ASTM G86-17

(Test Method)Standard Test Method for Determining Ignition Sensitivity of Materials to Mechanical Impact in Ambient Liquid Oxygen and Pressurized Liquid and Gaseous Oxygen Environments

Standard Test Method for Determining Ignition Sensitivity of Materials to Mechanical Impact in Ambient Liquid Oxygen and Pressurized Liquid and Gaseous Oxygen Environments

SIGNIFICANCE AND USE

5.1 This test method evaluates the relative sensitivity of materials to mechanical impact in ambient pressure liquid oxygen, pressurized liquid oxygen, and pressurized gaseous oxygen.

5.2 Any change or variation in test sample configuration, thickness, preparation, or cleanliness may cause a significant change in impact sensitivity/reaction threshold.

5.3 Suggested criteria for discontinuing the tests are: (1) occurrence of two reactions in a maximum of 60 samples or less tested at the maximum energy level of 98 J (72 ft•lbf) or one reaction in a maximum of 20 samples tested at any other energy level for a material that fails; (2) no reactions for 20 samples tested at the 98-J (72-ft•lbf) energy level; or (3) a maximum of one reaction in 60 samples tested at the maximum energy level.

SCOPE

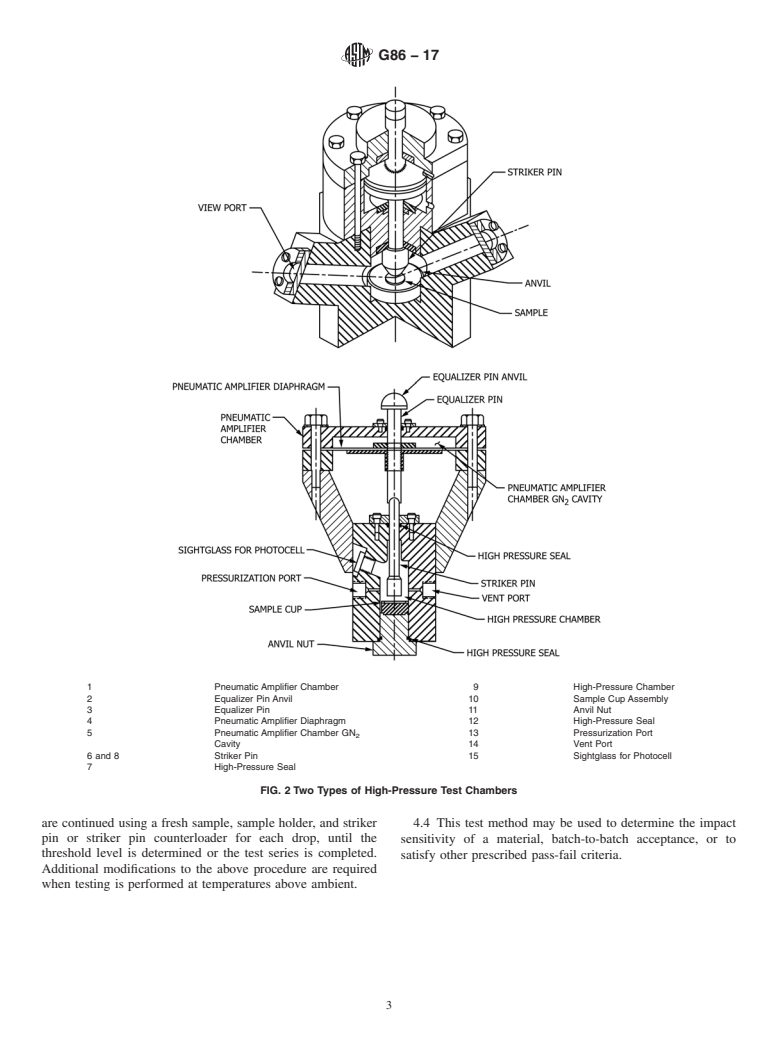

1.1 This test method2 describes test equipment and techniques to determine the impact sensitivity of materials in oxygen under two different conditions: (1) in ambient pressure liquid oxygen (LOX) or (2) under pressure-controlled conditions in LOX or gaseous oxygen (GOX). It is applicable to materials for use in LOX or GOX systems at pressures from ambient to 68.9 MPa (0 to 10 000 psig). The test method described herein addresses testing with pure oxygen environments; however, other oxygen-enriched fluids may be substituted throughout this document.

1.2 This test method provides a means for ranking nonmetallic materials as defined in Guide G63 for use in liquid and gaseous oxygen systems and may not be directly applicable to the determination of the sensitivity of the materials in an end-use configuration. This test method may be used to provide batch-to batch acceptance data. This test method may provide a means for evaluating metallic materials in oxygen-enriched atmospheres also; however, Guide G94 should be consulted for preferred testing methods.

1.3 Values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. See also Section 9.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: G86 − 17

Standard Test Method for

Determining Ignition Sensitivity of Materials to Mechanical

Impact in Ambient Liquid Oxygen and Pressurized Liquid

1

and Gaseous Oxygen Environments

ThisstandardisissuedunderthefixeddesignationG86;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Development of International Standards, Guides and Recom-

2

mendations issued by the World Trade Organization Technical

1.1 This test method describes test equipment and tech-

Barriers to Trade (TBT) Committee.

niques to determine the impact sensitivity of materials in

oxygen under two different conditions: (1) in ambient pressure

2. Referenced Documents

liquid oxygen (LOX) or (2) under pressure-controlled condi-

3

tions in LOX or gaseous oxygen (GOX). It is applicable to

2.1 ASTM Standards:

materials for use in LOX or GOX systems at pressures from

D1193 Specification for Reagent Water

ambient to 68.9 MPa (0 to 10 000 psig). The test method

D4080 Specification for Trichloroethylene, Technical and

described herein addresses testing with pure oxygen environ-

Vapor-Degreasing Grade

ments; however, other oxygen-enriched fluids may be substi-

G63 Guide for Evaluating Nonmetallic Materials for Oxy-

tuted throughout this document.

gen Service

1.2 This test method provides a means for ranking nonme-

G88 Guide for Designing Systems for Oxygen Service

tallic materials as defined in Guide G63 for use in liquid and

G93 Guide for Cleanliness Levels and Cleaning Methods for

gaseous oxygen systems and may not be directly applicable to

Materials and Equipment Used in Oxygen-Enriched En-

the determination of the sensitivity of the materials in an

vironments

end-useconfiguration.Thistestmethodmaybeusedtoprovide

G94 Guide for Evaluating Metals for Oxygen Service

batch-to batch acceptance data. This test method may provide

4

2.2 Military Document:

a means for evaluating metallic materials in oxygen-enriched

MIL-D-16791 Detergent, General Purpose (Liquid, Non-

atmospheresalso;however,GuideG94shouldbeconsultedfor

ionic), Type One

preferred testing methods.

5

2.3 American Chemical Society:

1.3 Values stated in SI units are to be regarded as the

Trichloroethylene, Reagent Grade

standard. The values given in parentheses are for information

6

only.

2.4 Compressed Gas Association:

G-4 Oxygen

1.4 This standard does not purport to address all of the

G-4.1 Cleaning Equipment for Oxygen Service

safety concerns, if any, associated with its use. It is the

G-4.3 Oxygen, Gaseous, Type I B

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter- G-4.3 Oxygen, Liquid, Type II B

mine the applicability of regulatory limitations prior to use. G-10.1 Nitrogen, Gaseous, Type I B

See also Section 9. G-10.1 Nitrogen, Liquid, Type II B

1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

1

This test method is under the jurisdiction of ASTM Committee G04 on the ASTM website.

4

Compatibility and Sensitivity of Materials in Oxygen EnrichedAtmospheres and is Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

the direct responsibility of G04.01 on Test Methods. Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

Current edition approved Dec. 1, 2017. Published February 2018. Originally dodssp.daps.dla.mil.

5

approvedin1984.Lastpreviouseditionapprovedin2011asG86 – 98a(2011).DOI: Available fromAmerican Chemical Society (ACS), 1155 Sixteenth Street, NW

10.1520/G0086-17. Washington, DC 20036, http://www.acs.org.

2 6

NASA Handbook 8060.1B, Pressurized Liquid and Gaseous Oxygen Mechani- Available from Compressed Gas Association (CGA), 4221 Walney Rd., 5th

cal Impact Test, Sept. 1981, pp. 4-72. Floor, Chantilly, VA 20151-2923, http://www.cganet.com.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G86−17

7

2.5 NASA Standard:

NSS 1740.15 Safety Standard for Oxygen and Oxygen

Systems

2.6 ASTM Adjuncts:

8

ABMA-Type Impact Tester and Anvil

3. Terminology

3.1

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G86 − 98a (Reapproved 2011) G86 − 17

Standard Test Method for

Determining Ignition Sensitivity of Materials to Mechanical

Impact in Ambient Liquid Oxygen and Pressurized Liquid

1

and Gaseous Oxygen Environments

This standard is issued under the fixed designation G86; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

2

1.1 This test method describes test equipment and techniques to determine the impact sensitivity of materials in oxygen under

two different conditions: (1) in ambient pressure liquid oxygen (LOX) or (2) under pressure-controlled conditions in LOX or

gaseous oxygen (GOX). It is applicable to materials for use in LOX or GOX systems at pressures from ambient to 68.9 MPa (0

to 10 000 psig). The test method described herein addresses testing with pure oxygen environments; however, other

oxygen-enriched fluids may be substituted throughout this document.

1.2 This test method provides a means for ranking nonmetallic materials as defined in Guide G63 for use in liquid and gaseous

oxygen systems and may not be directly applicable to the determination of the sensitivity of the materials in an end-use

configuration. This test method may be used to provide batch-to batch acceptance data. This test method may provide a means for

evaluating metallic materials in oxygen-enriched atmospheres also; however, Guide G94 should be consulted for preferred testing

methods.

1.3 Values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. See also Section 9.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

3

2.1 ASTM Standards:

D1193 Specification for Reagent Water

D4080 Specification for Trichloroethylene, Technical and Vapor-Degreasing Grade

G63 Guide for Evaluating Nonmetallic Materials for Oxygen Service

G88 Guide for Designing Systems for Oxygen Service

G93 Practice for Cleaning Methods and Cleanliness Levels for Material and Equipment Used in Oxygen-Enriched Environments

G94 Guide for Evaluating Metals for Oxygen Service

4

2.2 Military Document:

MIL-D-16791 Detergent, General Purpose (Liquid, Non-ionic), Type One

5

2.3 American Chemical Society:

Trichloroethylene, Reagent Grade

1

This test method is under the jurisdiction of ASTM Committee G04 on Compatibility and Sensitivity of Materials in Oxygen Enriched Atmospheres and is the direct

responsibility of G04.01 on Test Methods.

Current edition approved April 1, 2011Dec. 1, 2017. Published April 2011February 2018. Originally approved in 1984. Last previous edition approved in 20052011 as

G86 - 98aG86 – 98a(2005).(2011). DOI: 10.1520/G0086-98AR11.10.1520/G0086-17.

2

NASA Handbook 8060.1B, Pressurized Liquid and Gaseous Oxygen Mechanical Impact Test, Sept. 1981, pp. 4-72.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

4

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://dodssp.daps.dla.mil.

5

Available from American Chemical Society (ACS), 1155 Sixteenth Street, NW Washington, DC 20036, http://www.acs.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G86 − 17

6

2.4 Compressed Gas Association:

G-4 Oxygen

G-4.1 Cleaning Equipment for Oxygen Service

G-4.3 Oxygen, Gaseous, Type I B

G-4.3 Oxygen, Liquid, Type II B

G-10.1 Nitrogen, Gaseous, Type I B

G-10.1 Nitrogen, Liquid, Type II B

7

2.5 NASA Standard:

NSS

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.