ASTM C1678-09

(Practice)Standard Practice for Fractographic Analysis of Fracture Mirror Sizes in Ceramics and Glasses

Standard Practice for Fractographic Analysis of Fracture Mirror Sizes in Ceramics and Glasses

SIGNIFICANCE AND USE

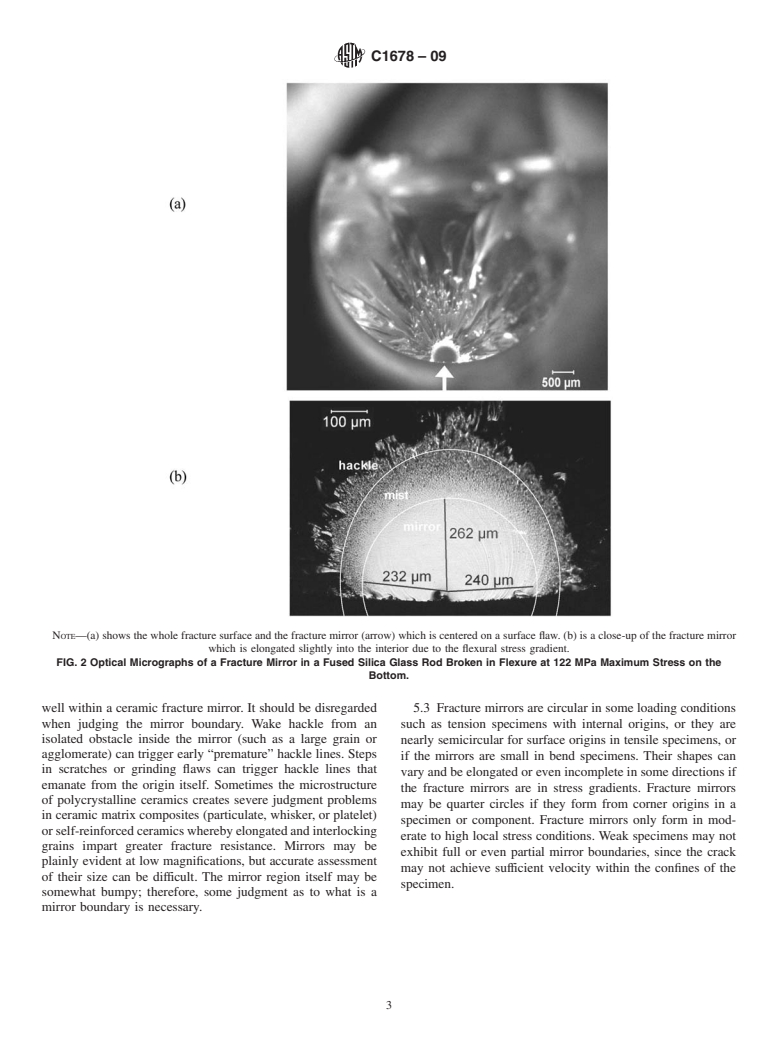

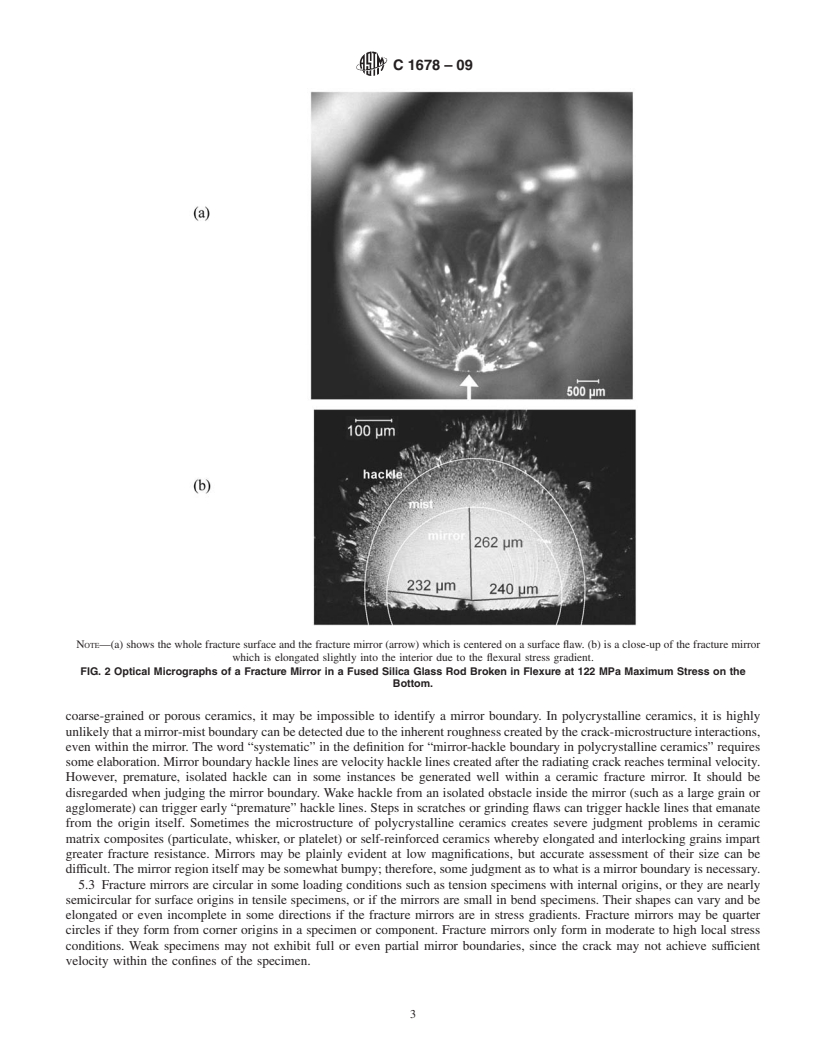

Fracture mirror size analysis is a powerful tool for analyzing glass and ceramic fractures. Fracture mirrors are telltale fractographic markings in brittle materials that surround a fracture origin as discussed in Practices C 1256 and C 1322. Fig. 1 shows a schematic with key features identified. Fig. 2 shows an example in glass. The fracture mirror region is very smooth and highly reflective in glasses, hence the name “fracture mirror.” In fact, high magnification microscopy reveals that, even within the mirror region in glasses, there are very fine features and escalating roughness as the crack advances away from the origin. These are submicrometer in size and hence are not discernable with an optical microscope. Early investigators interpreted fracture mirrors as having discrete boundaries including a “mirror-mist” boundary and also a “mist-hackle” boundary in glasses. These were also termed “inner mirror” or “outer mirror” boundaries, respectively. It is now known that there are no discrete boundaries corresponding to specific changes in the fractographic features. Surface roughness increases gradually from well within the fracture mirror to beyond the apparent boundaries. The boundaries were a matter of interpretation, the resolving power of the microscope, and the mode of viewing. In very weak specimens, the mirror may be larger than the specimen or component and the boundaries will not be present.

Figs. 3-5 show examples in ceramics. In polycrystalline ceramics, the qualifier “relatively” as in “relatively smooth” must be used, since there is an inherent roughness from the microstructure even in the area immediately surrounding the origin. In coarse-grained or porous ceramics, it may be impossible to identify a mirror boundary. In polycrystalline ceramics, it is highly unlikely that a mirror-mist boundary can be detected due to the inherent roughness created by the crack-microstructure interactions, even within the mirror. The word “systematic” in the defin...

SCOPE

1.1 This practice pertains to the analysis and interpretation of fracture mirror sizes in brittle materials. Fracture mirrors (Fig. 1) are telltale fractographic markings that surround a fracture origin in brittle materials. The fracture mirror size may be used with known fracture mirror constants to estimate the stress in a fractured component. Alternatively, the fracture mirror size may be used in conjunction with known stresses in test specimens to calculate fracture mirror constants. The practice is applicable to glasses and polycrystalline ceramic laboratory test specimens as well as fractured components. The analysis and interpretation procedures for glasses and ceramics are similar, but they are not identical. Different optical microscopy examination techniques are listed and described, including observation angles, illumination methods, appropriate magnification, and measurement protocols. Guidance is given for calculating a fracture mirror constant and for interpreting the fracture mirror size and shape for both circular and noncircular mirrors including stress gradients, geometrical effects, and/or residual stresses. The practice provides figures and micrographs illustrating the different types of features commonly observed in and measurement techniques used for the fracture mirrors of glasses and polycrystalline ceramics.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note—The initial flaw may grow stably to size ac prior to unstable fracture when the stress intensity reaches KIc. The mirror-mist radius is Ri, the mist-hackle radius is Ro, and...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:C1678–09

Standard Practice for

Fractographic Analysis of Fracture Mirror Sizes in Ceramics

1

and Glasses

This standard is issued under the fixed designation C1678; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This practice pertains to the analysis and interpretation 2.1 ASTM Standards:

of fracture mirror sizes in brittle materials. Fracture mirrors C1145 Terminology of Advanced Ceramics

(Fig. 1) are telltale fractographic markings that surround a C1256 Practice for Interpreting Glass Fracture Surface

fractureorigininbrittlematerials.Thefracturemirrorsizemay Features

be used with known fracture mirror constants to estimate the C1322 Practice for Fractography and Characterization of

stress in a fractured component. Alternatively, the fracture Fracture Origins in Advanced Ceramics

mirror size may be used in conjunction with known stresses in

3. Terminology

test specimens to calculate fracture mirror constants. The

practice is applicable to glasses and polycrystalline ceramic 3.1 Definitions: (See Fig. 1)

3.1.1 fracture mirror, n—as used in fractography of brittle

laboratory test specimens as well as fractured components.The

analysis and interpretation procedures for glasses and ceramics materials, a relatively smooth region in the immediate vicinity

of and surrounding the fracture origin C1145, C1322

are similar, but they are not identical. Different optical micros-

copy examination techniques are listed and described, includ- 3.1.2 fracture origin, n—the source from which brittle

fracture commences. C1145,C1322

ing observation angles, illumination methods, appropriate

magnification, and measurement protocols. Guidance is given 3.1.3 hackle, n—as used in fractography of brittle materials,

alineorlinesonthecracksurfacerunninginthelocaldirection

for calculating a fracture mirror constant and for interpreting

the fracture mirror size and shape for both circular and of cracking, separating parallel but noncoplanar portions of the

crack surface. C1145,C1322

noncircular mirrors including stress gradients, geometrical

3.1.4 mist, n—as used in fractography of brittle materials,

effects, and/or residual stresses. The practice provides figures

and micrographs illustrating the different types of features markings on the surface of an accelerating crack close to its

effective terminal velocity, observable first as a misty appear-

commonly observed in and measurement techniques used for

the fracture mirrors of glasses and polycrystalline ceramics. ance and with increasing velocity reveals a fibrous texture,

elongated in the direction of crack propagation.

1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this C1145,C1322

3.2 Definitions of Terms Specific to This Standard:

standard.

1.3 This standard does not purport to address all of the (See Fig. 1)

3.2.1 mirror-mist boundary in glasses, n—the periphery

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- where one can discern the onset of mist around a glass fracture

mirror. This boundary corresponds to A, the inner mirror

priate safety and health practices and determine the applica-

i

bility of regulatory limitations prior to use. constant.

3.2.2 mist-hackle boundary in glasses, n—the periphery

where one can discern the onset of systematic hackle around a

glass fracture mirror. This boundary corresponds to A , the

o

outer mirror constant.

3.2.3 mirror-hackle boundary in polycrystalline ceramics,,

n—theperipherywhereonecandiscerntheonsetofsystematic

1

This practice is under the jurisdiction of ASTM Committee C28 on Advanced

Ceramics and is the direct responsibility of Subcommittee C28.03 on Physical

2

Properties and Non-Destructive Evaluation. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2009. Published June 2009. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2007. Last previous edition approved in 2007 as C1678 – 07. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/C1678-09. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C1678–09

NOTE—The initial flaw may grow stably to size a prior to unstable fracture when the stress intensity reaches K . The mirror-mist radius is R, the

c Ic i

mist-hac

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C1678–07 Designation:C1678–09

Standard Practice for

Fractographic Analysis of Fracture Mirror Sizes in Ceramics

1

and Glasses

This standard is issued under the fixed designation C 1678; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice pertains to the analysis and interpretation of fracture mirror sizes in brittle materials. Fracture mirrors (Fig.

1) are telltale fractographic markings that surround a fracture origin in brittle materials. The fracture mirror size may be used with

known fracture mirror constants to estimate the stress in a fractured component.Alternatively, the fracture mirror size may be used

in conjunction with known stresses in test specimens to calculate fracture mirror constants. The practice is applicable to glasses

and polycrystalline ceramic laboratory test specimens as well as fractured components. The analysis and interpretation procedures

for glasses and ceramics are similar, but they are not identical. Different optical microscopy examination techniques are listed and

described, including observation angles, illumination methods, appropriate magnification, and measurement protocols. Guidance

is given for calculating a fracture mirror constant and for interpreting the fracture mirror size and shape for both circular and

noncircular mirrors including stress gradients, geometrical effects, and/or residual stresses. The practice provides figures and

micrographs illustrating the different types of features commonly observed in and measurement techniques used for the fracture

mirrors of glasses and polycrystalline ceramics.

1.2

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C 1145 Terminology of Advanced Ceramics

C 1256 Practice for Interpreting Glass Fracture Surface Features

C 1322 Practice for Fractography and Characterization of Fracture Origins in Advanced Ceramics

3. Terminology

3.1 Definitions: (See Fig. 1)

3.1.1 fracture mirror, n—asusedinfractographyofbrittlematerials,arelativelysmoothregionintheimmediatevicinityofand

surrounding the fracture origin C 1145, C 1322

3.1.2 fracture origin, n—the source from which brittle fracture commences. C 1145, C 1322

3.1.3 hackle, n—as used in fractography of brittle materials, a line or lines on the crack surface running in the local direction

of cracking, separating parallel but noncoplanar portions of the crack surface. C 1145, C 1322

3.1.4 mist, n—as used in fractography of brittle materials, markings on the surface of an accelerating crack close to its effective

terminal velocity, observable first as a misty appearance and with increasing velocity reveals a fibrous texture, elongated in the

direction of crack propagation. C 1145, C 1322

3.2 Definitions of Terms Specific to This Standard:

(See Fig. 1)

3.2.1 mirror-mist boundary in glasses, n— the periphery where one can discern the onset of mist around a glass fracture mirror.

This boundary corresponds to A, the inner mirror constant.

i

1

This practice is under the jurisdiction ofASTM Committee C28 onAdvanced Ceramics and is the direct responsibility of Subcommittee C28.03 on Physical Properties

and Non-Destructive Evaluation.

Current edition approved Oct. 15, 2007. Published February 2008.

Current edition approved May 1, 2009. Published June 2009. Originally approved in 2007. Last previous edition approved in 2007 as C 1678 – 07.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C1678–09

NOTE—The initial flaw may grow stably to size a prior to unstable fracture when the stress intensity reaches K . The mirror-m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.