ASTM C1230-96

(Test Method)Standard Test Method for Performing Tension Tests on Glass-Fiber Reinforced Concrete (GFRC) Bonding Pads

Standard Test Method for Performing Tension Tests on Glass-Fiber Reinforced Concrete (GFRC) Bonding Pads

SCOPE

1.1 This test method covers determination of the tensile load capacity of glass-fiber reinforced concrete (GFRC) bonding pads used for attaching steel anchors to GFRC architectural panels.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1230–96

Standard Test Method for

Performing Tension Tests on Glass-Fiber Reinforced

Concrete (GFRC) Bonding Pads

This standard is issued under the fixed designation C 1230; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 Thistestmethodcoversdeterminationofthetensileload

capacity of glass-fiber reinforced concrete (GFRC) bonding

pads used for attaching steel anchors to GFRC architectural

panels.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.3 The values stated in inch-pound units are to be regarded

as the standard. The values given in parentheses are provided

for information only.

2. Referenced Documents

2.1 ASTM Standards:

D 76 Specification for Tensile Testing Machines for Tex-

tiles

E 4 Practices for Force Verification of Testing Machines

3. Significance and Use

3.1 Tensile loads determined by this test method are useful

for quality control of GFRC architectural panels manufactured

using the steel panel frame support design. In addition, test

results may be used to verify compliance with governing

specifications, research and development, and generating data

for use in product design.

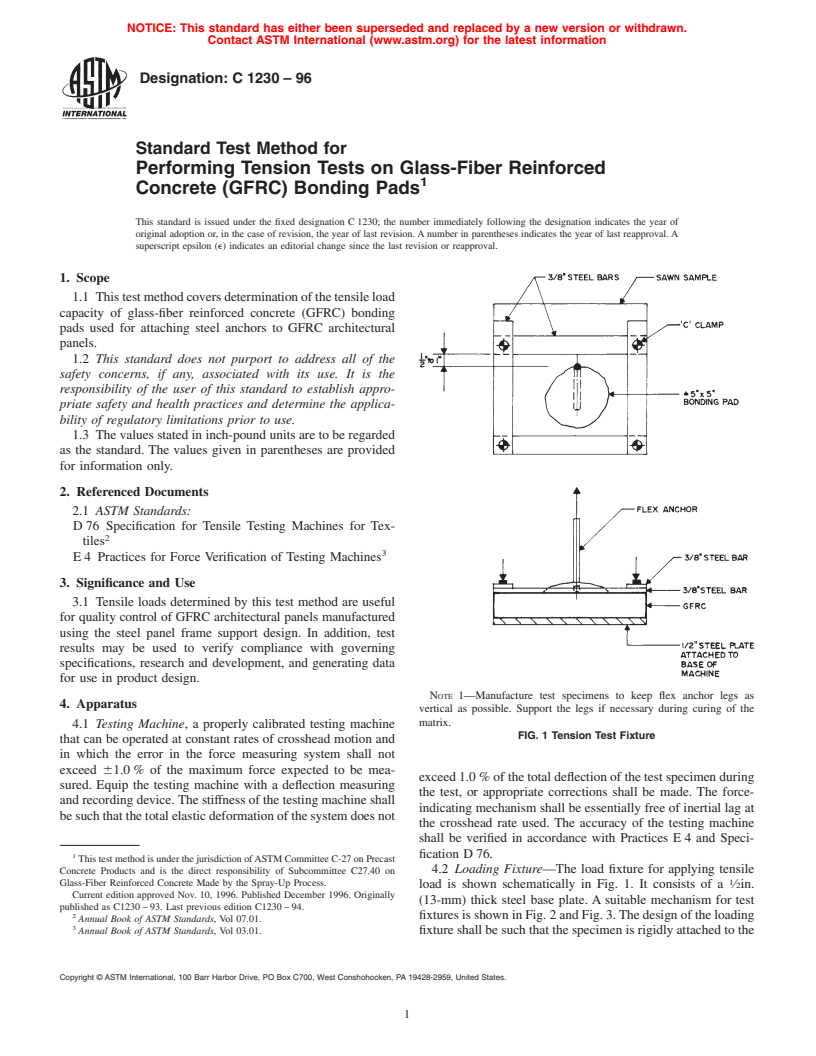

NOTE 1—Manufacture test specimens to keep flex anchor legs as

4. Apparatus

vertical as possible. Support the legs if necessary during curing of the

matrix.

4.1 Testing Machine, a properly calibrated testing machine

FIG. 1 Tension Test Fixture

that can be operated at constant rates of crosshead motion and

in which the error in the force measuring system shall not

exceed 61.0 % of the maximum force expected to be mea-

exceed 1.0 % of the total deflection of the test specimen during

sured. Equip the testing machine with a deflection measuring

the test, or appropriate corrections shall be made. The force-

and recording device. The stiffness of the testing machine shall

indicating mechanism shall be essentially free of inertial lag at

be such that the total elastic deformation of the system does not

the crosshead rate used. The accuracy of the testing machine

shall be verified in accordance with Practices E 4 and Speci-

1 fication D 76.

This test method is under the jurisdiction ofASTM Committee C-27 on Precast

4.2 Loading Fixture—The load fixture for applying tensile

Concrete Products and is the direct responsibility of Subcommittee C27.40 on

Glass-Fiber Reinforced Concrete Made by the Spray-Up Process.

load is shown schematically in Fig. 1. It consists of a ⁄2in.

Current edition approved Nov. 10, 1996. Published December 1996. Originally

(13-mm) thick steel base plate. A suitable mechanism for test

published as C1230 – 93. Last previous edition C1230 – 94.

fixtures is shown in Fig. 2 and Fig. 3.The design of the loading

Annual Book of ASTM Standards, Vol 07.01.

Annual Book of ASTM Standards, Vol 03.01. fixture shall be such that the specimen is rigidly attached to the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1230

FIG. 3 Suitable Test Fixture

FIG. 2 Suitable Test Fixture

8. Procedure

base support. In particular, the section of the specimen adjacent

8.1 Align the specimen in the center of the base plate or

to the flex a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.