ASTM D7953-14

(Practice)Standard Practice for Electrical Leak Location on Exposed Geomembranes Using the Arc Testing Method

Standard Practice for Electrical Leak Location on Exposed Geomembranes Using the Arc Testing Method

SIGNIFICANCE AND USE

4.1 Geomembranes are used as barriers to prevent liquids from leaking from landfills, ponds, and other containments. For this purpose, it is desirable that the geomembrane have as little leakage as practical.

4.2 The liquids may contain contaminants that if released can cause damage to the environment. Leaking liquids can erode the subgrade, causing further damage. Leakage can result in product loss or otherwise prevent the installation from performing its intended containment purpose.

4.3 Geomembranes are often assembled in the field, either by unrolling and welding panels of the geomembrane material together in the field, unfolding flexible geomembranes in the field, or a combination of both.

4.4 Geomembrane leaks can be caused by poor quality of the subgrade, poor quality of the material placed on the geomembrane, accidents, poor workmanship, manufacturing defects, and carelessness.

4.5 Electrical leak location methods are an effective and proven quality assurance measure to detect and locate leaks.

SCOPE

1.1 This practice is a performance-based standard for an electrical method for locating leaks in exposed geomembranes. For clarity, this practice uses the term “leak” to mean holes, punctures, tears, knife cuts, seam defects, cracks, and similar breaches in an installed geomembrane (as defined in 3.2.4).

1.2 This practice can be used for geomembranes installed in basins, ponds, tanks, ore and waste pads, landfill cells, landfill caps, canals, and other containment facilities. It is applicable for geomembranes made of materials such as polyethylene, polypropylene, polyvinyl chloride, chlorosulfonated polyethylene, bituminous geomembrane, and any other electrically insulating materials. This practice is best applicable for locating geomembrane leaks where the proper preparations have been made during the construction of the facility.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7953 − 14

Standard Practice for

Electrical Leak Location on Exposed Geomembranes Using

1

the Arc Testing Method

This standard is issued under the fixed designation D7953; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This practice is a performance-based standard for an

3.1 Definitions:

electrical method for locating leaks in exposed geomembranes.

3.1.1 For general definitions used in this practice, refer to

For clarity, this practice uses the term “leak” to mean holes,

Terminology D4439.

punctures, tears, knife cuts, seam defects, cracks, and similar

3.2 Definitions of Terms Specific to This Standard:

breaches in an installed geomembrane (as defined in 3.2.4).

3.2.1 conductive-backed geomembrane, n—a specialty

1.2 This practice can be used for geomembranes installed in

geomembrane manufactured using coextrusion technology fea-

basins, ponds, tanks, ore and waste pads, landfill cells, landfill

turing an insulating layer in intimate contact with a conductive

caps, canals, and other containment facilities. It is applicable

layer.

for geomembranes made of materials such as polyethylene,

polypropylene, polyvinyl chloride, chlorosulfonated

3.2.2 current, n—the flow of electricity or the flow of

polyethylene, bituminous geomembrane, and any other electri-

electric charge.

cally insulating materials. This practice is best applicable for

3.2.3 electrical leak location, n—a method which uses

locating geomembrane leaks where the proper preparations

electrical current or electrical potential to locate leaks in a

have been made during the construction of the facility.

geomembrane.

1.3 The values stated in SI units are to be regarded as

3.2.4 leak, n—for the purposes of this document, a leak is

standard. No other units of measurement are included in this

standard. any unintended opening, perforation, breach, slit, tear,

puncture, crack, or seam breach. Significant amounts of liquids

1.4 This standard does not purport to address all of the

or solids may or may not flow through a leak. Scratches,

safety concerns, if any, associated with its use. It is the

gouges, dents, or other aberrations that do not completely

responsibility of the user of this standard to establish appro-

penetrate the geomembrane are not considered to be leaks.

priate safety and health practices and determine the applica-

Types of leaks detected during surveys include but are not

bility of regulatory limitations prior to use.

limitedto;burns,circularholes,linearcuts,seamdefects,tears,

2. Referenced Documents

punctures and material defects.

2

2.1 ASTM Standards:

3.2.5 leak detection sensitivity, n—the smallest leak that the

D4439 Terminology for Geosynthetics

leak location equipment and survey methodology are capable

D6747 Guide for Selection of Techniques for Electrical

of detecting under a given set of conditions. The leak detection

Detection of Leaks in Geomembranes

sensitivity specification is usually stated as a diameter of the

D7002 Practice for Leak Location on Exposed Geomem-

smallest leak that can likely be detected.

branes Using the Water Puddle System

3.2.6 poor contact condition, n—for the purposes of this

D7703 Practice for Electrical Leak Location on Exposed

document, a poor contact condition means that a leak is not in

Geomembranes Using the Water Lance System

intimate contact with the conductive layer above or underneath

the geomembrane to be tested. This occurs on a wrinkle or

1

wave, under the overlap flap of a fusion weld, in an area of

This practice is under the jurisdiction of ASTM Committee D35 on Geosyn-

thetics and is the direct responsibility of Subcommittee D35.10 on Geomembranes.

liner bridging and in an area where there is a subgrade

Current edition approved July 1, 2014. Published July 2014. DOI: 10.1520/

depression or rut.

D7953–14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

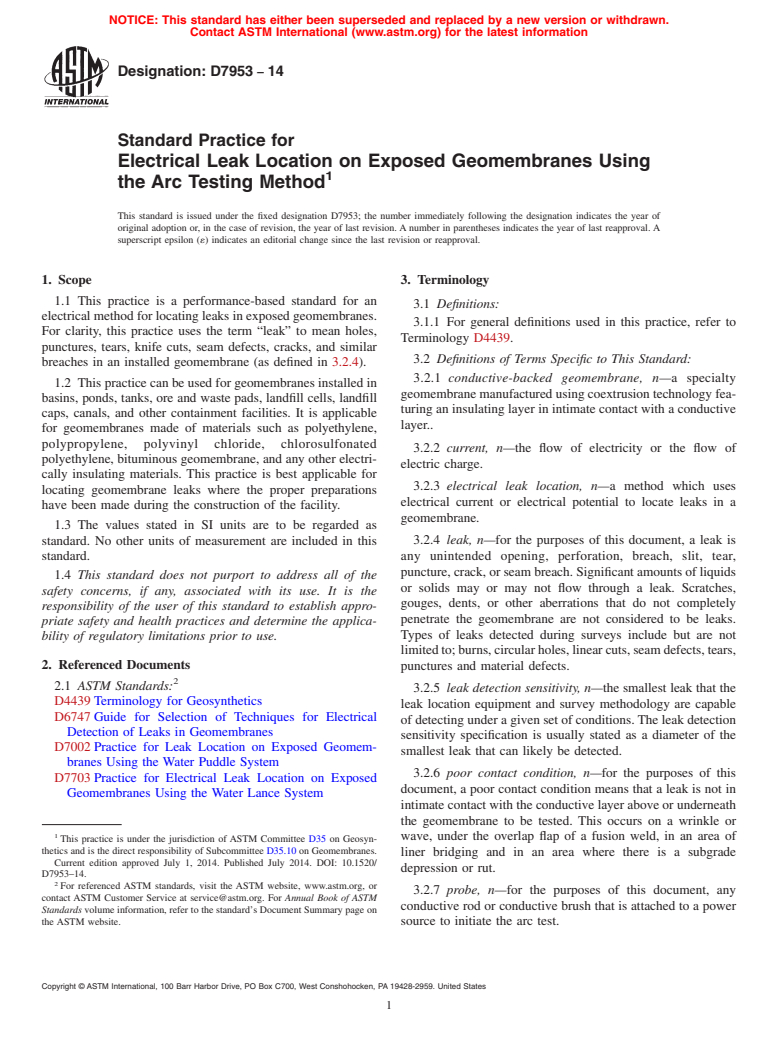

3.2.7 probe, n—for the purposes of this document, any

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

conductive rod or conductive brush that is attached to a power

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. source to initiate the arc test.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7953 − 14

4. Significance and Use 6. Arc Testing Method

4.1 Geomembranes are used as barriers to prevent liquids 6.1 Asummary of the method capabilities and limitations is

fromleakingfromlandfi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.