ASTM A563-07a(2014)

(Specification)Standard Specification for Carbon and Alloy Steel Nuts

Standard Specification for Carbon and Alloy Steel Nuts

ABSTRACT

This specification covers chemical and mechanical requirements for eight property classes of hex and hex-flange carbon and alloy steel nuts for general structural and mechanical uses on bolts, studs, and other externally threaded parts. Materials shall be tested and the individual grades shall conform to specified values of material such as hardness and proof load, chemical, and mechanical requirements. Classes 8S3 and 10S3 nuts have atmospheric corrosion resistance and weathering characteristics comparable to those of the steels. The atmospheric corrosion resistance of these steels is substantially better than that of carbon steel with or without copper addition. When properly exposed to the atmosphere, these steels can be used bare (uncoated) for many applications.

SCOPE

1.1 This specification2 covers chemical and mechanical requirements for eight grades of carbon and alloy steel nuts for general structural and mechanical uses on bolts, studs, and other externally threaded parts. Note 1—See Appendix X1 for guidance on suitable application of nut grades.

1.2 The requirements for any grade of nut may, at the supplier's option, and with notice to the purchaser, be fulfilled by furnishing nuts of one of the stronger grades specified herein unless such substitution is barred in the inquiry and purchase order.

1.3 Grades C3 and DH3 nuts have atmospheric corrosion resistance and weathering characteristics comparable to that of the steels covered in Specifications A242/A242M, A588/A588M, and A709/A709M. The atmospheric corrosion resistance of these steels is substantially better than that of carbon steel with or without copper addition (see 5.2). When properly exposed to the atmosphere, these steels can be used bare (uncoated) for many applications. Note 2—A complete metric companion to Specification A563 has been developed—A563M; therefore, no metric equivalents are presented in this specification.

1.4 Terms used in this specification are defined in Terminology F1789 unless otherwise defined herein.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A563 −07a(Reapproved 2014)

Standard Specification for

Carbon and Alloy Steel Nuts

This standard is issued under the fixed designation A563; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* for Bolts for High Pressure or High Temperature Service,

2 or Both

1.1 This specification covers chemical and mechanical

A242/A242M Specification for High-Strength Low-Alloy

requirements for eight grades of carbon and alloy steel nuts for

Structural Steel

general structural and mechanical uses on bolts, studs, and

A307 Specification for Carbon Steel Bolts, Studs, and

other externally threaded parts.

Threaded Rod 60 000 PSI Tensile Strength

NOTE 1—See Appendix X1 for guidance on suitable application of nut

A325 Specification for Structural Bolts, Steel, Heat Treated,

grades.

120/105 ksi Minimum Tensile Strength

1.2 The requirements for any grade of nut may, at the

A354 Specification for Quenched and TemperedAlloy Steel

supplier’s option, and with notice to the purchaser, be fulfilled

Bolts, Studs, and Other Externally Threaded Fasteners

by furnishing nuts of one of the stronger grades specified

A394 Specification for Steel Transmission Tower Bolts,

herein unless such substitution is barred in the inquiry and

Zinc-Coated and Bare

purchase order.

A449 Specification for Hex Cap Screws, Bolts and Studs,

Steel, Heat Treated, 120/105/90 ksi Minimum Tensile

1.3 Grades C3 and DH3 nuts have atmospheric corrosion

Strength, General Use

resistance and weathering characteristics comparable to that of

A490 Specification for Structural Bolts, Alloy Steel, Heat

the steels covered in Specifications A242/A242M, A588/

Treated, 150 ksi Minimum Tensile Strength

A588M, and A709/A709M. The atmospheric corrosion resis-

A563M Specification for Carbon andAlloy Steel Nuts (Met-

tance of these steels is substantially better than that of carbon

ric)

steel with or without copper addition (see 5.2). When properly

A588/A588M Specification for High-Strength Low-Alloy

exposed to the atmosphere, these steels can be used bare

Structural Steel, up to 50 ksi [345 MPa] Minimum Yield

(uncoated) for many applications.

Point, with Atmospheric Corrosion Resistance

NOTE 2—Acomplete metric companion to Specification A563 has been

A687 Specification for High-Strength Nonheaded Steel

developed—A563M; therefore, no metric equivalents are presented in this

Bolts and Studs (Withdrawn 1999)

specification.

A709/A709M Specification for Structural Steel for Bridges

1.4 Terms used in this specification are defined in Termi-

A751 Test Methods, Practices, and Terminology for Chemi-

nology F1789 unless otherwise defined herein.

cal Analysis of Steel Products

B695 Specification for Coatings of Zinc Mechanically De-

2. Referenced Documents

posited on Iron and Steel

2.1 ASTM Standards: D3951 Practice for Commercial Packaging

F606 Test Methods for Determining the Mechanical Proper-

A194/A194M Specification for Carbon andAlloy Steel Nuts

ties of Externally and Internally Threaded Fasteners,

Washers, Direct Tension Indicators, and Rivets

F812/F812M Specification for Surface Discontinuities of

This specification is under the jurisdiction of ASTM Committee F16 on

Nuts, Inch and Metric Series

Fasteners and is the direct responsibility of Subcommittee F16.02 on Steel Bolts,

Nuts, Rivets and Washers.

F1789 Terminology for F16 Mechanical Fasteners

Current edition approved April 1, 2014. Published May 2014. Originally

F2329 Specification for Zinc Coating, Hot-Dip, Require-

approved in 1966. Last previous edition approved in 2007 as A563 – 07a. DOI:

ments for Application to Carbon and Alloy Steel Bolts,

10.1520/A0563-07AR14.

Screws, Washers, Nuts, and Special Threaded Fasteners

For ASME Boiler and Pressure Vessel Code applications see related Specifi-

cation SA – 563 in Section II of that Code.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A563−07a (2014)

G101 Guide for Estimating the Atmospheric Corrosion Re- 4.7.3 When mechanically deposited is specified, the fasten-

sistance of Low-Alloy Steels ers shall be zinc coated by the mechanical deposition process

in accordance with the requirements of Class 55 of Specifica-

2.2 ANSI Standards:

tion B695.

ANSI B1.1 Unified Screw Threads

4.7.4 When no preference is specified, the supplier may

ANSI B18.2.2 Square and Hex Nuts

furnish either a hot-dip zinc coating in accordance with

3. Ordering Information

Specification F2329, or a mechanically deposited zinc coating

in accordance with Specification B695, Class 55. Threaded

3.1 Orders for nuts under this specification shall include the

components (bolts and nuts) shall be coated by the same

following:

zinc-coating process and the supplier’s option is limited to one

3.1.1 Quantity (number of nuts),

process per item with no mixed processes in a lot.

3.1.2 Nominal size and thread series of nuts,

4.7.5 Hot-dip zinc-coated nuts shall be tapped after zinc

3.1.3 Style of nut (for example, heavy hex),

coating.

3.1.4 Grade of nut,

4.7.6 Mechanically deposited zinc-coated nuts for assembly

3.1.5 Zinc Coating—Specify the zinc-coating process

with mechanically deposited zinc-coated bolts shall be tapped

required, for example, hot-dip, mechanically deposited, or no

oversize prior to zinc coating and need not be retapped

preference (see 4.7),

afterwards.

3.1.6 Other Finishes—Specify other protective finish if

required,

4.8 Lubricant:

3.1.7 ASTM designation and year of issue, and

4.8.1 Hot-dip and mechanically deposited zinc-coated

3.1.8 Supplementary or special requirements.

Grade DH nuts shall be provided with an additional lubricant

which shall be clean and dry to the touch (see Supplementary

NOTE 3—An example of an ordering description follows: 1000 ⁄8-9

Requirement S1 to specify lubrication requirements for plain

heavy hex nuts, Grade DH, hot-dip zinc-coated, and lubricated, ASTM

A563–XX.

finish nuts).

4.8.2 See Supplementary Requirement S2 for option to

4. Materials and Manufacture

specify a dye in the lubricant.

4.1 Steel for nuts shall be made by the open-hearth, basic-

5. Chemical Composition

oxygen, or electric-furnace process except that steel for Grades

O, A, and B nuts may be made by the acid-bessemer process.

5.1 Grades O, A, B, C, D, and DH shall conform to the

chemical composition specified in Table 1.

4.2 Nuts may be made cold or hot by forming, pressing, or

punching or may be machined from bar stock.

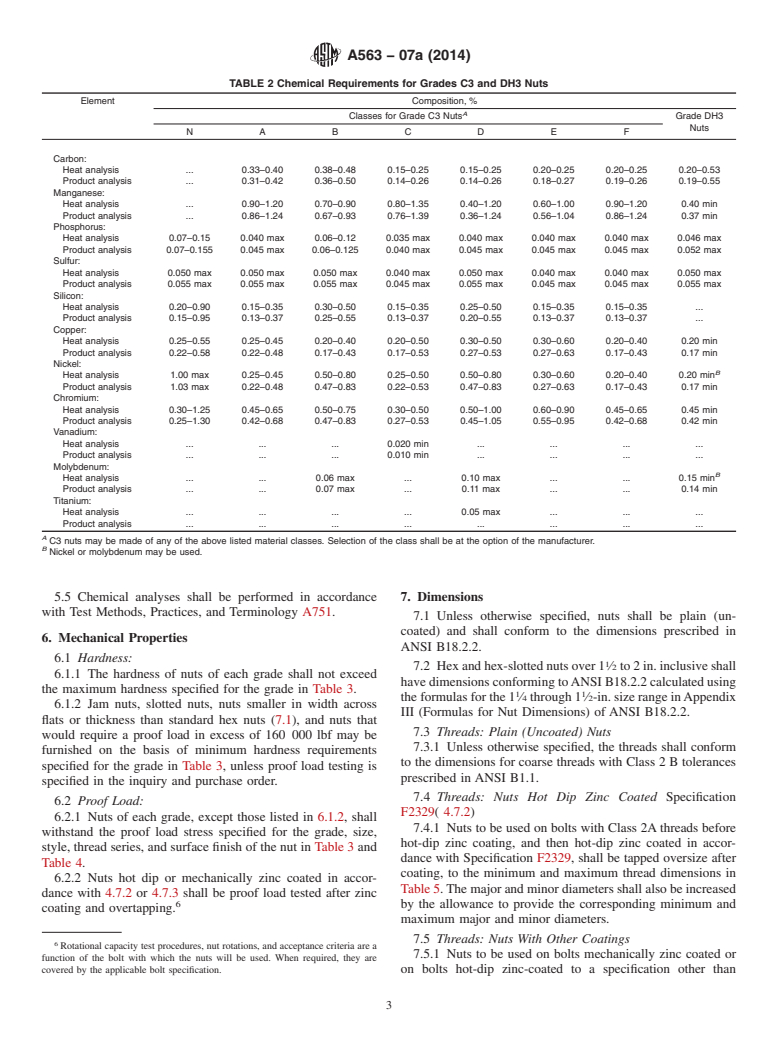

5.2 Grades C3 and DH3 shall conform to the chemical

composition specified in Table 2. See Guide G101 for methods

4.3 Grades DH and DH3 nuts shall be heat treated by

of estimating the atmospheric corrosion resistance of low alloy

quenching in a liquid medium from a temperature above the

steels.

transformation temperature and tempering at a temperature of

at least 800°F.

5.3 Resulfurized or rephosphorized steel, or both, are not

subject to rejection based on product analysis for sulfur or

4.4 Grades C and D nuts made of steel having carbon

phosphorus.

content not exceeding 0.20 %, phosphorus not exceeding

0.04 %, and sulfur not exceeding 0.05 % by heat analysis may

5.4 Application of heats of steel to which bismuth,

be heat treated by quenching in a liquid medium from a

selenium, tellurium, or lead has been intentionally added shall

temperatureabovethetransformationtemperatureandneednot

not be permitted for Grades D, DH, and DH3.

be tempered. When this heat treatment is used, there shall be

particular attention to the requirements in 6.1.1.

TABLE 1 Chemical Requirements for Grades O, A, B, C, D, and

DH Nuts

4.5 Grades C, C3, and D nuts made of any steel permitted

Grade of Composition, %

for these grades may be heat treated by quenching in a liquid

Nut

Analysis Carbon Manganese, Phospho- Sulfur,

medium from a temperature above the transformation tempera-

min rus, max max

ture and tempering at a temperature of at least 800°F.

4.6 Threads shall be formed by tapping or machining.

A

O, A, B, C heat 0.55 max . 0.12 0.15

B

4.7 Zinc Coatings, Hot-Dip and Mechanically Deposited:

product 0.58 max . 0.13 .

4.7.1 When zinc-coated fasteners are required, the pur-

C

D heat 0.55 max 0.30 0.04 0.05

chaser shall specify the zinc coating process, for example,

product 0.58 max 0.27 0.048 0.058

hot-dip, mechanically deposited, or no preference.

heat 0.20–0.55 0.60 0.04 0.05

4.7.2 When hot-dip is specified, the fasteners shall be

C

DH product 0.18–0.58 0.57 0.048 0.058

zinc-coated by the hot-dip process in accordance with the

A

For Grades O, A, and B a sulfur content of 0.23 % max is acceptable with the

requirements of Specification F2329.

purchasers approval.

B

Acid bessemer steel only.

C

For Grades D and DH a sulfur content of 0.05 – 0.15 % is acceptable provided

Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

the manganese is 1.35 % min.

4th Floor, New York, NY 10036, http://www.ansi.org.

A563−07a (2014)

TABLE 2 Chemical Requirements for Grades C3 and DH3 Nuts

Element Composition, %

A

Classes for Grade C3 Nuts Grade DH3

Nuts

NA BC DE F

Carbon:

Heat analysis . 0.33–0.40 0.38–0.48 0.15–0.25 0.15–0.25 0.20–0.25 0.20–0.25 0.20–0.53

Product analysis . 0.31–0.42 0.36–0.50 0.14–0.26 0.14–0.26 0.18–0.27 0.19–0.26 0.19–0.55

Manganese:

Heat analysis . 0.90–1.20 0.70–0.90 0.80–1.35 0.40–1.20 0.60–1.00 0.90–1.20 0.40 min

Product analysis . 0.86–1.24 0.67–0.93 0.76–1.39 0.36–1.24 0.56–1.04 0.86–1.24 0.37 min

Phosphorus:

Heat analysis 0.07–0.15 0.040 max 0.06–0.12 0.035 max 0.040 max 0.040 max 0.040 max 0.046 max

Product analysis 0.07–0.155 0.045 max 0.06–0.125 0.040 max 0.045 max 0.045 max 0.045 max 0.052 max

Sulfur:

Heat analysis 0.050 max 0.050 max 0.050 max 0.040 max 0.050 max 0.040 max 0.040 max 0.050 max

Product analysis 0.055 max 0.055 max 0.055 max 0.045 max 0.055 max 0.045 max 0.045 max 0.055 max

Silicon:

Heat analysis 0.20–0.90 0.15–0.35 0.30–0.50 0.15–0.35 0.25–0.50 0.15–0.35 0.15–0.35 .

Product analysis 0.15–0.95 0.13–0.37 0.25–0.55 0.13–0.37 0.20–0.55 0.13–0.37 0.13–0.37 .

Copper:

Heat analysis 0.25–0.55 0.25–0.45 0.20–0.40 0.20–0.50 0.30–0.50 0.30–0.60 0.20–0.40 0.20 min

Product analysis 0.22–0.58 0.22–0.48 0.17–0.43 0.17–0.53 0.27–0.53 0.27–0.63 0.17–0.43 0.17 min

Nickel:

B

Heat analysis 1.00 max 0.25–0.45 0.50–0.80 0.25–0.50 0.50–0.80 0.30–0.60 0.20–0.40 0.20 min

Product analysis 1.03 max 0.22–0.48 0.47–0.83 0.22–0.53 0.47–0.83 0.27–0.63 0.17–0.43 0.17 min

Chromium:

Heat analysis 0.30–1.25 0.45–0.65 0.50–0.75 0.30–0.50 0.50–1.00 0.60–0.90 0.45–0.65 0.45 min

Product analysis 0.25–1.30 0.42–0.68 0.47–0.83 0.27–0.53 0.45–1.05 0.55–0.95 0.42–0.68 0.42 min

Vanadium:

Heat analysis . . . 0.020 min . . . .

Product analysis . . . 0.010 min . . . .

Molybdenum:

B

Heat analysis . . 0.06 max . 0.10 max . . 0.15 min

Product analysis . . 0.07 max . 0.11 max . . 0.14 min

Titanium:

Heat analysis . . . . 0.05 max . . .

Product analysis . . . . . . . .

A

C3 nuts may be made of any of the above listed material classes. Selection of the class shall be at the option of the manufacturer.

B

Nickel or molybdenum may be used.

5.5 Chemical analyses shall be performed in accordance 7. Dimensions

with Test Methods, Practices, and Terminology A751.

7.1 Unless otherwise specified, nuts shall be plain (un-

coated) and shall conform to the dimensions prescribed in

6. Mechanical Properties

ANSI B18.2.2.

6.1 Hardness:

7.2 Hexandhex-slottednutsover1 ⁄2 to2in.inclusiveshall

6.1.1 The hardness of nuts of each grade shall not exceed

havedimensionsconformingtoANSIB18.2.2calculatedusing

the maximum hardness specified for the grade in Table 3.

1 1

the formulas for the 1 ⁄4 through 1 ⁄2-in. size range inAppendix

6.1.2 Jam nuts, slotted nuts, nuts smaller in width across

III (Formulas for Nut Dimensions) of ANSI B18.2.2.

flats or thickness than standard hex nuts (7.1), and nuts that

7.3 Threads: Plain (Uncoated) Nuts

would require a proof load in excess of 160 000 lbf may be

7.3.1 Unless otherwise specified, the threads shall conform

furnished on the basis of minimum hardness requirements

to the dimensions for coarse threads with Class 2 B tolerances

specified for the grade in Table 3, unless proof load testing is

prescribed in ANSI B1.1.

specified in the inquiry and purchase order.

7.4 Threads: Nuts Hot Dip Zinc Coated Specification

6.2 Proof Load:

F2329( 4.7.2)

6.2.1 Nuts of each grade, except those listed in 6.1.2, shall

7.4.1 Nuts to be used on bolts with Class 2Athreads before

withstand the proof load stress specified for the grade, size,

hot-dip zinc coating, and then hot-dip zinc coated in accor-

style, thread series, and surface finish of the nut in Table 3 and

dance with Specification F2329, shall be tapped oversize after

Table 4.

coating, to the minimum and maximum thread dimensions in

6.2.2 Nuts hot dip or mechanically zinc coated in accor-

Table 5.The major and minor diameters shall also be increased

dance with 4.7.2 or 4.7.3 shall be proof load tested after zinc

by the allowance to provide the corresponding minimum and

coating and overtapping.

maximum major and minor diameters.

7.5 Threads: Nuts With Other Coatings

Rotational capacity test procedures, nut rotations, and acceptance criteria are a

7.5.1 Nuts to be used on bolts mechanically zinc coated or

function of the bolt with which the nuts will be used. When required, they are

covered by the applicable bolt specification. on bolts hot-dip zinc-coated to a specification other than

A563−07a (2014)

TABLE 3 Mechanical Requirements

Nuts with UNC, 8 UN, 6 UN and Coarser Pitch Threads

A

Grade of Nut Nominal Nut Size, Style of Nut Proof Load Stress, ksi Hardness

in.

Non-Zinc-Coated Zinc-Coated Brinell Rockwell

B B

Nuts Nuts

min max min max

1 1

O ⁄4 to 1 ⁄2 square 69 52 103 302 B55 C32

1 1

A ⁄4 to 1 ⁄2 square 90 68 116 302 B68 C32

1 1

O ⁄4 to 1 ⁄2 hex 69 52 103 302 B55 C32

1 1

A ⁄4 to 1 ⁄2 hex 90 68 116 302 B68 C32

B ⁄4 to 1 hex 120 90 121 302 B69 C32

1 1

B1 ⁄8

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.