ASTM D8162-20

(Test Method)Standard Test Method for Determination of the Apparent Viscosity of Thermoplastic Pavement Marking Materials using a Rotational Viscometer with Temperature Control Heating Unit

Standard Test Method for Determination of the Apparent Viscosity of Thermoplastic Pavement Marking Materials using a Rotational Viscometer with Temperature Control Heating Unit

SIGNIFICANCE AND USE

5.1 This test method is used to measure the apparent viscosity of thermoplastic pavement marking at elevated temperatures. Elevated temperature viscosities of thermoplastic pavement marking may be related to the properties of coatings, adhesives, and composite thermoplastics. This method is helpful in determining the flow properties which can be used in determining processability when applied to the road surface.

5.2 Thermoplastic pavement markings may be applied to the road surface in several different ways. Typical methods of application are screed extrude, ribbon extrude, thin film spray, and standard spray. Proper application depends on the viscosity of the thermoplastic material at application temperatures for the method being used. Thin-line applied thermoplastic pavement marking, for example, requires a relatively lower viscosity. Screed extrude applied thermoplastic requires a higher viscosity.

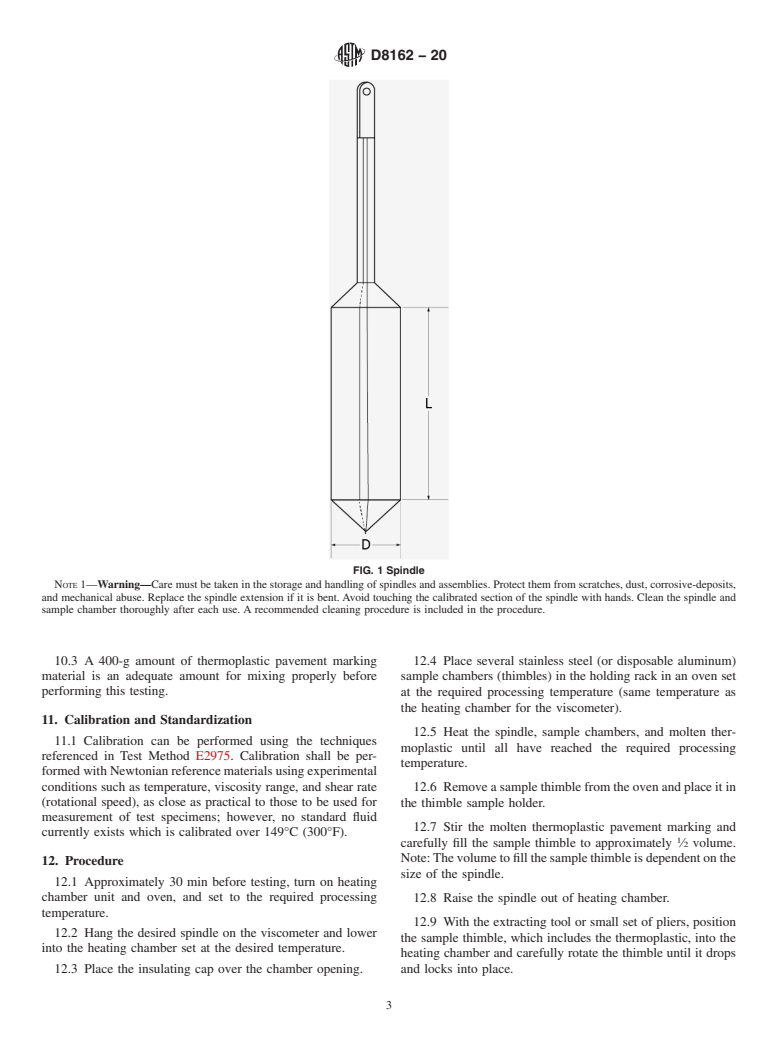

5.3 Materials of the type described in this procedure may be non-Newtonian, and as such, the apparent viscosity will be a function of shear rate under the conditions of test. Although the viscometer described in this test method operates under conditions of relatively low shear rate, differences in shear effect can exist depending upon the spindle and rotational speed conditions selected for the test program. Comparisons between non-Newtonian viscosity values should be made only for measurements made with similar viscometers under conditions of equivalent shear. For this method, “torpedo” spindles are recommended. Spindles considered torpedo spindles are ~1-in. long and come in many diameters with a 45° conical bottom. A diameter that is half the diameter of the thimbles used is recommended. If large glass beads are used in the pavement marking formulation, a smaller diameter spindle may be needed so the beads do not cause an impedance of the spindle due to a jamming between the inside wall of the thimble and the spindle.

SCOPE

1.1 This test method covers the sample preparation and testing procedure needed to determine the apparent viscosity of a thermoplastic pavement marking formulation at elevated temperatures to the specimen.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are customary units and are provided as a courtesy to the user.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D8162 − 20

Standard Test Method for

Determination of the Apparent Viscosity of Thermoplastic

Pavement Marking Materials using a Rotational Viscometer

1

with Temperature Control Heating Unit

This standard is issued under the fixed designation D8162; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Determine the Precision of a Test Method

E2975 Test Method for Calibration or Calibration Verifica-

1.1 This test method covers the sample preparation and

tion of Concentric Cylinder Rotational Viscometers

testing procedure needed to determine the apparent viscosity of

a thermoplastic pavement marking formulation at elevated

3. Terminology

temperatures to the specimen.

3.1 The terms and definitions in Terminology D883 and

1.2 The values stated in SI units are to be regarded as

Terminology E284 apply to this test method.

standard. The values given in parentheses after SI units are

customary units and are provided as a courtesy to the user. 3.2 Definitions of Terms Specific to This Standard:

3.2.1 apparent viscosity, n—the viscosity determined by this

1.3 This standard does not purport to address all of the

test method can be expressed in millipascal seconds,

safety concerns, if any, associated with its use. It is the

Centipoise, and Poise. Common viscosity units of Poise (P) are

responsibility of the user of this standard to establish appro-

related to the SI units by the equivalency 1 cP = 1 mPa·s.

priate safety, health, and environmental practices and deter-

3.2.1.1 Discussion—An apparent viscosity value may vary

mine the applicability of regulatory limitations prior to use.

with the spindle and rotational speed elected for measuring

1.4 This international standard was developed in accor-

non-Newtonian materials.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the 3.2.2 thermoplastic pavement marking (material), n—a

highly filled 100 % total solids highway marking system that

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical when heated to a molten state can be extruded or sprayed onto

a road surface. Retroreflective optics are applied (dropped on)

Barriers to Trade (TBT) Committee.

to the surface of the molten marking immediately after

2. Referenced Documents application to provide, when cooled, a solid durable delineator

2

or thermoplastic pavement marking usually melted to ~218°C

2.1 ASTM Standards:

(425°F)

D883 Terminology Relating to Plastics

D7307 PracticeforSamplingofThermoplasticTrafficMark- 3.2.3 viscosity, n—the ratio of shear stress to shear rate.

3.2.3.1 Discussion—The viscosity of a liquid is a measure

ing Materials

D7308 Practice for Sample Preparation of Thermoplastic of the resistance to flow of the liquid. The SI unit of dynamic

Pavement Marking Materials viscosity is the pascal second. For a Newtonian liquid, the

E177 Practice for Use of the Terms Precision and Bias in viscosity is constant at all shear rates. For a non-Newtonian

ASTM Test Methods liquid, viscosity will vary depending on shear rate.

E284 Terminology of Appearance

E691 Practice for Conducting an Interlaboratory Study to 4. Summary of Test Method

4.1 This viscosity method is used to determine the apparent

viscosity of thermoplastic pavement marking products at

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint

elevated temperatures. Apparent viscosity is determined under

and Related Coatings, Materials, andApplications and is the direct responsibility of

temperature equilibrium conditions using a rotating spindle

Subcommittee D01.44 on Traffic Coatings.

type viscometer. The torque on a spindle rotating in a

Current edition approved June 1, 2020. Published September 2020. DOI:

10.1520/D8162-20.

temperature-controlled sample holder containing a small

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

amount of sample is used to measure the relative resistance to

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

rotation. A factor is applied to the torque reading to yield the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. viscosity in mPa·s (cP or Poise).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D8162 − 20

5. Significance and Use 7.1.1 A drive motor, to apply a unidirectional torque to the

specimen constant to 61%;

5.1 This te

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.