ASTM B148-14

(Specification)Standard Specification for Aluminum-Bronze Sand Castings

Standard Specification for Aluminum-Bronze Sand Castings

ABSTRACT

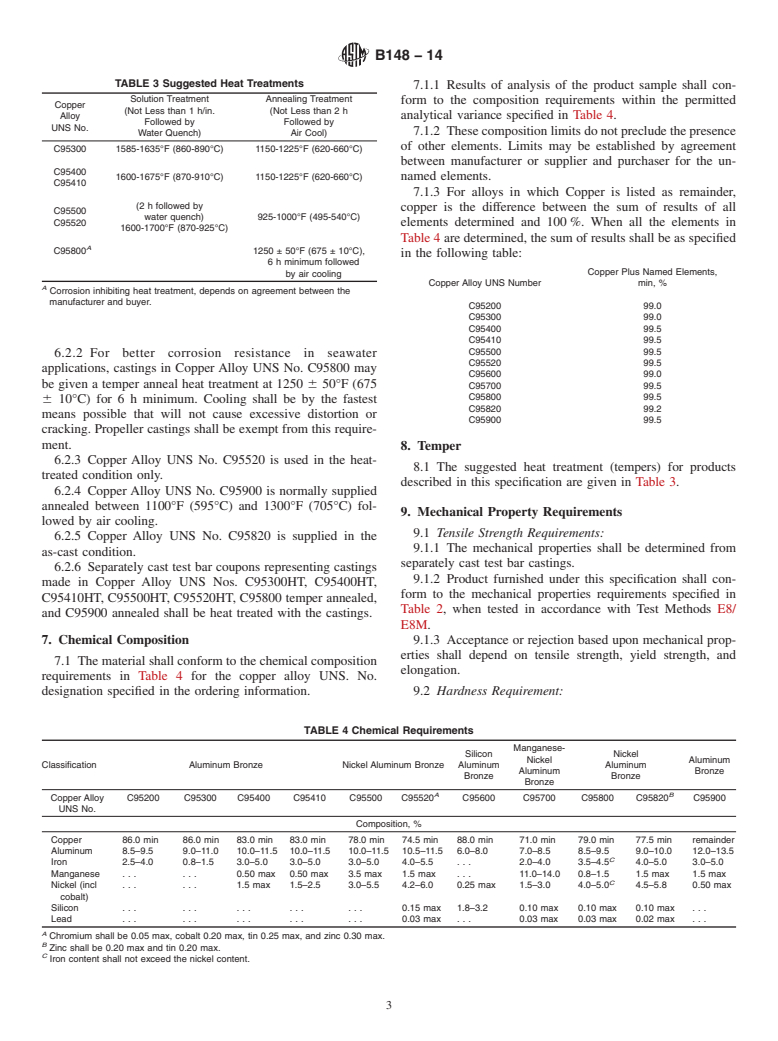

This specification establishes requirements for sand castings produced from copper-base alloys having the alloy numbers, commercial designations, and nominal compositions. The alloys the classified according to their nominal compositions: UNS No. C95200; UNS No. C95300; UNS No. C95400; UNS No. C95410; UNS No. C95500; UNS No. C95520; UNS No. C95600; UNS No. C95700; UNS No. C95800; UNS No. C95820; and UNS No. C95900. The castings shall conform to the chemical requirements specified. Mechanical properties shall be determined from separately cast test bar castings and shall meet the requirements. Brineel and Rockwell hardness readings shall be taken on the grip end of the tension test bar and shall be made in accordance with the specified requirements.

SCOPE

1.1 This specification establishes requirements for sand castings produced from copper-base alloys having the alloy numbers,2 commercial designations, and nominal compositions shown in Table 1.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B148 −14

Standard Specification for

1

Aluminum-Bronze Sand Castings

This standard is issued under the fixed designation B148; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* Unified Numbering System (UNS)

1.1 This specification establishes requirements for sand

3. Terminology

castings produced from copper-base alloys having the alloy

2

numbers, commercialdesignations,andnominalcompositions

3.1 For definitions of terms related to copper and copper

shown in Table 1.

alloys, refer to Terminology B846.

1.2 The values stated in inch-pound units are to be regarded

4. General Requirements

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

4.1 Material furnished under this specification shall con-

and are not considered standard.

form to the applicable requirements of Specification B824.

2. Referenced Documents

5. Ordering Information

2.1 The following documents of the issue in effect on date

5.1 Include the following specified choices when placing

of material purchase form a part of this specification to the

orders for product under this specification as applicable:

extent referenced herein:

5.1.1 ASTM designation and year of issue,

3

2.2 ASTM Standards:

5.1.2 Copper or Copper Alloy UNS. No. designation,

B208 Practice for Preparing Tension Test Specimens for

5.1.3 Temper, must include optional Heat Treatment when

Copper Alloy Sand, Permanent Mold, Centrifugal, and

needed,

Continuous Castings

5.1.4 Dimensions, diameter, and wall thickness (For tube or

B824 Specification for General Requirements for Copper

pipe: specify either O.D./I.D., O.D./Wall, or I.D./Wall unless

Alloy Castings

standard size such as type K are ordered; for flat products:

B846 Terminology for Copper and Copper Alloys

thickness, width, and edges; for rod, bar, or shapes: by

B950 Guide for Editorial Procedures and Form of Product

diameter or distance between parallel surfaces),

Specifications for Copper and Copper Alloys

5.1.5 Quantity of castings required,

E8/E8M Test Methods for Tension Testing of Metallic Ma-

5.1.6 Intended applications,

terials

5.1.7 Specification title, number, and year of issue,

E10 Test Method for Brinell Hardness of Metallic Materials

5.1.8 Pattern or drawing number and condition (cast,

E18 Test Methods for Rockwell Hardness of Metallic Ma-

machined, and so forth),

terials

5.1.9 Analysis of residual elements, if specified in the

E527 Practice for Numbering Metals and Alloys in the

purchase order (Specification B824),

5.1.10 Pressure test requirements, if specified in the pur-

1

chase order (Specification B824),

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

and Copper Alloys and is the direct responsibility of Subcommittee B05.05 on

5.1.11 Soundness requirements, if specified in the purchase

Castings and Ingots for Remelting.

order (Specification B824),

Current edition approved April 1, 2014. Published May 2014. Originally

5.1.12 Certification, if specified in the purchase order

approved in 1941. Last previous edition approved in 2009 as B148 – 97 (2009).

DOI: 10.1520/B0148-14.

(Specification B824),

2

The UNS system for copper and copper alloys (see Practice E527) is a simple

5.1.13 Test report, if specified in the purchase order (Speci-

expansion of the former standard designation system accomplished by the addition

fication B824),

of a prefix “C” and a suffix “00.” The suffix can be used to accommodate

composition variations of the base alloy.

5.1.14 Witness inspection, if specified in the purchase order

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

(Specification B824),

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1.15 Approvalofweldprocedureandrecordsofrepairs,if

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. specified in the purchase order (Section 10),

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B148−14

TABLE 1 Nominal Compositions

Nominal Composition, %

Copper Alloy Old Commercial

UNS No. Designation Designation

Copper Nickel Iron Aluminum Silicon Manganese

C95200 9A Grade A 88.0 . . . 3.0 9.0 . . . . . .

A

C95300 9B Grade B 89.0 . . . 1.0 10.0 . . . . . .

A

C95400 9C Grade C 85.0 . . . 4.0 11.0 . . . . . .

A

C95410 . . 84.0 2.0 4.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B148 − 97 (Reapproved 2009) B148 − 14

Standard Specification for

1

Aluminum-Bronze Sand Castings

This standard is issued under the fixed designation B148; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope Scope*

2

1.1 This specification establishes requirements for sand castings produced from copper-base alloys having the alloy numbers,

commercial designations, and nominal compositions shown in Table 1.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

2. Referenced Documents

2.1 The following documents of the issue in effect on date of material purchase form a part of this specification to the extent

referenced herein:

3

2.2 ASTM Standards:

B208 Practice for Preparing Tension Test Specimens for Copper Alloy Sand, Permanent Mold, Centrifugal, and Continuous

Castings

B824 Specification for General Requirements for Copper Alloy Castings

B846 Terminology for Copper and Copper Alloys

B950 Guide for Editorial Procedures and Form of Product Specifications for Copper and Copper Alloys

E8/E8M Test Methods for Tension Testing of Metallic Materials

E10 Test Method for Brinell Hardness of Metallic Materials

E18 Test Methods for Rockwell Hardness of Metallic Materials

E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

3. Terminology

3.1 For definitions of terms related to copper and copper alloys, refer to Terminology B846.

4. General Requirements

4.1 Material furnished under this specification shall conform to the applicable requirements of Specification B824.

5. Ordering Information

5.1 Orders for castingsInclude the following specified choices when placing orders for product under this specification shall

include the following information:as applicable:

5.1.1 ASTM designation and year of issue,

5.1.2 Copper or Copper Alloy UNS. No. designation,

5.1.3 Temper, must include optional Heat Treatment when needed,

5.1.4 Dimensions, diameter, and wall thickness (For tube or pipe: specify either O.D./I.D., O.D./Wall, or I.D./Wall unless

standard size such as type K are ordered; for flat products: thickness, width, and edges; for rod, bar, or shapes: by diameter or

distance between parallel surfaces),

1

This specification is under the jurisdiction of ASTM Committee B05 on Copper and Copper Alloys and is the direct responsibility of Subcommittee B05.05 on Castings

and Ingots for Remelting.

Current edition approved April 1, 2009April 1, 2014. Published May 2009May 2014. Originally approved in 1941. Last previous edition approved in 20032009 as

ε1

B148 – 97 (2003)(2009). . DOI: 10.1520/B0148-97R09.10.1520/B0148-14.

2

The UNS system for copper and copper alloys (see Practice E527) is a simple expansion of the former standard designation system accomplished by the addition of a

prefix “C” and a suffix “00.” The suffix can be used to accommodate composition variations of the base alloy.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

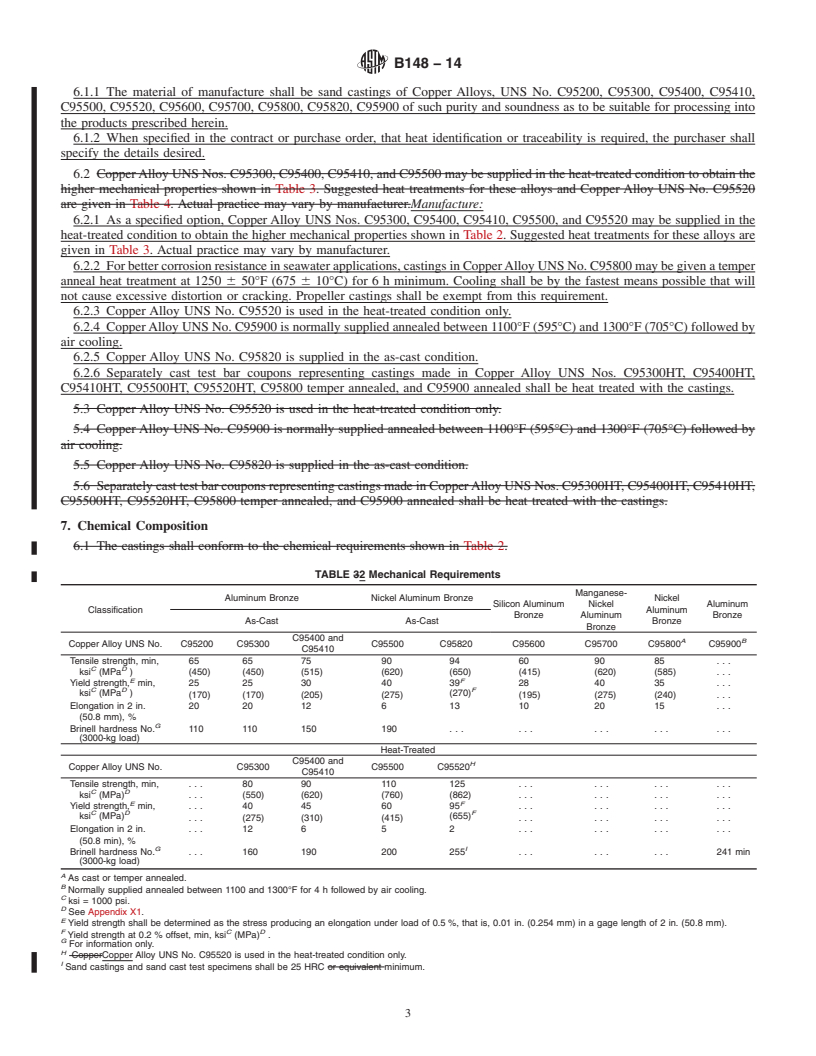

B148 − 14

TABLE 1 Nominal Compositions

Nominal Composition, %

Copper Alloy Old Desig- Commercial

UNS No. nationDesignation Designation

Copper Nickel Iron Aluminum Silicon Manganese

C95200 9A Grade A 88.0 . . . 3.0 9.0 . . . . . .

A

C95300 9B Grade B 89.0 . . . 1.0 10.0 . . . . . .

A

C95400 9C Grade C 85.0 . . . 4.0 11.0 . . . . . .

A

C95410 . . . . . . 84.0 2.0 4.0 10.0 . . . . . .

A

C95500 9D Grade D 81.0 4.0 4.0 11.0 . . . . . .

A

C95520 . . . . . . 78.5 5.5 5.0 11.0 . . . . . .

C95600 9E Grade E 91.0 . . . . . . 7.0 2.0 . . .

C95700 9F Grade F 75.0 2.0 3.0 8.0 . . . 12.0

C95800 . . . . . . 81.3 4.5 4.0 9.0 . . . 1.2

C95820 . . . . . . 79.0 5.2 4.5 9.5 . . . 1.0

C95900 . . . . . . 87.5 . . . 4.5 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.