ASTM D6723-01

(Test Method)Standard Test Method for Determining the Fracture Properties of Asphalt Binder in Direct Tension (DT)

Standard Test Method for Determining the Fracture Properties of Asphalt Binder in Direct Tension (DT)

SCOPE

1.1 This test method covers the determination of the failure strain and failure stress of asphalt binders by means of a direct tension test. It can be used with unaged material or with material aged using Test Method D 2872 (RTFOT), Practice D 6521 (PAV), or AASHTO T240 (RTFOT) and AASHTO PP1 (PAV). The test apparatus is designed for testing within the temperature range from +6 to -36°C.

1.2 This test method is limited to asphalt binders containing particulate material having dimensions less than 250 μm.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 6723 – 01

Standard Test Method for

Determining the Fracture Properties of Asphalt Binder in

Direct Tension (DT)

This standard is issued under the fixed designation D 6723; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 83 Practice for Verification and Classification of Exten-

someters

1.1 This test method covers the determination of the failure

E 220 Test Method for Calibration of Thermocouples by

strain and failure stress of asphalt binders by means of a direct

Comparison Techniques

tension test. It can be used with unaged material or with

2.2 Deutche Industrie Norm (DIN) Standard:

material aged using Test Method D 2872 (RTFOT), Practice

43760 Standard for Calibrating Thermocouples

D 6521 (PAV), or AASHTO T240 (RTFOT) and AASHTO PP1

2.3 AASHTO Standards:

(PAV). The test apparatus is designed for testing within the

T 240

temperature range from +6 to -36°C.

PPI (PAV)

1.2 This test method is limited to asphalt binders containing

particulate material having dimensions less than 250 μm.

3. Terminology

1.3 The values stated in SI units are to be regarded as the

3.1 Definitions—For definitions of general terms used in

standard.

this standard, refer to Terminology D 8.

1.4 This standard does not purport to address all of the

3.2 Definitions of Terms Specific to This Standard:

safety concerns, if any, associated with its use. It is the

3.2.1 brittle, adj—type of failure in a direct tension test

responsibility of the user of this standard to establish appro-

where the stress-strain curve is essentially linear up to the point

priate safety and health practices and determine the applica-

of failure and the failure is by sudden rupture of the test

bility of regulatory limitations prior to use.

specimen without appreciable reduction in cross-section of the

2. Referenced Documents specimen.

3.2.2 brittle-ductile, adj—type of failure in a direct tension

2.1 ASTM Standards:

test where the stress-strain curve is curvilinear and the failure

C 670 Practice for Preparing Precision and Bias Statements

is by sudden rupture of the test specimen. Limited reduction in

for Test Methods for Construction Materials

cross-section of the specimen occurs before rupture.

D 8 Terminology Relating to Materials for Roads and Pave-

3.2.3 ductile, adj—type of failure in a direct tension test

ments

where the specimen does not rupture but fails by flow at large

D 140 Practice for Sampling Bituminous Materials

strains.

D 2872 Test Method for Effect of Heat and Air on a Moving

3.2.4 effective gage length, n—for specimens used in this

Film of Asphalt (Rolling Thin-Film Oven Test)

test, the effective gauge length, L , has been determined to be

e

D 6373 Specification for Performance Graded Asphalt

3 33.8 mm. This is an effective gauge length that represents the

Binder

portion of the specimen that contributes to the majority of the

D 6521 Practice for Accelerated Aging of Asphalt Binder

3 strain.

Using a Pressurized Aging Vessel (PAV)

3.2.5 failure, n—point at which the tensile load reaches a

E 1 Specification for ASTM Thermometers

5 maximum value as the test specimen is pulled at a constant rate

E 4 Practices for Force Verification of Testing Machines

of elongation.

E 77 Test Method for the Inspection and Verification of

4 3.2.6 failure strain, n—the tensile strain corresponding to

Thermometers

the failure stress.

3.2.7 failure stress, n—the tensile stress on the test speci-

This test method is under the jurisdiction of ASTM Committee D04 on Road

men when the load reaches a maximum value during the test

and Paving Materials and is the direct responsibility of Subcommittee D04.44 on

Rheological Tests. method specified in this standard.

Current edition approved Nov. 10, 2001. Published December 2001. Originally

published as D 6723 – 01.

2 6

Annual Book of ASTM Standards, Vol 04.02. Deutsches Institut fur Normung e.V. (German Standards Institute), Beuth

Annual Book of ASTM Standards, Vol 04.03. Verlag GmbH, Burggrafenstrasse 6, 10787, Berlin Germany.

4 7

Annual Book of ASTM Standards, Vol 14.03. Available from the American State Highway and Transportation Officials, 444

Annual Book of ASTM Standards, Vol 03.01. N. Capitol Street, N.W., Washington, DC 20001.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 6723

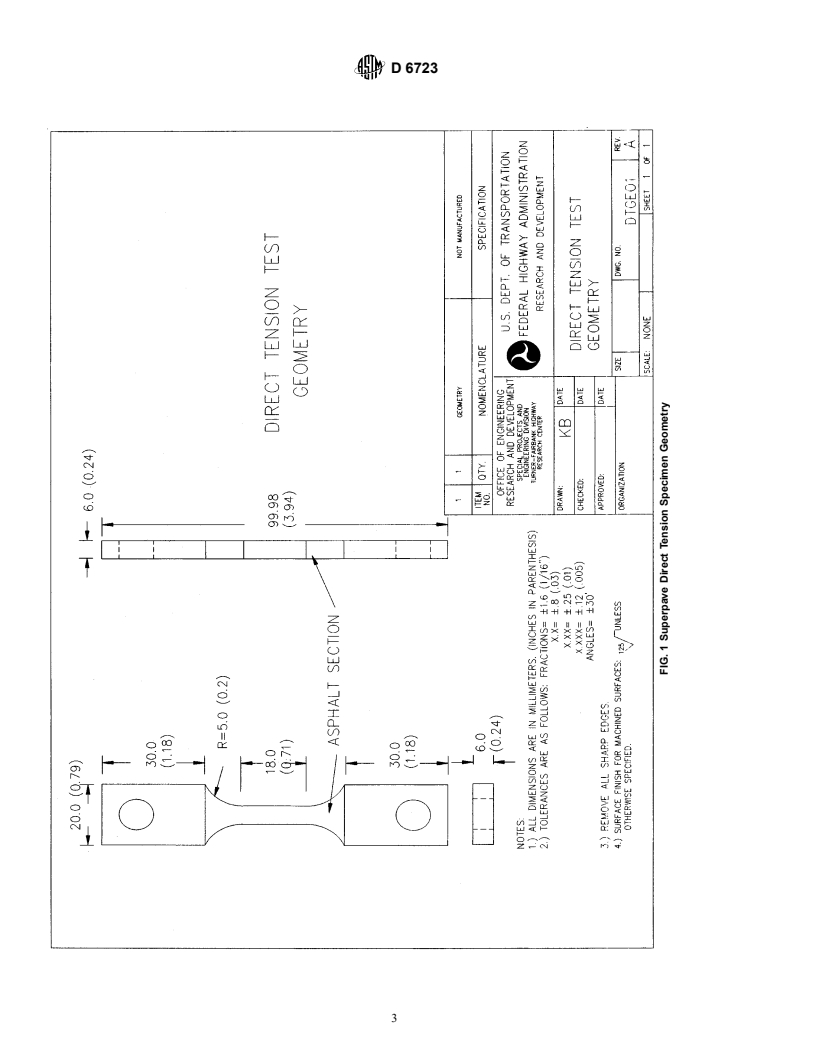

3.2.8 gage section, n—the central portion of the specimen reliable, accurate and uniform temperature control during

where the cross-section does not change with length. For the

testing and conditioning of specimen, (4) real-time load mea-

geometry used in this test method, the gage section is 18 mm suring and recording devices, (5) real-time elongation measur-

in length (see Fig. 1).

ing and recording devices, (6) a real-time temperature detec-

3.2.9 tensile strain, n—axial strain resulting from the appli- tion and recording device, and (7) real-time data acquisition

cation of a tensile load and calculated as the change in length

and display devices. The system shall have an electro-

of the effective gage length caused by the application of the mechanical or servo-hydraulic loading unit capable of applying

tensile load divided by the original unloaded effective gage

and measuring tension and compression forces of at least 500

length.

N and actuator travel of 20 mm. The system stiffness shall be

3.2.10 tensile stress, n—axial stress resulting from the

at least 3 MN/m including the load cell and the loading pins.

application of a tensile load and calculated as the tensile load

The unit shall have a transducer to measure and control grip

divided by the original area of cross-section of the specimen.

separation and provide a feedback for strain control with a

displacement resolution of 1.0 μm. The system shall be capable

4. Summary of Test Method

of closed loop elongation rate control accurate to at least 1 %

4.1 This test method describes the procedure used to mea-

of the commanded specimen elongation rate using feedback

sure the stress at failure and strain at failure in an asphalt binder

from a displacement transducer mounted between the loading

test specimen pulled at a constant rate of elongation. Test

pins or a non-contact extensometer measuring the elongation of

specimens are prepared by pouring hot asphalt binder into a

the specimen.

suitable mold. Two plastic end tabs are used to bond the asphalt

6.1.1 Tensile Loading Machine Equipped With Temperature

binder during the test and to transfer the tensile load from the

Control—A tensile loading machine with a controlled-

test machine to the asphalt binder.

displacement loading frame capable of producing at least a

4.2 This test method was developed for asphalt binders at

500.00 N load is required. The loading frame shall be table

temperatures where they exhibit brittle or brittle-ductile failure.

mounted. The gripping system (loading pins and platens) shall

A brittle or brittle-ductile failure will result in a fracture of the

be completely submerged under the cooling fluid if a fluid

test specimen as opposed to a ductile failure in which the

based system is used. The gripping system shall be a minimum

specimen simply stretches without fracturing. The test method

of 25 mm under the cooling fluid surface. Loading shall be

is not applicable at temperatures where failure is by ductile

accomplished by pulling directly in tension in the plane of the

flow.

specimen. The distance between the load frame’s loading

4.3 A displacement transducer is used to measure the

points (between loading pins) shall accommodate specimens

elongation of the test specimen as it is pulled in tension at a

with total length (including the end tabs) of at least 100.0 mm,

constant rate of 1.00 mm/min. The load developed during the

(see Fig. 1). If an air cooled system is used, the testing frame

test is monitored and the tensile strain and stress in the test

shall be equipped with two standards (columns) with sufficient

specimen when the load reaches a maximum are reported as the

clear space between the standards so that an insulated tempera-

failure strain and failure stress, respectively.

ture control chamber can be placed between the standards.

5. Significance and Use 6.1.2 Specimen Gripping System—The gripping system

must produce a self-aligning uniaxial test load and accept the

5.1 Stress at failure is used in a mechanistic pavement

end tabs described in 6.1.2.1 and be designed so that test

cracking model to compute critical cracking temperature. The

specimens can be easily mounted in the machine. The system

procedure to compute critical cracking temperature is de-

shall include two grips. Each grip shall include a specially-

scribed in Practice D 6521. The critical cracking temperature is

shaped pin that is mounted rigidly to the loading platens of the

then used in specifying the low temperature grade of asphalt

testing machine. Fig. 2 shows a typical grip and loading pin

binder in accordance with Specification D 6373.

assembly. One grip shall be fixed and remain stationary during

5.2 The test method is designed to measure the strength of

the test while the other grip is displaced at the desired

the asphalt binder at the critical cracking temperature. The

elongation rate.

asphalt binder has limited ability to resist stress without

cracking. In the asphalt binder Specification D 6373, failure 6.1.2.1 Specimen End Tabs—End tabs made from Phenolic

G-10 material having the dimensions specified in Figs. 3-5

stress is used to determine the critical cracking temperature.

5.3 For evaluating an asphalt binder for conformance to shall be bonded to both ends of the test specimen to transfer the

tensile load to the asphalt binder. The end tabs shall be

Specification D 6373, the elongation rate of the gage section is

machined from standard G-10 Phenolic sheet. Each end tab

1.0 mm/min and the test temperature is selected from Table

shall contain a precisely machined hole lined with a 304

number 1 of Specification D 6373 according to the grade of

stainless steel ring. The diameter of the lined hole shall be

asphalt binder. Other rates of elongation and test temperatures

10.00 6 0.05 mm. Gripping of the specimen is accomplished

may be used to test asphalt binders.

through the bond (adhesion) between the asphalt binder test

6. Apparatus

specimen and the end tab. Each end tab shall be mounted on a

6.1 Direct Tension Test System—A direct tension test system specially shaped pin that is part of the gripping system. The

consisting of (1) a closed feed-back loop displacement- specimen shall be mounted on the grips by positioning the end

controlled tensile loading machine, (2) a specimen gripping tabs in the test machine such that the end tabs fit onto the pins

system, (3) either a fluid bath or an insulated chamber for and are indexed against the face of the grips. Matching the

D 6723

FIG. 1 Superpave Direct Tension Specimen Geometry

D 6723

FIG. 2 Loading Pin and Grip Assembly for the Superpave Direct Tension Test

D 6723

FIG. 3 Superpave End Insert for Direct Tension Test (See Fig. 4 for the Metal Ring Dimensions to be Press Fitted into this End Insert)

D 6723

FIG. 4 Superpave End Insert Metal Ring for Direct Tension Test

D 6723

FIG. 5 Superpave Direct Tension Specimen Mold

D 6723

the required 42 to 58 % potassium acetate to deionized water combination

coefficient of thermal expansion of the asphalt binder and the

may be obtained by mixing the commercially available 50:50 deicing fluid

end tabs is necessary to reduce thermal shrinkage stresses at the

with deionized or distilled water until a density value between 1.235 and

interface that otherwise cause bond failures.

1.240 is obtained at 25°C. The density may be measured using a suitable

6.1.3 Test Chamber for Temperature Control and Testing—

hydrometer.

The temperature control chamber shall have sufficient space for

6.1.5 Load Measuring and Recording Devices—Load shall

storing at least eight (8) specimens. The temperature control

be measured with a load cell having a minimum capacity of

range for the cooling chamber, without asphalt binder speci-

500 N and a sensitivity of 0.1 N. The load cell shall be

mens, at all points within the bath, shall be from +6°C to -36°C

calibrated at least annually in accordance with Practices E 4.

with temperature stability as a minimum of 60.1°C. Placing a

The load and elongation shall be monitored with the data

room temperature specimen in the cold chamber is allowed to

acquisition system such that they can be resolved to 1.0 percent

cause the chamber temperature between the grips to fluctuate

of the failure load and elongation, respectively. Once the test

60.2°C from the target test temperature during testing and

has started, the data acquisition system shall be able to detect

isothermal conditioning of the specimen. However, during

the point in time when the load starts to change as a result of

testing the temperature gradient between the grips shall not

elongation in the sample. This shall be accomplished by

exceed 60.1°C. The temperature measurement shall be accom-

monitoring the load cell signal with time. A change in the load

plished with a calibrated Platinum Resistance Temperature

signal equivalent to 2 N 6 0.3 N (threshold load) shall be used

Detector (PRTD) located in the chamber in proximity of test

to mark the point in time where zero reading of the displace-

area (NIST Traceable, calibrated at 8 temperatures in the range

ment transducer is obtained. The point in time where the peak

+6°C to -36°C). If an air based cooling system is used

load is obtained will be captured by the data acquisition system

mechanical cooling or liquid nitrogen may be used to cool the

and the accumulated elongation from the zero reading to the

chamber. It shall have a dehumidifying system with a capacity

elongation corresponding to the peak load shall be used to

such that the formation of frost on the interior of the chamber,

calculate the failure strain. Once the test is complete, the device

the test specimen, or any of the test fixtures is eliminated. The

shall display the strain at failure. Peak loads typically range

chamber shall be capable of storing a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.