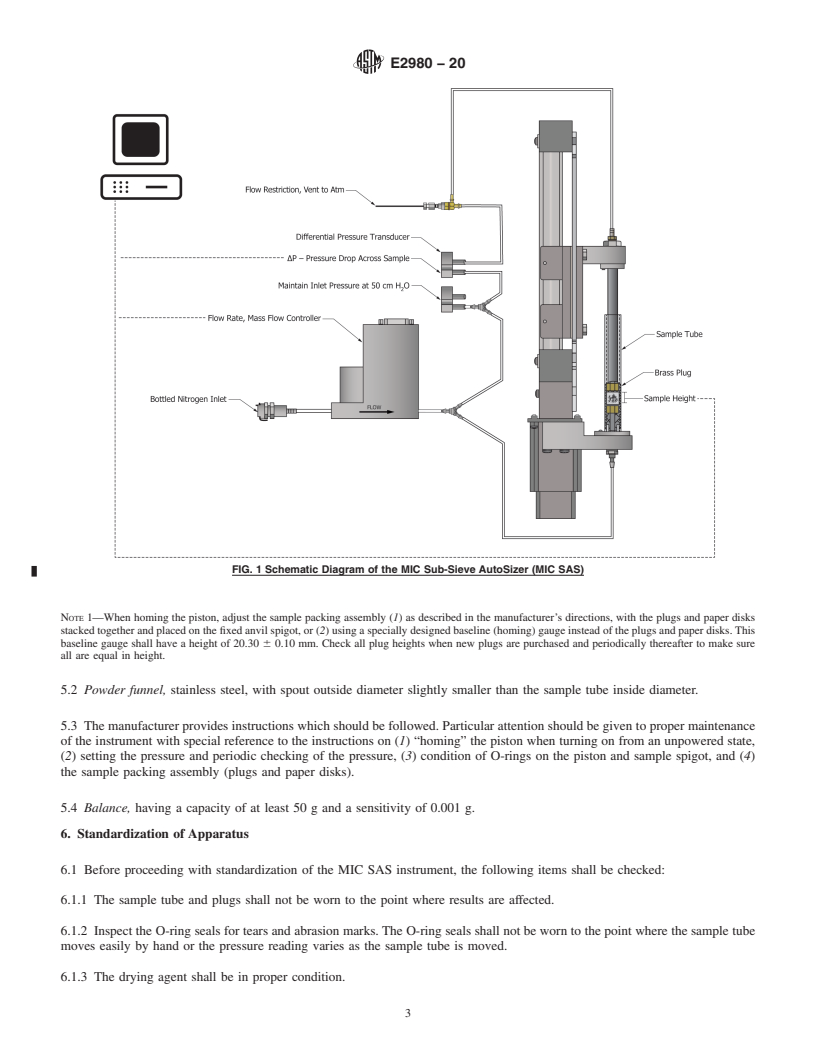

3.2.5 MIC Sub-Sieve AutoSizer (MIC SAS), n—a commer-

cially available permeability instrument for measuring

envelope-specific surface area and estimating average particle

1

These test methods are under the jurisdiction of ASTM Committee E29 on

size from 0.2 to 75 µm.

Particle and Spray Characterization and is the direct responsibility of Subcommittee

E29.02 on Non-Sieving Methods.

3.2.6 porosity of a bed of powder, n—ratio of the volume of

Current edition approved Oct. 1, 2020. Published October 2020. Originally

the void space in the powder bed to that of the overall volume

approved in 2014. Last previous edition approved in 2015 as E2980 – 15. DOI:

of the powder bed.

10.1520/E2980-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

----------------------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2980 − 15 E2980 − 20

Standard Test Methods for

Estimating Average Particle Size of Powders Using Air

1

Permeability

This standard is issued under the fixed designation E2980; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 These test methods use air permeability to determine an envelope-specific surface area and its associated average equivalent

spherical diameter (from 0.2 to 75 μm) of powders. Two test methods are described: One test method for inorganic materials (Test

Method 1), and another test method for organic materials (Test Method 2). The values obtained are not intended to be absolute

but are generally useful on a relative basis for control purposes.

1.2 Units—With the exception of the values for density and the mass used to determine density, for which the use of the gram per

3

cubic centimetre (g/cm ) and gram (g) units is the longstanding industry practice; and the units for pressure, cm H O—also O –

2

also long-standing practice; the values in SI units are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

B330 Test Methods for Estimating Average Particle Size of Metal Powders and Related Compounds Using Air Permeability

B859 Practice for De-Agglomeration of Refractory Metal Powders and Their Compounds Prior to Particle Size Analysis

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E1638 Terminology Relating to Sieves, Sieving Methods, and Screening Media

E2589 Terminology Relating to Nonsieving Methods of Powder Characterization

3

2.2 ISO Documents:

ISO 10070 Metallic Powders: Determinations of Envelope-Specific Surface Area from Measurements of the Permeability to Air

of a Powder Bed Under Steady-State Flow Conditions

3. Terminology

3.1 Definitions—Many terms used in this test method are defined in Terminologies E1638 and E2589.

1

These test methods are under the jurisdiction of ASTM Committee E29 on Particle and Spray Characterization and is the direct responsibility of Subcommittee E29.02

on Non-Sieving Methods.

Current edition approved Dec. 1, 2015Oct. 1, 2020. Published January 2016October 2020. Originally approved in 2014. Last previous edition approved in 20142015 as

E2980 – 14.15. DOI: 10.1520/E2980-15.10.1520/E2980-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2980 − 20

3.2 Definitions of Terms Specific to This Standard:

3.2.1 air permeability, n—measurement of air pressure drop across a packed bed of powder.

3.2.2 average particle size, n—for the purposes of these test methods only, an estimate of the equivalent average spherical particle

diameter, calculated from the measured envelope-specific surface area, assuming that all the powder particles are spherical and that

all are exactly the same size.

3.2.3 de-agglomeration, n—process used to break up agglomerates of particles.

3.2.4 envelope-specific surface area, n—specific surface area of a powder as determined by gas permeametry in accordance with

ISO 10070.

3.2.5 MIC Sub-Sieve AutoSizer (MIC SAS), n—a commercially available permeability instrument for mea

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.