ASTM D3760-98

(Test Method)Standard Test Method for Analysis of Isopropylbenzene (Cumene) by Gas Chromatography

Standard Test Method for Analysis of Isopropylbenzene (Cumene) by Gas Chromatography

SCOPE

1.1 This test method covers the determination of the purity of isopropylbenzene (cumene) by gas chromatography.

1.2 This test method has been found applicable to the measurement of impurities such as nonaromatic hydrocarbons, benzene, ethylbenzene, t-butylbenzene, n-propylbenzene, alpha-methylstyrene, sec-butylbenzene, and diisopropylbenzene, which are common to the manufacturing process of isopropylbenzene. Limit of detection for these impurities is 10 mg/kg (see 5.1).

1.3 The following applies to all specified limits in this standard: for purposes of determining conformance with this standard, an observed value or a calculated value shall be rounded off "to the nearest unit" in the last right-hand digit used in expressing the specification limit, in accordance with the rounding-off method of Practice E 29.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 3760 – 98

Standard Test Method for

Analysis of Isopropylbenzene (Cumene) by Gas

Chromatography

This standard is issued under the fixed designation D 3760; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Summary of Test Method

1.1 This test method covers the determination of the purity 3.1 A known amount of internal standard is added to a

of isopropylbenzene (cumene) by gas chromatography. sample of isopropylbenzene. The prepared sample is mixed

1.2 This test method has been found applicable to the and analyzed by a gas chromatograph equipped with a flame

measurement of impurities such as nonaromatic hydrocarbons, ionization detector (FID). The peak area of each impurity and

benzene, ethylbenzene, t-butylbenzene, n-propylbenzene, the internal standard is measured and the amount of each

alpha-methylstyrene, sec-butylbenzene, and diisopropylben- impurity is calculated from the ratio of the peak area of the

zene, which are common to the manufacturing process of internal standard versus the peak area of the impurity. Purity by

isopropylbenzene. Limit of detection for these impurities is 10 GC (the isopropylbenzene content) is calculated by subtracting

mg/kg (see 5.1). the sum of the impurities found from 100.00. Results are

1.3 The following applies to all specified limits in this reported in weight percent.

standard: for purposes of determining conformance with this

4. Significance and Use

standard, an observed value or a calculated value shall be

rounded off “to the nearest unit” in the last right-hand digit 4.1 This test method is suitable for setting specifications on

the materials referenced in 1.2 and for use as an internal quality

used in expressing the specification limit, in accordance with

the rounding-off method of Practice E 29. control tool where isopropylbenzene is produced or is used in

a manufacturing process. It may also be used in development

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the or research work involving isopropylbenzene.

4.2 This test method is useful in determining the purity of

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- isopropylbenzene with normal impurities present including

diisopropylbenzenes. If extremely high boiling or unusual

bility of regulatory limitations prior to use. For specific hazard

statements, see Section 7. impurities are present in the isopropylbenzene, this test method

would not necessarily detect them and the purity calculation

2. Referenced Documents

would be erroneous.

2.1 ASTM Standards: 4.3 Cumene hydroperoxide, if present, will yield decompo-

D 3437 Practice for Sampling and Handling Liquid Cyclic sition products that will elute in the chromatogram thereby

Products giving incorrect results.

E 29 Practice for Using Significant Digits in Test Data to 4.4 The nonaromatic hydrocarbons commonly present from

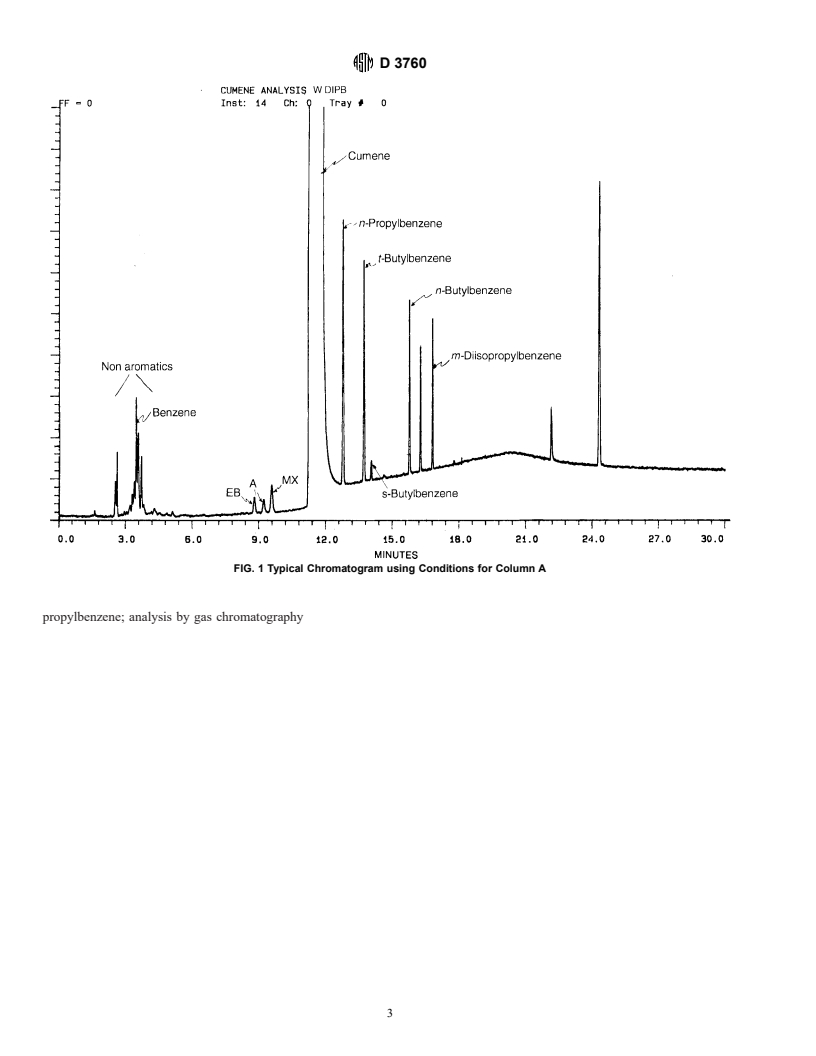

Determine Conformance with Specifications the isopropylbenzene manufacturing process will interfere with

E 260 Practice for Packed Gas Chromatography the determination of benzene when Column A in Table 1 is

E 355 Practice for Gas Chromatography Terms and Rela- used.

tionships 4.5 The internal standard must be sufficiently resolved from

2.2 Other Document: any impurity and the isopropylbenzene peak.

OSHA Regulations, 29CFR, paragraphs 1910.1000 and

4 5. Apparatus

1910.1200

5.1 Gas Chromatograph—Any instrument having a flame

ionization detector that can be operated at the conditions given

This test method is under the jurisdiction of ASTM Committee D16 on

in Table 1. The system should have sufficient sensitivity to

Aromatic Hydrocarbons and Related Chemicals and is the direct responsibility of

Subcommittee D16.0H on Styrene, Ethylbenzene, and C and C Aromatic obtain a minimum peak height response for 10 mg/kg

9 10

Hydrocarbons.

n-butylbenzene of twice the height of the signal background

Current edition approved May 10, 1998. Published August 1998. Originally

e1 noise.

published as D 3760 – 79. Last previous edition D 3760 – 93 .

Annual Book of ASTM Standards, Vol 06.04. 5.2 Columns—The choice of column is based on resolution

Annual Book of ASTM Standards, Vol 14.02.

requirements. Any column may be used that is capable of

Available from Superintendent of Documents, U.S. Government Printing

resolving all significant impurities from isopropylbenzene and

Office, Washington, DC 20402.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 3760

TABLE 1 Instrumental Parameters

conditioning the column into the chromatograph and adjusting

Column A Column B the instrument to the conditions described in Table 1 allowing

sufficient time for the equipment to reach equilibrium. See

Detector Flame Ionization Flame Ionization

Column:

Practices E 260 and E 355 for additional information on gas

Tubing fused silica fused silica

chromatography practices and terminology.

Stationary phase polyethylene glycol methyl silicone

Solid support crosslinked crosslinked

10. Procedure

Film thickness 0.25 μ 0.5 μ

Length, m 50 50

10.1 Into a 100-mL volumetric flask, add 100 μL of nBB to

Diameter, mm 0.32 mm ID 0.32 mm ID

99.90 mL of cumene. Mix well. Assuming a density of 0.856

Temperatures:

for nBB and 0.857 for cumene, the resulting nBB concentration

Injector, °C 275 275

Detector, °C 300 300

will be 0.1000 weight %.

Oven:

10.2 Inject into the gas chromatography an appropriate

Initial, °C 60 35

Time 1, min 10 10 amount of sample as previously determined according to 6.1

Final, °C 175 275

and start the analysis.

Rate, °C/min 10 5

10.3 Obtain a chromatograph and peak integration report.

Time 2, min 10 0

Fig. 1 and Fig. 2 illustrate a typical analysis of cumene for

Carrier gas hydrogen helium

Flow rate, mL/min 1.0 1.0

Columns A and B, respectively.

Split ratio 100:1 100:1

Sample size, μL

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.