ASTM E592-15

(Guide)Standard Guide to Obtainable ASTM Equivalent Penetrameter Sensitivity for Radiography of Steel Plates 14 to 2 in. (6 to 51 mm) Thick with X-Rays and 1 to 6 in. (25 to 152 mm) Thick with Cobalt-60

Standard Guide to Obtainable ASTM Equivalent Penetrameter Sensitivity for Radiography of Steel Plates <fraction><num>1</num><den>4 </den></fraction> to 2 in. (6 to 51 mm) Thick with X-Rays and 1 to 6 in. (25 to 152 mm) Thick with <brk/>Cobalt-60

SIGNIFICANCE AND USE

4.1 A key consideration with any radiographic system is its contrast resolution and spatial resolution capability (that is, sensitivity). The degree of obtainable sensitivity with a given system is dependent upon several radiographic parameters such as source energy level, film system class, type and thickness of intensifying screens, exposure (density), etc. This guide permits the user to estimate the degree of sensitivity that may be obtained with X-rays and cobalt-60 gamma rays when using a prescribed set of radiographic parameters. This guide may also be used in conjunction with Test Methods E746 or E1735 to provide a basis for developing data for evaluation of a user's specific system. This data may assist a user in determining appropriate parameters for obtaining desired degrees of radiographic system sensitivity. An alternate to this approach is the use of those adjunct radiographic illustrations detailed in Section 6.

SCOPE

1.1 This guide to obtainable equivalent penetrameter sensitivity covers the minimum penetrameter thicknesses for which the image of the 1T and 2T holes is visible for a few practical radiographic conditions. The values represent near optimum sensitivity for flat steel plates. Radiographic conditions that give higher values of scatter buildup from the specimen or backscattered radiation at the image plane will give poorer sensitivity.

1.2 Eight radiographs that illustrate sensitivities obtainable with practical radiographic systems are included as adjuncts to this guide and may be obtained from ASTM.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E592 −15

Standard Guide to

Obtainable ASTM Equivalent Penetrameter Sensitivity for

1

Radiography of Steel Plates ⁄4 to 2 in. (6 to 51 mm) Thick

with X-Rays and 1 to 6 in. (25 to 152 mm) Thick with

1

Cobalt-60

This standard is issued under the fixed designation E592; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* dicators (IQI) Used for Radiology

E1316 Terminology for Nondestructive Examinations

1.1 This guide to obtainable equivalent penetrameter sensi-

E1742 Practice for Radiographic Examination

tivity covers the minimum penetrameter thicknesses for which

E1735 Test Method for Determining Relative Image Quality

the image of the 1T and 2T holes is visible for a few practical

of Industrial Radiographic Film Exposed to X-Radiation

radiographic conditions. The values represent near optimum

from4to25MeV

sensitivity for flat steel plates. Radiographic conditions that

E1815 Test Method for Classification of Film Systems for

give higher values of scatter buildup from the specimen or

Industrial Radiography

backscattered radiation at the image plane will give poorer

2.2 ISO Standard:

sensitivity.

ISO 7004 Photography—Industrial Radiographic Films—

1.2 Eight radiographs that illustrate sensitivities obtainable

Determination of ISO Speed, ISO Average Gradient, and

with practical radiographic systems are included as adjuncts to

ISO Gradients G2 and G4 When Exposed to X- and

this guide and may be obtained from ASTM. 3

Gamma-Radiation

1.3 The values stated in inch-pound units are to be regarded 2.3 Military Standard:

as the standard. The values given in parentheses are for NAVSEA Technical Publication T9074-AS-GIB-010/

271 Requirements for Nondestructive Testing Methods

information only.

2.4 ASTM Adjuncts:

1.4 This standard does not purport to address all of the

Guide for Equivalent Penetrameter Sensitivity Between

safety concerns, if any, associated with its use. It is the

4

X-Rays and Cobalt-60

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3. Terminology

bility of regulatory limitations prior to use.

3.1 Definitions: For definitions of terms used in this

2. Referenced Documents

standard, refer to Terminology E1316, Section D.

2

2.1 ASTM Standards:

4. Significance and Use

E746 Practice for Determining Relative Image Quality Re-

4.1 Akey consideration with any radiographic system is its

sponse of Industrial Radiographic Imaging Systems

contrast resolution and spatial resolution capability (that is,

E999 Guide for Controlling the Quality of Industrial Radio-

sensitivity). The degree of obtainable sensitivity with a given

graphic Film Processing

systemisdependentuponseveralradiographicparameterssuch

E1025 Practice for Design, Manufacture, and Material

as source energy level, film system class, type and thickness of

Grouping Classification of Hole-Type Image Quality In-

intensifying screens, exposure (density), etc. This guide per-

mits the user to estimate the degree of sensitivity that may be

1

This guide is under the jurisdiction of ASTM Committee E07 on Nondestruc-

obtained with X-rays and cobalt-60 gamma rays when using a

tive Testing and is the direct responsibility of Subcommittee E07.02 on Reference

prescribed set of radiographic parameters. This guide may also

Radiological Images.

be used in conjunction with Test Methods E746 or E1735 to

Current edition approved June 1, 2015. Published June 2015. Originally

ε1

approved in 1977. Last previous edition approved in 2009 as E592 - 99(2009) . provide a basis for developing data for evaluation of a user’s

DOI: 10.1520/E0592-99R15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

Standards volume information, refer to the standard’s Document Summary page on 4th Floor, New York, NY 10036.

4

the ASTM website. Available from ASTM Headquarters. Order RRE0592.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E592−15

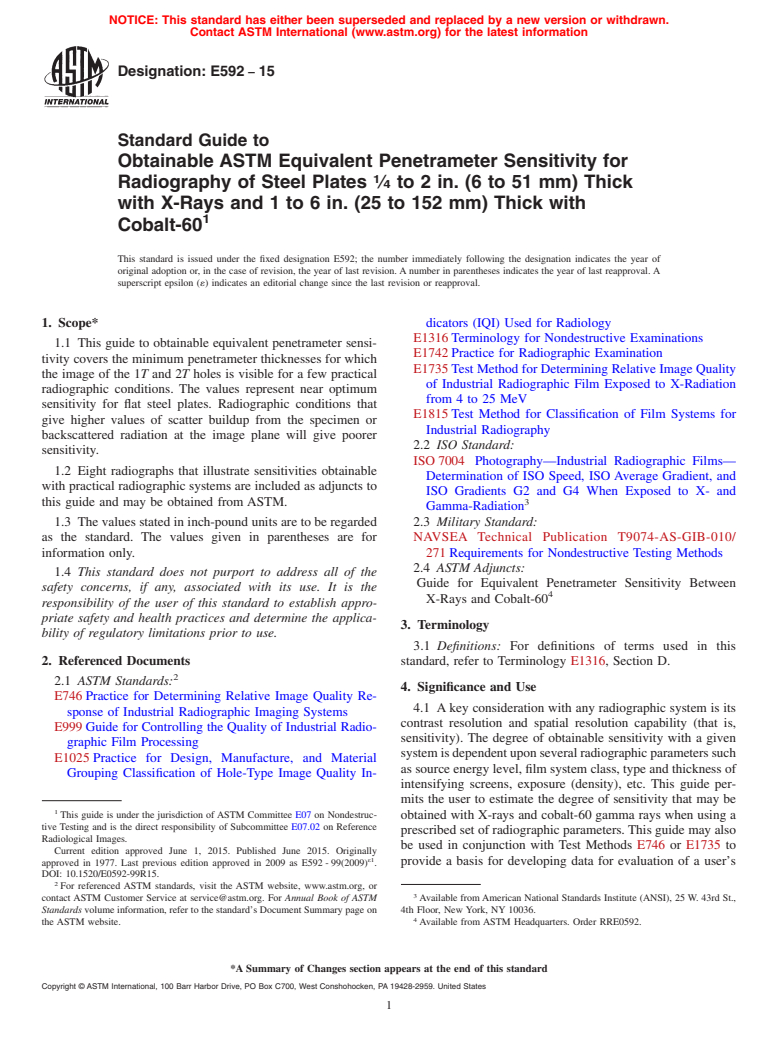

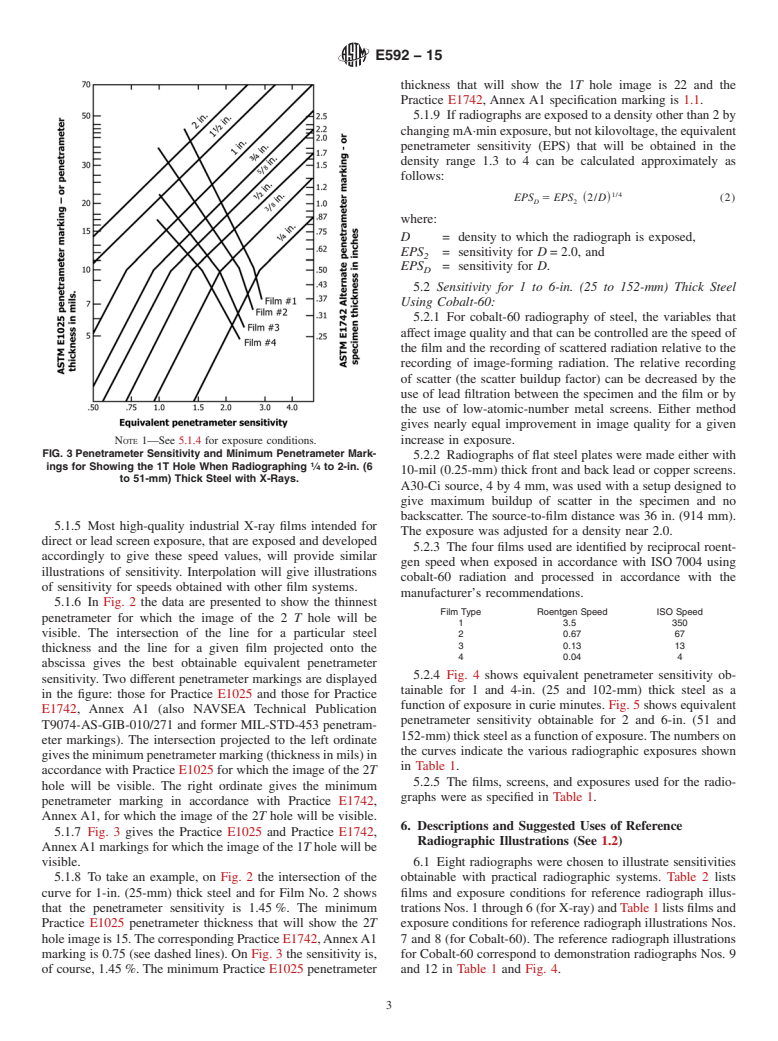

NOTE 1—See 5.1.4 for exposure conditions.

1

FIG. 1Obtainable Penetrameter Sensitivity for ⁄4 to 2-in. (6 to 51-mm) Thick Steel When Radiographing with X-Rays.

specific system. This data may assist a user in determining

appropriate parameters for obtaining desired degrees of radio-

graphic system sens

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: E592 − 99 (Reapproved 2009) E592 − 15

Standard Guide to

Obtainable ASTM Equivalent Penetrameter Sensitivity for

1

Radiography of Steel Plates ⁄4 to 2 in. (6 to 51 mm) Thick

with X Rays X-Rays and 1 to 6 in. (25 to 152 mm) Thick with

1

Cobalt-60

This standard is issued under the fixed designation E592; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Reapproved with editorial changes in June 2009.

1. Scope Scope*

1.1 This guide to obtainable equivalent penetrameter sensitivity covers the minimum penetrameter thicknesses for which the

image of the 1T and 2T holes is visible for a few practical radiographic conditions. The values represent near optimum sensitivity

for flat steel plates. Radiographic conditions that give higher values of scatter buildup from the specimen or backscattered radiation

at the image plane will give poorer sensitivity.

1.2 Eight radiographs that illustrate sensitivities obtainable with practical radiographic systems are included as adjuncts to this

guide and may be obtained from ASTM.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information

only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E746 Practice for Determining Relative Image Quality Response of Industrial Radiographic Imaging Systems

E999 Guide for Controlling the Quality of Industrial Radiographic Film Processing

E1025 Practice for Design, Manufacture, and Material Grouping Classification of Hole-Type Image Quality Indicators (IQI)

Used for Radiology

E1316 Terminology for Nondestructive Examinations

E1742 Practice for Radiographic Examination

E1735 Test Method for Determining Relative Image Quality of Industrial Radiographic Film Exposed to X-Radiation from 4 to

25 MeV

E1815 Test Method for Classification of Film Systems for Industrial Radiography

2.2 ISO Standard:

ISO 7004 Photography—Industrial Radiographic Films—Determination of ISO Speed, ISO Average Gradient, and ISO

3

Gradients G2 adnand G4 When Exposed to X- and Gamma-Radiation

2.3 Military Standard:

4

MIL-STD-271 Nondestructive Testing Requirements for Metals

NAVSEA Technical Publication T9074-AS-Gib-010/271T9074-AS-GIB-010/271 Requirements for Nondestructive Testing

Methods

1

This guide is under the jurisdiction of ASTM Committee E07 on Nondestructive Testing and is the direct responsibility of Subcommittee E07.02 on Reference

Radiological Images.

Current edition approved June 1, 2009June 1, 2015. Published July 2009June 2015. Originally approved in 1977. Last previous edition approved in 20042009 as

ε1

E592 - 99(2004).(2009) . DOI: 10.1520/E0592-99R09E01.10.1520/E0592-99R15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E592 − 15

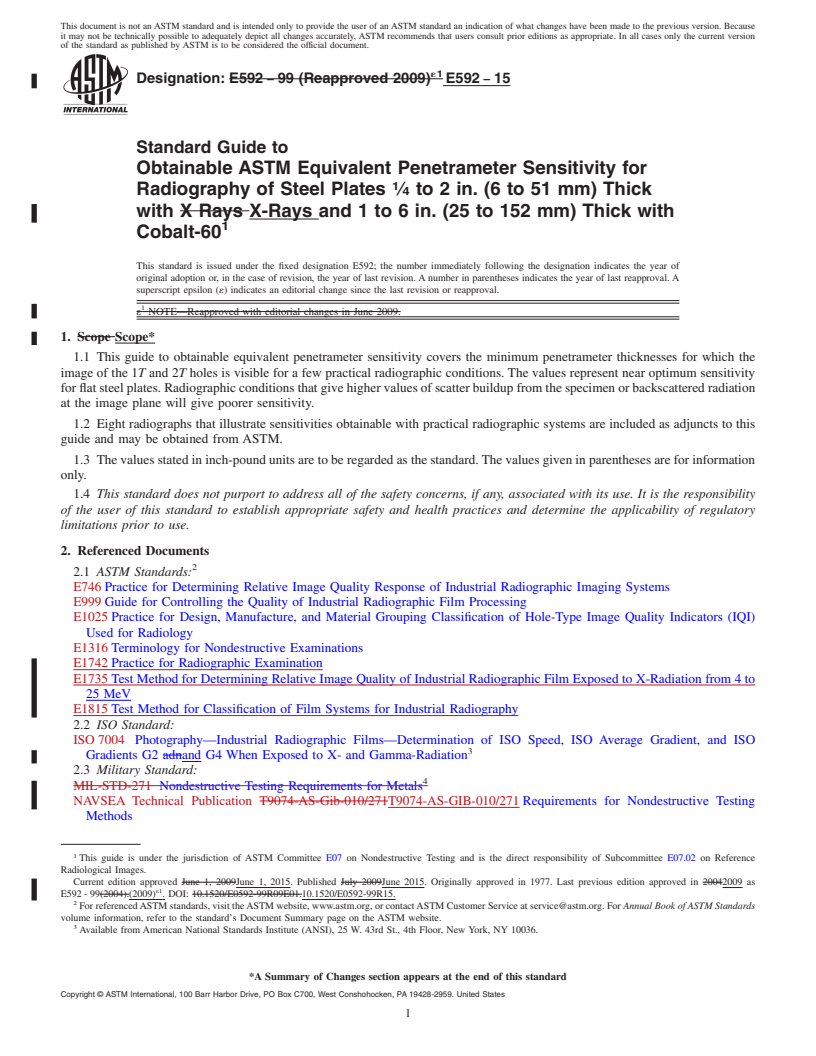

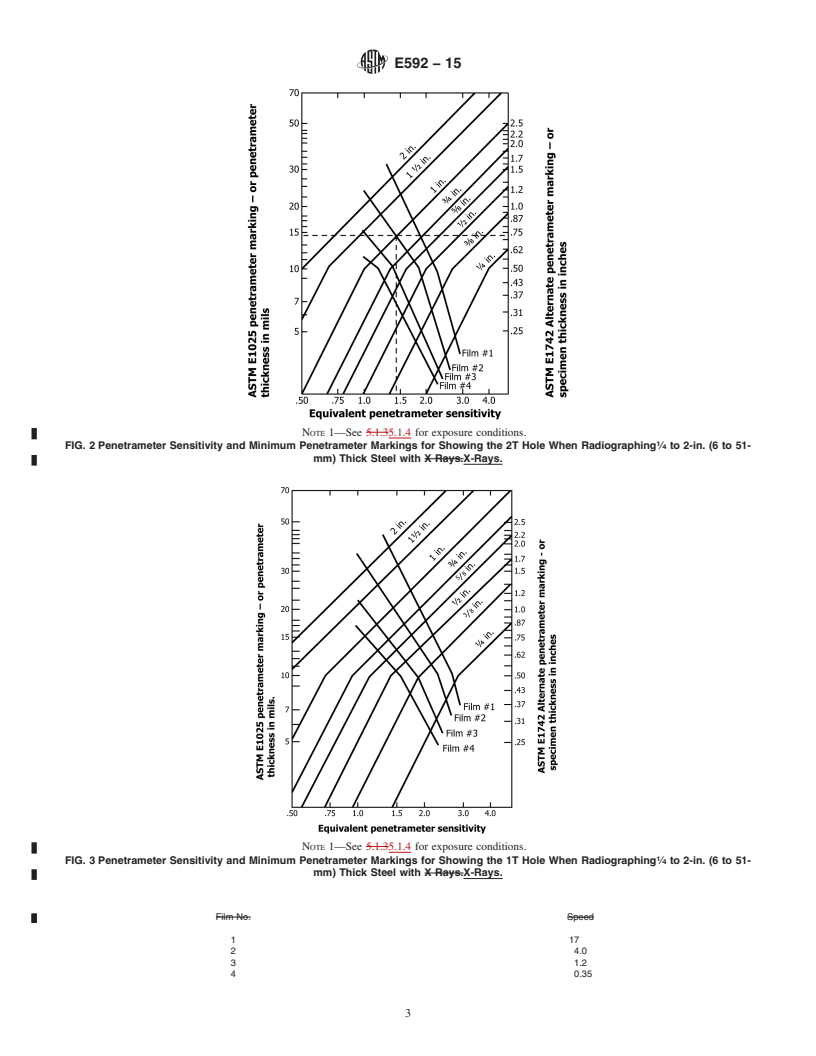

NOTE 1—See 5.1.35.1.4 for exposure conditions.

1

FIG. 1 Obtainable Penetrameter Sensitivity for ⁄4 to 2-in. (6 to 51-mm) Thick Steel When Radiographing with X Rays.X-Rays.

2.4 ASTM Adjuncts:

4

Guide for Equivalent Penetrameter Sensitivity Between X Rays X-Rays and Cobalt-60

3. Terminology

3.1 Definitions: For definitions of terms used in this standard, refer to Terminology E1316, Section D.

4. Significance and Use

4.1 A key consideration with any radiographic system is its capability to resolve detail contrast resolution and spatial resolution

capability (that is, sensitivity). The degree of obtainable sensitivity with a given system is dependent upon several radiographic

parameters such as source energy level, film type, system class, type and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.