ASTM E639-78(1996)e1

(Test Method)Standard Test Method for Measuring Total-Radiance Temperature of Heated Surfaces Using a Radiation Pyrometer

Standard Test Method for Measuring Total-Radiance Temperature of Heated Surfaces Using a Radiation Pyrometer

SCOPE

1.1 This test method covers the measurement of the total-radiance temperature (see section 2.1.20) of surfaces using a radiation pyrometer that is not in contact with the surface. The measured total-radiance temperature is then converted to the "true" surface temperature using an assumed or measured value of the surface emittance.

1.2 This test method includes those pyrometers which respond to a wide band of radiant energy (heat), that is, total radiation pyrometers, as well as those which respond to a relatively narrow band of radiant energy, that is, monochromatic or pseudomonochromatic radiation pyrometers. The latter are often referred to as "optical" pyrometers. The visual optical pyrometer, sometimes referred to as a "disappearing-filament" or "brightness" pyrometer, is not covered by this test method.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: E 639 – 78 (Reapproved 1996)

Standard Test Method for

Measuring Total-Radiance Temperature of Heated Surfaces

Using a Radiation Pyrometer

This standard is issued under the fixed designation E 639; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Sections 9 was added editorially in May 1996.

1. Scope

el 5 spectral emissivity of that surface at the same

temperature,

1.1 This test method covers the measurement of the total-

L ,l5 spectral radiance of a blackbody radiator at

radiance temperature (see section 2.1.20) of surfaces using a

e

that temperature, and

radiation pyrometer that is not in contact with the surface. The

l and l 5 limits of the spectral band involved.

measured total-radiance temperature is then converted to the 1 2

For a pyrometer in which the spectral response varies over

“true” surface temperature using an assumed or measured

its wavelength range of sensitivity, the band emissivity should

value of the surface emittance.

also be weighted by the relative spectral responsivity, R (l), of

1.2 This test method includes those pyrometers which

the pyrometer. The equation then becomes:

respond to a wide band of radiant energy (heat), that is, total

l2

radiation pyrometers, as well as those which respond to a

el L R~l! dl

* e,l

l1

relatively narrow band of radiant energy, that is, monochro-

e 5 (2)

b l2

matic or pseudomonochromatic radiation pyrometers. The

L R~l!dl

* e,l

l1

latter are often referred to as “optical” pyrometers. The visual

Eq 2 is required only when both the spectral emissivity, e ,

optical pyrometer, sometimes referred to as a “disappearing-

l

and the relative spectral responsivity, R (l), vary over the

filament” or “brightness” pyrometer, is not covered by this test

wavelength band of interest. If e is constant, its value is used,

method.

l

and neither equation is required. If R (l) is constant, but e

1.3 This standard does not purport to address all of the

l

varies, Eq 1 is used.

safety concerns, if any, associated with its use. It is the

It should be noted that e is a function of temperature even

responsibility of the user of this standard to establish appro-

b

for those materials whose spectral emissivity is independent of

priate safety and health practices and determine the applica-

temperature, since the relative distribution of L ,lvaries mark-

bility of regulatory limitations prior to use.

e

edly with temperature.

2. Terminology

2.1.2 blackbody—a thermal radiator that completely ab-

sorbs all incident radiation, whatever the wavelength or direc-

2.1 Definitions:

tion of incidence. This radiator has the maximum spectral

2.1.1 band emissivity—the weighted average spectral emis-

concentration of radiant emittance at a given temperature (1) ;

sivity of a given surface at a given temperature and over a

that is, blackbody is an ideal thermal radiator. Devices can be

specified wavelength band, with the spectral radiance of a

blackbody radiator at the given temperature as the weighting constructed which approximate an ideal blackbody by provid-

ing an opaque-walled heated cavity with a small opening (for

function. Expressed mathematically:

example, 2, 3) and are commonly called laboratory blackbod-

l2

el L dl

* e,l

ies.

l1

e 5 (1)

b l2

2.1.3 directional—in a given direction from a surface. For

L dl

* e,l

l1

isotropic surfaces this may be designated by the polar angle, u,

from the normal to the surface to the given direction. For

where:

nonisometric surfaces, the azimuth angle, f, measured from a

eb 5 band emissivity of a surface at some known

fiducial mark on the sample to the plane of incidence, must also

temperature,

be given. Directional is indicated in the general case by the

symbol (u)or(u,f) following the symbol for the quantity or

property, as L (u,f)or e(u). For a specific case the angle in

This test method is under the jurisdiction of ASTM Committee E-21 on Space

Simulation, and is the direct responsibility of Subcommittee E 21.08 on Thermal

Protection. The boldface numbers in parentheses refer to the list of references appended to

Current edition approved March 31, 1978. Published May 1978. this test method.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 639

degrees is substituted for u and f. property, as L or e . It generally refers to quantities of

t t

2.1.4 emissivity, e—the ratio of the radiant existance of the backbody radiation, or properties involving blackbody radia-

thermal radiator to that of a blackbody at the same temperature. tion, and is precisely indicated by giving the temperature of the

The emissivity is a measure of the extent to which a surface blackbody source, in kelvins, as L (300K) or e (300K).

t t

deviates from an ideal radiative surface.

2.1.16 total directional emissivity, e (u,f,T)—is the emissiv-

t

2.1.5 hemispherical—in all directions from a surface, and

ity in direction u averaged over all wavelengths, or the ratio of

generally refers only to properties. It is indicated by the

the radiance of a given surface at a given temperature in a

subscript h as e , and means properly weighted averaged over

given direction to that of a blackbody radiator at the same

h

all directions.

temperature.

2.1.6 irradiance, E 5 dF /dA—the ratio of the radiant flux

e e 2.1.17 total emissivity, e (T)—the weighted average spectral

t

incident on an infinitesimal surface element, to the area of that

emissivity, e(l,T) in which the weighting function is the

element (4).

spectral radiance of a blackbody radiator at temperature T, and

2.1.7 irradiation—the exposure of an object to radiation (1).

the average is taken over all wavelengths at which significant

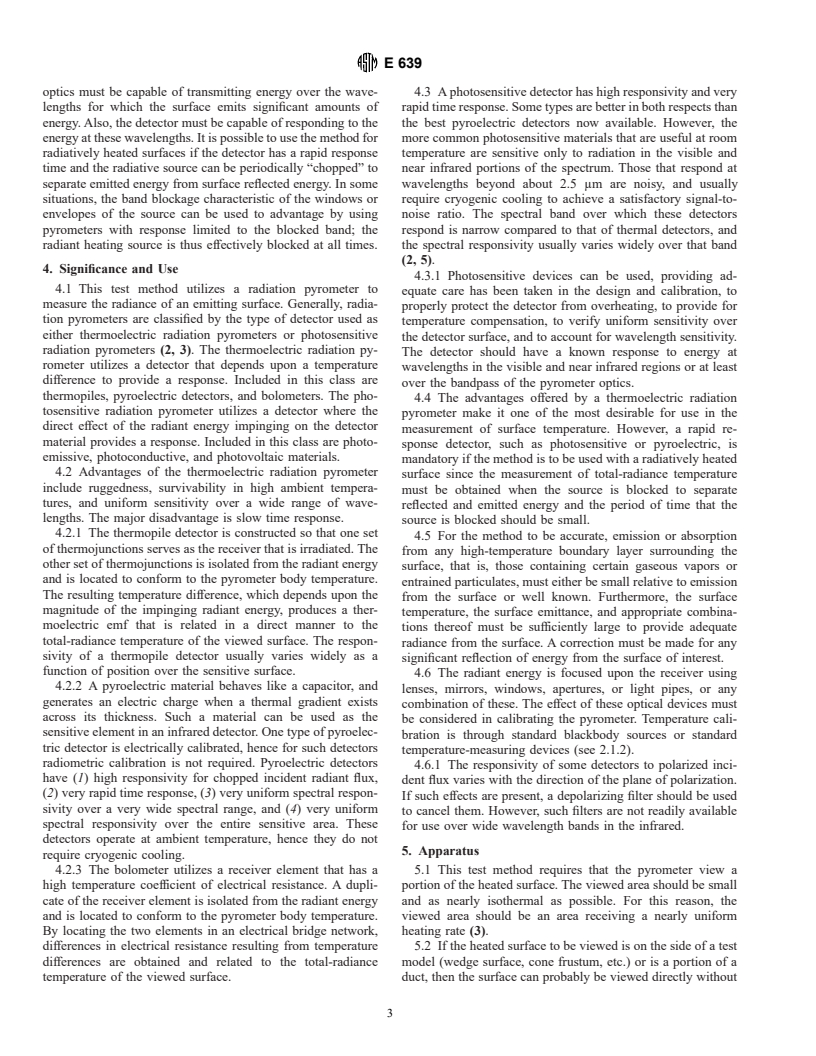

2.1.8 radiance, L 5 dF /dv dA cos u,(in a given direction,

emission occurs.

e e

at a point on a surface)—quotient of the radiant flux leaving,

2.1.18 total hemispherical emissivity, e (T)—emissivity

t,h

arriving at, or passing through an element of area surrounding

averaged over all wavelengths and all directions, or the ratio of

the point and propagated in direction s, u, v, defined by an

the total exitance from a given surface at a given temperature,

elementary cone containing the direction, by the product of the

T, to the blackbody radiator at the same temperature.

solid angle of the cone, dv, and the area of the orthogonal

2.1.18.1 Discussion—A true blackbody radiator is lamber-

projection of the element of surface on a plane perpendicular to

tain; that is, its radiance is independent of direction. However,

the given direction, dA cos u. See Fig. 1.

laboratory blackbodies (heated cavities) are usually lambertian

2.1.9 radiant energy, Q —the quantity of energy transferred

e

over only a relatively small solid angle about the normal to the

by radiation (4).

plane of the aperture of the cavity.

2.1.10 radiant exitance, M 5 dF /dA—the ratio of the

°

e e

2.1.19 total normal emissivity, e (0 ,T)—the total direc-

t

radiant flux emitted by an infinitesimal surface element to the

tional emissivity normal to the surface.

area of that element (4). Note that this a hemispherical quantity.

2.1.20 total-radiance temperature—the temperature of a

2.1.11 radiant flux, F —the energy per unit time (power)

e

blackbody that has the same total-radiance as the body consid-

emited, transmitted, or incident in the form of radiation (4).

ered. The radiance of the body must be averaged over the solid

2.1.12 responsivity (of the pyrometer)—the ratio of detector

angle subtended by the entrance window of the pyrometer used

output to radiance input. It may vary with wavelength.

for the measurement, from the surface of the body (4).

2.1.13 spectral—for a radiometeric quantity (energy, flux,

2.1.20.1 Discussion—No radiation pyrometer can collect

radiance, exitance), the spectral concentration of the quantity

the radiant flux emitted by a body into a complete hemisphere,

per unit wavelength interval at a given wavelength, l, indicated

and most radiation pyrometers collect the radiant flux emitted

by the subscript l following the symbol for the property, as L .

l

into a very small solid angle. Since for many materials the

For a radiometric property (absorptance, emissivity, etc.), it is

directional emissivity varies markedly with direction, signifi-

the value of the property at a specified wavelength, l, indicated

cant errors can result if total hemispherical emissivity is used

by the symbol (l) following the symbol for the property, as

for the emissivity correction instead of total directional emis-

e(l). For precise indication, the symbol l is replaced by the

sivity in the direction of viewing.

value of the wavelength, usually in micrometres.

2.1.14 spectral emissivity, e(l,T)—the emissivity at wave-

3. Summary of Test Method

length l, or the ratio of the radiance or exitance at wavelength

3.1 Many surfaces reach high temperatures when exposed to

l of a given surface at a given temperature to that of a

high-energy convective flows or other heating environments.

blackbody at the same temperture.

The hot surfaces emit radiant energy that can be used to

2.1.15 total—integrated (for a quantity) or averaged (for a

determine surface temperature. The energy is emitted in a

property) over all wavelengths. It is generally indicated by

given direction in a known solid angle and from a known

adding the subscript t to the symbol for the quantity or

surface area, that is, the radiance is focused on a detector that

is responsive to the incident energy. The total-radiance tem-

perature of the surface is then determined from the electrical

output of the detector, through proper calibration of the

detector using a blackbody source at a known temperature. A

measurement or estimate of the emittance of the emitting

surface is then used to convert the total-radiance temperature to

the “true” surface temperature. For the method to be accurate,

radiation reflected from the surface and absorption by and

emission from gaseous vapors and entrained particulates be-

tween the surface and the detector must be accurately ac-

counted for or determined to be negligible. When this criterion

FIG. 1 Illustration of Radiance is met, the method can be used with ablating surfaces. The

E 639

optics must be capable of transmitting energy over the wave- 4.3 A photosensitive detector has high responsivity and very

lengths for which the surface emits significant amounts of rapid time response. Some types are better in both respects than

energy. Also, the detector must be capable of responding to the the best pyroelectric detectors now available. However, the

energy at these wavelengths. It is possible to use the method for more common photosensitive materials that are useful at room

radiatively heated surfaces if the detector has a rapid response temperature are sensitive only to radiation in the visible and

time and the radiative source can be periodically “chopped” to near infrared portions of the spectrum. Those that respond at

separate emitted energy from surface reflected energy. In some wavelengths beyond about 2.5 μm are noisy, and usually

situations, the band blockage characteristic of the windows or require cryogenic cooling to achieve a satisfactory signal-to-

envelopes of the source can be used to advantage by using noise ratio. The spectral band over which these detectors

pyrometers with response limited to the blocked band; the respond is narrow compared to that of thermal detectors, and

radiant heating source is thus effectively blocked at all times. the spectral responsivity usually varies widely over that band

(2, 5).

4. Significance and Use

4.3.1 Photosensitive devices can be used, providing ad-

4.1 This test method utilizes a radiation pyrometer to

equate care has been taken in the design and calibration, to

measure the radiance of an emitting surface. Generally, radia-

properly protect the detector from overheating, to provide for

tion pyrometers are classified by the type of detector used as

temperature compensation, to verify uniform sensitivity over

either thermoelectric radiation pyrometers or photosensitive

the detector surface, and to account for wavelength sensitivity.

radiation pyrometers (2, 3). The thermoelectric radiation py-

The detector should have a known response to energy at

rometer utilizes a detector that depends upon a temperature

wavelengths in the visible and near infrared regions or at least

difference to provide a response. Included in this class are

over the bandpass of the pyrometer optics.

thermopiles, pyroelectric detectors, and bolometers. The pho-

4.4 The advantages offered by a thermoelectric radiation

tosensitive radiation pyrometer utilizes a detector where the

pyrometer make it one of the most desirable for use in the

direct effect of the radiant energy impinging on the detector

measurement of surface temperature. However, a rapid re-

material provides a response. Included in this class are photo-

sponse detector, such as photosensitive or pyroelectric, is

emissive, photoconductive, and photovoltaic materials.

mandatory if the method is to be used with a radiatively heated

4.2 Advantages of the thermoelectric radiation pyrometer

surface since the measurement of total-radiance temperature

include ruggedness, survivability in high ambient tempera-

must be obtained when the source is blocked to separate

tures, and uniform sensitivity over a wide range of wave-

reflected and emitted energy and the period of time that the

lengths. The major disadvantage is slow time response.

source is blocked should be small.

4.2.1 The thermopile detector is constructed so that one set

4.5 For the method to be accurate, emission or absorption

of thermojunctions serves as the receiver that is irradiated. The

from any high-temperature boundary layer surrounding the

other set of thermojunctions is isolated from the radiant energy

surface, that is, those containing certain gaseous vapors or

and is located to conform to the pyrometer body temperature.

entrained particulates, must either be small relative to emission

The resulting temperature difference, which depends upon the

from the surface or well known. Furthermore, the surface

magnitude of the impinging radiant energy, produces a ther-

temperature, the surface emittance, and appropriate combina-

moelectric emf that is related in a direct manner to the

tions thereof must be sufficiently large to provide adequate

total-radiance temperature of the viewed surface. The respon-

radiance from the surface. A correction must be made for any

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.