ASTM E2431-12(2020)

(Practice)Standard Practice for Determining the Resistance of Single Glazed Annealed Architectural Flat Glass to Thermal Loadings

Standard Practice for Determining the Resistance of Single Glazed Annealed Architectural Flat Glass to Thermal Loadings

SIGNIFICANCE AND USE

5.1 Use of this practice assumes:

5.1.1 the glass edges shall be free from damage,

5.1.2 the glass shall be properly glazed,

5.1.3 the glass shall not have been subjected to abuse, and

5.1.4 the glass edge support allows in-plane movement of the glass due to thermal expansion and contraction.

5.2 This practice does not address all factors that cause thermally induced stresses in annealed glass. Factors that are not addressed include: transient thermal stresses, HVAC registers, thermally insulating window coverings, drop ceilings and other heat traps, increased solar irradiance caused by exterior reflections, variations in heat transfer coefficients other than those assumed for the steady state analysis described herein, and stresses induced by thermal sources other than the sun. Factors other than those listed above may also induce thermal stress.

5.3 Many other factors shall be considered in glass selection. These factors include, but are not limited to, mechanically induced stresses, wind effects, windborne debris impacts, excessive deflections, seismic effects, heat flow, noise abatement, potential post-breakage consequences, and so forth. In addition, considerations set forth in building codes along with criteria presented in safety glazing standards and site specific concerns may control the ultimate glass type and thickness selection.

5.4 The proper use of this practice is intended to reduce the risk of thermally induced breakage of annealed window glass in buildings.

SCOPE

1.1 This practice covers a procedure to determine the resistance of annealed architectural flat glass to thermally induced stresses caused by exposure to sun and shadows for a specified probability of breakage (Pb). Proper use of this procedure is intended to reduce the possibility of thermal breakage of annealed glass in buildings.

1.2 This practice applies to vertical or sloped glazing in buildings.

1.3 This practice applies to monolithic and laminated glass of rectangular shape and assumes that all glass edges are simply supported.

1.4 This practice applies only to annealed flat soda-lime silica glass with clean cut, seamed, flat ground, or ground and polished edges that are free from damage. The glass may be clear or tinted as well as coated (not including coatings that reduce emissivity of the glass).

1.5 This practice does not apply to any form of wired, patterned, etched, sandblasted, drilled, notched, or grooved glass or glass with surface and edge treatments, other than those described in 1.4, that alter the glass strength.

1.6 This practice does not address uniform loads such as wind and snow loads, safety requirements, fire, or impact resistance.

1.7 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard. For conversion of quantities in various systems of measurements to SI units, refer to IEEE/ASTM SI-10.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2431 − 12 (Reapproved 2020)

Standard Practice for

Determining the Resistance of Single Glazed Annealed

Architectural Flat Glass to Thermal Loadings

This standard is issued under the fixed designation E2431; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.9 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 This practice covers a procedure to determine the

ization established in the Decision on Principles for the

resistance of annealed architectural flat glass to thermally

Development of International Standards, Guides and Recom-

induced stresses caused by exposure to sun and shadows for a

mendations issued by the World Trade Organization Technical

specified probability of breakage (P ). Proper use of this

b

Barriers to Trade (TBT) Committee.

procedure is intended to reduce the possibility of thermal

breakage of annealed glass in buildings.

2. Referenced Documents

1.2 This practice applies to vertical or sloped glazing in

buildings. 2.1 ASTM Documents:

C162 Terminology of Glass and Glass Products

1.3 This practice applies to monolithic and laminated glass

E631 Terminology of Building Constructions

of rectangular shape and assumes that all glass edges are

IEEE/ASTM SI-10 Use of the International System of Units

simply supported.

(SI) (the Modernized Metric System)

1.4 This practice applies only to annealed flat soda-lime

2.2 Other Document:

silica glass with clean cut, seamed, flat ground, or ground and

2005 ASHRAE Handbook Fundamentals

polished edges that are free from damage. The glass may be

clear or tinted as well as coated (not including coatings that

3. Terminology

reduce emissivity of the glass).

3.1 Definitions:

1.5 This practice does not apply to any form of wired,

3.1.1 For definitions of general terms related to building

patterned, etched, sandblasted, drilled, notched, or grooved

construction used in this test method refer to Terminology

glass or glass with surface and edge treatments, other than

E631, and for general terms related to glass and glass products,

those described in 1.4, that alter the glass strength.

refer to Terminology C162.

1.6 This practice does not address uniform loads such as

3.2 Definitions of Terms Specific to This Standard:

wind and snow loads, safety requirements, fire, or impact

3.2.1 edge bite, n—the width of the glass edge (measured

resistance.

perpendicular to the cut edge, in the plane of the glass) that is

1.7 The values stated in SI units are to be regarded as protected from direct exposure to solar irradiance by the

window frame edge conditions expressed in mm (in.) (see

standard. The values given in parentheses after SI units are

provided for information only and are not considered standard. Table 1).

For conversion of quantities in various systems of measure-

3.2.2 edge thermal stress factor (TSF ),n—the ratio of

edge

ments to SI units, refer to IEEE/ASTM SI-10.

induced thermal stress to the solar load, SL, as the result of the

edge bite condition expressed in MPa/(W/m ).

1.8 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3.2.3 frame type, n—the manner in which the edges of the

responsibility of the user of this standard to establish appro-

glass are supported in the window frame (see Table 1).

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

This practice is under the jurisdiction of ASTM Committee E06 on Perfor- contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

mance of Buildings and is the direct responsibility of Subcommittee E06.52 on Standards volume information, refer to the standard’s Document Summary page on

Glass Use in Buildings. the ASTM website.

Current edition approved July 1, 2020. Published July 2020. Originally approved Available from American Society of Heating, Refrigerating, and Air-

in 2006. Last previous edition approved in 2012 as E2431 – 12. DOI: 10.1520/ Conditioning Engineers, Inc. (ASHRAE), 1791 Tullie Circle, NE, Atlanta, GA

E2431-12R20. 30329, http://www.ashrae.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2431 − 12 (2020)

TABLE 1 Frame Types

Frame Type Sketch

Insulated edge -- This condition should only be used in the analysis if it can

reasonably be assumed that the heat loss from the glass to the glazing

pocket is negligible.

Conventional edge -- This condition should be used in the analysis only when

the glazing pocket is fabricated with thin walled members and the glass is

cushioned with gasket materials as shown.

High heat mass edge -- This condition should be used in the analysis when the

glazing is encapsulated in a material with a high heat mass such as concrete,

heavy metal, and so forth.

3.2.4 glass dimensions, n—the rectangular dimensions of 3.2.6 probability of breakage (P ),n—the number of lites

b

the glass (not the daylight opening), with the width being the per 1000 that would be predicted to break when exposed to the

smaller dimension and the length being the larger dimension

specified thermal loading conditions.

both expressed in mm.

3.2.7 shadow thermal stress factor (TSF ),n—the ratio

shadow

3.2.5 incident solar irradiance (Insolation), (I ),n—amount

s

of induced thermal stress to the solar load, SL, as the result of

of solar energy per unit time per unit area normal to glass, to

2 2

shadow condition expressed in MPa/(W/m ) (psi/Btu/hr·ft ).

which the glass is exposed expressed in W/m .

E2431 − 12 (2020)

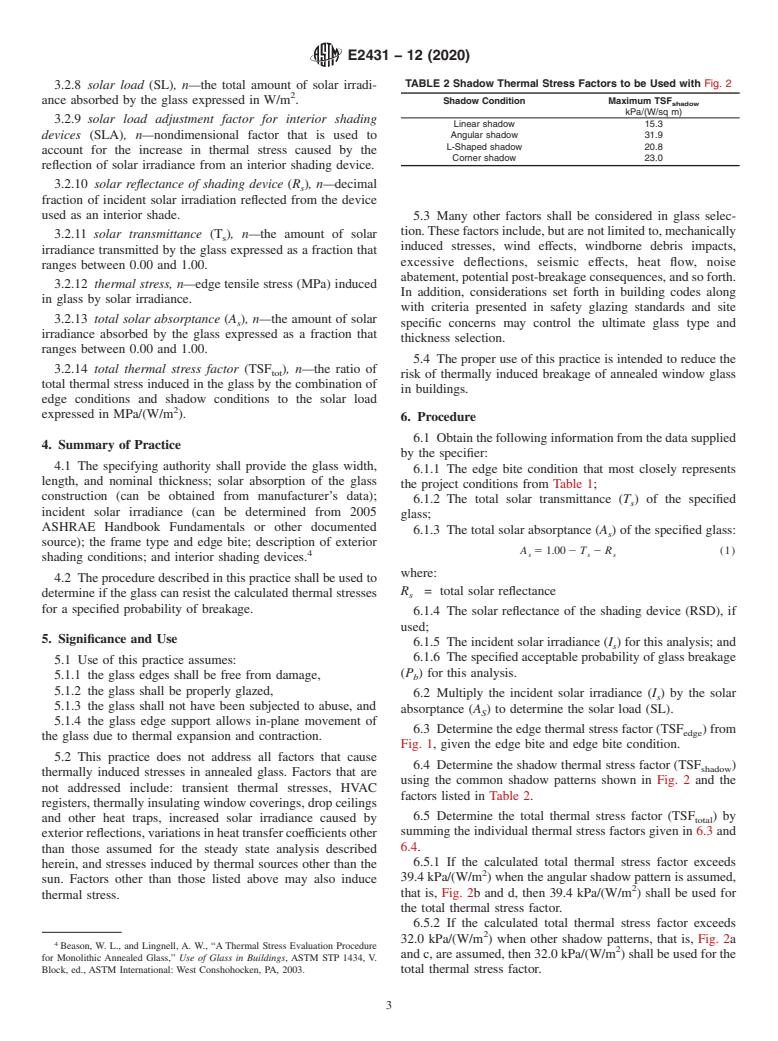

TABLE 2 Shadow Thermal Stress Factors to be Used with Fig. 2

3.2.8 solar load (SL),n—the total amount of solar irradi-

ance absorbed by the glass expressed in W/m . Shadow Condition Maximum TSF

shadow

kPa/(W/sq m)

3.2.9 solar load adjustment factor for interior shading

Linear shadow 15.3

Angular shadow 31.9

devices (SLA),n—nondimensional factor that is used to

L-Shaped shadow 20.8

account for the increase in thermal stress caused by the

Corner shadow 23.0

reflection of solar irradiance from an interior shading device.

3.2.10 solar reflectance of shading device (R ),n—decimal

s

fraction of incident solar irradiation reflected from the device

used as an interior shade.

5.3 Many other factors shall be considered in glass selec-

tion.These factors include, but are not limited to, mechanically

3.2.11 solar transmittance (T ),n—the amount of solar

s

induced stresses, wind effects, windborne debris impacts,

irradiance transmitted by the glass expressed as a fraction that

excessive deflections, seismic effects, heat flow, noise

ranges between 0.00 and 1.00.

abatement, potential post-breakage consequences, and so forth.

3.2.12 thermal stress, n—edge tensile stress (MPa) induced

In addition, considerations set forth in building codes along

in glass by solar irradiance.

with criteria presented in safety glazing standards and site

3.2.13 total solar absorptance (A ),n—the amount of solar

s

specific concerns may control the ultimate glass type and

irradiance absorbed by the glass expressed as a fraction that

thickness selection.

ranges between 0.00 and 1.00.

5.4 The proper use of this practice is intended to reduce the

3.2.14 total thermal stress factor (TSF ),n—the ratio of

tot

risk of thermally induced breakage of annealed window glass

total thermal stress induced in the glass by the combination of

in buildings.

edge conditions and shadow conditions to the solar load

expressed in MPa/(W/m ).

6. Procedure

6.1 Obtain the following information from the data supplied

4. Summary of Practice

by the specifier:

4.1 The specifying authority shall provide the glass width,

6.1.1 The edge bite condition that most closely represents

length, and nominal thickness; solar absorption of the glass

the project conditions from Table 1;

construction (can be obtained from manufacturer’s data);

6.1.2 The total solar transmittance (T ) of the specified

s

incident solar irradiance (can be determined from 2005

glass;

ASHRAE Handbook Fundamentals or other documented

6.1.3 The total solar absorptance (A ) of the specified glass:

s

source); the frame type and edge bite; description of exterior

A 5 1.00 2 T 2 R (1)

s s s

shading conditions; and interior shading devices.

where:

4.2 The procedure described in this practice shall be used to

R = total solar reflectance

determine if the glass can resist the calculated thermal stresses s

for a specified probability of breakage.

6.1.4 The solar reflectance of the shading device (RSD), if

used;

5. Significance and Use

6.1.5 The incident solar irradiance (I ) for this analysis; and

s

6.1.6 The specified acceptable probability of glass breakage

5.1 Use of this practice assumes:

(P ) for this analysis.

5.1.1 the glass edges shall be free from damage, b

5.1.2 the glass shall be properly glazed,

6.2 Multiply the incident solar irradiance (I ) by the solar

s

5.1.3 the glass shall not have been subjected to abuse, and

absorptance (A ) to determine the solar load (SL).

S

5.1.4 the glass edge support allows in-plane movement of

6.3 Determine the edge thermal stress factor (TSF ) from

edge

the glass due to thermal expansion and contraction.

Fig. 1, given the edge bite and edge bite condition.

5.2 This practice does not address all factors that cause

6.4 Determine the shadow thermal stress factor (TSF )

shadow

thermally induced stresses in annealed glass. Factors that are

using the common shadow patterns shown in Fig. 2 and the

not addressed include: transient thermal stresses, HVAC

factors listed in Table 2.

registers, thermally insulating window coverings, drop ceilings

6.5 Determine the total thermal stress factor (TSF )by

and other heat traps, increased solar irradiance caused by

total

summing the individual thermal stress factors given in 6.3 and

exteriorreflections,variationsinheattransfercoefficientsother

6.4.

than those assumed for the steady state analysis described

6.5.1 If the calculated total thermal stress factor exceeds

herein, and stresses induced by thermal sources other than the

39.4 kPa/(W/m ) when the angular shadow pattern is assumed,

sun. Factors other than those listed above may also induce

that is, Fig. 2b and d, then 39.4 kPa/(W/m ) shall be used for

thermal stress.

the total thermal stress factor.

6.5.2 If the calculated total thermal stress factor exceeds

32.0 kPa/(W/m ) when other shadow patterns, that is, Fig. 2a

Beason, W. L., and Lingnell, A. W., “A Thermal Stress Evaluation Procedure

and c, are assumed, then 32.0 kPa/(W/m ) shall be used for the

for Monolithic Annealed Glass,” Use of Glass in Buildings, ASTM STP 1434, V.

Block, ed., ASTM International: West Conshohocken, PA, 2003. total thermal stress factor.

E2431 − 12 (2020)

FIG. 1 Edge Thermal Stress Factor Chart

6.6 To determine the solar load adjustment factor (SLA) 7. Report

using Fig. 3, enter the vertical axis with the solar reflectance of

7.1 The report shall consist of the design example work-

the shading device (RSD) and the horizontal axis with total

sheet presented in Fig. 5 or, as a minimum, shall include:

solar transmittance of the glass (T ) to determine the solar load

S

7.1.1 Project name,

adjustment factor (SLA) for interior shading devices. If nec-

7.1.2 Date,

essary use interpolation to estimate the solar load adjustment

7.1.3 Project location,

factor (SLA). If no shading device is used, the solar load

7.1.4 Glass type,

adjustment factor (SLA) shall be taken to be 1.0.

7.1.5 Glass dimensions,

6.7 Determine the calculated thermal stress, σ ,by 7.1.6 Edge bite,

calculated

multiplyingthetotalthermalstressfactor(TSF )bythesolar 7.1.7 Frame type,

total

load (SL) and by the solar load adjustment factor (SLA). 7.1.8 Solar absorptance (A ),

s

7.1.9 Solar transmittance (T ),

s

6.8 Determinetheperimeteroftheglasslitebyaddingtwice

7.1.10 Total Solar Reflectance of Shade Device (RSD),

the width to twice the height.

7.1.11 Incident solar irradiance (I ),

s

6.9 Determine the allowable thermal stress, σ , from

allowable

7.1.12 Acceptable probability of breakage (P ),

b

Fig.4usingtheglassperimeterandthespecifiedacceptable P .

b

7.1.13 Allowable thermal stress (σ ),

allowable

7.1.14 Calculated thermal stress (σ ), and

6.10 If σ > σ , P for the glass exceeds the

calculated allowable b calculated

specified probability of breakage for the thermal design con- 7.1.15 Conclusion.

ditions. If P for the glass exceeds the specified probability of

b

8. Keywords

breakage, the user shall consider using strengthened glass,

modifying the controllable design conditions, or having a more 8.1 annealed glass; flat glass; glass; thermal breakage;

comprehensive thermal stress analysis performed. thermal load; thermal stress; soda-lime silica glass

E2431 − 12 (2020)

FIG. 2 Shadow Conditions

E2431 − 12 (2020)

FIG. 3 Solar Load Adjustment Factor, SLA

FIG. 4 Probability of Breakage (POB) Chart

E2431 − 12 (2020)

DESIGN WORKSHEET FOR THERMAL STRESS EVALUATION

PROJECT: NAME: ______________________DATE:__________________

LOCATION: _______________________________________

Glass Type: _______________________

Glass Dimensions: width _________mm length ____________mm thickness____________mm

Perimeter _____________________m

Edge Bite: ______________________________mm

Frame Type: ___________________________

Solar Absorptance (A )__________________

s

Solar Transmittance (T )________________

s

Solar Reflectance of Shade Device (R )__________________

s

Incident solar irradiance (I )___________________W/m

s

Acceptable Probability of Breakage (P ) _____________

b

Compute Solar Load (SL)

SL = I × A = _______ W/m

s s

Determine Edge Thermal Stress Factor: Use Figure 1

TSF = ______________kPa/( W/m )

edge

Shadow Thermal Stress Factor (TSF )__________ kPa/(W/m ) (Use Figure 2 and Table 2)

shadow

Determine Total Thermal Stress Factor (TSF )

total

TSF = TSF + TSF , but no greater than 39.4 kPa/(W/m ) for angular shadows or 32.0

total edge shadow

kPa/(W/m ) for all

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.