ASTM D4080-00

(Specification)Standard Specification for Trichloroethylene, Technical and Vapor-Degreasing Grade

Standard Specification for Trichloroethylene, Technical and Vapor-Degreasing Grade

SCOPE

1.1 This specification covers technical and vapor degreasing grade trichloroethylene.

Note 1--Practices D3844 and D4276, and MNL2 provide additional important information on vapor degreasing and solvent properties.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4080 – 00

Standard Specification for

1

Trichloroethylene, Technical and Vapor-Degreasing Grade

This standard is issued under the fixed designation D 4080; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

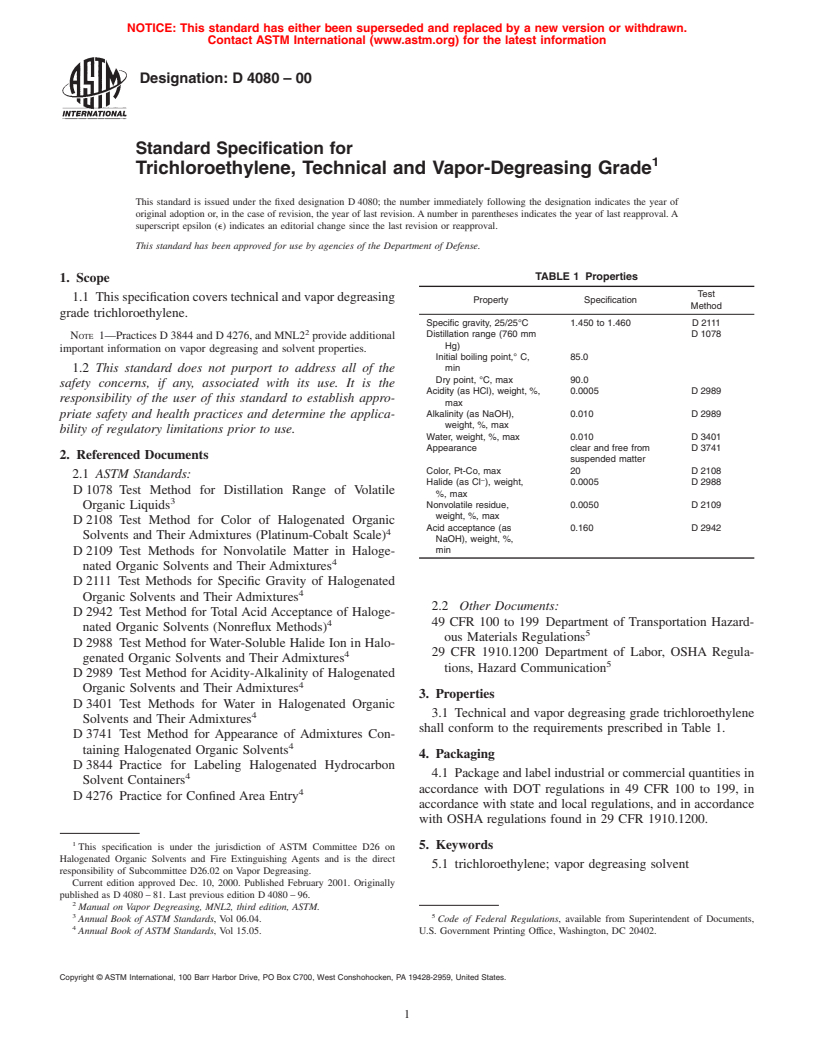

TABLE 1 Properties

1. Scope

Test

1.1 Thisspecificationcoverstechnicalandvapordegreasing

Property Specification

Method

grade trichloroethylene.

Specific gravity, 25/25°C 1.450 to 1.460 D 2111

2

NOTE 1—Practices D 3844 and D 4276, and MNL2 provide additional Distillation range (760 mm D 1078

Hg)

important information on vapor degreasing and solvent properties.

Initial boiling point,° C, 85.0

1.2 This standard does not purport to address all of the min

Dry point, °C, max 90.0

safety concerns, if any, associated with its use. It is the

Acidity (as HCl), weight, %, 0.0005 D 2989

responsibility of the user of this standard to establish appro-

max

Alkalinity (as NaOH), 0.010 D 2989

priate safety and health practices and determine the applica-

weight, %, max

bility of regulatory limitations prior to use.

Water, weight, %, max 0.010 D 3401

Appearance clear and free from D 3741

2. Referenced Documents

suspended matter

Color, Pt-Co, max 20 D 2108

2.1 ASTM Standards:

−

Halide (as Cl ), weight, 0.0005 D 2988

D 1078 Test Method for Distillation Range of Volatile

%, max

3

Organic Liquids Nonvolatile residue, 0.0050 D 2109

weight, %, max

D 2108 Test Method for Color of Halogenated Organic

Acid acceptance (as 0.160 D 2942

4

Solvents and Their Admixtures (Platinum-Cobalt Scale)

NaOH), weight, %,

min

D 2109 Test Methods for Nonvolatile Matter in Haloge-

4

nated Organic Solvents and Their Admixtures

D 2111 Test Methods for Specific Gravity of Halogenated

4

Organic Solvents and Their Admixtures

2.2 Other Documents:

D 2942 Test Method for Total Acid Acceptance of Haloge-

4 49 CFR 100 to 199 Department of Transportation Hazard-

nated Organic Solvents (Nonreflux Methods)

5

ous Materials Regulations

D 2988 Test Method for Water-Soluble Halide Ion in Halo-

4 29 CFR 1910.1200 Department of Labor, OSHA Regula-

genated Organic Solvents and Their Admixtures

5

tions, Hazard Communication

D 2989 Test Method for Acidity-Alkalinity of Halogenated

4

Organic Solvents and Their Admixtures

3. Properties

D 3401 Test Methods for Water in Halogenated Organic

3.1 Technical and vapor degreasi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.