ASTM D6391-99

(Test Method)Standard Test Method for Field Measurement of Hydraulic Conductivity Limits of Porous Materials Using Two Stages of Infiltration from a Borehole

Standard Test Method for Field Measurement of Hydraulic Conductivity Limits of Porous Materials Using Two Stages of Infiltration from a Borehole

SCOPE

1.1 This test method covers field measurement of limiting values for vertical and horizontal hydraulic conductivities (also referred to as coefficients of permeability) of porous materials using the two-stage, cased borehole technique. These limiting hydraulic conductivity values are the maximum possible for the vertical direction and minimum possible for the horizontal direction. Determination of actual hydraulic conductivity values requires further analysis by qualified personnel.

1.2 This test method may be utilized for compacted fills or natural deposits, above or below the water table, that have a mean hydraulic conductivity less than or equal to 1X10-15 m/s (1X10-3 cm/s).

1.3 Hydraulic conductivity greater than 1X10-5 m/s may be determined by ordinary borehole tests, for example, U.S. Bureau of Reclamation 7310 (1); however, the resulting value is an apparent conductivity.

1.4 For this field test method, a distinction must be made between "saturated" (Ks) and "field-saturated" (Kfs) hydraulic conductivity. True saturated conditions seldom occur in the vadose zone except where impermeable layers result in the presence of perched water tables. During infiltration events or in the event of a leak from a lined pond, a "field-saturated" condition develops. True saturation does not occur due to entrapped air (2). The entrapped air prevents water from moving in air-filled pores that, in turn, may reduce the hydraulic conductivity measured in the field by as much as a factor of two compared to conditions when trapped air is not present (3). This field test method simulates the "field-saturated" condition.

1.5 Experience with this test method has been predominantly in materials having a degree of saturation of 70 % or more, and where the stratification or plane of compaction is relatively horizontal. Its use in other situations should be considered experimental.

1.6 As in the case of all tests for hydraulic conductivity, the results of this test pertain only to the volume of soil permeated. Extending the results to the surrounding area requires both multiple tests and the judgment of qualified personnel. The number of tests required depends on among other things: the size of the area, the uniformity of the material in that area, and the variation in data from multiple tests.

1.7 The values stated in SI units are to be regarded as the standard unless other units specifically are given. By tradition in U.S. practice, hydraulic conductivity is reported in cm/s although the common SI units for hydraulic conductivity are m/s.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. This test method does not purport to address environmental protection problems, as well.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 6391 – 99

Standard Test Method for

Field Measurement of Hydraulic Conductivity Limits of

Porous Materials Using Two Stages of Infiltration from a

Borehole

This standard is issued under the fixed designation D 6391; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 As in the case of all tests for hydraulic conductivity, the

results of this test pertain only to the volume of soil permeated.

1.1 This test method covers field measurement of limiting

Extending the results to the surrounding area requires both

values for vertical and horizontal hydraulic conductivities (also

multiple tests and the judgment of qualified personnel. The

referred to as coeffıcients of permeability) of porous materials

number of tests required depends on among other things: the

using the two-stage, cased borehole technique. These limiting

size of the area, the uniformity of the material in that area, and

hydraulic conductivity values are the maximum possible for

the variation in data from multiple tests.

the vertical direction and minimum possible for the horizontal

1.7 The values stated in SI units are to be regarded as the

direction. Determination of actual hydraulic conductivity val-

standard unless other units specifically are given. By tradition

ues requires further analysis by qualified personnel.

in U.S. practice, hydraulic conductivity is reported in cm/s

1.2 This test method may be utilized for compacted fills or

although the common SI units for hydraulic conductivity are

natural deposits, above or below the water table, that have a

–5

m/s.

mean hydraulic conductivity less than or equal to 1310 m/s

–3

1.8 This standard does not purport to address the safety

(1310 cm/s).

–5

concerns, if any, associated with its use. It is the responsibility

1.3 Hydraulic conductivity greater than 1310 m/s may be

of the user of this standard to establish appropriate safety and

determined by ordinary borehole tests, for example, U.S.

health practices and determine the applicability of regulatory

Bureau of Reclamation 7310(1) ; however, the resulting value

limitations prior to use. This test method does not purport to

is an apparent conductivity.

address environmental protection problems, as well.

1.4 For this field test method, a distinction must be made

between “saturated” (K ) and “field-saturated” (K ) hydraulic

s fs

2. Referenced Documents

conductivity. True saturated conditions seldom occur in the

2.1 ASTM Standards:

vadose zone except where impermeable layers result in the

D 653 Terminology Relating to Soil, Rock, and Contained

presence of perched water tables. During infiltration events or

Fluids

in the event of a leak from a lined pond, a “field-saturated”

D 1452 Practice for Soil Investigation and Sampling by

condition develops. True saturation does not occur due to

2 Auger Borings

entrapped air (2). The entrapped air prevents water from

D 1587 Practice for Thin-Walled Tube Geotechnical Sam-

moving in air-filled pores that, in turn, may reduce the

pling of Soils

hydraulic conductivity measured in the field by as much as a

D 2937 Test Method for Density of Soil in Place by the

factor of two compared to conditions when trapped air is not

Drive-Cylinder Method

present (3). This field test method simulates the “field-

D 3740 Practice for Minimum Requirements for Agencies

saturated” condition.

Engaged in the Testing and/or Inspection of Soil and Rock

1.5 Experience with this test method has been predomi-

as Used in Engineering Design and Construction

nantly in materials having a degree of saturation of 70 % or

D 5084 Test Method for Measurement of Hydraulic Con-

more, and where the stratification or plane of compaction is

ductivity of Saturated Porous Materials Using a Flexible

relatively horizontal. Its use in other situations should be

Wall Permeameter

considered experimental.

D 5092 Practice for Design and Installation of Ground

Water Monitoring Wells in Aquifers

D 5126 Guide for Comparison of Field Methods for Deter-

This test method is under the jurisdiction of ASTM Committee D-18 on Soil

mining Hydraulic Conductivity in the Vadose Zone

and Rock and is the direct responsibility of Subcommittee D18.04 on Hydrologic

Properties of Soil & Rock.

Current edition approved April 10, 1999. Published July 1999.

The boldface numbers in parentheses refer to the list of references at the end of

this standard. Annual Book of ASTM Standards, Vol 04.08.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6391–99

3. Terminology liners such as those used for retention ponds or storage tanks.

Due to the boundary condition assumptions used in deriving

3.1 Definitions—For definitions of terms used in this test

the equations for the limiting hydraulic ocnductivities, the

method, see Terminology D 653.

thickness of the unit tested must be at least six times the test

3.2 Definitions of Terms Specific to This Standard:

diameter. This requirement must be increased to eight test

3.2.1 horizontal conductivity, k , n—the hydraulic conduc-

h

diameters if the barrier is not underlain by a drainage blanket

tivity in (approximately) the horizontal direction.

or by a material far less permeable than the barrier being tested.

3.2.2 hydraulic conductivity, (coeffıcient of permeability) k,

5.3 The soil layer being tested must have sufficient cohesion

n—the rate of discharge of water under laminar flow conditions

to stand open during excavation of the borehole.

through a unit cross-sectional area of a porous medium under

5.4 This test method provides a means to measure infiltra-

a unit hydraulic gradient and standard temperature conditions

tion rate into a moderately large volume of soil. Tests on large

(20°C).

volumes of soil can be more representative than tests on small

3.2.2.1 Discussion—The term coeffıcient of permeability

volumes of soil. Multiple installations properly spaced provide

often is used instead of hydraulic conductivity, but hydraulic

a greater volume and an indication of spatial variability.

conductivity is used exclusively in this test method. A more

5.5 The data obtained from this test method are most useful

complete discussion of the terminology associated with Dar-

when the soil layer being tested has a uniform distribution of

cy’s law is given in the literature (4). It should be noted that

hydraulic conductivity and of pore space and when the upper

both natural soils and recompacted soils usually are not

and lower boundary conditions of the soil layer are well

isotropic with respect to hydraulic conductivity. Except for

defined.

unusual materials, k > k .

h v

5.6 Changes in water temperature can introduce significant

3.2.3 limiting horizontal conductivity, K2, n—the hydraulic

errors in the flow measurements. Temperature changes cause

conductivity as determined in Stage 2 of this test method,

fluctuations in the standpipe levels, which are not related to

assuming the tested medium to be isotropic. For ordinary soils,

flow. This problem is most pronounced when a small diameter

both compacted and natural, this is the minimum possible

standpipe is used in soils having hydraulic conductivities of 5

value for k .

h

–10

3 10 m/s or less.

3.2.4 limiting vertical conductivity, K1, n—the hydraulic

5.7 The effects of temperature changes are taken into

conductivity as determined in Stage 1 of this test method,

account by the use of a dummy installation, the temperature

assuming the tested medium to be isotropic. For ordinary soils,

effect gage (TEG). The base of the TEG must be sealed to

both compacted and natural, this is the maximum possible

prevent flow. The fluctuations of the TEG are due solely to

value for k .

v

ambient changes and are used to correct the readings at the

3.2.5 test diameter, n—the inside diameter (ID) of the

flowing tests.

casing.

3.2.6 vertical conductivity, k , n—the hydraulic conductiv- 5.8 If the soil being tested will later be subjected to

v

increased overburden stress, then the hydraulic conductivities

ity in (approximately) the vertical direction.

can be expected to decrease as the overburden stress increases.

Laboratory hydraulic conductivity tests or these tests under

4. Summary of Test Method

varying surface loads are recommended for studies of the

4.1 The rate of flow of water into soil through the bottom of

influence of level of stress on the hydraulic properties of the

a sealed, cased borehole is measured in each of two stages,

soil.

normally with a standpipe in the falling-head procedure. The

standpipe can be refilled as necessary.

NOTE 1—Notwithstanding the statements on precision and bias con-

4.2 In Stage 1, the bottom of the borehole is flush with the

tained in this standard: the precision of this test method is dependent on

the competence of the personnel performing it and the suitability of the

bottom of the casing for maximum effect of k . The test is

v

equipment and the facilities used. Agencies that meet the criteria of

continued until the flow rate becomes quasi-steady.

Practice D 3740 are generally considered capable of competent and

4.3 For Stage 2, the borehole is extended below the bottom

objective testing. Users of this test method are cautioned that compliance

of the casing for maximum effect of k . This stage of the test

h

with Practice D 3740 does not in itself assure reliable testing. Reliable

also is continued until the flow rate becomes quasi-steady.

testing depends on many factors; Practice D 3740 provides a means of

4.4 The direct results of the test are the limiting hydraulic

evaluating some of those factors.

conductivities K1 and K2. The actual hydraulic conductivities

6. Apparatus

k and k can be calculated from these values (5).

v h

6.1 Boring/Reaming Tools:

5. Significance and Use

6.1.1 Drilling Equipment—Equipment must be available to

5.1 This test method provides a means to measure both the advance the borehole to the desired test level. This borehole

maximum vertical and minimum horizontal hydraulic conduc- diameter must be at least 5 cm (2 in.) larger than the outside

tivities, especially in the low ranges associated with fine- diameter of the casing. The auger or bit used to advance the

–7 –11

grained clayey soils, 1310 m/s to 1310 m/s. borehole below the casing for Stage 2 shall have a diameter

5.2 This test method particularly is useful for measuring about 1 cm ( ⁄2 in.) less than the inside diameter of the casing.

liquid flow through soil moisture barriers such as compacted For tests in compacted materials above the water table, and

clay liners or covers used at waste disposal facilities, for canal wherever else possible, the borehole shall be advanced by dry

and reservoir liners, for seepage blankets, and for amended soil augering. Either hand or mechanical augers are acceptable.

D6391–99

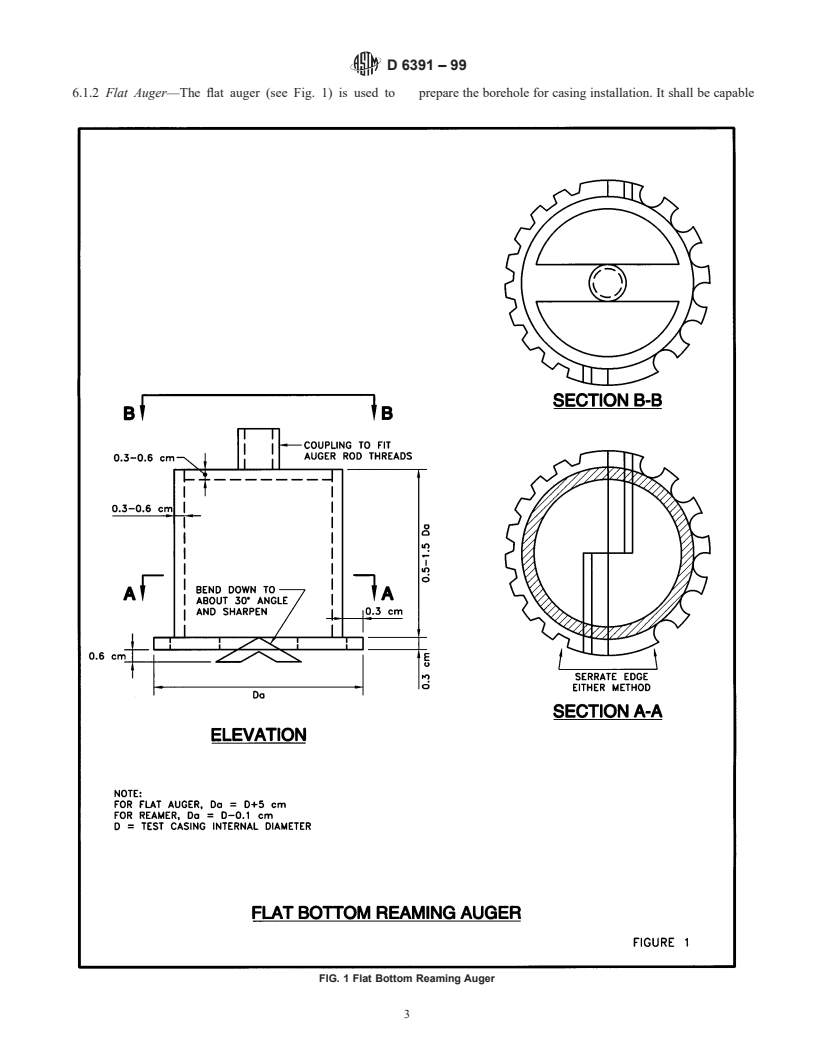

6.1.2 Flat Auger—The flat auger (see Fig. 1) is used to prepare the borehole for casing installation. It shall be capable

FIG. 1 Flat Bottom Reaming Auger

D6391–99

of reaming the bottom of the borehole to a level plane diameter of pellets or granules selected should be less than one

perpendicular to the borehole axis. The flat auger shall have a fifth the width of the annular space into which they are placed.

diameter about 5 cm (2 in.) larger than the outside diameter of

The directly placed sealant shall extend to the ground surface

the casing.

or to a minimum of1m(3ft) above the bottom of the casing,

6.1.3 Reamer—The reamer (see Fig. 1) is used to complete

whichever is lesser. Either the placed sealant or the grouted

the Stage 2 cavity. The base of the reamer shall be capable of

sealant shall extend to the ground surface.

reaming the bottom of the advanced borehole to a level plane,

6.2.3.2 Grouted Sealant—The annular space may be

perpendicular to the borehole axis, and having the inside

grouted above the placed sealant. Any of the grouting methods

diameter of the casing. The bottom plate of the reamer shall

specified in Practice D 5092 may be used.

have a diameter about 0.1 cm (0.04 in.) less than the inside

6.2.3.3 Sock—The sock protects the soil at the bottom of the

diameter of the casing. The vertical side of the cutting plate

casing from disturbance when water is introduced and prevents

shall be serrated.

collapse of the Stage 2 cavity. It is a cylinder composed of a

6.1.4 Scarifier—A bent fork, wire brush, or similar rough-

semi-rigid, porous sidewall and bottom (such as a geogrid),

ener small enough to fit easily within the casing and having a

lined with a geotextile, and filled with pea gravel or other

handle long enough to reach the bottom of Stage 2, is used to

highly pervious material. The hydraulic conductivity of all

roughen the walls of the Stage 2 cavity.

sock materials shall be at least ten times the anticipated

6.2 Borehole Casing:

hydraulic conductivity of the tested stratum in the horizontal

6.2.1 Casing—The casing shall be watertight but may be of

direction. The outer diameter is 0.6 cm ( ⁄4 in.) less than the

any material or diameter. Its minimum ID shall be 10 cm (4 in.)

inner diameter of the casing. The length is approximately 8 cm

unless the clearance provisions specified in 7.7 cannot be met.

(3 in.) longer than will be the borehole extension for Stage 2.

In such cases only, the ID may be reduced to 7.5 cm (3 in.). The

Wires or other suitable means for retrieving the sock should be

wall thickness shall be adequate to prevent collapse under the

provided.

lateral pressure of the overburden and swelling bentonite.

Standard 10-cm (4-in.) ID Schedule 40 PVC threaded pipe is

6.3 Pressure/Flow System:

satisfactory. The bottom of the casing shall be cut off smooth

6.3.1 Flow Control System—The plumbing for the flow

and square. The casing shall have flush threads; external

control system is illustrated on Fig. 2. It can be composed of

couplers interfere with sealing the annulus and internal cou-

metal or plastic components. All flow system components shall

plers with advancing the borehole for Stage 2. Neither shall be

have a diameter of at least 75 % that of the standpipe. Nominal

used. The top of the casing shall be provided with a means of

13-mm (0.5-in.) components have been satisfactory for 10-cm

attaching the top assembly. Typical modifications include

(4-in.) diameter tests.

threading the top or attaching a flange. When threads are used,

6.3.2 Standpipe—The standpipe, also shown on Fig. 2,

they must be flush. When a flange is used,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.