ASTM F2203-13(2018)

(Test Method)Standard Test Method for Linear Measurement Using Precision Steel Rule

Standard Test Method for Linear Measurement Using Precision Steel Rule

SIGNIFICANCE AND USE

4.1 This test method provides a means for measuring linear dimensions. Accurate measurement of dimensions can be critical to meeting specifications and characterizing process performance.

4.2 This test method should not be applied to tolerance ranges of less than 3 mm (1/8 in.) when it is preferable that test error does not exceed 30 % of tolerance range. See Precision and Bias Section for gage repeatability and reproducibility results.

4.3 This test method does not address acceptability criteria. These need to be jointly determined by the user and producer of the product.

SCOPE

1.1 This test method covers the measurement of linear dimension of flexible packages and packaging materials. It is recommended for use with an allowable tolerance range of 3 mm (1/8 in.) or greater based on gage repeatability and reproducibility presented in the Precision and Bias section.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2203 − 13 (Reapproved 2018)

Standard Test Method for

Linear Measurement Using Precision Steel Rule

This standard is issued under the fixed designation F2203; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope looking at a measurement gage from different angles can cause

variation in the reporting of that measurement.

1.1 This test method covers the measurement of linear

dimension of flexible packages and packaging materials. It is

4. Significance and Use

recommended for use with an allowable tolerance range of 3

mm ( ⁄8 in.) or greater based on gage repeatability and 4.1 This test method provides a means for measuring linear

reproducibility presented in the Precision and Bias section. dimensions. Accurate measurement of dimensions can be

critical to meeting specifications and characterizing process

1.2 The values stated in either SI units or inch-pound units

performance.

are to be regarded separately as standard. The values stated in

each system may not be exact equivalents; therefore, each 4.2 This test method should not be applied to tolerance

system shall be used independently of the other. Combining ranges of less than 3 mm ( ⁄8 in.) when it is preferable that test

error does not exceed 30 % of tolerance range. See Precision

values from the two systems may result in non-conformance

with the standard. and Bias Section for gage repeatability and reproducibility

results.

1.3 This international standard was developed in accor-

dance with internationally recognized principles on standard-

4.3 This test method does not address acceptability criteria.

ization established in the Decision on Principles for the These need to be jointly determined by the user and producer

Development of International Standards, Guides and Recom-

of the product.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. 5. Apparatus

5.1 Precision Steel Rule:

2. Referenced Documents

5.1.1 Tempered steel rule in increments of ⁄64 in., 100ths, or

2.1 ASTM Standards: ⁄2 mm.

E171/E171M Practice for Conditioning and Testing Flexible 5.1.2 Steel rule should be of sufficient length to measure full

Barrier Packaging dimension of interest.

E691 Practice for Conducting an Interlaboratory Study to 5.1.3 It is recommended that a calibration be performed on

Determine the Precision of a Test Method the apparatus used and it is certified to a recognized industry

standard.

3. Terminology

6. Sampling

3.1 Definitions:

6.1 The number of samples tested should be adequate to be

3.1.1 linear dimension—the measurement of length, width

or relative positions. predictive of performance. Caution should be taken when

eliminating samples with defects as this can bias results.

3.1.2 parallax error—the error resulting from a change in

observational relationship to a fixed position. For example,

7. Conditioning

7.1 Conditioning of the samples will depend on the material

under evaluation. If conditioning before testing is appropriate,

This test method is under the jurisdiction ofASTM Committee F02 on Primary

Barrier Packaging and is the direct responsibility of Subcommittee F02.20 on normal, and desirable, refer to Specification E171/E171M.

Physical Properties.

Current edition approved Sept. 1, 2018. Published November 2018. Originally

8. Procedure

approved in 2002. Last previous edition approved in 2013 as F2203 – 13. DOI:

10.1520/F2203-13R18.

8.1 Review applicable specifications, drawings, or proce-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

dures. Specify unit of measure to be used and directions related

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

to precision requirements (for example, measure to nearest 0.5

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. mm, round up or down to nearest 0.5 mm, to ⁄64 in., etc.).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2203 − 13 (2018)

TABLE 1 Description of Materials Measured in Round Robin

end point of the measurement. Determine the measurement by

Studies

subtracting the start point measurement from the end point.

Measurement Measurement Ruler Scaling

Record the number in the unit of measure and precision

Material Type

Set Characteristic Applied

required by specification.

A Foil Web Web Width in.

B Paper Web Web Width in.

9. Report

C Spunbonded Olefin Web Web Width mm

D Printed Foil Web Print Repeat Length in.

9.1 Report the following information:

E Printed Paper Web Print Repeat Length in.

9.1.1 Lot number and source of material, date, time, loca-

F Printed Spunbonded Olefin Print Repeat Length mm

Web tion and operator of test and complete identification of mate-

G Forming Film Web Web Width mm

rials being tested,

H Finished Pouch Dimension A in.

9.1.2 Any conditioning of the materials,

I Finished Pouch Dimension B in.

J Finished Pouch Dimension C in. 9.1.3 Any and all deviations from standard, and

K Finished Pouch Dimension D in.

9.1.4 The sampling plan and number of specimens tested

L Finished Pouch Dimension E in.

along with test results.

M Finished Pouch Dimension F in.

10. Precision and Bias

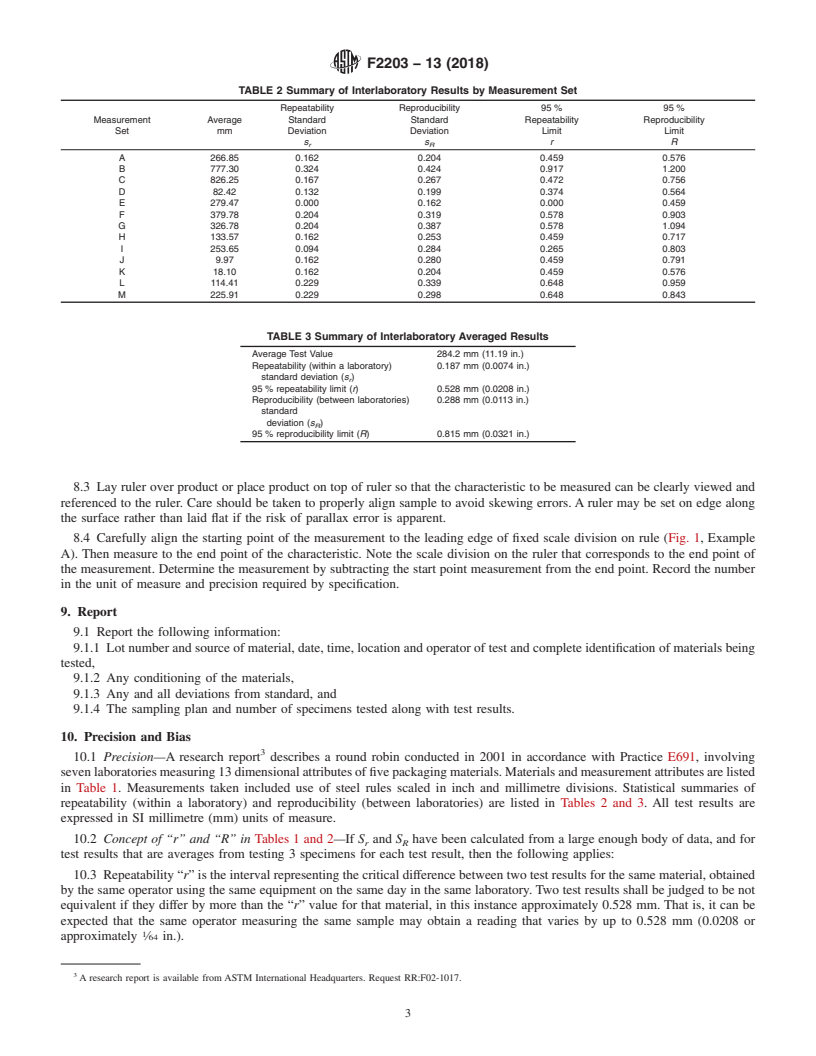

10.1 Precision—A research report describes a round robin

Depending upon the level of accuracy and visual acuity, image

conducted in 2001 in accordance w

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2203 − 13 F2203 − 13 (Reapproved 2018)

Standard Test Method for

Linear Measurement Using Precision Steel Rule

This standard is issued under the fixed designation F2203; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the measurement of linear dimension of flexible packages and packaging materials. It is

recommended for use with an allowable tolerance range of 3 mm ( ⁄8 in.) or greater based on gage repeatability and reproducibility

presented in the Precision and Bias section.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

E171E171/E171M Practice for Conditioning and Testing Flexible Barrier Packaging

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions:

3.1.1 linear dimension—the measurement of length, width or relative positions.

3.1.2 parallax error—the error resulting from a change in observational relationship to a fixed position. For example, looking

at a measurement gage from different angles can cause variation in the reporting of that measurement.

4. Significance and Use

4.1 This test method provides a means for measuring linear dimensions. Accurate measurement of dimensions can be critical

to meeting specifications and characterizing process performance.

4.2 This test method should not be applied to tolerance ranges of less than 3 mm ( ⁄8 in.) when it is preferable that test error

does not exceed 30 % of tolerance range. See Precision and Bias Section for gage repeatability and reproducibility results.

4.3 This test method does not address acceptability criteria. These need to be jointly determined by the user and producer of

the product.

5. Apparatus

5.1 Precision Steel Rule:

1 1

5.1.1 Tempered steel rule in increments of ⁄64 in., 100ths, or ⁄2 mm.

5.1.2 Steel rule should be of sufficient length to measure full dimension of interest.

5.1.3 It is recommended that a calibration be performed on the apparatus used and it is certified to a recognized industry

standard.

This test method is under the jurisdiction of ASTM Committee F02 on FlexiblePrimary Barrier Packaging and is the direct responsibility of Subcommittee F02.20 on

Physical Properties.

Current edition approved May 1, 2013Sept. 1, 2018. Published June 2013November 2018. Originally approved in 2002. Last previous edition approved in 20122013 as

F2203 – 02 (2012).F2203 – 13. DOI: 10.1520/F2203-13.10.1520/F2203-13R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2203 − 13 (2018)

TABLE 1 Description of Materials Measured in Round Robin

Studies

Measurement Measurement Ruler Scaling

Material Type

Set Characteristic Applied

A Foil Web Web Width in.

B Paper Web Web Width in.

C Spunbonded Olefin Web Web Width mm

D Printed Foil Web Print Repeat Length in.

E Printed Paper Web Print Repeat Length in.

F Printed Spunbonded Olefin Print Repeat Length mm

Web

G Forming Film Web Web Width mm

H Finished Pouch Dimension A in.

I Finished Pouch Dimension B in.

J Finished Pouch Dimension C in.

K Finished Pouch Dimension D in.

L Finished Pouch Dimension E in.

M Finished Pouch Dimension F in.

6. Sampling

6.1 The number of samples tested should be adequate to be predictive of performance. Caution should be taken when

eliminating samples with defects as this can bias results.

7. Conditioning

7.1 Conditioning of the samples will depend on the material under evaluation. If conditioning before testing is appropriate,

normal, and desirable, refer to Specification E171E171/E171M.

8. Procedure

8.1 Review applicable specifications, drawings, or procedures. Specify unit of measure to be used and directions related to

precision requirements (for example, measure to nearest 0.5 mm, round up or down to nearest 0.5 mm, to ⁄64 in., etc.). Depending

upon the level of accuracy and visual acuity, image magnification may be an aid.

8.2 Lay sample to be measured on flat surface with sufficient color contrast to distinguish the edge of the sample. Sample should

lay flat and smooth without wrinkles, creases or folds. Material should not be under tension when measured.

NOTE 1—Example A and Example B begin at the leading edge of fixed scale division on rule at a point within the scale, at 1 in. or 10 mm, for example.

FIG. 1 Proper Alignment to Ruler Scale Divisions

F2203 − 13 (2018)

TABLE 2 Summa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.