ASTM D7613-10

(Specification)Standard Specification for Flexible Polypropylene Reinforced (fPP-R) and Nonreinforced (fPP) Geomembranes

Standard Specification for Flexible Polypropylene Reinforced (fPP-R) and Nonreinforced (fPP) Geomembranes

SCOPE

1.1 This specification covers flexible polypropylene reinforced (fPP-R) and nonreinforced (fPP) geomembranes made from flexible polypropylene as the principal polymer prepared by the polymerization of propylene with or without other alpha olefin monomers.

1.2 The tests and property limits used to characterize the sheet are values intended to ensure minimum quality. In-place system design criteria, such as field-seaming strength and material compatibility among others, are factors that should be considered but are beyond the scope of this specification.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7613 −10

Standard Specification for

Flexible Polypropylene Reinforced (fPP-R) and

Nonreinforced (fPP) Geomembranes

This standard is issued under the fixed designation D7613; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D4439Terminology for Geosynthetics

D4833 Test Method for Index Puncture Resistance of

1.1 This specification covers flexible polypropylene rein-

Geomembranes and Related Products

forced (fPP-R) and nonreinforced (fPP) geomembranes made

D5199Test Method for Measuring the Nominal Thickness

from flexible polypropylene as the principal polymer prepared

of Geosynthetics

bythepolymerizationofpropylenewithorwithoutotheralpha

D5538 Practice for Thermoplastic Elastomers—

olefin monomers.

Terminology and Abbreviations

1.2 The tests and property limits used to characterize the

D5884Test Method for Determining Tearing Strength of

sheet are values intended to ensure minimum quality. In-place

Internally Reinforced Geomembranes

system design criteria, such as field-seaming strength and

D6636Test Method for Determination of Ply Adhesion

material compatibility among others, are factors that should be

Strength of Reinforced Geomembranes

considered but are beyond the scope of this specification.

D6693Test Method for Determining Tensile Properties of

1.3 The values stated in SI units are to be regarded as Nonreinforced Polyethylene and Nonreinforced Flexible

Polypropylene Geomembranes

standard. No other units of measurement are included in this

standard. D7004Test Method for Grab Tensile Properties of Rein-

forced Geomembranes

1.4 This standard does not purport to address all of the

G151PracticeforExposingNonmetallicMaterialsinAccel-

safety concerns, if any, associated with its use. It is the

erated Test Devices that Use Laboratory Light Sources

responsibility of the user of this standard to establish appro-

G154PracticeforOperatingFluorescentLightApparatusfor

priate safety and health practices and determine the applica-

UV Exposure of Nonmetallic Materials

bility of regulatory limitations prior to use.

G155Practice for Operating XenonArc LightApparatus for

2. Referenced Documents Exposure of Non-Metallic Materials

2.1 ASTM Standards:

3. Terminology

D573Test Method for Rubber—Deterioration in an Air

Oven

3.1 Definitions—For definitions of terms used in this

D751Test Methods for Coated Fabrics

specification, refer to Terminologies D883 and D4439 and

D883Terminology Relating to Plastics

Practice D5538.

D1004Test Method for Tear Resistance (Graves Tear) of

Plastic Film and Sheeting

4. Materials and Manufacture

D1204Test Method for Linear Dimensional Changes of

4.1 The sheet shall be capable of being heat welded, fused,

Nonrigid Thermoplastic Sheeting or Film at Elevated

or adhesively bonded to itself for making watertight field

Temperature

splices and repairs.

D2136Test Method for Coated Fabrics—Low-Temperature

Bend Test

4.2 Geomembrane can be nonreinforced or reinforced with

fabric or scrim.

This specification is under the jurisdiction of ASTM Committee D35 on

GeosyntheticsandisthedirectresponsibilityofSubcommitteeD35.10onGeomem-

5. Chemical Composition

branes.

5.1 The geomembrane shall be formulated from virgin

Current edition approved Sept. 15, 2010. Published October 2010. DOI:

10.1520/D7613-10.

flexible polypropylene, in amounts greater than 85 %, by

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

weight of the total polymer content. The remaining 15 % shall

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

be comprised of compatible polymers or pigments or both,

Standardsvolumeinformation,refertothespecification’sDocumentSummarypage

on the ASTM website. stabilizers, and colorants that are suitably compounded to

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7613−10

satisfy the physical requirements in the specification (see nicks and cuts, voids, thin areas, delaminations, or other

Practice D5538 for definitions). manufacturing defects that might adversely affect serviceabil-

ity.

NOTE 1—The compound shall not contain postconsumer (PCR) com-

ponents containing bitumen or any other ingredients that could interfere

with the long-term stability of the geomembrane. No more than 10 % 9. Test Methods

rework resin is allowed for the production of the membrane and shall be

9.1 Dimensions—Test Methods , after permitting the sheet

fully compatible with the parent material.

to relax at 23°C for 1 h.

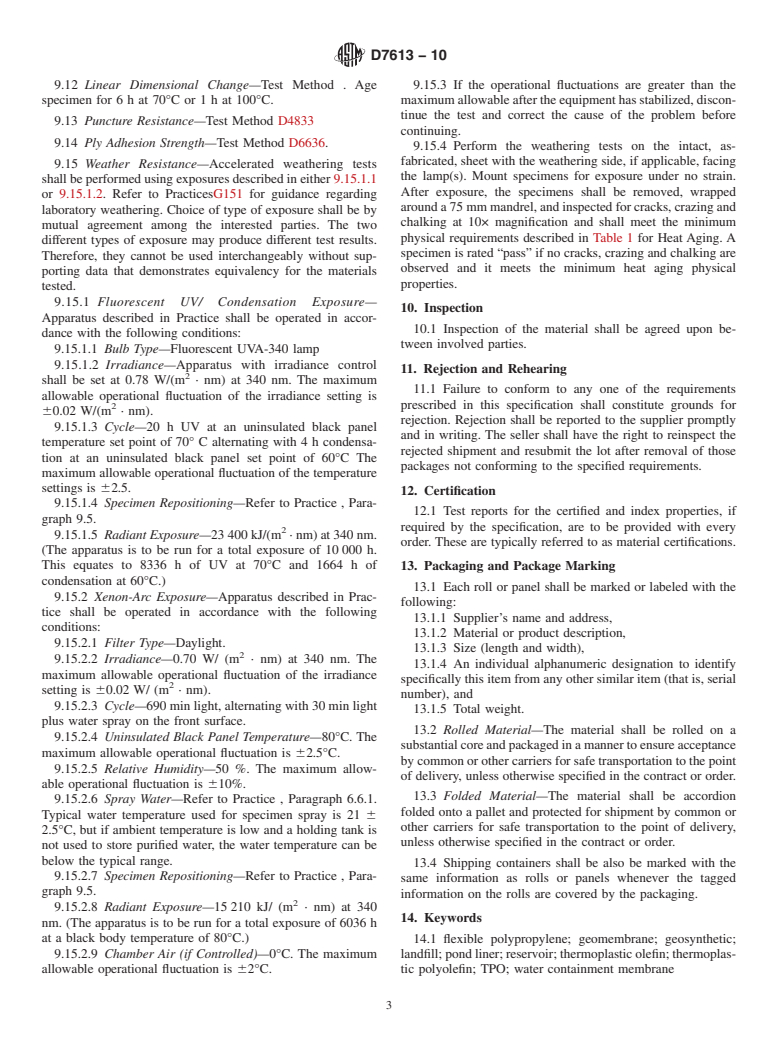

6. Physical Properties

9.2 Thickness—Test Method for reinforced and nonrein-

6.1 Each sheet specimen shall meet or exceed the physical

forced.

requirements prescribed in Table 1.

9.3 Thickness of Coating Over Scrim (Reinforcing

6.2 The tolerance for time conditions (aging, weathering,

Fabric)—Optical method described in Annex A1.

and so forth) is 615 min or 61 % of the period, whichever is

9.4 Breaking Strength—Test Method D7004.

greater, unless otherwise specified.

9.5 Tensile Strength—Test Method D66933.

6.3 The tolerance for temperature conditions (aging and so

9.6 Elongation at Break—Test Method D7004.

forth) is 62°C of the specified temperature, unless otherwise

specified.

9.7 Ultimate Elongation %—Test Method D6693.

9.8 Tearing Strength—Test Method D5884 for reinforced.

7. Dimensions, Mass, and Permissible Variations

9.9 Tear Resistance—Test Method D1004 for nonrein-

7.1 The width and length of the sheet shall be agreed upon

between the purchaser and the supplier. forced.

9.10 Low-TemperatureBend—TestMethodD2136at-40°C.

7.2 The tolerance for both width and length shall be +3 %,

-1 %.

9.11 Heat Aging—Test Method D573.Age sheet specimens

7.3 The thickness tolerance shall be +15 %, –10 % of for670hat116°C.Specimensarethencutfromtheagedsheet

thickness agreed upon by the purchaser and supplier, but in no for testing of breaking strength, elongation, and tearing

case shall the thickness be less than the minimum in Table 1. strength.Afterexposure,thesheetspecimensshallberemoved

fromtheoven;specimenscutfromtheagedsheetfortestingof

8. Workmanship, Finish, and Appearance

breaking strength, elongation, and tearing strength; and

wrapped around a 75 mm diameter mandrel.

8.1 The sheet, including factory seams, if present, shall be

watertight and free of pinholes, particles of foreign matter, 9.11.1 Aspecimen is rated “pass” if no cracks or crazing is

protruding fibers or reinforcement, undispersed raw material, observed using a 10× magnification.

TABLE 1 Physical Requirements

Physical Requirements Method fPP-R fPP

Thickness, lowest individual reading, D5199 0.82 mm

Reinforced

Thickness over scrim Annex A1 0.305 mm

Thickness, lowest individual reading, D5199 0.68 mm

non-reinforced

Breaking strength, minimum 980 N

Tensile strength, kN/m 10.5 kN/m

Elongation at break, minimum % D7004 15 %

Ultimate elongation % D6693 700 %

Tearing strength, minimum D5884 244 N

Tear resistance, minimum D1004 45 N

Low-temperature bend -40°C -40°C

Properties after heat aging & Weather- D573, G151, G154, G155

ing

Retention of breaking strength, mini- 85 %

mum

Retention of tensile strength 85 %

Retention of elongation at break, mini- 85 %

mum

Retention of ultimate elongation, % 85 %

Retention of tearing strength, minimum 60 %

Retention of tear resistance, minimum 60 %

Visual inspection no cracks Pass Pass Pass Pass

or crazing (10×)

Linear dimensional change, maximum D1204 1.0% 3%

change

Puncture resistance reinforced D4833 330 N

Puncture resistance non- reinforced 110 N

Factory prepared, ply adhesion D6636 65 N NA

strength, min

D7613−10

9.12 Linear Dimensional Change—Test Method . Age 9.15.3 If the operational fluctuations are greater than the

specimen for6hat 70°C or1hat 100°C. maximumallowableaftertheequipmenthasstabilized,discon-

tinue the test and correct the cause of the problem before

9.13 Puncture Resistance—Test Method D4833

continuing.

9.14 Ply Adhesion Strength—Test Method D6636.

9.15.4 Perform the weathering tests on the intact, as-

fabricated, sheet with the weathering side, if applicable, facing

9.15 Weather Resistance—Accelerated weathering tests

the lamp(s). Mount specimens for exposure under no strain.

shallbeperformedusingexposuresdescribedineither9.15.1.1

After exposure, the specimens shall be removed,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.