ASTM D3939-03(2004)

(Test Method)Standard Test Method for Snagging Resistance of Fabrics (Mace)

Standard Test Method for Snagging Resistance of Fabrics (Mace)

SCOPE

1.1 This test method determines the snagging resistance of a fabric.

1.2 Studies of fabric snagging have shown that this test method is suitable for a range of woven and knitted fabrics made from textured or untextured filament yarns or spun yarns or combinations of these yarns., This test method is not suitable for (1) open construction fabrics (such as a net) because the points on the mace will snag the felt pad rather than the specimen, (2) very heavy or very stiff fabrics that cannot be made to fit tightly on the drum and felt pad, and ( 3) tufted or nonwoven fabrics because the apparatus is designed for woven and knitted fabrics.

1.3 The values stated in either acceptable metric units or in other units shall be regarded separately as the standard. The values stated in each system may not be exact equivalents; therefore, each system must be used independently of the other, without combining values in any way. In case of referee decisions, the metric units will prevail.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3939–03 (Reapproved 2004)

Standard Test Method for

Snagging Resistance of Fabrics (Mace)

This standard is issued under the fixed designation D 3939; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 1335 Test Method for Tuft Bind of Pile Floor Coverings

D 1776 Practice for Conditioning and Testing Textiles

1.1 Thistestmethoddeterminesthesnaggingresistanceofa

D 2724 Test Methods for Bonded, Fused, and Laminated

fabric.

Apparel Fabrics

1.2 Studies of fabric snagging have shown that this test

D 3136 TerminologyRelatingtoCareLabelingforApparel,

method is suitable for a range of woven and knitted fabrics

Textile, Home Furnishing, and Leather Products

made from textured or untextured filament yarns or spun yarns

2,3

D 4467 Practice for InterlaboratoryTesting of aTextileTest

or combinations of these yarns. This test method is not

Method that Produces Non-Normally Distributed Data

suitable for (1) open construction fabrics (such as a net)

D 4850 Terminology Relating to Fabric

because the points on the mace will snag the felt pad rather

D 5362 Test Method for Snagging Resistance of Fabrics

than the specimen, (2) very heavy or very stiff fabrics that

(Bean Bag)

cannot be made to fit tightly on the drum and felt pad, and (3)

2.2 AATCC Standards:

tufted or nonwoven fabrics because the apparatus is designed

65 Test Method for Snag Resistance of Women’s Nylon

for woven and knitted fabrics.

Hosiery (see Note 1)

1.3 The values stated in either acceptable metric units or in

135 Test Method for Dimensional Changes in Automatic

other units shall be regarded separately as the standard. The

Home Laundering of Woven and Knit Fabrics

values stated in each system may not be exact equivalents;

therefore,eachsystemmustbeusedindependentlyoftheother,

NOTE 1—In 1988, theAATCC voted to withdraw this test method from

without combining values in any way. In case of referee

its technical manual; however, the ASTM task group on fabric snagging

decided it should be listed as an alternative for testing open construction

decisions, the metric units will prevail.

fabrics.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Terminology

responsibility of the user of this standard to establish appro-

3.1 For definitions of textile terms used in this test method:

priate safety and health practices and determine the applica-

(color contrast, in textiles; distortion, in fabrics; protrusion, in

bility of regulatory limitations prior to use. Specific precau-

fabrics; snag, in fabrics; snagging resistance, in fabrics), refer

tionary statements are given in Section 7.

to Terminology D 4850.

2. Referenced Documents 3.2 For definitions of other textile terms used in this test

4 method, refer to Terminology D 123.

2.1 ASTM Standards:

D 123 Terminology Relating to Textiles

4. Summary of Test Method

4.1 A tubular specimen is placed on a cylindrical drum.

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

Then a mace (spiked ball) bounces randomly against the

and is the direct responsibility of Subcommittee D13.59 on Fabric Test Methods,

rotating specimen. Snags are produced to a degree affected by

General.

a variety of factors. The degree of fabric snagging is then

Current edition approved Oct. 1, 2003. Published November 2003. Originally

approved in 1980. Last previous edition approved in 1997 as D 3939 – 97a.

evaluated by comparison of the tested specimens with visual

Finnigan, J. A., “Laboratory Prediction of the Tendency of a Fabric to Snag

standards that may be either fabrics or photographs of fabrics.

During Wear,” Textile Institute and Industry, Vol 10, No. 6, 1972, pp. 164–167.

Leung, P., and Hershkowitz, R., “Snag- and Fuzz-Resistant Double Knits via

Fabric Construction,” Textile Research Journal, Vol 45, No. 2, 1975, pp. 93–102.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standardsvolume information, refer to the standard’s Document Summary page on Available from American Association of Textile Chemists and Colorists, P.O.

the ASTM website. Box 12215, Research Triangle Park, NC 27709.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3939–03 (2004)

The observed resistance to snagging is reported on a scale snags. See Section 13 for a description of color contrast,

ranging from 5 (no or insignificant snagging) to 1 (very severe distortion, and protrusion as used in this test method; and see

snagging). Figs. 1 through 3 in Test Method D 5362 for pictures of fabric

defects due to snagging. Because the overall acceptability of a

5. Significance and Use

specific fabric is dependent on both the characteristics of the

5.1 This test method is not considered satisfactory for

snags and other factors affecting fabric appearance, it is

acceptance testing of commercial shipments of fabrics because

recommended that fabrics tested in the laboratory be evaluated

thebetween-laboratoryprecisionofthetestmethodispoor(see

with regard to the defects that may be observed visually and

15.1).

not rated solely on the number of snags developed.Aseries of

5.1.1 If there are differences of practical significance be-

visual rating standards (see 6.3.5) may be set up to provide a

tween reported test results for two laboratories (or more),

basis for the ratings. The visual rating standards are most

comparative test should be performed to determine if there is a

advantageous when the tested laboratory specimens correlate

statisticalsignificantdifferencebetweenthem,usingcompetent

closely in appearance with fabrics from a wear test, for

statistical assistance. As a minimum, use the samples for such

example, when tested laboratory specimens and fabrics from a

a comparative test that are as homogeneous as possible, drawn

wear test show similar color contrasts. In the preceding

from the same lot of material as the samples that resulted in

example, a series of fabrics from the wear test would be a good

disparateresultsduringinitialtestingandrandomlyassignedin

choice for the fabric standards described in 6.3.5.2.

equal numbers to each laboratory. The test results from the

laboratories involved should be compared using a statistical

6. Apparatus and Materials

test for unpaired data, at a probability level chosen prior to the

6.1 Procedure 1:

testing series. If bias is found, either its cause must be found 6

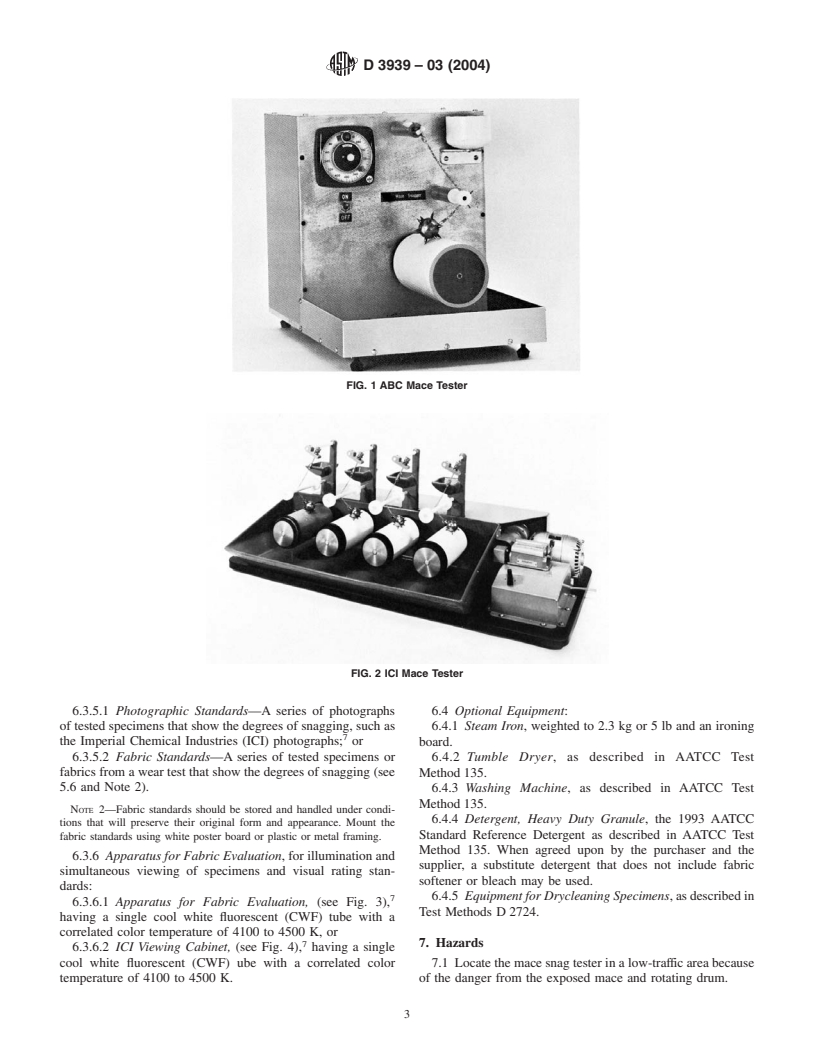

6.1.1 ABC Snag Tester —(see Fig. 1).

and corrected or future testing for that material must be 6

6.1.2 Specimen Template, 150 by 330 mm or 6 by 13 in.

adjusted in consideration of the statistically significant differ- 7

6.1.3 Felt, for 150- by 330-mm or 6- by 13-in. pads.

ences. 6

6.1.4 Gage, for ABC Snag Tester, for setting position of

5.2 This test method may be used for quality control testing

mace (calibration block).

of fabrics during manufacturing and product comparisons of

6.1.5 MaskingTape,25-mmor1-in.single-face,and50-mm

differentfabricsbymanufacturers,retailers,andusers.Thistest

or 2-in. double face.

method may also be used by researchers to examine the effect

6.2 Procedure 2:

of new fibers, yarns, fabric constructions, and finishes on the 7

6.2.1 ICI Mace Snag Tester (see Fig. 2).

snagging resistance of fabrics.

6.2.2 SpecimenTemplates,205by330mmor8by13in.for

5.3 This test method may be used to test the snagging

weftknitfabricsand205by320mmor8by12.5in.forwoven

resistance of most apparel and home furnishings fabrics.

fabrics and warp knit fabrics.

However, a different test method may be needed for different

6.2.3 Felt Sleeves, Green S/924 (70 % wool, 30 % rayon),

types of fabrics and different end-uses (such as towels, pants,

1.6 mm or 1/16 in. in thickness, approximately 235 g/m 2 or 7

and upholstery) (see 5.3.1). 7

oz/yd

5.3.1 Some fabrics that may not be suitable for this test 7

6.2.4 Gage, for ICI Mace Snag Tester, for setting position

method are described in 1.2. Many open construction fabrics

of mace (calibration block).

can be tested for snagging resistance using AATCC Test 7

6.2.5 Rubber O-Rings.

Method 65. The snagging resistance of many pile floor

6.3 Both Procedures:

coverings can be tested by Test Method D 1335. Test Method

6.3.1 Sewing Machine, with a sewing needle that is appro-

D 5362 (Bean Bag) may also be considered as an alternative

priate for the fabric being tested for snagging resistance, or

for testing the snagging resistance of fabrics.

6.3.2 Sharps Hand Sewing Needle.

5.4 Since fabric snagging can be affected by laundering or

6.3.3 Sewing Thread, cotton, Tex ticket 35 to 50, or equiva-

drycleaning, it may be advisable to test the snagging resistance

lent polyester and cotton.

of a fabric before and after laundering or drycleaning.

6.3.4 Standard Calibration Fabric, having an established

5.5 The snagging resistance of a specific fabric varies with

snagging resistance rating that has been agreed upon by the

individual wearers and general conditions of use. Therefore, it

purchaser and the supplier. (No standard calibration fabric has

can be expected that garments of the same fabric will show a

been specified by Subcommittee D13.59.)

fairly wide snagging resistance spectrum after wear and much

6.3.5 Visual Rating Standards:

greater variation in wear than in replicate fabric specimens

subjected to controlled laboratory tests. This factor should be

considered when adopting levels of acceptability for any

No company is currently manufacturing the ABC Snag Tester and there is no

specification that includes snagging resistance.

known supplier of parts for this tester. Information on the ABC Mace Tester is

5.6 Snags observed in worn garments vary appreciably in

included in this test method because the tester is still being used to determine fabric

number and appearance. The appearance of a snag depends

snagging. The sole source of supply of equipment and supplies known to the

committee at this time is shown in footnotes 8 and 9. If you are aware of alternative

particularly on (1) the degree of color contrast between the

suppliers, please provide this information to ASTM headquarters. Your comments

snag and the surrounding area of the fabric or (2) the presence

will receive careful consideration at a meeting of the responsible technical

of long distortions or long protrusions. These conditions are

committee, which you may attend.

not evaluated when snagging is rated solely on the number of Available from SDLAtlas LLC, 1813AAssociates Lane, Charlotte, NC 28217.

D3939–03 (2004)

FIG. 1 ABC Mace Tester

FIG. 2 ICI Mace Tester

6.3.5.1 Photographic Standards—A series of photographs 6.4 Optional Equipment:

of tested specimens that show the degrees of snagging, such as 6.4.1 Steam Iron, weighted to 2.3 kg or 5 lb and an ironing

the Imperial Chemical Industries (ICI) photographs; or

board.

6.3.5.2 Fabric Standards—A series of tested specimens or

6.4.2 Tumble Dryer, as described in AATCC Test

fabrics from a wear test that show the degrees of snagging (see

Method 135.

5.6 and Note 2).

6.4.3 Washing Machine, as described in AATCC Test

Method 135.

NOTE 2—Fabric standards should be stored and handled under condi-

6.4.4 Detergent, Heavy Duty Granule, the 1993 AATCC

tions that will preserve their original form and appearance. Mount the

fabric standards using white poster board or plastic or metal framing. Standard Reference Detergent as described in AATCC Test

Method 135. When agreed upon by the purchaser and the

6.3.6 Apparatus for Fabric Evaluation, for illumination and

supplier, a substitute detergent that does not include fabric

simultaneous viewing of specimens and visual rating stan-

softener or bleach may be used.

dards:

7 6.4.5 EquipmentforDrycleaningSpecimens,asdescribedin

6.3.6.1 Apparatus for Fabric Evaluation, (see Fig. 3),

Test Methods D 2724.

having a single cool white fluorescent (CWF) tube with a

correlated color temperature of 4100 to 4500 K, or

7. Hazards

6.3.6.2 ICI Viewing Cabinet, (see Fig. 4), having a single

cool white fluorescent (CWF) ube with a correlated color 7.1 Locate the mace snag tester in a low-traffic area because

temperature of 4100 to 4500 K. of the danger from the exposed mace and rotating drum.

D3939–03 (2004)

Metric Equivalents

in. mm in. mm

⁄32 1 8 203

0.7 18 8 ⁄2 215

2 50 12 305

4 100 15 380

1 1

6 ⁄4 159 21 ⁄4 540

6 ⁄16 160 37 940

7 ⁄2 190 40 1020

FIG. 3 Apparatus for Fabric Evaluation

FIG. 4 ICI Viewing Cabinet

D3939–03 (2004)

7.2 Check that all parts of the mace snag tester are secure randomize the specimens in such a manner that no two contain

and are in good working condition. the same set of yarns. Mark each specimen near an edge to

7.3 Wear protective gloves when examining the points on indicate the following: (1) the face side that will later be tested

the mace snag tester or removing fibers and yarns from the for snagging resistance, and (2) the type of specimen (

mace points. lengthwise or widthwise direction).

7.4 Observe the following safety precautions when operat- 9.2.1 Similarly cut specimens from laundered or drycleaned

ing the tester: (1) do not wear loose or dangling clothing that swatches, when required.

can get caught in the mace points or moving parts; (2)donot 9.3 Fold each specimen face side in and form a sleeve by

attempt to change a specimen while the drum is rotating; and sewing a seam parallel to the shorter dimension of the

(3) do not injure your hands on the sharp mace points when specimen at a distance from the edge sufficient for a tight fit on

placing a specimen on the drum. the drum (see Note 4). Use a minimum of 0.4 stitches/mm or

10 stitches/in. when machine or hand sewing the seam.

8. Sampling

NOTE 4—It might be necessary to vary the distance of the seam line

8.1 Lot Sample—As a lot sample for acceptance testing,

from the short edges to have a good running test specimen that is smooth

take at random the number of rolls of fabric directed in an

and snug on the drum. The ICI Mace Snag Tester is supplied with a

template for cutting out and marking weft knit fabrics and a template for

applicable material specification or other agreement between

cutting out and marking woven fabrics and warp knit fabrics. The weft

thepurchaserandthesupplier.Considerrollsoffabrictobethe

knit templat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.