ASTM D6635-01(2007)

(Test Method)Standard Test Method for Performing the Flat Plate Dilatometer

Standard Test Method for Performing the Flat Plate Dilatometer

SIGNIFICANCE AND USE

Soundings performed using this test method provide a detailed record of dilatometer results which are useful for evaluation of site stratigraphy, homogeneity, depth to firm layers, voids or cavities, and other discontinuities. The penetration resistance and subsequent membrane expansion are used for soil classification and correlation with engineering properties of soils. When properly performed at suitable sites, the test provides a rapid means of characterizing subsurface conditions.

The DMT test provides measurements of penetration resistance, lateral stress, deformation modulus and pore-water pressure (in sands). However, the in-situ soil properties are affected by the penetration of the blade. Therefore, published correlations are used to estimate soil properties for the design and construction of earthworks and foundations for structures, and to predict the behavior of soils subjected to static or dynamic loads.

This test method tests the soil in-situ and soil samples are not obtained. However, the interpretation of the results from this test method does provide an estimate of the types of soil penetrated. Soil samples from parallel borings may be obtained for correlation purposes, but prior information or experience may preclude the need for borings.

SCOPE

1.1 This test method describes an in-situ penetration plus expansion test. The test is initiated by forcing the steel, flat plate, dilatometer blade , with its sharp cutting edge, into a soil. Each test consists of an increment of penetration, generally vertical, followed by the expansion of a flat, circular, metallic membrane into the surrounding soil. The test provides information about the soil's in-situ stratigraphy, stress, strength, compressibility, and pore-water pressure for use in the design of earthworks and foundations.

1.2 This method includes specific requirements for the preliminary reduction of dilatometer test data. It does not specify how to assess or use soil properties for engineering design.

1.3 This method applies best to those sands, silts, clays, and organic soils that can be readily penetrated with the dilatometer blade, preferably using static push (see 4.2). Test results for soils containing primarily gravel-sized particles and larger may not be useful without additional research.

1.4 This method is not applicable to soils that cannot be penetrated by the dilatometer blade without causing significant damage to the blade or its membrane.

1.5 The American Society for Testing and Materials takes no position respecting the validity of any patent rights asserted in connection with any item mentioned in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk of infringement of such rights, are entirely their own responsibility.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6635 − 01(Reapproved 2007)

Standard Test Method for

Performing the Flat Plate Dilatometer

This standard is issued under the fixed designation D6635; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 This test method describes an in-situ penetration plus

expansion test. The test is initiated by forcing the steel, flat

2. Referenced Documents

plate, dilatometer blade , with its sharp cutting edge, into a

2.1 ASTM Standards:

soil. Each test consists of an increment of penetration, gener-

D653 Terminology Relating to Soil, Rock, and Contained

ally vertical, followed by the expansion of a flat, circular,

Fluids

metallic membrane into the surrounding soil. The test provides

D1586 Test Method for Penetration Test (SPT) and Split-

information about the soil’s in-situ stratigraphy, stress,

Barrel Sampling of Soils

strength,compressibility,andpore-waterpressureforuseinthe

D2435 Test Methods for One-Dimensional Consolidation

design of earthworks and foundations.

Properties of Soils Using Incremental Loading

1.2 This method includes specific requirements for the

D3441 Test Method for Mechanical Cone Penetration Tests

preliminary reduction of dilatometer test data. It does not 4

of Soil (Withdrawn 2014)

specify how to assess or use soil properties for engineering

D3740 Practice for Minimum Requirements for Agencies

design.

Engaged in Testing and/or Inspection of Soil and Rock as

1.3 This method applies best to those sands, silts, clays, and Used in Engineering Design and Construction

organicsoilsthatcanbereadilypenetratedwiththedilatometer D5778 Test Method for Electronic Friction Cone and Piezo-

blade, preferably using static push (see 4.2). Test results for cone Penetration Testing of Soils

soils containing primarily gravel-sized particles and larger may

3. Terminology

not be useful without additional research.

3.1 Definitions of Terms Specific to This Standard:

1.4 This method is not applicable to soils that cannot be

3.1.1 A-pressure—the gage gas pressure against the inside

penetrated by the dilatometer blade without causing signifi-

of the membrane when the center of the membrane has lifted

cant damage to the blade or its membrane.

above its support and moved laterally 0.05-mm (tolerance

1.5 The American Society for Testing and Materials takes

+0.02, -0.00 mm) into the soil surrounding the blade.

no position respecting the validity of any patent rights asserted

3.1.2 B-pressure—the gage gas pressure against the inside

in connection with any item mentioned in this standard. Users

of the membrane when the center of the membrane has lifted

of this standard are expressly advised that determination of the

above its support and moved laterally 1.10-mm (6 0.03 mm)

validity of any such patent rights, and the risk of infringement

into the soil surrounding the blade.

of such rights, are entirely their own responsibility.

3.1.3 C-pressure—The gage gas pressure against the inside

1.6 This standard does not purport to address all of the

of the membrane when the center of the membrane returns to

safety concerns, if any, associated with its use. It is the

the A-pressure position during a controlled, gradual deflation

responsibility of the user of this standard to establish appro-

following the B-pressure.

3.1.4 DMT—abbreviation for the flat plate dilatometer test

ThistestmethodisunderthejurisdictionofASTMCommitteeD18onSoiland

as described herein.

Rock and is the direct responsibility of Subcommittee D18.02 on Sampling and

3.1.5 DMT sounding—the entire sequence of dilatometer

Related Field Testing for Soil Evaluations.

Current edition approved July 1, 2007. Published August 2007. Originally

tests and results along a vertical line of penetration in the soil.

approved in 2001. Last previous edition approved in 2001 as D6635 – 01. DOI:

10.1520/D6635-01R07.

2 3

The dilatometer is covered by a patent held by Dr. Silvano Marchetti, Via For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Bracciano 38, 00189, Roma, Italy. Interested parties are invited to submit informa- contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

tionregardingtheidentificationofacceptablealternativestothispatenteditemtothe Standards volume information, refer to the standard’s Document Summary page on

Committee on Standards, ASTM Headquarters, 100 Barr Harbor Drive, West the ASTM website.

Conshohocken, PA 19428–2959. Your comments will receive careful consideration The last approved version of this historical standard is referenced on

at the meeting of the responsible technical committee, which you may attend. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6635 − 01 (2007)

3.1.6 DMT test—the complete procedure of penetration, 3.1.21 Z —the gage pressure deviation from zero when

m

membrane inflation and then deflation for a single test depth vented to atmospheric pressure (an offset used to correct

using the fiat plate dilatometer. pressure readings to the true gage pressure).

3.1.7 ∆A—the gage gas pressure inside the membrane (cor-

4. Summary of Test Method

rected for Z ) required to overcome the stiffness of the

m

4.1 A dilatometer test (DMT) consists of forcing the

membrane and move it inward to a center-expansion of 0.05

dilatometer blade into the soil, with the membrane facing the

mm (a negative gage or suction pressure, but recorded as

horizontal direction, to a desired test penetration, measuring

positive) with only ambient atmospheric pressure acting exter-

the thrust to accomplish this penetration and then using gas

nally.

pressure to expand a circular steel membrane located on one

3.1.8 ∆B—the gage gas pressure inside the membrane (cor-

side of the blade. The operator measures and records the

rected for Z ) required to overcome the stiffness of the

m

pressure required to produce expansion of the membrane into

membrane and move it outward to a center-expansion of 1.10

the soil at two preset deflections.The operator then deflates the

mm against only the ambient atmospheric pressure.

membrane, possibly recording an optional third measurement,

3.1.9 E —the dilatometer modulus, based on linear elastic

D

advances the blade the desired penetration increment and

theory, and the primary index used in the correlation for the

repeats the test. Each test sequence typically requires about 2

constrained and Young’s moduli (see Section 9).

minutes.Adilatometer sounding consists of the results from all

3.1.10 G —bulk specific gravity = moist soil unit weight the tests at one location presented in a fashion indicating

m

divided by the unit weight of water.

variation with depth.

3.1.11 I —the dimensionless dilatometer material index,

D 4.2 The operator may advance the blade using either a

used to identify soil type and delineate stratigraphy (see

quasi-staticpushforceordynamicimpactfromahammer,with

Section 9).

quasi-static push preferred. A record of the penetration resis-

3.1.12 K —the dimensionless dilatometer horizontal stress tance (thrust force or blows per penetration increment) is

D

index, the primary index used in the correlation for in-situ desirable both for control of the penetration and later analyses.

horizontal stress, overconsolidation ratio, and undrained shear

NOTE 1—In soils sensitive to impact and vibrations, such as medium to

strengthincohesivesoils.K issimilartotheat-restcoefficient

D

loosesandsorsensitiveclays,dynamicinsertionmethodscansignificantly

of earth pressure except that it includes blade penetration

change the test results compared to those obtained using a quasi-static

push.Ingeneral,structurallysensitivesoilswillappearmorecompressible

effects.

when tested using dynamic insertion methods. In such cases check for

3.1.13 membrane—a thin, flexible, 60-mm diameter circular

dynamic effects and, if important, calibrate and adjust test interpretations

piece of sheet metal (usually stainless steel), fixed around its

accordingly.

edges, that mounts on one side of the dilatometer blade and

4.3 The penetration increment typically used in a dilatom-

which, as a result of an applied internal gas pressure, expands

etertest(DMT)soundingvariesfrom0.15to0.30m(0.5to1.0

into the soil in an approximate spherical shape along an axis

ft). Most soundings are performed vertically and this Test

perpendicular to the plane of the blade.

Method requires that the membrane face the horizontal direc-

3.1.14 P—the total push, or thrust force required to advance

tion. Testing below impenetrable layers will require preboring

only the dilatometer blade to its test depth, measured at its test

and supporting (if required) a borehole with a diameter of at

depthandexclusiveofsoilorotherfrictionalongthepushrods.

least 100 mm (4 in.).

3.1.15 p —the A-pressure reading, corrected for Z , the∆A

0 m

4.4 The operator performs a membrane calibration before

membrane stiffness at 0.05-mm expansion, and the 0.05-mm

and after each DMT sounding.

expansion itself, to estimate the total soil stress acting normal

4.5 The field data is then interpreted to obtain profiles of

to the membrane immediately before its expansion into the soil

those engineering soil properties of interest over the depth

(0.00-mm expansion, see Section 9).

range of the DMT sounding.

3.1.16 p —the B-pressure reading corrected for Z and the

1 m

∆B membrane stiffness at 1.10-mm expansion to give the total

5. Significance and Use

soil stress acting normal to the membrane at 1.10-mm mem-

5.1 Soundings performed using this test method provide a

brane expansion (see Section 9).

detailed record of dilatometer results which are useful for

3.1.17 p —The C-pressure reading corrected for Z and the

2 m evaluation of site stratigraphy, homogeneity, depth to firm

∆A membrane stiffness at 0.05-mm expansion and used to

layers, voids or cavities, and other discontinuities. The pen-

estimate pore-water pressure (see 9.3).

etration resistance and subsequent membrane expansion are

3.1.18 σ' —vertical effective stress at the center of the

used for soil classification and correlation with engineering

v

membrane before the insertion of the DMT blade. properties of soils. When properly performed at suitable sites,

the test provides a rapid means of characterizing subsurface

3.1.19 σ —totalverticalstressatthecenterofthemembrane

v

conditions.

before the insertion of the DMT blade, generally calculated

from unit weights estimated using the DMT results.

5.2 The DMT test provides measurements of penetration

3.1.20 u —the pore-water pressure acting at the center of resistance, lateral stress, deformation modulus and pore-water

the membrane before the insertion of the DMT blade (often pressure (in sands). However, the in-situ soil properties are

assumed as hydrostatic below the water table surface). affected by the penetration of the blade. Therefore, published

D6635 − 01 (2007)

correlations are used to estimate soil properties for the design 6.1.5 Pneumatic-Electrical Cable, (7) to transmit gas pres-

and construction of earthworks and foundations for structures, sure and electrical continuity from the control unit to the blade.

and to predict the behavior of soils subjected to static or

6.1.6 Ground Cable, (8) to provide electrical continuity

dynamic loads.

between the push rod system and the calibration unit.

5.3 This test method tests the soil in-situ and soil samples

6.2 Insertion equipment is required to advance the blade to

are not obtained. However, the interpretation of the results

the test depth. The blade may be pushed using the quasi-static

from this test method does provide an estimate of the types of

thrust of a drill rig or cone penetrometer rig (CPT, see Test

soil penetrated. Soil samples from parallel borings may be

Method D3441, D5778), driven using a hammer such as in the

obtained for correlation purposes, but prior information or

standard penetration test (SPT, see Test Method D1586 and

experience may preclude the need for borings.

Note 1), or inserted using other suitable equipment. Drill rig

support may be required to born through impenetrable soil or

6. Apparatus

rock layers above the desired test depth.

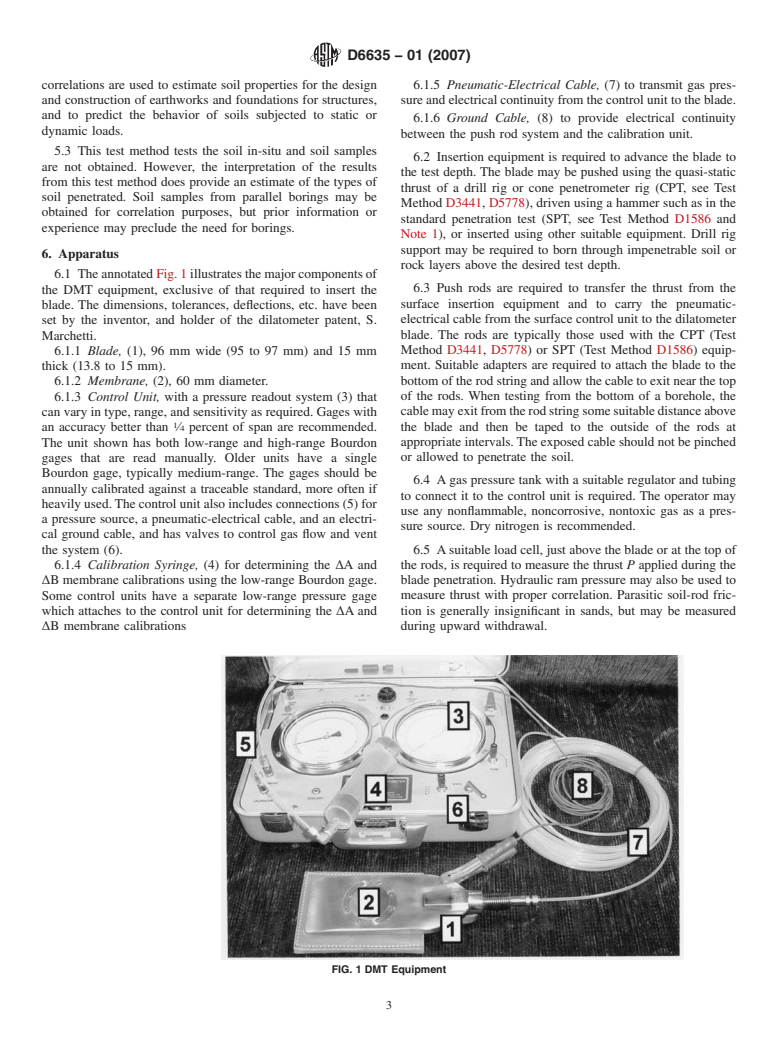

6.1 TheannotatedFig.1illustratesthemajorcomponentsof

6.3 Push rods are required to transfer the thrust from the

the DMT equipment, exclusive of that required to insert the

surface insertion equipment and to carry the pneumatic-

blade. The dimensions, tolerances, deflections, etc. have been

electrical cable from the surface control unit to the dilatometer

set by the inventor, and holder of the dilatometer patent, S.

blade. The rods are typically those used with the CPT (Test

Marchetti.

Method D3441, D5778) or SPT (Test Method D1586) equip-

6.1.1 Blade, (1), 96 mm wide (95 to 97 mm) and 15 mm

ment. Suitable adapters are required to attach the blade to the

thick (13.8 to 15 mm).

6.1.2 Membrane, (2), 60 mm diameter. bottom of the rod string and allow the cable to exit near the top

of the rods. When testing from the bottom of a borehole, the

6.1.3 Control Unit, with a pressure readout system (3) that

cablemayexitfromtherodstringsomesuitabledistanceabove

can vary in type, range, and sensitivity as required. Gages with

an accuracy better than ⁄4 percent of span are recommended. the blade and then be taped to the outside of the rods at

appropriate intervals.The exposed cable should not be pinched

The unit shown has both low-range and high-range Bourdon

gages that are read manually. Older units have a single or allowed to penetrate the soil.

Bourdon gage, typically medium-range. The gages should be

6.4 Agas pressure tank with a suitable regulator and tubing

annually calibrated against a traceable standard, more often if

to connect it to the control unit is required. The operator may

heavily used.The control unit also includes connections (5) for

use any nonflammable, noncorrosive, nontoxic gas as a pres-

a pressure source, a pneumatic-electrical cable, and an electri-

sure source. Dry nitrogen is recommended.

cal ground cable, and has valves to control gas flow and vent

the system (6). 6.5 Asuitable load cell, just above the blade or at the top of

6.1.4 Calibration Syringe, (4) for determining the ∆A and the rods, is required to measure the thrust P applied during the

∆B membrane calibrations using the low-range Bourdon gage. blade penetration. Hydraulic ram pressure may

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.