ASTM D6088-06(2022)

(Practice)Standard Practice for Installation of Geocomposite Pavement Drains

Standard Practice for Installation of Geocomposite Pavement Drains

SIGNIFICANCE AND USE

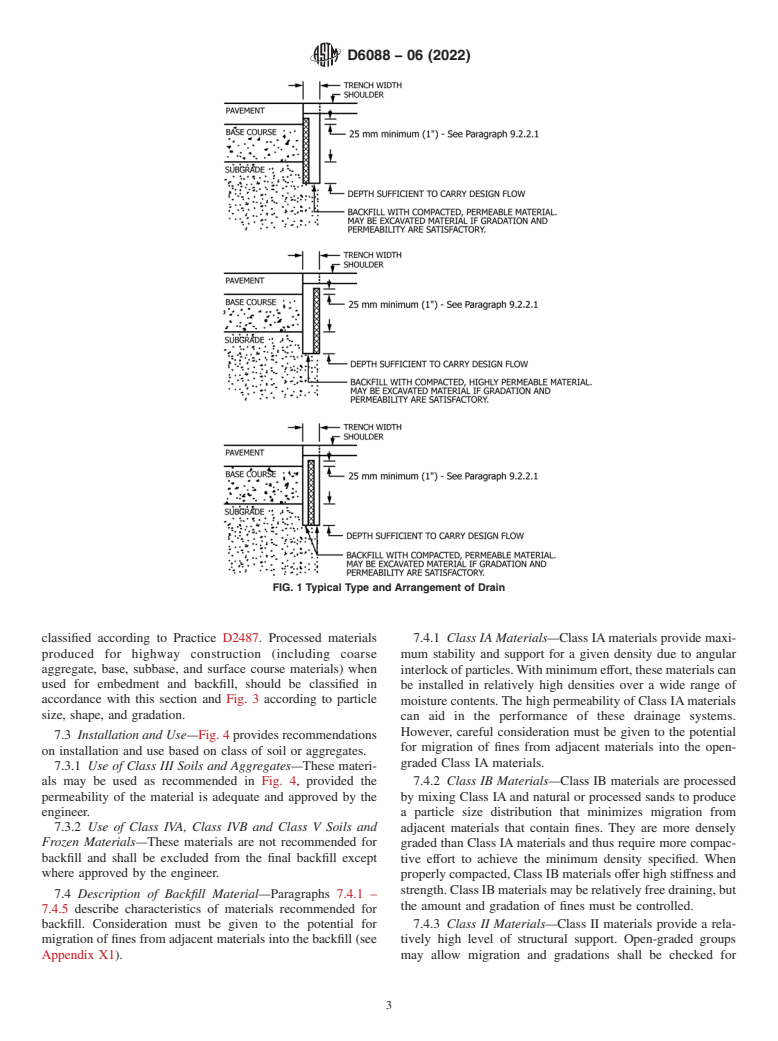

5.1 This practice is intended to provide installation guidance for designers, specifiers, installation contractors, regulatory agencies, owners, and inspectors who are involved in the planning and installation of geocomposite pavement edgedrains and underdrains. As with any standard practice, modification may be required for specific project conditions or for special local or regional conditions. Fig. 1 shows the proper horizontal alignment of the drain based on various trench conditions outlined in 9.2, and the vertical depth of placement of the drain needed for a geocomposite edge drain to function most effectively as both a collector and conduit.

FIG. 1 Typical Type and Arrangement of Drain

5.2 Fig. 2 shows the typical type and arrangement of equipment used to install geocomposite highway edgedrains. The combination of these recommended installation conditions, techniques, and equipment are critical to the satisfactory long-term performance of these products.

FIG. 2 Proper Horizontal Alignment

Note 1: Drain positioning gate should be located and adjusted to position, and hold the geocomposite drain against the trench wall, to prevent possible “J”-ing or “C”-ing of the drain during backfilling and compaction.

SCOPE

1.1 This practice covers recommendations and identifies pertinent areas of consideration for the installation of buried geocomposite drains used for highway edgedrains, under-drains, or other pavement drainage applications meeting the requirements of Specification D7001. These recommendations are intended as guidelines for developing a satisfactory construction and installation method to minimize installation-caused deformation or damage and to provide long-term performance of these products. It is also intended as a guideline for ensuring a stable underground environment for these materials under a wide range of service conditions. Because of the numerous and diverse product designs available and the inherent variability of natural ground conditions, achieving satisfactory performance of any one product may require review by the engineer and modification to provisions contained herein to meet specific project requirements.

1.2 The scope of this practice necessarily excludes product performance criteria such as compressibility in any plane, flow capacity, inlet capacity, or geotextile selection and use. It is, therefore, incumbent upon the product manufacturer, specifier, and project engineer to verify that the product specified for an intended application, when installed according to procedures outlined in this practice, will provide satisfactory long-term performance according to criteria established by the owner for that application. A commentary of product performance and installation factors important in achieving a satisfactory installation is included in Appendix X1.

1.3 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6088 − 06 (Reapproved 2022)

Standard Practice for

1

Installation of Geocomposite Pavement Drains

This standard is issued under the fixed designation D6088; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 This practice covers recommendations and identifies

ization established in the Decision on Principles for the

pertinent areas of consideration for the installation of buried

Development of International Standards, Guides and Recom-

geocomposite drains used for highway edgedrains, under-

mendations issued by the World Trade Organization Technical

drains, or other pavement drainage applications meeting the

Barriers to Trade (TBT) Committee.

requirements of Specification D7001. These recommendations

are intended as guidelines for developing a satisfactory con-

2. Referenced Documents

struction and installation method to minimize installation-

2

2.1 ASTM Standards:

caused deformation or damage and to provide long-term

D8 Terminology Relating to Materials for Roads and Pave-

performanceoftheseproducts.Itisalsointendedasaguideline

ments

for ensuring a stable underground environment for these

D420 Guide for Site Characterization for Engineering De-

materials under a wide range of service conditions. Because of

sign and Construction Purposes

the numerous and diverse product designs available and the

D653 Terminology Relating to Soil, Rock, and Contained

inherent variability of natural ground conditions, achieving

Fluids

satisfactory performance of any one product may require

D698 Test Methods for Laboratory Compaction Character-

review by the engineer and modification to provisions con-

3

istics of Soil Using Standard Effort (12,400 ft-lbf/ft (600

tained herein to meet specific project requirements.

3

kN-m/m ))

1.2 The scope of this practice necessarily excludes product

D2321 PracticeforUndergroundInstallationofThermoplas-

performance criteria such as compressibility in any plane, flow

tic Pipe for Sewers and Other Gravity-Flow Applications

capacity, inlet capacity, or geotextile selection and use. It is,

D2487 Practice for Classification of Soils for Engineering

therefore, incumbent upon the product manufacturer, specifier,

Purposes (Unified Soil Classification System)

and project engineer to verify that the product specified for an

D3839 Guide for Underground Installation of “Fiberglass”

intended application, when installed according to procedures

(Glass-Fiber Reinforced Thermosetting-Resin) Pipe

outlined in this practice, will provide satisfactory long-term

D4318 Test Methods for Liquid Limit, Plastic Limit, and

performance according to criteria established by the owner for

Plasticity Index of Soils

that application. A commentary of product performance and

D4439 Terminology for Geosynthetics

installation factors important in achieving a satisfactory instal-

D7001 Specification for Geocomposites for Pavement Edge

lation is included in Appendix X1.

Drains and Other High-Flow Applications

1.3 The values stated in SI units are to be regarded as the

F412 Terminology Relating to Plastic Piping Systems

standard. The inch-pound units given in parentheses are for

3. Terminology

information only.

1.4 This standard does not purport to address all of the 3.1 Definitions:

safety concerns, if any, associated with its use. It is the 3.1.1 Definitionsusedinthispracticeareinaccordancewith

responsibility of the user of this standard to establish appro- Terminologies F412, D8, and D653 unless otherwise indicated.

priate safety, health, and environmental practices and deter- 3.2 Definitions:

mine the applicability of regulatory limitations prior to use. 3.2.1 aggregate—a granular material of mineral composi-

tion such as sand, gravel, shell, slag or crushed stone (see

Terminology D8).

1

This practice is under the jurisdiction of ASTM Committee D35 on Geosyn-

thetics and is the direct responsibility of Subcommittee D35.03 on Permeability and

2

Filtration. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2022. Published May 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1997. Last previous edition approved in 2016 as D6088 – 06 (2016). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D6088-

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.