ASTM E2141-01

(Test Method)Standard Test Methods for Assessing the Durability of Absorptive Electrochromic Coatings on Sealed Insulating Glass Units

Standard Test Methods for Assessing the Durability of Absorptive Electrochromic Coatings on Sealed Insulating Glass Units

SCOPE

1.1 The tests described are methods for the accelerated aging and monitoring of the time-dependent performance of electrochromic windows. Cross sections of typical electrochromic windows are shown in which devices have four or five-layers of coatings that include the two or three active layers sandwiched between transparent conducting electrodes (TCEs, see Section 3).

1.2 The test methods are applicable only for multilayered (two or more coatings between the TCEs) absorptive electrochromic coatings on sealed insulating glass (IG) units fabricated for vision glass (superstrate and substrate) areas for use in buildings, such as sliding doors, windows, skylights, and exterior wall systems. The multilayers used for electrochromically changing the optical properties may be inorganic or organic materials between the superstrate and substrate.

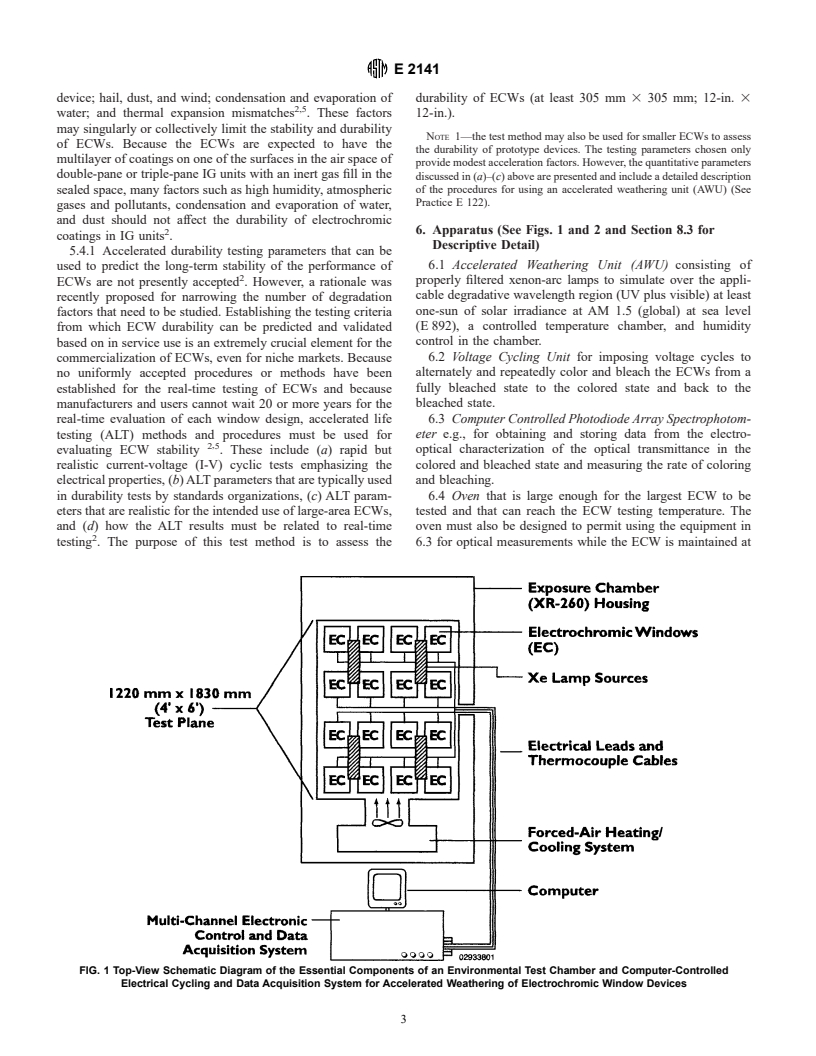

1.3 The electrochromic coatings used in this test method are exposed to solar radiation and are deployed to control the amount of radiation by absorption and reflection and thus, limit the solar heat gain and amount of solar radiation that is transmitted into the building.

1.4 The test methods are not applicable to other chromogenic devices, e.g., photochromic and thermochromic devices.

1.5 The test methods are not applicable to electrochromic devices consisting of three layers of coatings including the two transparent conducting electrodes (see Section 3 ).

1.6 The test methods are not applicable to electrochromic windows that are constructed from superstrate or substrate materials other than glass.

1.7 The test methods referenced herein are laboratory tests conducted under specified conditions. These tests are intended to simulate and, in some cases, to also accelerate actual in-service use of the electrochromic windows. Results from these tests cannot be used to predict the performance with time of in-service units unless actual corresponding in-service tests have been conducted and appropriate analyses have been conducted to show how performance can be predicted from the accelerated aging tests.

1.8 The values stated in metric (SI) units are to be regarded as the standard.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

Designation: E 2141 – 01

Standard Test Methods for

Assessing the Durability of Absorptive Electrochromic

1

Coatings on Sealed Insulating Glass Units

This standard is issued under the fixed designation E 2141; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope accelerated aging tests.

1.8 The values stated in metric (SI) units are to be regarded

1.1 The tests described are methods for the accelerated

as the standard.

aging and monitoring of the time-dependent performance of

1.9 This standard does not purport to address all of the

electrochromic windows. Cross sections of typical electrochro-

2

safety concerns, if any, associated with its use. It is the

mic windows are shown in which devices have four or

responsibility of the user of this standard to establish appro-

five-layers of coatings that include the two or three active

priate safety and health practices and determine the applica-

layers sandwiched between transparent conducting electrodes

bility of regulatory limitations prior to use.

(TCEs, see Section 3).

1.2 The test methods are applicable only for multilayered

2. Referenced Documents

(two or more coatings between the TCEs) absorptive electro-

2.1 ASTM Standards:

chromic coatings on sealed insulating glass (IG) units fabri-

3

C 168 Terminology Relating to Building Materials

cated for vision glass (superstrate and substrate) areas for use

C 1199 Test Method for Measuring the Steady State Ther-

in buildings, such as sliding doors, windows, skylights, and

mal Transmittance of Fenestration Systems Using Hot Box

exterior wall systems. The multilayers used for electrochromi-

3

Methods

cally changing the optical properties may be inorganic or

E 122 Practice for Choice of Sample Size to Estimate a

organic materials between the superstrate and substrate.

4

Measure of Quality for a Lot or Process

1.3 The electrochromic coatings used in this test method are

E 632 Practice to Aid Prediction of Service Life of Building

exposed to solar radiation and are deployed to control the

3

Components and Materials

amount of radiation by absorption and reflection and thus, limit

E 773 Test Method for Accelerated Weathering of Sealed

the solar heat gain and amount of solar radiation that is

3

Insulating Glass Units

transmitted into the building.

E 774 Specification for the Classification of the Durability

1.4 The test methods are not applicable to other chromoge-

3

of Sealed Insulating Glass Units

nic devices, e.g., photochromic and thermochromic devices.

E 891 Tables for Terrestrial Direct Normal Solar Spectral

1.5 The test methods are not applicable to electrochromic

3

Irradiance for Air Mass 1.5

devices consisting of three layers of coatings including the two

E 892 Tables for Terrestrial Solar Spectral Irradiance at Air

transparent conducting electrodes (see Section 3).

3

Mass 1.5 for a 37º Tilted Surface

1.6 The test methods are not applicable to electrochromic

E 903 Test Method for Solar Absorptance, Reflectance, and

windows that are constructed from superstrate or substrate

3

Transmittance of Materials Using Integrating Spheres

materials other than glass.

E 1423 Practice for Determining the Steady State Thermal

1.7 The test methods referenced herein are laboratory tests

3

Transmittance of Fenestration Systems

conducted under specified conditions. These tests are intended

3

E 1887 Test Method for Fog Determination

to simulate and, in some cases, to also accelerate actual

E 2094 Practice for Evaluating the Service Lifetime of

in-service use of the electrochromic windows. Results from

3

Chromogenic Glazings

these tests cannot be used to predict the performance with time

G 113 Terminology Relating to Natural and Artificial

of in-service units unless actual corresponding in-service tests

3

Weathering Tests of Non- Metallic Materials

have been conducted and appropriate analyses have been

G 151 Practice for Exposing Nonmetallic Materials in ac-

conducted to show how performance can be predicted from the

3

celerated Test Devices that Use Laboratory Light Source

G 155 Practice for Operating Xenon Arc Light Apparatus

1 3

This test method is under the jurisdiction of ASTM Committee E06 on

for Exposure of Non-Metallic Materials

Performance of Building Constructions and is the direct responsibility of Subcom-

2.2 Canadian Standards:

mittee E06.22 on Durability of Building Constructions.

Current edition approved April 10, 2001. Published August 2001.

2

A. W. Czanderna and C. M. Lampert, “Evaluation Criteria and Test Methods for

3

Electrochromic Windows,” SERI/PR-255-3537 (July 1990), Golden, CO: Solar Annual Book of ASTM Standards, Vol 04.07.

4

Energy Research Institute. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-29

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.