ASTM A679/A679M-06(2012)

(Specification)Standard Specification for Steel Wire, High Tensile Strength, Cold Drawn

Standard Specification for Steel Wire, High Tensile Strength, Cold Drawn

ABSTRACT

This specification covers round, uncoated, high tensile strength, cold-drawn steel spring wires having properties and quality suitable for the manufacture of mechanical springs and wire forms subject to high static stresses or infrequent dynamic load, or both. The steel shall be made by any commercially accepted steel making process. The steel shall either be ingot cast or continuous strand cast. The finished wire shall be free from detrimental pipe and undue segregation. The wire shall be cold drawn to produce the desired tensile strength. The wire finish shall be suitable for forming or coiling. It is not intended that this material be furnished with a metallic coating. Heat and product analysis shall be conducted wherein the material shall conform to the required chemical composition values of carbon, manganese, phosphorus, sulfur, and silicon. The material shall undergo tensile and wrap tests. The steel shall have fine pearlite microstructure and the wire surface shall not exhibit imperfections.

SCOPE

1.1 This specification covers round, uncoated, high tensile strength, cold-drawn steel spring wire, having properties and quality suitable for the manufacture of mechanical springs and wire forms subject to high static stresses or infrequent dynamic load, or both.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A679/A679M −06 (Reapproved 2012)

Standard Specification for

Steel Wire, High Tensile Strength, Cold Drawn

This standard is issued under the fixed designationA679/A679M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2.3 Federal Standard:

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

1.1 This specification covers round, uncoated, high tensile

2.4 AIAG Standard:

strength, cold-drawn steel spring wire, having properties and

AIAGB-5 02.00 Primary Metals Identification Tag Applica-

quality suitable for the manufacture of mechanical springs and

tion Standard

wireformssubjecttohighstaticstressesorinfrequentdynamic

load, or both.

3. Terminology

1.2 The values stated in either SI units or inch-pound units

3.1 Definitions—For definitions of terms used in this

are to be regarded separately as standard. The values stated in

specification, refer to Terminology A941.

each system are not exact equivalents; therefore, each system

must be used independently of the other.

4. Ordering Information

2. Referenced Documents 4.1 It shall be the responsibility of the purchaser to specify

2 all requirements that are necessary for material under this

2.1 ASTM Standards:

specification. Such requirements may include, but are not

A370 Test Methods and Definitions for Mechanical Testing

limited to, the following:

of Steel Products

4.1.1 Quantity (mass),

A510 Specification for General Requirements forWire Rods

4.1.2 Name of material (steel wire, high tensile strength,

and Coarse Round Wire, Carbon Steel

hard drawn),

A510M Specification for General Requirements for Wire

4.1.3 Dimensions (Table 1 and Section 9),

Rods and Coarse Round Wire, Carbon Steel (Metric)

3 4.1.4 Packaging (Section 15),

(Withdrawn 2011)

4.1.5 Heat analysis report, if requested (6.2),

A700 Guide for Packaging, Marking, and Loading Methods

4.1.6 Certification or test report, or both, if specified (Sec-

for Steel Products for Shipment

tion 14), and

A751 Test Methods, Practices, and Terminology for Chemi-

4.1.7 ASTM designation and year of issue.

cal Analysis of Steel Products

A941 TerminologyRelatingtoSteel,StainlessSteel,Related

NOTE 1—A typical ordering description is as follows: 20 Mg high

tensile strength, hard-drawn steel mechanical spring wire, 5.00-mm

Alloys, and Ferroalloys

diameter, 500-kg coils to ASTM A679/A679M dated ____ , or for

E29 Practice for Using Significant Digits in Test Data to

inch-pound units, 40 000-lb high tensile strength, hard-drawn steel me-

Determine Conformance with Specifications

chanical spring wire, 0.192-in. diameter, in 1000-lb coils to ASTM

2.2 ANSI Standard:

A679/A679M dated ____ .

B32.4 Preferred Metric Sizes for Round, Square, Rectangle,

5. Materials and Manufacture

and Hexagon Metal Products

5.1 The steel may be made by any commercially accepted

steel making process. The steel may be either ingot cast or

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

continuous strand cast. The rod to be used in the manufacture

A01.03 on Steel Rod and Wire.

of wire furnished to this specification shall be in accordance

Current edition approved March 1, 2012. Published March 2012. Originally

with Specifications A510 or A510M.

approved in 1973. Last previous edition approved in 2006 as A679/A679M – 06.

DOI: 10.1520/A0679_A0679M-06R12.

5.2 The finished wire shall be free from detrimental pipe

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and undue segregation.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 5

The last approved version of this historical standard is referenced on Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

www.astm.org. Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098.

4 6

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St., Available fromAutomotive IndustryAction Group (AIAG), 26200 Lahser Rd.,

4th Floor, New York, NY 10036. Suite 200, Southfield, MI 48034.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

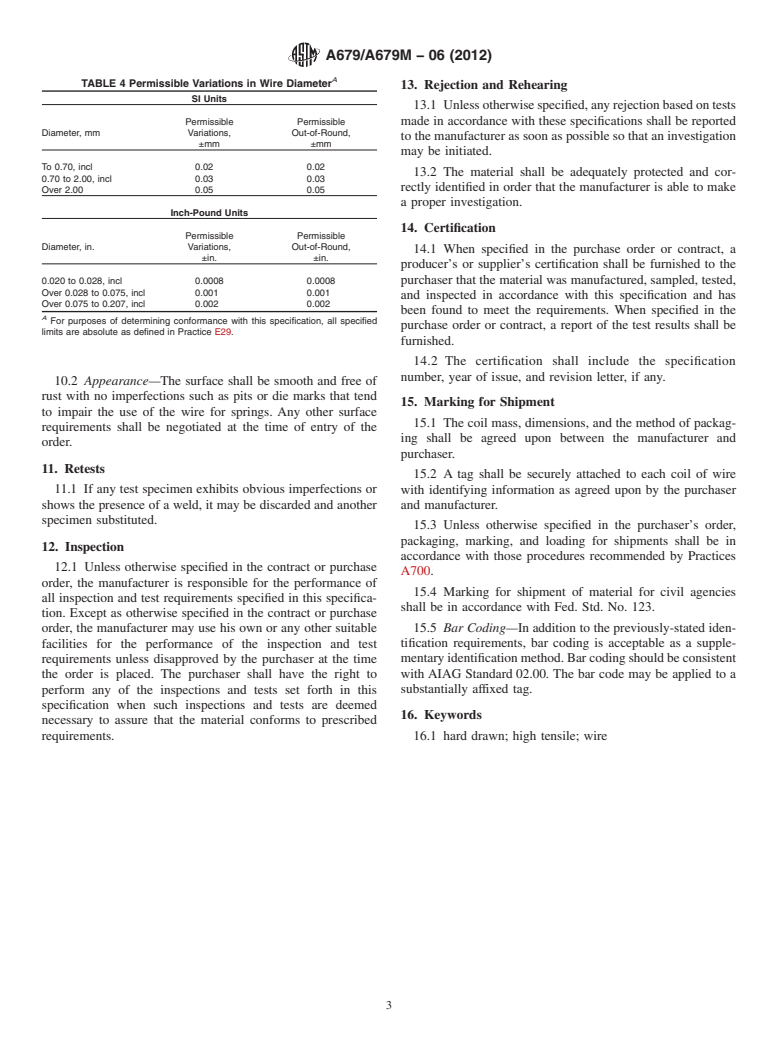

A679/A679M−06 (2012)

TABLE 1 Tensile Requirements

6.4 For referee purposes, Test Methods, Practices, and

SI Units Inch-Pound Units Terminology A751 shall be used.

Tensile Strength, MPa Tensile Strength, ksi

Diameter,

Diameter, in.

A,B

mm

7. Mechanical Properties

min max min max

7.1 Tension Test:

0.50 2400 2650 0.020 350 387

7.1.1 Requirements—The material as represented by tension

0.55 2380 2620 0.023 343 380

0.60 2350 2600 0.026 337 373

test specimens shall conform to the requirements prescribed in

0.65 2320 2580 0.029 331 366

Table 1.

0.70 2300 2550 0.032 327 361

7.1.2 Number of Tests—Onetestspecimenshallbetakenfor

0.80 2250 2500 0.035 322 356

0.90 2200 2450 0.041 314 347

each 10 coils or fraction thereof, in a lot. Each heat in a given

1.00 2150 2400 0.048 306 339

lot shall be tested.

1.10 2120 2380 0.054 300 331

7.1.3 Test Method—The tension test shall be made in

1.20 2100 2350 0.062 293 324

1.40 2050 2300 0.072 287 317

accordance with Test Methods and Definitions A370.

1.60 2000 2250 0.080 282 312

7.2 Wrap Test:

1.80 1980 2220 0.092 275 304

2.00 1950 2200 0.106 268 296

7.2.1 Requirements—The material as represented by the

2.20 1900 2150 0.120 263 290

wrap test specimens shall conform to the requirements speci-

2.50 1850 2100 0.135 258 285

2.80 1820 2050 0.148 253 279 fied in Table 3.

3.00 1800 2000 0.162 249 275

7.2.2 Number of Tests—Onetestspecimenshallbetakenfor

3.50 1750 1950 0.177 245 270

each 10 coils, or fraction thereof, in a lot. Each heat in a given

4.00 1700 1900 0.1927 241 267

4.50 1680 1880 0.207 238 264 lot shall be tested.

5.00 1650 1850

7.2.3 Location of Test—Test specimens shall be taken from

A

Tensile strength values for intermediate diameters shall be interpolated.

either end of the coil.

B

Preferred sizes. For a complete list, refer to ANSI B32.4

7.2.4 Test Method—The wrap test shall be made in accor-

dance with Test Methods and Definitions A370.

8. Metallurgical Requirements

5.3 The wire shall be cold drawn to produce the desired

8.1 Microstructure—The wire shall be cold drawn with a

mechanical properties.

fine pearlite structure.

5.4 The wire finish shall be suitable for forming or coiling.

8.2 Surface Conditions—The wire surface shall not exhibit

It is not intended that this material be furnished with a metallic

imperfections that exceed 3.5 % of the wire diameter or 0.25

coating.

mm (0.010 in.) in depth, whichever is smaller.

6. Chemical Composition

9. Dimensions and Permissible Variations

6.1 Thesteelshallconformtotherequirementsf

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.