ASTM F218-13(2020)

(Test Method)Standard Test Method for Measuring Optical Retardation and Analyzing Stress in Glass

Standard Test Method for Measuring Optical Retardation and Analyzing Stress in Glass

SIGNIFICANCE AND USE

4.1 The performance of glass products may be affected by presence of residual stresses due to process, differential thermal expansion between fused components, and by inclusions. This test method provides means of quantitative evaluation of stresses.

SCOPE

1.1 This test method covers the analysis of stress in glass by means of a polarimeter based on the principles developed by Jessop and Friedel (1, 2).2 Stress is evaluated as a function of optical retardation, that is expressed as the angle of rotation of an analyzing polarizer that causes extinction in the glass.

1.2 There is no known ISO equivalent to this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F218 − 13 (Reapproved 2020)

Standard Test Method for

Measuring Optical Retardation and Analyzing Stress in

1

Glass

ThisstandardisissuedunderthefixeddesignationF218;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E177Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

1.1 Thistestmethodcoverstheanalysisofstressinglassby

E691Practice for Conducting an Interlaboratory Study to

means of a polarimeter based on the principles developed by

2 Determine the Precision of a Test Method

Jessop and Friedel (1, 2). Stress is evaluated as a function of

optical retardation, that is expressed as the angle of rotation of

3. Terminology

an analyzing polarizer that causes extinction in the glass.

3.1 Definitions:

1.2 There is no known ISO equivalent to this standard.

3.1.1 For definitions of terms used in this test method, refer

1.3 This standard does not purport to address all of the

to Terminology C162.

safety concerns, if any, associated with its use. It is the

4. Significance and Use

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

4.1 The performance of glass products may be affected by

mine the applicability of regulatory limitations prior to use.

presence of residual stresses due to process, differential ther-

1.4 This international standard was developed in accor-

mal expansion between fused components, and by inclusions.

dance with internationally recognized principles on standard-

This test method provides means of quantitative evaluation of

ization established in the Decision on Principles for the

stresses.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical 5. Calibration and Standardization

Barriers to Trade (TBT) Committee.

5.1 Whenever calibration of the polarimeter is required by

product specification, Practices C1426 for verification and

2. Referenced Documents

calibration should be used.

3

2.1 ASTM Standards:

6. Polarimeter

C162Terminology of Glass and Glass Products

C770Test Method for Measurement of Glass Stress—

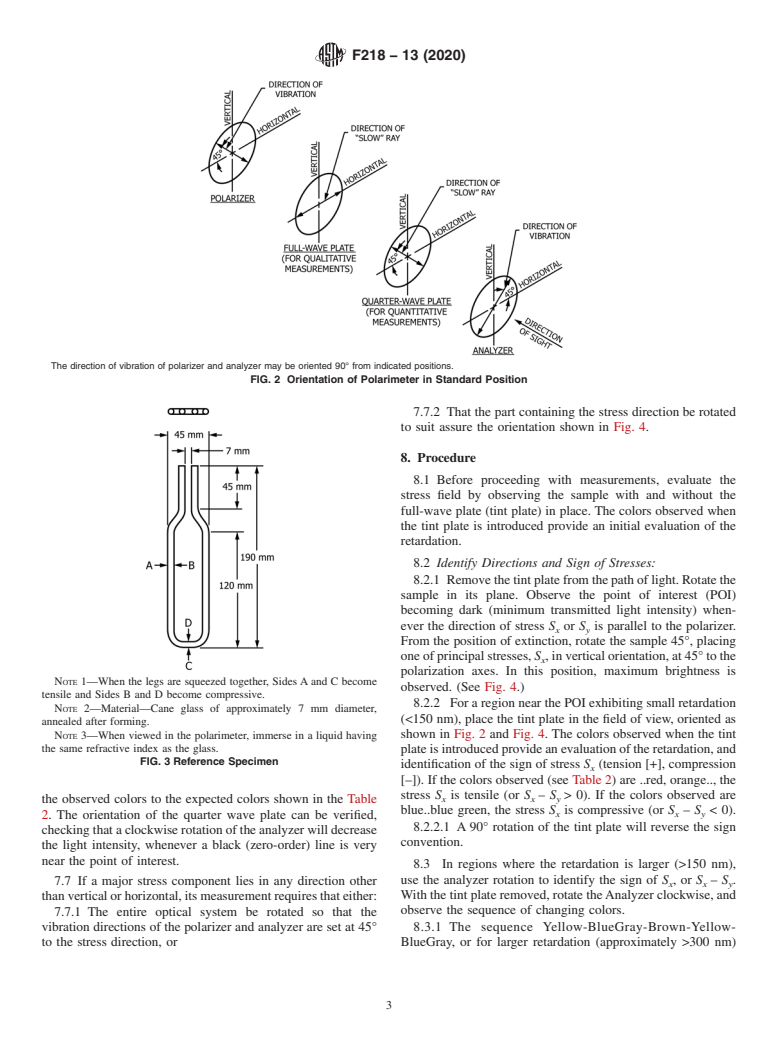

6.1 The polarimeter shall consist of an arrangement similar

Optical Coefficient

to that shown in Fig. 1. A description of each component

C978Test Method for Photoelastic Determination of Re-

follows:

sidual Stress in a Transparent Glass Matrix Using a

6.1.1 Source of Light—Either a white light or a monochro-

Polarizing Microscope and Optical Retardation Compen-

matic source such as sodium light (λ 589 nm) or a white light

sation Procedures

covered with a narrow-band interferential filter B (see Fig. 1)

C1426Practices forVerification and Calibration of Polarim-

transmitting the desired monochromatic wavelength.

eters

NOTE 1—The white light should provide a source of illumination with

solar temperature of at least that of Illuminant A.

6.1.2 Filter—The filter should be placed between the light

1

This test method is under the jurisdiction of ASTM Committee C14 on Glass

source and the polarizer, or between the analyzer and the

and Glass Products and is the direct responsibility of Subcommittee C14.04 on

Physical and Mechanical Properties.

viewer (see Fig. 1).

Current edition approved Aug. 1, 2020. Published September 2020. Originally

6.1.3 Diffuser—A piece of opal glass or a ground glass of

approved in 1950. Last previous edition approved in 2013 as F218 – 13. DOI:

photographic quality.

10.1520/F0218-13R20.

2

6.1.4 Polarizer—Apolarizing element housed in a rotatable

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

this test method.

mount capable of being locked in a fixed position shown in

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Fig. 2 and Fig. 4.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.1.5 Immersion Cell—Rectangular glass jar with strain-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. free, retardation-free viewing sides filled with a liquid having

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F218 − 13 (2020)

7.2 As usually employed, the polarimeter measures retarda-

tions in a sample that is placed in the polarimeter and rotated

until the measured stresses S and S are oriented along V and

x y

H (vertical or a horizontal) direction. Th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.