ASTM F704-81(2018)e1

(Practice)Standard Practice for Selecting Bolting Lengths for Piping System Flanged Joints

Standard Practice for Selecting Bolting Lengths for Piping System Flanged Joints

ABSTRACT

This practice covers bolt and stud bolt lengths, quantities, and thread series for pipe to pipe and pipe to valve flanged joints. This specification presents tables of bolting lengths for different steel flanged joints.

SCOPE

1.1 This practice covers bolt and stud bolt lengths, quantities, and thread series for pipe to pipe and pipe to valve flanged joints (Note 1) in the nominal pipe size ranges of 1/2 through 48-in. (12.7 through 1219-mm) diameter and pressure range of 125 through 2500 psi (0.8 through 17 236 kPa).

Note 1: This is applicable when flange of valve has the same thickness as mating flange.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: F704 − 81 (Reapproved 2018) An American National Standard

Standard Practice for

Selecting Bolting Lengths for Piping System Flanged

Joints

ThisstandardisissuedunderthefixeddesignationF704;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

ε NOTE—Editorial corrections were made to Section 2 in September 2018.

1. Scope B16.5 Pipe Flanges and Flanged Fittings: NPS 1/2 through

NPS 24 Metric/Inch Standard

1.1 This practice covers bolt and stud bolt lengths,

B16.24 Cast Copper Alloy Pipe Flanges, Flanged Fittings,

quantities, and thread series for pipe to pipe and pipe to valve

and Valves: Classes 150, 300, 600, 900, 1500, and 2500

flanged joints (Note 1) in the nominal pipe size ranges of ⁄2

B18.2.1 Square, Hex, Heavy Hex, and Askew Head Bolts

through 48-in. (12.7 through 1219-mm) diameter and pressure

and Hex, Heavy Hex, Hex Flange, Lobed Head, and Lag

range of 125 through 2500 psi (0.8 through 17 236 kPa).

Screws (Inch Series)

NOTE1—Thisisapplicablewhenflangeofvalvehasthesamethickness

B18.2.2 Nuts for General Applications: Machine Screw

as mating flange.

Nuts, Hex, Square, Hex Flange, and Coupling Nuts (Inch

1.2 The values stated in inch-pound units are to be regarded

Series)

as standard. The values given in parentheses are mathematical

2.2 MSS Standards:

conversions to SI units that are provided for information only

MSS-SP-44 Steel Pipe Flanges

and are not considered standard.

3. Bolting Criteria

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3.1 Bolt and stud bolt lengths are computed using the

responsibility of the user of this standard to establish appro-

following (see Annex A1):

priate safety, health, and environmental practices and deter-

3.1.1 Includes maximum nut thickness in accordance with

mine the applicability of regulatory limitations prior to use.

ASME B18.2.2.

1.4 This international standard was developed in accor-

3.1.2 Does not include washer thickness.

dance with internationally recognized principles on standard-

3.1.3 Does not include bolt or stud bolt point height.

ization established in the Decision on Principles for the 1

3.1.4 Includes allowance for up to ⁄8-in. (3.2-mm) thick

Development of International Standards, Guides and Recom-

gaskets, except butterfly valves.

mendations issued by the World Trade Organization Technical 1

3.1.5 Includes ⁄4-in. (6.3-mm) raised face in addition to

Barriers to Trade (TBT) Committee.

flange thickness listed in tables for flanges rated at 400 psi (2.8

kPa) and above.

2. Referenced Documents

3.1.6 Includes use of heavy hex nut and bolt design.

2.1 ASME Standards:

3.1.7 Includes plus tolerance for flange thickness in accor-

B1.1 Unified Inch Screw Threads (UN and UNR Thread

dance with ASME B16.5.

Form)

3.2 All bolts and stud bolts have threads in accordance with

B16.1 Gray Iron Pipe Flanges and Flanged Fittings: Classes

ASME B1.1, Class 2A dimensioning and nuts Class 2B.

25, 125, and 250

3.3 The material requirements for bolts, stud bolts, and nuts

are obtained from the material specifications of individual

This practice is under the jurisdiction of ASTM Committee F25 on Ships and

system diagrams.

Marine Technology and is the direct responsibility of Subcommittee F25.11 on

Machinery and Piping Systems.

3.4 Alloy steel bolting 1-in. (25.4-mm) nominal diameter

Current edition approved Sept. 1, 2018. Published October 2018. Originally

and smaller and all carbon steel bolting has threads of the UNC

approved in 1981. Last previous edition approved in 2014 as F704 – 81 (2014).

DOI: 10.1520/F0704-81R18E01.

Available from American Society of Mechanical Engineers (ASME), ASME

International Headquarters, Two Park Ave., New York, NY 10016-5990, http:// AvailablefromManufacturersStandardizationSocietyoftheValveandFittings

www.asme.org. Industry (MSS), 127 Park St., NE, Vienna, VA22180-4602, http://www.mss-hq.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F704 − 81 (2018)

Series; alloy steel bolting above 1-in. nominal diameter has

Bolting Lengths for Tapped Lug-Type Butterfly Valve Table 18

and 150 lb Bronze Flanges to ASME B16.24

threads of the 8-UN Series.

3.5 For detailed descriptions of flange bolting assemblies,

butterfly valve bolting assemblies, and tapped lug-type butter-

fly valve bolting assemblies, refer to Figs. 1–7.

5. Keywords

5.1 bolting lengths; cover bolt; flange joint(s); marine tech-

4. List of Tables

nology; ships; stud bolts

4.1 The tables are arranged in the following sequence:

150-lb Steel Flanged Joints Table 1

300-lb Steel Flanged Joints Table 2

400-lb Steel Flanged Joints Table 3

600-lb Steel Flanged Joints Table 4

900-lb Steel Flanged Joints Table 5

1500-lb Steel Flanged Joints Table 6

2500-lb Steel Flanged Joints Table 7

150-lb Bronze Flanged Joints Table 8

300-lb Bronze Flanged Joints Table 9

150-lb Steel Flat Face to 150-lb Bronze Flanged Table 10

Joints

300-lb Steel Flat Face to 300-lb Bronze Flanged Table 11

Joints

125-lb Cast Iron to 150-lb Steel Flat Face Flanged Table 12

Joints

250-lb Cast Iron to 300-lb Steel Flat Face Flanged Table 13

Joints

800-lb Cast Iron to 600-lb Steel Flanged Joints Table 14

Wafer-Type Butterfly Valve and 150-lb Steel Flanges Table 15

Wafer-Type Butterfly Valve and 150-lb Bronze Flanges Table 16

Bolting Lengths for Tapped Lug-Type Butterfly Valve Table 17

and 150-lb Steel Flanges to ASME B16.5

TABLE 1 Bolting Lengths for 150-lb Steel Flanged Joints to ASME B16.5 and MSS-SP-44 (see Fig. 1 and Fig. 2)

Bolt Bolt Length Stud Bolt

Nominal Quantity Flange Bolt Stud

Diameter, Carbon Steel, Length

A

Pipe Size, in. per Joint Thickness, in. Bolt Thread

A A A

in. in. Carbon Steel, in.

1 1 7 1 3 1

⁄2 ⁄2 4 ⁄16 ⁄2-13 UNC-2A 1 ⁄4 2 ⁄4

3 1 1 1 1

⁄4 ⁄2 4 ⁄2 ⁄2-13 UNC-2A 2 2 ⁄2

1 9 1 1

1 ⁄2 4 ⁄16 ⁄2-13 UNC-2A 2 2 ⁄2

1 1 5 1 1 3

1 ⁄4 ⁄2 4 ⁄8 ⁄2-13 UNC-2A 2 ⁄4 2 ⁄4

1 1 11 1 1 3

1 ⁄2 ⁄2 4 ⁄16 ⁄2-13 UNC-2A 2 ⁄4 2 ⁄4

5 3 5 3 1

2 ⁄8 4 ⁄4 ⁄8-11 UNC-2A 2 ⁄4 3 ⁄4

1 5 7 5 1

2 ⁄2 ⁄8 4 ⁄8 ⁄8-11 UNC-2A 3 3 ⁄2

5 15 5 1

3 ⁄8 4 ⁄16 ⁄8-11 UNC-2A 3 3 ⁄2

1 5 15 5 1

3 ⁄2 ⁄8 8 ⁄16 ⁄8-11 UNC-2A 3 3 ⁄2

5 15 5 1

4 ⁄8 8 ⁄16 ⁄8-11 UNC-2A 3 3 ⁄2

3 15 3 1 3

5 ⁄4 8 ⁄16 3 ⁄4-11 UNC-2A 3 ⁄4 3 ⁄4

3 3 1

6 ⁄4 81 ⁄4-10 UNC-2A 3 ⁄4 4

3 1 3 1 1

8 ⁄4 81 ⁄8 ⁄4-10 UNC-2A 3 ⁄2 4 ⁄4

7 3 7 3 1

10 ⁄8 12 1 ⁄16 ⁄8-9 UNC-2A 3 ⁄4 4 ⁄2

7 1 7 3

12 ⁄8 12 1 ⁄4 ⁄8-9 UNC-2A 4 4 ⁄4

3 1 1

14 1 12 1 ⁄8 1-8 UNC-2A 4 ⁄4 5 ⁄4

7 1 1

16 1 16 1 ⁄16 1-8 UNC-2A 4 ⁄2 5 ⁄4

1 9 1 3

18 1 ⁄8 16 1 ⁄16 1 ⁄8-7 UNC-2A 5 ⁄4

1 11 1 1 1

20 1 ⁄8 20 1 ⁄16 1 ⁄8-7 UNC-2A 5 ⁄4 6 ⁄4

1 7 1 3 3

24 1 ⁄4 20 1 ⁄8 1 ⁄4-7 UNC-2A 5 ⁄4 6 ⁄4

1 11 11 1 1

26 1 ⁄4 24 2 ⁄16 1 ⁄16-7 UNC-2A 7 ⁄4 8 ⁄2

1 13 1 1 3

28 1 ⁄4 28 2 ⁄16 1 ⁄4-7 UNC-2A 7 ⁄2 8 ⁄4

1 15 1 3

30 1 ⁄4 28 2 ⁄16 1 ⁄4-7 UNC-2A 7 ⁄4 9

1 3 1 3

32 1 ⁄2 28 3 ⁄16 1 ⁄2-6 UNC-2A 8 ⁄4 10

1 1 1 3

34 1 ⁄2 32 3 ⁄4 1 ⁄2-6 UNC-2A 8 ⁄4 10

1 9 1 1 3

36 1 ⁄2 32 3 ⁄16 1 ⁄2-6 UNC-2A 9 ⁄2 10 ⁄4

1 7 1 1 1

38 1 ⁄2 32 3 ⁄16 1 ⁄2-6 UNC-2A 9 ⁄4 10 ⁄2

1 9 1 1 3

40 1 ⁄2 36 3 ⁄16 1 ⁄2-6 UNC-2A 9 ⁄2 10 ⁄4

1 13 1 1

42 1 ⁄2 36 3 ⁄16 1 ⁄2-6 UNC-2A 10 11 ⁄4

1 1 1 1

44 1 ⁄2 40 4 1 ⁄2-6 UNC-2A 10 ⁄4 11 ⁄2

1 1 1 1 3

46 1 ⁄2 40 4 ⁄16 1 ⁄2-6 UNC-2A 10 ⁄2 11 ⁄4

1 1 1 3 1

48 1 ⁄2 44 4 ⁄4 1 ⁄2-6 UNC-2A 10 ⁄4 12 ⁄4

A

1 in. = 25.4 mm.

´1

F704 − 81 (2018)

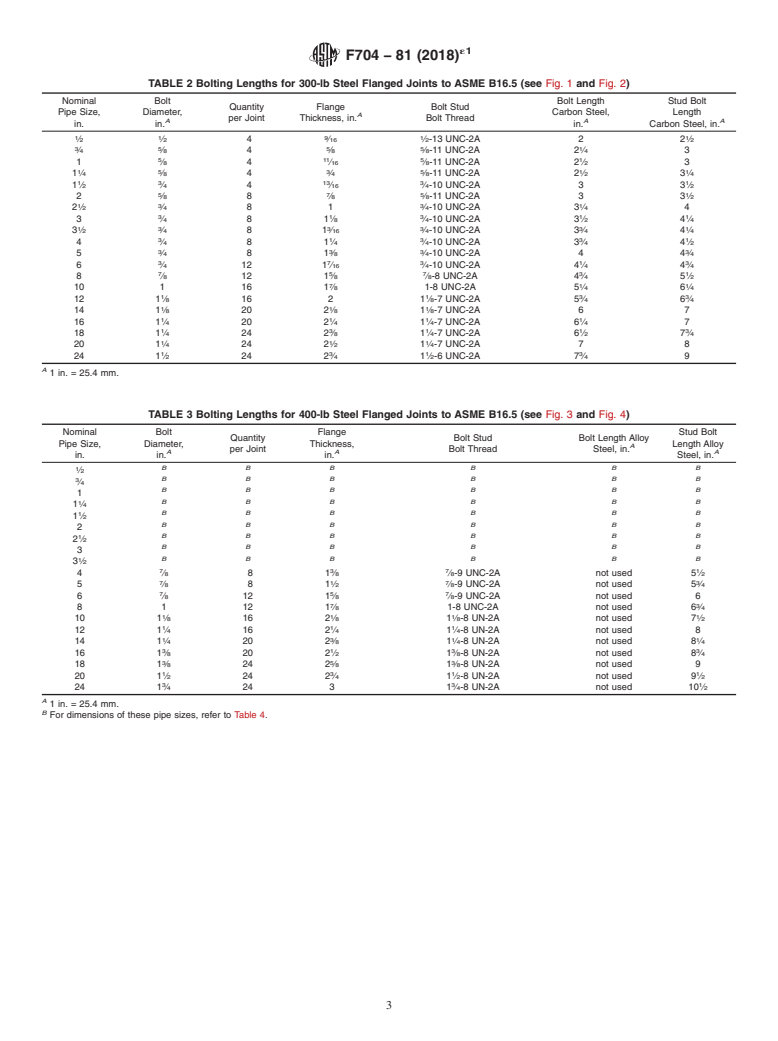

TABLE 2 Bolting Lengths for 300-lb Steel Flanged Joints to ASME B16.5 (see Fig. 1 and Fig. 2)

Nominal Bolt Bolt Length Stud Bolt

Quantity Flange Bolt Stud

Pipe Size, Diameter, Carbon Steel, Length

A

per Joint Thickness, in. Bolt Thread

A A A

in. in. in. Carbon Steel, in.

1 1 9 1 1

⁄2 ⁄2 4 ⁄16 ⁄2-13 UNC-2A 2 2 ⁄2

3 5 5 5 1

⁄4 ⁄8 4 ⁄8 ⁄8-11 UNC-2A 2 ⁄4 3

5 11 5 1

1 ⁄8 4 ⁄16 ⁄8-11 UNC-2A 2 ⁄2 3

1 5 3 5 1 1

1 ⁄4 ⁄8 4 ⁄4 ⁄8-11 UNC-2A 2 ⁄2 3 ⁄4

1 3 13 3 1

1 ⁄2 ⁄4 4 ⁄16 ⁄4-10 UNC-2A 3 3 ⁄2

5 7 5 1

2 ⁄8 8 ⁄8 ⁄8-11 UNC-2A 3 3 ⁄2

1 3 3 1

2 ⁄2 ⁄4 81 ⁄4-10 UNC-2A 3 ⁄4 4

3 1 3 1 1

3 ⁄4 81 ⁄8 ⁄4-10 UNC-2A 3 ⁄2 4 ⁄4

1 3 3 3 3 1

3 ⁄2 ⁄4 81 ⁄16 ⁄4-10 UNC-2A 3 ⁄4 4 ⁄4

3 1 3 3 1

4 ⁄4 81 ⁄4 ⁄4-10 UNC-2A 3 ⁄4 4 ⁄2

3 3 3 3

5 ⁄4 81 ⁄8 ⁄4-10 UNC-2A 4 4 ⁄4

3 7 3 1 3

6 ⁄4 12 1 ⁄16 ⁄4-10 UNC-2A 4 ⁄4 4 ⁄4

7 5 7 3 1

8 ⁄8 12 1 ⁄8 ⁄8-8 UNC-2A 4 ⁄4 5 ⁄2

7 1 1

10 1 16 1 ⁄8 1-8 UNC-2A 5 ⁄4 6 ⁄4

1 1 3 3

12 1 ⁄8 16 2 1 ⁄8-7 UNC-2A 5 ⁄4 6 ⁄4

1 1 1

14 1 ⁄8 20 2 ⁄8 1 ⁄8-7 UNC-2A 6 7

1 1 1 1

16 1 ⁄4 20 2 ⁄4 1 ⁄4-7 UNC-2A 6 ⁄4 7

1 3 1 1 3

18 1 ⁄4 24 2 ⁄8 1 ⁄4-7 UNC-2A 6 ⁄2 7 ⁄4

1 1 1

20 1 ⁄4 24 2 ⁄2 1 ⁄4-7 UNC-2A 7 8

1 3 1 3

24 1 ⁄2 24 2 ⁄4 1 ⁄2-6 UNC-2A 7 ⁄4 9

A

1 in. = 25.4 mm.

TABLE 3 Bolting Lengths for 400-lb Steel Flanged Joints to ASME B16.5 (see Fig. 3 and Fig. 4)

Nominal Bolt Flange Stud Bolt

Quantity Bolt Stud Bolt Length Alloy

Pipe Size, Diameter, Thickness, Length Alloy

A

per Joint Bolt Thread Steel, in.

A A A

in. in. in. Steel, in.

B B BBB B

⁄2

B B BBB B

⁄4

B B BBB B

B B BBB B

1 ⁄4

B B BBB B

1 ⁄2

B B BBB B

B B BBB B

2 ⁄2

B B BBB B

1 B B BBB B

3 ⁄2

7 3 7 1

4 ⁄8 81 ⁄8 ⁄8-9 UNC-2A not used 5 ⁄2

7 1 7 3

5 ⁄8 81 ⁄2 ⁄8-9 UNC-2A not used 5 ⁄4

7 5 7

6 ⁄8 12 1 ⁄8 ⁄8-9 UNC-2A not used 6

7 3

81 12 1 ⁄8 1-8 UNC-2A not used 6 ⁄4

1 1 1 1

10 1 ⁄8 16 2 ⁄8 1 ⁄8-8 UN-2A not used 7 ⁄2

1 1 1

12 1 ⁄4 16 2 ⁄4 1 ⁄4-8 UN-2A not used 8

1 3 1 1

14 1 ⁄4 20 2 ⁄8 1 ⁄4-8 UN-2A not used 8 ⁄4

3 1 3 3

16 1 ⁄8 20 2 ⁄2 1 ⁄8-8 UN-2A not used 8 ⁄4

3 5 3

18 1 ⁄8 24 2 ⁄8 1 ⁄8-8 UN-2A not used 9

1 3 1 1

20 1 ⁄2 24 2 ⁄4 1 ⁄2-8 UN-2A not used 9 ⁄2

3 3 1

24 1 ⁄4 24 3 1 ⁄4-8 UN-2A not used 10 ⁄2

A

1 in. = 25.4 mm.

B

For dimensions of these pipe sizes, refer to Table 4.

´1

F704 − 81 (2018)

TABLE 4 Bolting Lengths for 600-lb Steel Flanged Joints to ASME B16.5 (see Fig. 3 and Fig. 4)

Nominal Bolt Flange Stud Bolt

Quantity Bolt Stud Bolt Length Alloy

Pipe Size, Diameter, Thickness, Length Alloy

A

per Joint Bolt Thread Steel, in.

A A A

in. in. in. Steel, in.

1 1 9 1

⁄2 ⁄2 4 ⁄16 ⁄2-13 UNC-2A not used 3

3 5 5 5 1

⁄4 ⁄8 4 ⁄8 ⁄8-11 UNC-2A not used 3 ⁄2

5 11 5 1

1 ⁄8 4 ⁄16 ⁄8-11 UNC-2A not used 3 ⁄2

1 5 13 5 3

1 ⁄4 ⁄8 4 ⁄16 ⁄8-11 UNC-2A not used 3 ⁄4

1 3 7 3 1

1 ⁄2 ⁄4 4 ⁄8 ⁄4-10 UNC-2A not used 4 ⁄4

5 5 1

2 ⁄8 81 ⁄8-11 UNC-2A not used 4 ⁄4

1 3 1 3 3

2 ⁄2 ⁄4 81 ⁄8 ⁄4-10 UNC-2A not used 4 ⁄4

3 1 3

3 ⁄4 81 ⁄4 ⁄4-10 UNC-2A not used 5

1 7 3 7 1

3 ⁄2 ⁄8 81 ⁄8 ⁄8-9 UNC-2A not used 5 ⁄2

7 1 7 3

4 ⁄8 81 ⁄2 ⁄8-9 UNC-2A not used 5 ⁄4

3 1

51 8 1 ⁄4 1-8 UNC-2A not used 6 ⁄2

7 3

61 12 1 ⁄8 1-8 UNC-2A not used 6 ⁄4

1 3 1 1

81 ⁄8 12 2 ⁄16 1 ⁄8-8 UN-2A not used 7 ⁄2

1 1 1 1

10 1 ⁄4 16 2 ⁄2 1 ⁄4-8 UN-2A not used 8 ⁄2

1 5 1 3

12 1 ⁄4 20 2 ⁄8 1 ⁄4-8 UN-2A not used 8 ⁄4

3 3 3 1

14 1 ⁄8 20 2 ⁄4 1 ⁄8-8 UN-2A not used 9 ⁄4

1 1

16 1 ⁄2 20 3 1 ⁄2-8 UN-2A not used 10

5 1 5 3

18 1 ⁄8 20 3 ⁄4 1 ⁄8-8 UN-2A not used 10 ⁄4

5 1 5 1

20 1 ⁄8 24 3 ⁄2 1 ⁄8-8 UN-2A not used 11 ⁄4

7 7

24 1 ⁄8 24 4 1 ⁄8-8 UN-2A not used 13

A

1 in. = 25.4 mm.

TABLE 5 Bolting Lengths for 900-lb Steel Flanged Joints to ASME B16.5 (see Fig. 3 and Fig. 4)

Nominal Bolt Flange Stud Bolt

Quantity Bolt Stud Bolt Length Alloy

Pipe Size, Diameter, Thickness, Length Alloy

A

per Joint Bolt Thread Steel, in.

A A A

in. in. in. Steel, in.

B B BBB B

⁄2

B B BBB B

⁄4

B B BBB B

B B BBB B

1 ⁄4

B B BBB B

1 ⁄2

B B BBB B

B B BBB B

2 ⁄2

7 1 7 3

3 ⁄8 81 ⁄2 ⁄8-9 UNC-2A not used 5 ⁄4

1 3 1 3

41 ⁄8 81 ⁄4 1 ⁄8-8 UN-2A not used 6 ⁄4

1 1 1

51 ⁄4 82 1 ⁄4-8 UN-2A not used 7 ⁄2

1 3 1 1

61 ⁄8 12 2 ⁄16 1 ⁄8-8 UN-2A not used 7 ⁄2

3 1 3 3

81 ⁄8 12 2 ⁄2 1 ⁄8-8 UN-2A not used 8 ⁄4

3 3 3 1

10 1 ⁄8 16 2 ⁄4 1 ⁄8-8 UN-2A not used 9 ⁄4

3 1 3

12 1 ⁄8 20 3 ⁄8 1 ⁄8-8 UN-2A not used 10

1 3 1 3

14 1 ⁄2 20 3 ⁄8 1 ⁄2-8 UN-2A not used 10 ⁄4

5 1 5 1

16 1 ⁄8 20 3 ⁄2 1 ⁄8-8 UN-2A not used 11 ⁄4

7 7 3

18 1 ⁄8 20 4 1 ⁄8-8 UN-2A not used 12 ⁄4

1 3

20 2 20 4 ⁄4 2-8 UN-2A not used 13 ⁄4

1 1 1 1

24 2 ⁄2 20 5 ⁄2 2 ⁄2-8 UN-2A not used 17 ⁄4

A

1 in. = 25.4 mm.

B

For dimensions of these pipe sizes, refer to Table 6.

´1

F704 − 81 (2018)

TABLE 6 Bolting Lengths for 1500-lb Steel Flanged Joints to ASME B16.5 (see Fig. 3 and Fig. 4)

Nominal Bolt Flange Stud Bolt

Quantity Bolt Stud Bolt Length Alloy

Pipe Size, Diameter, Thickness, Length Alloy

A

per Joint Bolt Thread Steel, in.

A A A

in. in. in. Steel, in.

1 3 7 3 1

⁄2 ⁄4 4 ⁄8 ⁄4-10 UNC-2A not used 4 ⁄4

3 3 3 1

⁄4 ⁄4 41 ⁄4-10 UNC-2A not used 4 ⁄2

7 1 7

1 ⁄8 41 ⁄8 ⁄8-9 UNC-2A not used 5

1 7 1 7

1 ⁄4 ⁄8 41 ⁄8 ⁄8-9 UNC-2A not used 5

1 1 1

1 ⁄2 14 1 ⁄4 1-8 UNC-2A not used 5 ⁄2

7 1 7 3

2 ⁄8 81 ⁄2 ⁄8-9 UNC-2A not used 5 ⁄4

1 5 1

2 ⁄2 18 1 ⁄8 1-8 UNC-2A not used 6 ⁄4

1 7 1

31 ⁄8 81 ⁄8 1 ⁄8-8 UN-2A not used 7

1 1 1 3

41 ⁄4 82 ⁄8 1 ⁄4-8 UN-2A not used 7 ⁄4

1 7 1 3

51 ⁄2 82 ⁄8 1 ⁄2-8 UN-2A not used 9 ⁄4

3 1 3 1

61 ⁄8 12 3 ⁄4 1 ⁄8-8 UN-2A not used 10 ⁄4

5 5 5 1

81 ⁄8 12 3 ⁄8 1 ⁄8-8 UN-2A not used 11 ⁄2

7 1 7 1

10 1 ⁄8 12 4 ⁄4 1 ⁄8-8 UN-2A not used 13 ⁄4

7 3

12 2 16 4 ⁄8 2-8 UN-2A not used 14 ⁄4

1 1 1

14 2 ⁄4 16 5 ⁄4 2 ⁄4-8 UN-2A not used 16

1 3 1 1

16 2 ⁄2 16 5 ⁄4 2 ⁄2-8 UN-2A not used 17 ⁄2

3 3 3 1

18 2 ⁄4 16 6 ⁄8 2 ⁄4-8 UN-2A not used 19 ⁄2

20 3 16 7 3-8 UN-2A not used 21 ⁄4

1 1 1

24 3 ⁄2 16 8 3 ⁄2-8 UN-2A not used 24 ⁄4

A

1 in. = 25.4 mm.

TABLE 7 Bolting Lengths for 2500-lb Steel Flanged Joints to ASME B16.5 (see Fig. 3 and Fig. 4)

Bolt Flange Stud Bolt

Nominal Quantity Bolt Stud Bolt Length Alloy

Diameter, Thickness, Length Alloy

A

Pipe Size, in. per Joint Bolt Thread Steel, in.

A A A

in. in. Steel, in.

1 3 3 3 3

⁄2 ⁄4 41 ⁄16 ⁄4-10 UNC-2A not used 4 ⁄4

3 3 1 3

⁄4 ⁄4 41 ⁄4 ⁄4-10 UNC-2A not used 5

7 3 7 1

1 ⁄8 41 ⁄8 ⁄8-9 UNC-2A not used 5 ⁄2

1 1

1 ⁄4 14 1 ⁄2 1-8 UNC-2A not used 6

1 1 3 1 3

1 ⁄2 1 ⁄8 41 ⁄4 1 ⁄8-8 UN-2A not used 6 ⁄4

2 1 8 2 1-8 UNC-2A not used 7

1 1 1 1 3

2 ⁄2 1 ⁄8 82 ⁄4 1 ⁄8-8 UN-2A not used 7 ⁄4

1 5 1 3

31 ⁄4 82 ⁄8 1 ⁄4-8 UN-2A not used 8 ⁄4

1 1

41 ⁄2 83 1 ⁄2-8 UN-2A not used 10

3 5 3 3

51 ⁄4 83 ⁄8 1 ⁄4-8 UN-2A not used 11 ⁄4

1 1

62 8 4 ⁄4 2-8 UN-2A not used 13 ⁄2

8 2 12 5 2-8 UN-2A not used 15

1 1 1 1

10 2 ⁄2 12 6 ⁄2 2 ⁄2-8 UN-2A not used 19 ⁄4

3 1 3 1

12 2 ⁄4 12 7 ⁄4 2 ⁄4-8 UN-2A not used 21 ⁄4

A

1 in. = 25.4 mm.

TABLE 8 Bolting Lengths for 150-lb Bronze Flanged Joints to ASME B16.24 (see Fig. 1 and Fig. 2)

Bolt Flange Bolt Length Stud Bolt

Nominal Quantity Bolt Stud

Diameter, Thickness, Carbon Steel, Length

Pipe Size, in. per Joint Bolt Thread

A A A A

in. in. in. Carbon Steel, in.

1 1 5 1 1

⁄2 ⁄2 4 ⁄16 ⁄2-13 UNC-2A 1 ⁄2 2

3 1 11 1 3 1

⁄4 ⁄2 4 ⁄32 ⁄2-13 UNC-2A 1 ⁄4 2 ⁄4

1 3 1 3 1

1 ⁄2 4 ⁄8 ⁄2-13 UNC-2A 1 ⁄4 2 ⁄4

1 1 13 1 3 1

1 ⁄4 ⁄2 4 ⁄32 ⁄2-13 UNC-2A 1 ⁄4 2 ⁄4

1 1 7 1 3 1

1 ⁄2 ⁄2 4 ⁄16 ⁄2-13 UNC

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: F704 − 81 (Reapproved 2014) F704 − 81 (Reapproved 2018)An American National Standard

Standard Practice for

Selecting Bolting Lengths for Piping System Flanged

Joints

This standard is issued under the fixed designation F704; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

ε NOTE—Editorial corrections were made to Section 2 in September 2018.

1. Scope

1.1 This practice covers bolt and stud bolt lengths, quantities, and thread series for pipe to pipe and pipe to valve flanged joints

(Note 1) in the nominal pipe size ranges of ⁄2- through through 48-in. (12.7-(12.7 through 1219-mm) diameter and pressure range

of 125 through 2500 psi (0.8 through 17 236 kPa).

NOTE 1—This is applicable when flange of valve has the same thickness as mating flange.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ANSIASME Standards:

B1.1 Unified Inch Screw Threads (UN and UNR Thread Form)

B16.1 CastGray Iron Pipe Flanges and Flanged Fittings (25, 125, 250, and 800 lb)Fittings: Classes 25, 125, and 250

B16.5 Steel Pipe Flanges and Flanged Fittings (150, 300, 400, 600, 900, 1500, and 2500 lb Including Reference to

Valves)Fittings: NPS 1/2 through NPS 24 Metric/Inch Standard

B16.24 Bronze Flanges and Flanged Fittings (150 and 300 lb)Cast Copper Alloy Pipe Flanges, Flanged Fittings, and Valves:

Classes 150, 300, 600, 900, 1500, and 2500

B18.2.1 Square and Hex Bolts and ScrewsSquare, Hex, Heavy Hex, and Askew Head Bolts and Hex, Heavy Hex, Hex Flange,

Lobed Head, and Lag Screws (Inch Series)

B18.2.2 Square and Hex NutsNuts for General Applications: Machine Screw Nuts, Hex, Square, Hex Flange, and Coupling Nuts

(Inch Series)

2.2 MSS Standards:

MSS SP-44MSS-SP-44 Steel Pipe Flanges

3. Bolting Criteria

3.1 Bolt and stud bolt lengths are computed using the following (see Annex A1):

3.1.1 Includes maximum nut thickness in accordance with ANSIASME B18.2.2.

This practice is under the jurisdiction of ASTM Committee F25 on Ships and Marine Technology and is the direct responsibility of Subcommittee F25.11 on Machinery

and Piping Systems.

Current edition approved Nov. 1, 2014Sept. 1, 2018. Published November 2014October 2018. Originally approved in 1981. Last previous edition approved in 20092014

as F704 – 81 (2009).(2014). DOI: 10.1520/F0704-81R14.10.1520/F0704-81R18E01.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, Society of Mechanical Engineers (ASME), ASME International Headquarters,

Two Park Ave., New York, NY 10036, http://www.ansi.org.10016-5990, http://www.asme.org.

Available from Manufacturers Standardization Society of the Valve and Fittings Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602, http://www.mss-

hq.com.http://www.mss-hq.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F704 − 81 (2018)

3.1.2 Does not include washer thickness.

3.1.3 Does not include bolt or stud bolt point height.

3.1.4 Includes allowance for up to ⁄8-in. (3.2-mm) thick gaskets, except butterfly valves.

3.1.5 Includes ⁄4-in. (6.3-mm) raised face in addition to flange thickness listed in tables for flanges rated at 400 psi (2.8 kPa)

and above.

3.1.6 Includes use of heavy hex nut and bolt design.

3.1.7 Includes plus tolerance for flange thickness in accordance with ANSIASME B16.5.

3.2 All bolts and stud bolts have threads in accordance with ANSIASME B1.1, Class 2A dimensioning and nuts Class 2B.

3.3 The material requirements for bolts, stud bolts, and nuts are obtained from the material specifications of individual system

diagrams.

3.4 Alloy steel bolting 1-in. (25.4-mm) nominal diameter and smaller and all carbon steel bolting has threads of the UNC Series;

alloy steel bolting above 1-in. nominal diameter has threads of the 8-UN Series.

3.5 For detailed descriptions of flange bolting assemblies, butterfly valve bolting assemblies, and tapped lug-type butterfly valve

bolting assemblies, refer to Figs. 1–7.

4. List of Tables

4.1 The tables are arranged in the following sequence:

150-lb Steel Flanged Joints Table 1

300-lb Steel Flanged Joints Table 2

400-lb Steel Flanged Joints Table 3

600-lb Steel Flanged Joints Table 4

900-lb Steel Flanged Joints Table 5

1500-lb Steel Flanged Joints Table 6

2500-lb Steel Flanged Joints Table 7

150-lb Bronze Flanged Joints Table 8

300-lb Bronze Flanged Joints Table 9

150-lb Steel Flat Face to 150-lb Table 10

Bronze Flanged Joints

150-lb Steel Flat Face to 150-lb Table 10

Bronze Flanged Joints

300-lb Steel Flat Face to 300-lb Table 11

Bronze Flanged Joints

300-lb Steel Flat Face to 300-lb Table 11

Bronze Flanged Joints

125-lb Cast Iron to 150-lb Steel Flat Table 12

Face Flanged Joints

125-lb Cast Iron to 150-lb Steel Flat Table 12

Face Flanged Joints

250-lb Cast Iron to 300-lb Steel Flat Table 13

Face Flanged Joints

250-lb Cast Iron to 300-lb Steel Flat Table 13

Face Flanged Joints

800-lb Cast Iron to 600-lb Steel Table 14

Flanged Joints

800-lb Cast Iron to 600-lb Steel Table 14

Flanged Joints

Wafer-Type Butterfly Valve and Table 15

150-lb Steel Flanges

Wafer-Type Butterfly Valve and Table 15

150-lb Steel Flanges

Wafer-Type Butterfly Valve and Table 16

150-lb Bronze Flanges

Wafer-Type Butterfly Valve and Table 16

150-lb Bronze Flanges

Bolting Lengths for Tapped Lug- Table 17

Type Butterfly Valve and 150-lb

Steel Flanges to ANSI B16.5

Bolting Lengths for Tapped Lug-Type Table 17

Butterfly Valve and 150-lb

Steel Flanges to ASME B16.5

Bolting Lengths for Tapped Lug- Table 18

Type Butterfly Valve and 150 lb

Bronze Flanges to ANSI B16.24

Bolting Lengths for Tapped Lug-Type Table 18

Butterfly Valve and 150 lb

Bronze Flanges to ASME B16.24

´1

F704 − 81 (2018)

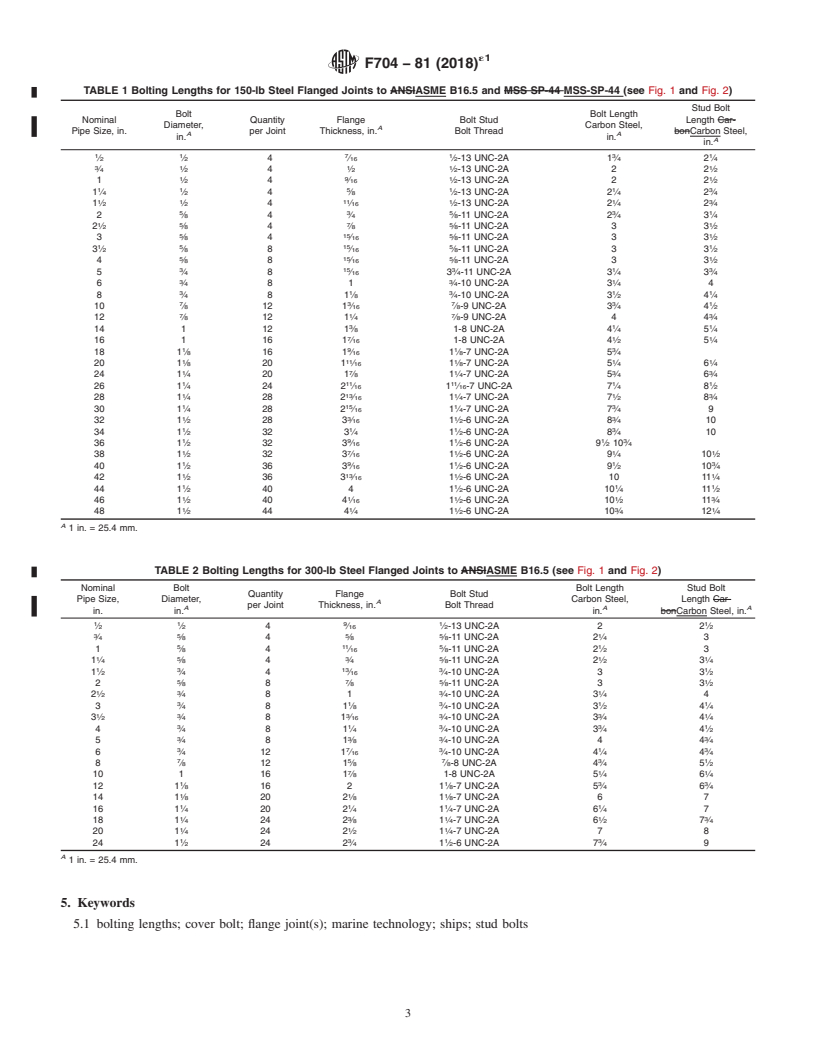

TABLE 1 Bolting Lengths for 150-lb Steel Flanged Joints to ANSIASME B16.5 and MSS SP-44 MSS-SP-44 (see Fig. 1 and Fig. 2)

Stud Bolt

Bolt Bolt Length

Nominal Quantity Flange Bolt Stud Length Car-

Diameter, Carbon Steel,

A

Pipe Size, in. per Joint Thickness, in. Bolt Thread bonCarbon Steel,

A A

in. in.

A

in.

1 1 7 1 3 1

⁄2 ⁄2 4 ⁄16 ⁄2-13 UNC-2A 1 ⁄4 2 ⁄4

3 1 1 1 1

⁄4 ⁄2 4 ⁄2 ⁄2-13 UNC-2A 2 2 ⁄2

1 9 1 1

1 ⁄2 4 ⁄16 ⁄2-13 UNC-2A 2 2 ⁄2

1 1 5 1 1 3

1 ⁄4 ⁄2 4 ⁄8 ⁄2-13 UNC-2A 2 ⁄4 2 ⁄4

1 1 11 1 1 3

1 ⁄2 ⁄2 4 ⁄16 ⁄2-13 UNC-2A 2 ⁄4 2 ⁄4

5 3 5 3 1

2 ⁄8 4 ⁄4 ⁄8-11 UNC-2A 2 ⁄4 3 ⁄4

1 5 7 5 1

2 ⁄2 ⁄8 4 ⁄8 ⁄8-11 UNC-2A 3 3 ⁄2

5 15 5 1

3 ⁄8 4 ⁄16 ⁄8-11 UNC-2A 3 3 ⁄2

1 5 15 5 1

3 ⁄2 ⁄8 8 ⁄16 ⁄8-11 UNC-2A 3 3 ⁄2

5 15 5 1

4 ⁄8 8 ⁄16 ⁄8-11 UNC-2A 3 3 ⁄2

3 15 3 1 3

5 ⁄4 8 ⁄16 3 ⁄4-11 UNC-2A 3 ⁄4 3 ⁄4

3 3 1

6 ⁄4 8 1 ⁄4-10 UNC-2A 3 ⁄4 4

3 1 3 1 1

8 ⁄4 8 1 ⁄8 ⁄4-10 UNC-2A 3 ⁄2 4 ⁄4

7 3 7 3 1

10 ⁄8 12 1 ⁄16 ⁄8-9 UNC-2A 3 ⁄4 4 ⁄2

7 1 7 3

12 ⁄8 12 1 ⁄4 ⁄8-9 UNC-2A 4 4 ⁄4

3 1 1

14 1 12 1 ⁄8 1-8 UNC-2A 4 ⁄4 5 ⁄4

7 1 1

16 1 16 1 ⁄16 1-8 UNC-2A 4 ⁄2 5 ⁄4

1 9 1 3

18 1 ⁄8 16 1 ⁄16 1 ⁄8-7 UNC-2A 5 ⁄4

1 11 1 1 1

20 1 ⁄8 20 1 ⁄16 1 ⁄8-7 UNC-2A 5 ⁄4 6 ⁄4

1 7 1 3 3

24 1 ⁄4 20 1 ⁄8 1 ⁄4-7 UNC-2A 5 ⁄4 6 ⁄4

1 11 11 1 1

26 1 ⁄4 24 2 ⁄16 1 ⁄16-7 UNC-2A 7 ⁄4 8 ⁄2

1 13 1 1 3

28 1 ⁄4 28 2 ⁄16 1 ⁄4-7 UNC-2A 7 ⁄2 8 ⁄4

1 15 1 3

30 1 ⁄4 28 2 ⁄16 1 ⁄4-7 UNC-2A 7 ⁄4 9

1 3 1 3

32 1 ⁄2 28 3 ⁄16 1 ⁄2-6 UNC-2A 8 ⁄4 10

1 1 1 3

34 1 ⁄2 32 3 ⁄4 1 ⁄2-6 UNC-2A 8 ⁄4 10

1 9 1 1 3

36 1 ⁄2 32 3 ⁄16 1 ⁄2-6 UNC-2A 9 ⁄2 10 ⁄4

1 7 1 1 1

38 1 ⁄2 32 3 ⁄16 1 ⁄2-6 UNC-2A 9 ⁄4 10 ⁄2

1 9 1 1 3

40 1 ⁄2 36 3 ⁄16 1 ⁄2-6 UNC-2A 9 ⁄2 10 ⁄4

1 13 1 1

42 1 ⁄2 36 3 ⁄16 1 ⁄2-6 UNC-2A 10 11 ⁄4

1 1 1 1

44 1 ⁄2 40 4 1 ⁄2-6 UNC-2A 10 ⁄4 11 ⁄2

1 1 1 1 3

46 1 ⁄2 40 4 ⁄16 1 ⁄2-6 UNC-2A 10 ⁄2 11 ⁄4

1 1 1 3 1

48 1 ⁄2 44 4 ⁄4 1 ⁄2-6 UNC-2A 10 ⁄4 12 ⁄4

A

1 in. = 25.4 mm.

TABLE 2 Bolting Lengths for 300-lb Steel Flanged Joints to ANSIASME B16.5 (see Fig. 1 and Fig. 2)

Nominal Bolt Bolt Length Stud Bolt

Quantity Flange Bolt Stud

Pipe Size, Diameter, Carbon Steel, Length Car-

A

per Joint Thickness, in. Bolt Thread

A A A

in. in. in. bonCarbon Steel, in.

1 1 9 1 1

⁄2 ⁄2 4 ⁄16 ⁄2-13 UNC-2A 2 2 ⁄2

3 5 5 5 1

⁄4 ⁄8 4 ⁄8 ⁄8-11 UNC-2A 2 ⁄4 3

5 11 5 1

1 ⁄8 4 ⁄16 ⁄8-11 UNC-2A 2 ⁄2 3

1 5 3 5 1 1

1 ⁄4 ⁄8 4 ⁄4 ⁄8-11 UNC-2A 2 ⁄2 3 ⁄4

1 3 13 3 1

1 ⁄2 ⁄4 4 ⁄16 ⁄4-10 UNC-2A 3 3 ⁄2

5 7 5 1

2 ⁄8 8 ⁄8 ⁄8-11 UNC-2A 3 3 ⁄2

1 3 3 1

2 ⁄2 ⁄4 8 1 ⁄4-10 UNC-2A 3 ⁄4 4

3 1 3 1 1

3 ⁄4 8 1 ⁄8 ⁄4-10 UNC-2A 3 ⁄2 4 ⁄4

1 3 3 3 3 1

3 ⁄2 ⁄4 8 1 ⁄16 ⁄4-10 UNC-2A 3 ⁄4 4 ⁄4

3 1 3 3 1

4 ⁄4 8 1 ⁄4 ⁄4-10 UNC-2A 3 ⁄4 4 ⁄2

3 3 3 3

5 ⁄4 8 1 ⁄8 ⁄4-10 UNC-2A 4 4 ⁄4

3 7 3 1 3

6 ⁄4 12 1 ⁄16 ⁄4-10 UNC-2A 4 ⁄4 4 ⁄4

7 5 7 3 1

8 ⁄8 12 1 ⁄8 ⁄8-8 UNC-2A 4 ⁄4 5 ⁄2

7 1 1

10 1 16 1 ⁄8 1-8 UNC-2A 5 ⁄4 6 ⁄4

1 1 3 3

12 1 ⁄8 16 2 1 ⁄8-7 UNC-2A 5 ⁄4 6 ⁄4

1 1 1

14 1 ⁄8 20 2 ⁄8 1 ⁄8-7 UNC-2A 6 7

1 1 1 1

16 1 ⁄4 20 2 ⁄4 1 ⁄4-7 UNC-2A 6 ⁄4 7

1 3 1 1 3

18 1 ⁄4 24 2 ⁄8 1 ⁄4-7 UNC-2A 6 ⁄2 7 ⁄4

1 1 1

20 1 ⁄4 24 2 ⁄2 1 ⁄4-7 UNC-2A 7 8

1 3 1 3

24 1 ⁄2 24 2 ⁄4 1 ⁄2-6 UNC-2A 7 ⁄4 9

A

1 in. = 25.4 mm.

5. Keywords

5.1 bolting lengths; cover bolt; flange joint(s); marine technology; ships; stud bolts

´1

F704 − 81 (2018)

TABLE 3 Bolting Lengths for 400-lb Steel Flanged Joints to ANSIASME B16.5 (see Fig. 3 and Fig. 4)

Nominal Bolt Flange Stud Bolt

Quantity Bolt Stud Bolt Length Alloy

Pipe Size, Diameter, Thickness, Length Alloy

A

per Joint Bolt Thread Steel, in.

A A A

in. in. in. Steel, in.

B B B B B B

⁄2

B B B B B B

⁄4

B B B B B B

B B B B B B

1 ⁄4

B B B B B B

1 ⁄2

B B B B B B

B B B B B B

2 ⁄2

B B B B B B

B B B B B B

3 ⁄2

7 3 7 1

4 ⁄8 8 1 ⁄8 ⁄8-9 UNC-2A not used 5 ⁄2

7 1 7 3

5 ⁄8 8 1 ⁄2 ⁄8-9 UNC-2A not used 5 ⁄4

7 5 7

6 ⁄8 12 1 ⁄8 ⁄8-9 UNC-2A not used 6

7 3

8 1 12 1 ⁄8 1-8 UNC-2A not used 6 ⁄4

1 1 1 1

10 1 ⁄8 16 2 ⁄8 1 ⁄8-8 UN-2A not used 7 ⁄2

1 1 1

12 1 ⁄4 16 2 ⁄4 1 ⁄4-8 UN-2A not used 8

1 3 1 1

14 1 ⁄4 20 2 ⁄8 1 ⁄4-8 UN-2A not used 8 ⁄4

3 1 3 3

16 1 ⁄8 20 2 ⁄2 1 ⁄8-8 UN-2A not used 8 ⁄4

3 5 3

18 1 ⁄8 24 2 ⁄8 1 ⁄8-8 UN-2A not used 9

1 3 1 1

20 1 ⁄2 24 2 ⁄4 1 ⁄2-8 UN-2A not used 9 ⁄2

3 3 1

24 1 ⁄4 24 3 1 ⁄4-8 UN-2A not used 10 ⁄2

A

1 in. = 25.4 mm.

B

For dimensions of these pipe sizes, refer to Table 4.

TABLE 4 Bolting Lengths for 600-lb Steel Flanged Joints to ANSIASME B16.5 (see Fig. 3 and Fig. 4)

Nominal Bolt Flange Stud Bolt

Quantity Bolt Stud Bolt Length Alloy

Pipe Size, Diameter, Thickness, Length Alloy

A

per Joint Bolt Thread Steel, in.

A A A

in. in. in. Steel, in.

1 1 9 1

⁄2 ⁄2 4 ⁄16 ⁄2-13 UNC-2A not used 3

3 5 5 5 1

⁄4 ⁄8 4 ⁄8 ⁄8-11 UNC-2A not used 3 ⁄2

5 11 5 1

1 ⁄8 4 ⁄16 ⁄8-11 UNC-2A not used 3 ⁄2

1 5 13 5 3

1 ⁄4 ⁄8 4 ⁄16 ⁄8-11 UNC-2A not used 3 ⁄4

1 3 7 3 1

1 ⁄2 ⁄4 4 ⁄8 ⁄4-10 UNC-2A not used 4 ⁄4

5 5 1

2 ⁄8 8 1 ⁄8-11 UNC-2A not used 4 ⁄4

1 3 1 3 3

2 ⁄2 ⁄4 8 1 ⁄8 ⁄4-10 UNC-2A not used 4 ⁄4

3 1 3

3 ⁄4 8 1 ⁄4 ⁄4-10 UNC-2A not used 5

1 7 3 7 1

3 ⁄2 ⁄8 8 1 ⁄8 ⁄8-9 UNC-2A not used 5 ⁄2

7 1 7 3

4 ⁄8 8 1 ⁄2 ⁄8-9 UNC-2A not used 5 ⁄4

3 1

5 1 8 1 ⁄4 1-8 UNC-2A not used 6 ⁄2

7 3

6 1 12 1 ⁄8 1-8 UNC-2A not used 6 ⁄4

1 3 1 1

8 1 ⁄8 12 2 ⁄16 1 ⁄8-8 UN-2A not used 7 ⁄2

1 1 1 1

10 1 ⁄4 16 2 ⁄2 1 ⁄4-8 UN-2A not used 8 ⁄2

1 5 1 3

12 1 ⁄4 20 2 ⁄8 1 ⁄4-8 UN-2A not used 8 ⁄4

3 3 3 1

14 1 ⁄8 20 2 ⁄4 1 ⁄8-8 UN-2A not used 9 ⁄4

1 1

16 1 ⁄2 20 3 1 ⁄2-8 UN-2A not used 10

5 1 5 3

18 1 ⁄8 20 3 ⁄4 1 ⁄8-8 UN-2A not used 10 ⁄4

5 1 5 1

20 1 ⁄8 24 3 ⁄2 1 ⁄8-8 UN-2A not used 11 ⁄4

7 7

24 1 ⁄8 24 4 1 ⁄8-8 UN-2A not used 13

A

1 in. = 25.4 mm.

´1

F704 − 81 (2018)

TABLE 5 Bolting Lengths for 900-lb Steel Flanged Joints to ANSIASME B16.5 (see Fig. 3 and Fig. 4)

Nominal Bolt Flange Stud Bolt

Quantity Bolt Stud Bolt Length Alloy

Pipe Size, Diameter, Thickness, Length Alloy

A

per Joint Bolt Thread Steel, in.

A A A

in. in. in. Steel, in.

B B B B B B

⁄2

B B B B B B

⁄4

B B B B B B

B B B B B B

1 ⁄4

B B B B B B

1 ⁄2

B B B B B B

B B B B B B

2 ⁄2

7 1 7 3

3 ⁄8 8 1 ⁄2 ⁄8-9 UNC-2A not used 5 ⁄4

1 3 1 3

4 1 ⁄8 8 1 ⁄4 1 ⁄8-8 UN-2A not used 6 ⁄4

1 1 1

5 1 ⁄4 8 2 1 ⁄4-8 UN-2A not used 7 ⁄2

1 3 1 1

6 1 ⁄8 12 2 ⁄16 1 ⁄8-8 UN-2A not used 7 ⁄2

3 1 3 3

8 1 ⁄8 12 2 ⁄2 1 ⁄8-8 UN-2A not used 8 ⁄4

3 3 3 1

10 1 ⁄8 16 2 ⁄4 1 ⁄8-8 UN-2A not used 9 ⁄4

3 1 3

12 1 ⁄8 20 3 ⁄8 1 ⁄8-8 UN-2A not used 10

1 3 1 3

14 1 ⁄2 20 3 ⁄8 1 ⁄2-8 UN-2A not used 10 ⁄4

5 1 5 1

16 1 ⁄8 20 3 ⁄2 1 ⁄8-8 UN-2A not used 11 ⁄4

7 7 3

18 1 ⁄8 20 4 1 ⁄8-8 UN-2A not used 12 ⁄4

1 3

20 2 20 4 ⁄4 2-8 UN-2A not used 13 ⁄4

1 1 1 1

24 2 ⁄2 20 5 ⁄2 2 ⁄2-8 UN-2A not used 17 ⁄4

A

1 in. = 25.4 mm.

B

For dimensions of these pipe sizes, refer to Table 6.

TABLE 6 Bolting Lengths for 1500-lb Steel Flanged Joints to ANSIASME B16.5 (see Fig. 3 and Fig. 4)

Nominal Bolt Flange Stud Bolt

Quantity Bolt Stud Bolt Length Alloy

Pipe Size, Diameter, Thickness, Length Alloy

A

per Joint Bolt Thread Steel, in.

A A A

in. in. in. Steel, in.

1 3 7 3 1

⁄2 ⁄4 4 ⁄8 ⁄4-10 UNC-2A not used 4 ⁄4

3 3 3 1

⁄4 ⁄4 4 1 ⁄4-10 UNC-2A not used 4 ⁄2

7 1 7

1 ⁄8 4 1 ⁄8 ⁄8-9 UNC-2A not used 5

1 7 1 7

1 ⁄4 ⁄8 4 1 ⁄8 ⁄8-9 UNC-2A not used 5

1 1 1

1 ⁄2 1 4 1 ⁄4 1-8 UNC-2A not used 5 ⁄2

7 1 7 3

2 ⁄8 8 1 ⁄2 ⁄8-9 UNC-2A not used 5 ⁄4

1 5 1

2 ⁄2 1 8 1 ⁄8 1-8 UNC-2A not used 6 ⁄4

1 7 1

3 1 ⁄8 8 1 ⁄8 1 ⁄8-8 UN-2A not used 7

1 1 1 3

4 1 ⁄4 8 2 ⁄8 1 ⁄4-8 UN-2A not used 7 ⁄4

1 7 1 3

5 1 ⁄2 8 2 ⁄8 1 ⁄2-8 UN-2A not used 9 ⁄4

3 1 3 1

6 1 ⁄8 12 3 ⁄4 1 ⁄8-8 UN-2A not used 10 ⁄4

5 5 5 1

8 1 ⁄8 12 3 ⁄8 1 ⁄8-8 UN-2A not used 11 ⁄2

7 1 7 1

10 1 ⁄8 12 4 ⁄4 1 ⁄8-8 UN-2A not used 13 ⁄4

7 3

12 2 16 4 ⁄8 2-8 UN-2A not used 14 ⁄4

1 1 1

14 2 ⁄4 16 5 ⁄4 2 ⁄4-8 UN-2A not used 16

1 3 1 1

16 2 ⁄2 16 5 ⁄4 2 ⁄2-8 UN-2A not used 17 ⁄2

3 3 3 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.